FINITE ELEMENT ANALYSIS OF GAS FOIL BEARINGS

Abstract - Micro turbomachinery demands gas comportments to be light compact and should operate at varying temperatureconditions.Lowheatgenerationdisunion and lack of lubricant rotation system makes it compact dependable andeco-friendly. still low stiffness and damping portions, high cost and lack of sufficient knowledge and prophetic tools kindly restricts GFBs use in mass produced operation. Current marketable and engineering operation demands further and more aggressive designs with high face speed and unit loads as well as thinner fluid film. Again rotordynamics analysis uses stiffness and damping portions to represent fluid film geste or in other words theseportionsplay the crucial part in determining dynamic characteristics of a rotor shaft. Stiffness portions depend substantially on two factors first the static deviation of antipode due to shaft cargo and second the hydrodynamic effect produced due to the fluid film. Then's an approach to calculate the stiffness measure produced due to static deviation of GFBs due to static cargo using finite element analysis and the stiffness measure has been calculated. Reynold’s equation is to be answered using FDM to gain pressure profile during hydrodynamic action of fluid film and using these pressure values in thebearingmodel dynamic element of stiffness can be produced. Adding both factors will produce the overall stiffness measure of a gas antipode bearing.

Key Words: FEA, gas foil bearing, stiffness coefficients.

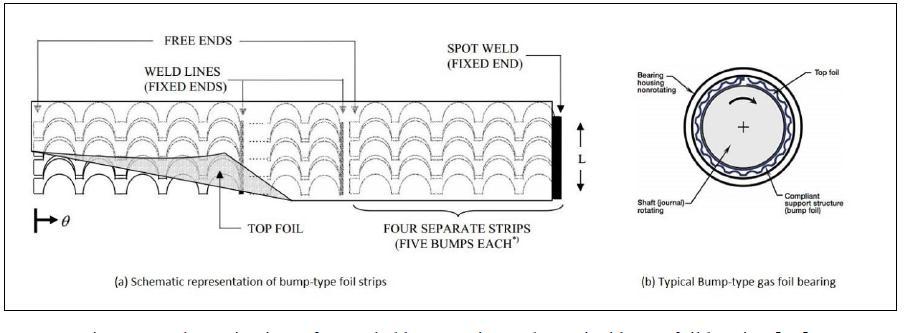

1. INTRODUCTION

A bearing is a mechanical device that separates two opposingshellsfullybyasubcasteoffluidlubricant.Plain journalbearingisusedcommerciallyinnearlyallbiasthat hasa rotating part.Compressors,pumpsturbines,motors creatorsaremanyexemplificationsneedtobementioned. Journal bearing is a structure where two cylinders rotate concentrically relative to each other. One being the shaft, rotatingataparticularangularspeed,andotherthebearing. Themainidealistosupporttherotatingstructuresandgive sufficientlubricationtoavoiddisunionthatcauseswearand tear and gash to machine corridor. The fluid film at high pressure provides the hydrodynamic film lubrication and determinesthecargocapacityofthebearing.curiosityisa bearing parameter which is defined as the relegation betweenshaftandbearingcenter.

2. MODELLING PARAMETERS OF BEARING

Table-1: Parametersanddimensionsof3gasfoilbearings tobemodelledandanalyzed

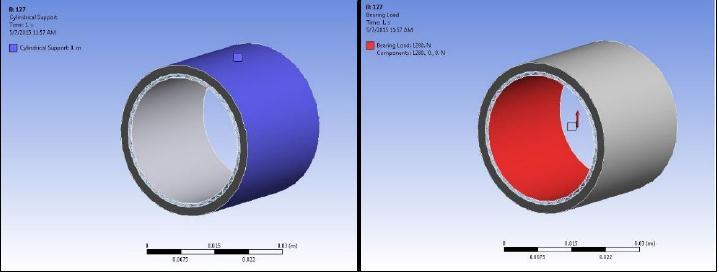

3. FINITE ELEMENT ANALYSIS USING ANSYS

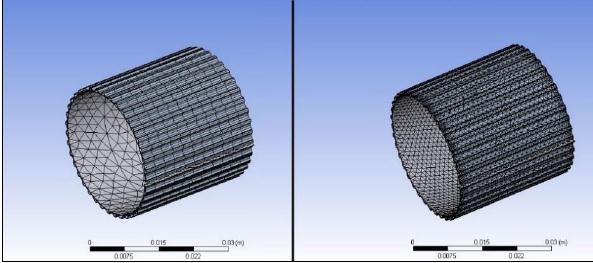

3.1 GENERATION OF MESH

Generatingmeshisthemostimportantandcriticalwork inengineeringsimulationinAnsyssoftware.Largenoofcells may take longer time to produce solutions without increasingaccuracywhereasveryfewnumberofcellsmight produceinaccurateresults.

