BRIEF REVIEW PAPER ON IOT-BASED ADVANCED SEMI-AUTONOMOUS SAFETY ROBOTS FOR MINING PERSONALS.

Abstract: This paper describes a robot that uses wireless technology to detect coal mines. Because coal minesaredangerousdeposits,peoplearethreatenedby many deadly factors. First of all, it is very dangerous to enter a tunnel without knowing the situation in advance because an explosion can happen at any time. Rescuerobotseagertoworkcanbesentfromhereinto an explosive environment to determine gas content, temperature, and more. Meanwhile, the environmental datadetectedbytherobotistransmittedtotherescuer via SMS using a telegram app. It transmits data using Bluetoothwirelesstechnology.Inthisway,rescuers can devise a plan to save the miner's life in the shortest amount of time. Therefore, coal mine detection and rescue robots are very useful robots in coal mine accidents. Human exposure to toxic fumes while working in underground tunnels can be fatal. To avoid suchcases,thesystemmustbeautomatedusingspecific robots. A Robot can provide prior knowledge to the workers about the level of danger so the workerscan have preparatory plans which will reduce the loss of human life due to disaster by enhancing the effective operationinmines.

Keywords: Wirelesstechnologyrobot,Bluetooth,MQ-4, CH4,WirelessCamera.

1. INTRODUCTION

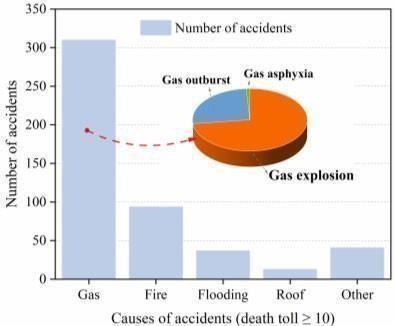

Mining is an industrial activity that takeout rock from the Earth's crust and processes it to take out valuable minerals for us to use. We need mineral resources to make several of the things we use in our daily lives, from toothpaste to buildings, and computers to cars. In mining, a distinction is built in the context of mining technology between extraction as the separation of mineralsfromtherock,galleries,sitepreparationusing shafts, and drifts, preparation for extraction, ventilation, water management, as delivery and auxiliary technologies. This paper is a complete framework presentation of building a low-cost robot prototyping based on a microcontroller controlled and capable of detecting toxic gases, obstacle detecting, humidity, and explosion. An underground Mining operation proves to be a risky venture as far as the safetyandhealthofworkersareconcerned.

These risks are related to the different methodsused to extract different minerals. The deeper the mine, the greater the risk. These safety issues areofgreatconcern, especially for the coal industry. Therefore, worker safety must always be of paramount importance in all forms of mining, be it coal or other minerals. Underground coal mining is riskier than open-cast mining. To ventilation problems and possible collapses. However, the use of heavymachineryanddiggingmethodspresentsafetyrisks in all types of mining. Modern mines often implement several safety procedures, worker education and training, and health and safety standards, resulting in significant improvements in both surface and underground mine safety.[1,2]

2. LITERATURE REVIEW

ProvidesRescuerobotsthatdetecthazardousgasesincoal mines.Itisharmfultorescuerstoentermineswithoutfirst examining the environment. Because explosions can happen just in time.

Landslides, gas leaks, high temperatures, and more. The robot is designed to detect explosions such as toxic gases and high temperatures. This robot has a wireless surveillancecamera.

G.BhaskarPhani Ram 1 *, Dr.L. Koteswara Rao1, Eliyaz Muhammad 1,

A. Bhanuchander 1,

providesaCoalMineDisasterManagementRobotUsing IoT Technology. The main goal of the proposed work is tocreatearescuerobotthatcanbecontrolledviaaweb page.AWi-Ficonnectioniscreatedbetweenthecontrol room and the Raspberry Pi. Commands to move the robot are sent via a web page. When a dangerous situation is detected in the mine, the robot sends information about temperature and toxic gas levels. Then a buzzer sounds to initiate the precautionary measures to normalize the atmosphere by providing ventilation with a fan. Formation such as location, temperature,andtoxicgasconcentration istransmitted to the control room via the Wi-Fi network. The DC motor is connected to the Raspberry Pi for control and motioncontrolinthecontrolroom. DCmotorsareused to drive the robot's wheels. Left, right, forward, or backward.