3.2

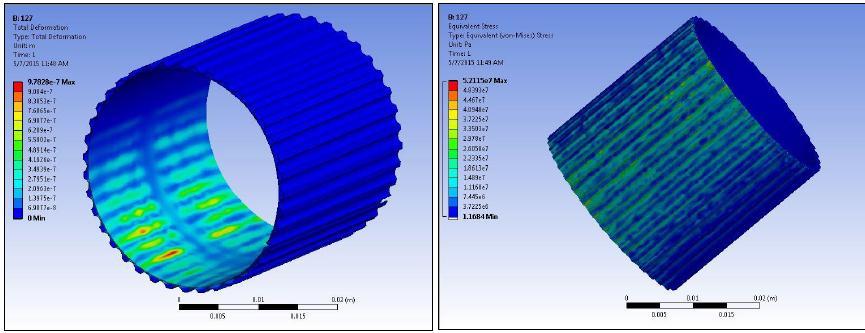

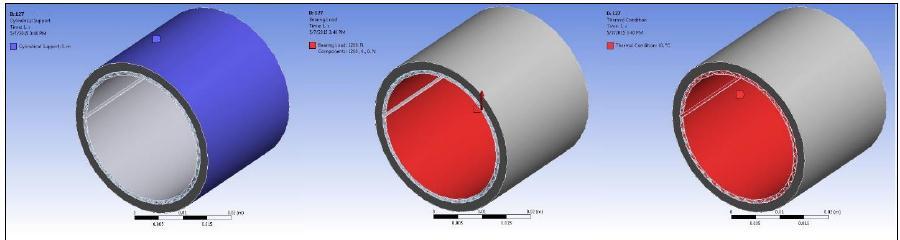

to1N/mm2andtemperature10oC.

4.