GUODONG ZHAI, WENTAO ZHANG, WENYUAN HU, AND ZHENDONG JI [11]

ProvidesaCoalMineRescueRobotsBasedonBinocular Vision: A Review of the State of theArt In the field, the binocular vision module ofthe robotic sensor system collectsimageinformation,performsimageanalysisand processing, and performs obstacle recognition and 3D reconstruction. The concept of binocular vision originated from the basic theory of vision created by Marr and Poggio. Later, Grimson supplemented and modifiedthetheory.

Prof. A. H. Ansari, Karishma Shaikh, PoojaKadu, and Nikam [12] This monitoring system contains several components such as boards (PIC board, Xbee module, and Zigbee USB interface board), liquid crystal display (LCD), various sensors, and other small electronic components. This chapter provides adetailed overview of each of these parts and how they work. In the proposed system, the coal mine safety system is fixed with a gas sensor module, temperature sensor, and waterlevelsensor.Andrelay.Integratesallsensorsinto the controller. First, you need to create an account on theThingSpeakplatform.

The system has a monitoring and control system. The monitoring system monitors all data from various sensors. Gas sensors detect gases in coal mine environments. When the gas level exceeds the normal level, the buzzer goes high to alerttheminer.

3. ALGORITHM USE IN COAL MINE ROBOTS [2]

Step 1. A Specified power supply is given totheboard.

Step 2. GPIOportsareinitialized.

Step 3. Buzzer gives an indication whenever

the threshold isexceeded.

Step 4. If the temperature exceeds a thresholdvalue,The coolingfanwillbeON.

Step 5. If the gas value exceeds a threshold

value,the oxygencylinderwillbeopened.

Step 6. If the fire value exceeds a thresholdvalue,thewater sprinklerwillbeON.

Step 7. The Camera captures the presentsituationinacoal mine.

Step 8. SMSande-mailare sent tothe controlroom

Step 9. Sensor data is read by Raspberry Pi sothat the data issaved in a file and displayedonWebpage

Step 10. TheProcessisrepeateduntiltheuserintervenes

4. EXPERIMENTAL SETUP:

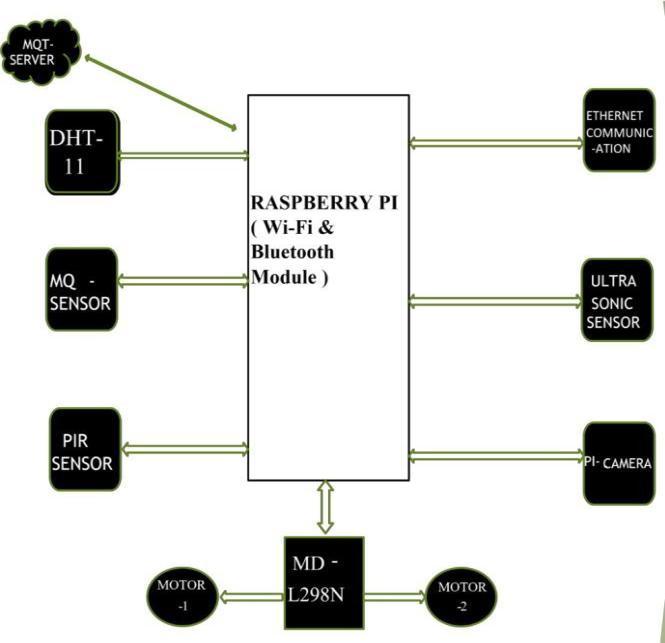

The block diagram shows the functional flow of how the robot works. The vital components of the proposed system include sensors, a control unit, Bluetooth, a wireless camera, and a power supply unit. Bluetooth is used to transfer data and messages. All these sensors are directly connected to the raspberry pi which has a default program in it. The working power for the robotis obtainedfroma batteryconnectedtotheraspberrypi.