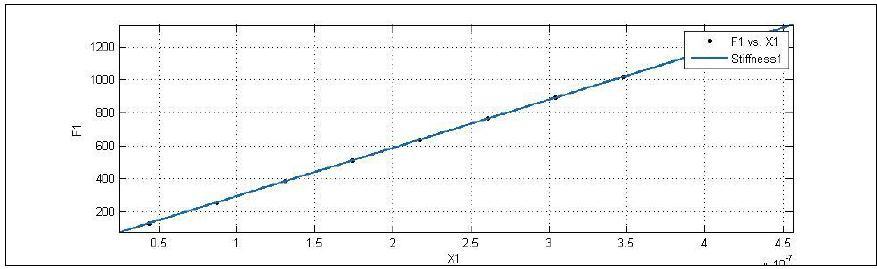

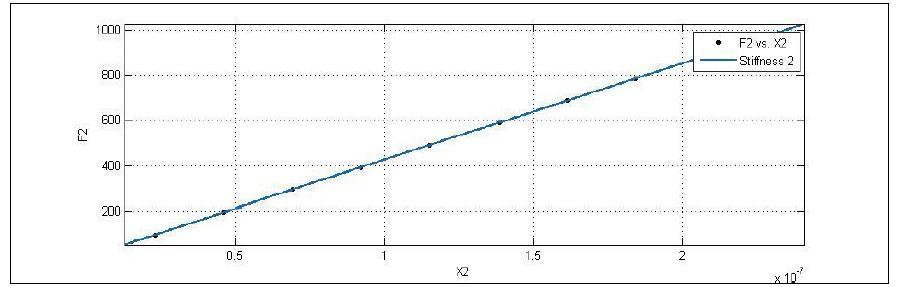

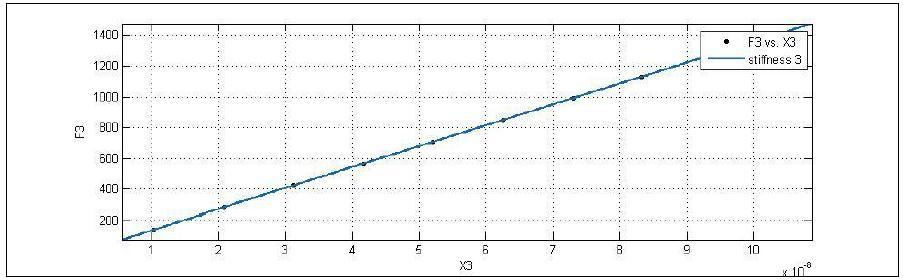

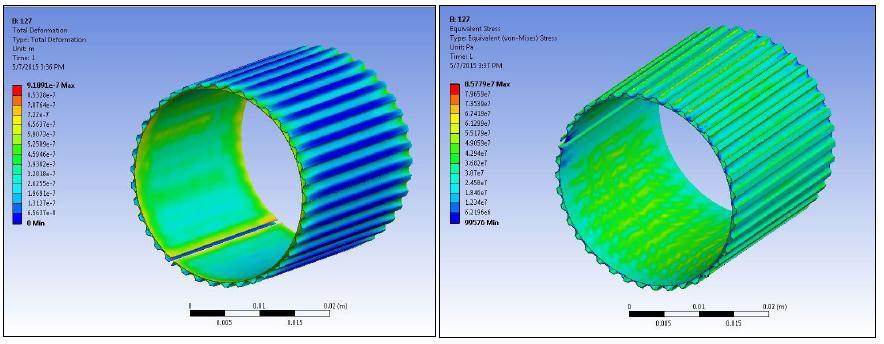

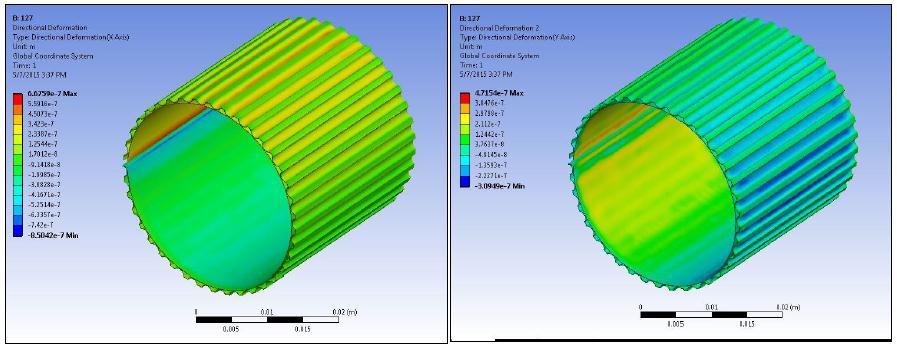

4.1 CALCULATION OF STIFFNESS

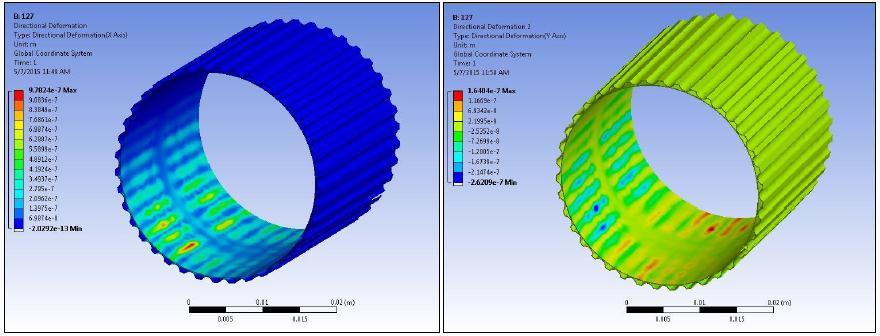

Ansys simulation of all 3 gasfoil bearings for a varying pressure range (0.1-1 N/mm2) is carried out and total deformation,directionaldeformationandvon-Misesstress areobtained.ResultsforGFB1at1280Nareshownhere.