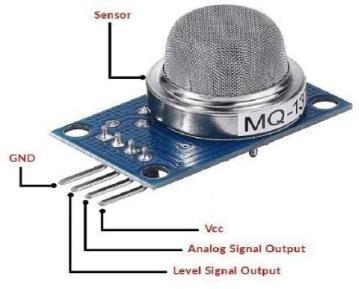

The main aim of this robot is gas detection and screeningthe operation in mines. MQ-4 is used for detecting hazardous gas and PIR is used for detecting obstacles. AWireless camera is used for screening the operation inmines. The visualization of all details is done by using the wireless LCD connected to the robot so that all details of the environmentcanbetracedeasily.[1]

6. OVERVIEW OF MICROCONTROLLER

The project's core aspect is the Raspberry Pi. Since we planto present the results in audio format, we chose to use a headphone. The Raspberry Pi also supports high-bass headphones. The Raspberry pi (3B+) model was used in this project. We choose use a power bank as the Raspberry Pi's power source to give mobility to the user.

One of the most well-liked single-board computers is the Raspberry Pi. Open CV on the Raspberry Pi makes it simple to implement all the major image processing algorithms and operations. The Raspberry Pi is connected to a 32 GB class SD card. The Raspberry Pi or the minicomputer is used because it can interface the camera module with it and provide good results after processing theimage.RaspberryPi.

Afterconsideringtheproblemsofcoalmines,wedeveloped a robot. The robot consists of a mechanical vehicle, a control system, a drive system, a communication system, and sensors. Thisrobot is made of a light frame and a DC motor is used to drive the robot vehicle. The Engine speed is60 rpm. The movement of the robot is done by placing 2 motors on each side. The robot can move forward, backward,left,andright.[1]

It is highly sensitive to LPG, iso-butane, andpropane and less sensitive to alcohol, cooking fume, and cigarette smoke. The resistance of the sensitive component changes as the target gaschanges.[4]

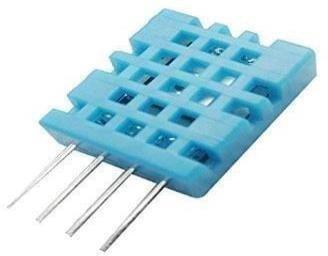

This sensor is the basic, ultra-low-cost digital temperature and humidity sensor. It uses A Capacitive humidity sensor and a thermistor to measure thesurrounding air and spits out adigital signal on the data. These four pins Sensor equipment i.e.,VCC,GND,DATA,and

NC.[4]

It is sometimes called PID Sensor and is commonly known as PIR also. For "passive Infrared Detector. The term passive refers to the fact that PIR devices do not radiate energy for detection purposes. They work entirely by detecting infrared radiation emitted by or reflectedfromobjects.

7.5 L298 DC MOTOR DRIVER

The L298 is an integrated monolithic circuit in a 15- wire Multi Watt package and PowerSO20.It is a high-voltage, high-current dual full-bridge driver designed to accept standard TTL logic levelsanddriveinductiveloadssuchasrelays,solenoids,DC, and steppermotors.[4]

7.6 WIRELESS PI CAMERA

Theenvironmentintheminescanbemonitoredusingawireless camera.Imagecanalsobespotted.Thecameraisconnectedto thescreenwirelessly.[4]

8. CONCLUSION

Thispaperexplainstheframeworkforthedesignof temperature sensor and gas sensor-based mine detection units. A prototype scanning and search robot using mine detection units is also explained.Wewillthencreateasmartphone-compatibleAndroid applicationcapableofcontrollingtherobotremotely.Themining robotforgasdetectionanddisastermonitoringisdevelopedwith sensors, cameras, and other components. A 12v/3s battery is used to run the robot. An MQ-4 sensor is used for gas detection and a wireless camera for surveillance. The robot can run in terrain. When the measured value exceeds the set values, the workers will beinformed the "gas level exceeded". The gas level willbedisplayedontheLCD.Thisrobotisusedfortraffic

andgas leakmonitoringtoprotectpeople(workers)andprovidesecurity to enhance defensive traffic detection. In 2012, 92 workers died due to methane leaks in Turkey and China, to prevent these disasters,ourproposedsystemwillbebeneficial.[1,4]

9. REFERENCES

A DC motor is designed to run on DC electric power.ThemostcommonDCmotortypesarethe brushed and brushless types, which use internal andexternalcommutationrespectively to create an oscillating AC from the DC source so they are notpurelyDCmachinesinastrictsense.[4]

[1]. Deepan A, Jayakrishna SV, Nagha Abirami S (2018) Detection of hazardous gas using Land rover in mines first. IRJETJ5(4):2735–2736

[2]. Coal mine disaster management robot using IoT technology by Dr. L. Koteswara Rao,GBhaskarPhani Ram, and Eliyaz MuhammadEngineering & Technology 7(3):1204 issued on:June2018)DOI:10.14419/jetit.v7i3.12294

[3].Pathplanningforcoalminerobottoavoidanobstacle in gas distribution area by Xiliang Ma, Ruiqing Mao (International Journal of Advanced Robotic Systems issued on: January 2018) DOI:10.1177/1729881417751505

[4]. Vasanthi D, Logeshwari M, Priyadharshini S, Karthiga L (2019) Mine detecting robot usingwirelesstechnologyandIoT. IOSR JEng.22–26

[5]. Coal mine intelligent safety system andkeytechnologies by S. Li, G. Xue, and X.Fang (Meitan Xuebao/Journal of the China Coal Society 45(6):2320-2330 issued on: June2020)DOI:10.13225/j.cnki.js.ZN20.0356

[6].Coal MineRescueRobots Based onBinocular Vision: A Review of the State of the Art by Guodong Zhai,WentaoZhang,Wenyuan Hu(IEEE AccessPP(99):1-1issuedon: July2020)DOI:10.1109/ACCESS.2020.3009387

[7]. Coal mine intelligent safety system and key technologies by S. Li, G. Xue, and X. Fang(Meitan Xuebao/Journal of the China Coal Society 45(6):2320-2330 issued on: June 2020)DOI:10.13225/j.cnki.jccs.ZN20.0356

[8]. Problems and Research on Underground Charging Safety of Power Battery for Coal Mine Robot by Long Ma, Qing Chen (IOP Conference Series Earth and Environmental Science 651(3):032100 issued on:February 2021)DOI:10.1088/1755-1315/651/3/032100

[9]. Safety Monitoring System in Coal MineUsing IoT by N Sathish Kumar, A M Manoj, KMuniraj (Journal of Physics Conference Series 1916(1):012196issuedon:May2021) DOI:10.1088/1742-6596/1916/1/012196

[10]. Optimization of the suspension system and analysisoftheride performance of the crawlertype coal mine search and rescue robot by Yutan Li, Chengjun Wang, Chuanjin Zhangissued on:May2022)DOI:10.1007/s40430-021-03332-

[11] Coal Mine Detect and Rescue Robot Design and Research GAO junyao, GAO xueshan, ZHU Wei,ZHUjianguo,WEIboyu

DOI: 10.1109/ICNSC.2008.4525321

[12] IOT Based Coal Mine Safety Monitoring and Alerting System Prof. A. H. Ansari, Karishma Shaikh, Pooja Kadu, Nikam Rishikesh DOI: 10.32628/IJSRSET2183188.