4.4

5. CONCLUSIONS

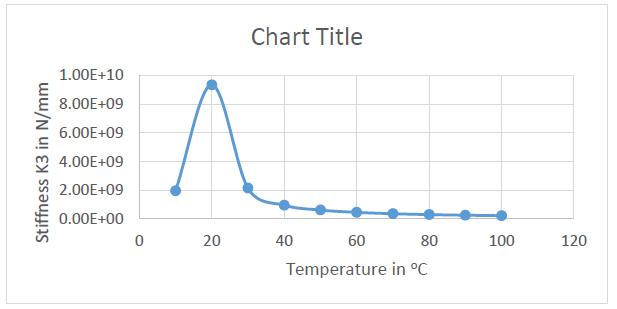

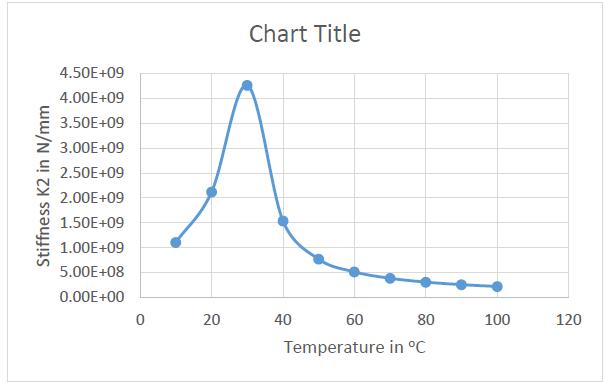

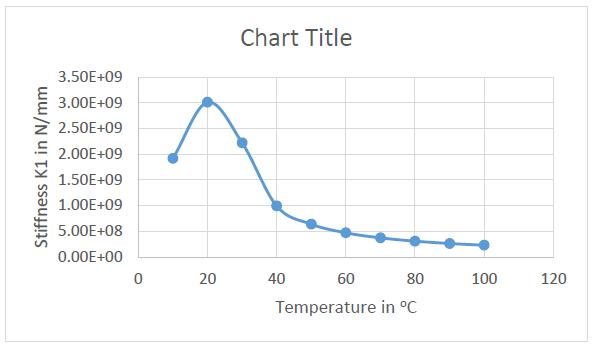

Bearingloadisappliedtothreedifferentmodelsofgasfoil bearings.Deflectionsfordifferentloadvaluesobtainedusing finiteelementanalysis.Graphisplottedbetweenloadand deflectionandastraightlineisobtained,theslopeofeach curverepresentsstiffnessofeachbearing.

Graphbetweenstiffnessandtemperatureisplottedandthe variation is obtained. It is observed that the stiffness is maximumasthetemperatureofthebearingcoincideswith the ambient temperature and stiffness reduces as the temperature difference between the bearing and working environmentincreases.

ACKNOWLEDGEMENT

It gives us an immense pleasure to write an acknowledgementtothisPaper,acontributionofallpeople whohelpedusrealizeit.Wetakethisopportunitytoexpress ourrespectfulregardstoourbeloved Principal Prof. K. S. Joshi formotivateustopublishthispaper.Alsoweexpress ourdeepsenseofgratitudeandappreciationtoourbeloved Project Guide Prof. Srinath Ingale for this enthusiastic inspirationandamicableinallphasesofourPaper.

REFERENCES

1) [1].SanAndrésL,HybridFlexurePivot–TiltingPad GasBearings:AnalysisandExperimentalValidation, Magnetic Storage Tribology Manufacturing/Metal working Tribology Nano-tribology Engineered Surfaces Bio-tribology Emerging Technologies Special Symposia on Contact Mechanics Special SymposiumonNanotribology,2006.

2) SanAndrésL,Notes15,GasFilmLubrication,Texas A&MUniversity,2010.

3) CarpinoMand PengJ,Calculationofstiffnessand damping coefficients for elastically supported gas foilbearings.ASME/STLETribologyConference,92Trib-24ASME,1993.

4) Heshmat H, Walowitt J, Pinkus O, Analysis of gas lubricated foil journal bearing, ASME/ASLE Joint Lubrication conference, ASME Journal of LubricationTechnology,82-Lub-40,1983.

5) Heshmat C, Xu D, Heshmat H, Analysis of Gas Lubricated Foil Thrust Bearings Using Coupled Finite Element and Finite Difference Methods. ASME/STLETribologyConference,PaperNo.99Trib-34,1999.

6) CzotczyfiskiK,Howtoobtainstiffnessanddamping coefficientsofgasbearings, DivisionofDynamics, Technical University of Stefonowslaego 1/15.90.924,Poland,1996.

7) Leeetal.,Identificationofthedynamicperformance of a gas foil journal bearing operating at high temperatures, Journal of Mechanical Science and Technology28(1)(2014).

8) Park D, Lee Y, Kim C, Ryu K, Rotor-dynamic characteristics of a micro turbo generator supported by air foil bearings. Journal of Micromechanics and Micro engineering, J. Micromech.Microeng.17(2007)297-303.