Comparative Design of Column for Different Strengthening Techniques (CFRP)

Mahesh Sawant1 , Nagesh Shelke2

1PG Student, Department of Civil Engineering Dr. D Y Patil School of Engineering and Technology, Charholi (BK), Pune-412 105, Maharashtra, India

2Associate Professor, Dept. of Civil Engineering, Dr. D Y Patil School of Engineering and Technology, Charholi (BK), Pune-412 105 Pune, Maharashtra, India ***

Abstract - Structures with the passing of time, they lose their strength because of various factors like improper maintenance, corrosion of steel reinforcement, poor construction exposure to harmful environments and improvement in design guidelines. These structural elements becomestaticallyunsafe.Enhancementofperformanceofsuch RCstructuralelementscanbedonebyincreasingstrengthand strengthofstructuralelementscanbeincreasedbyprocessof Retrofitting.

As per the report of the rebound hammer test and core compressive test performed on columns at the 2nd and 3rd Floor levels, it was observed that total 56 numbers of columns have inadequate compressive strength as compared to their original design grade which was M40. Hence these columns require structural strengthening to achieve the required strength.

Key Words: CFRP,Retrofitting,ColumnStrengthening,RC Structural

1.INTRODUCTION

Retrofitting is defined as the process of modification of existing structures like buildings, bridges to make more resistant to seismic activity and other natural calamities. Structureswiththepassingoftimetheylosetheirstrength becauseofmanyreasonslikeseismicactivity,soilfailuredue to ground motion, arises problem like damaging of roof, foundation, walls, pillars, column and beams for these structuresbecomesstaticallyunsafeandsolutiontothese problem is Retrofitting. The structure performs normally during their life span but at the end of design period of structure,thestructuremaynotbecapableoftakingload. Strengthening with Fiber Reinforced Polymers (FRP) compositematerialsintheformofexternalreinforcementis ofgreatinteresttothecivilengineeringcommunity.

OrchidCityCentreMallisacommercialbuildinglocatedat MumbaiCentral,Mumbai,Maharashtra.Thebuildingisan RCC-framedStructure.Yearslaterthebuildingexperienceda fireatthe2ndand3rdFloorlevels.Furthertotheincident, the fire-affected areas were structurally assessed, the investigation includes the visual, non-destructive &

destructive testing of the structural members in the fireaffectedareas.

Thisproposalreportcomprisesastructuralstrengthening scheme,designcalculation,andconstructionmethodology fortheColumns.

2.METHODOLOGY

1. Surface Preparation

2. Forming Radius at Corners

3. Marking on The Surface

4. Drilling for Anchors

5. Applying R&M Primer Coating

6. Application of R&M Resin Putty

7. Cutting Fiber to The Required Length

8. Application of Carbon Fiber Wrap

9. Fixing of R&M Fiber Anchors, Top Coat, And Sand Sprinkling

10. Protective Coating

2.1 SURFACE PREPARATION

2.1.1 General:

Preparingthesubstratesurface(concrete,brick,steel,or timber)foreffectivebondingoftheoverlayisanimportant step in the methodology of CFRP Application. It includes varioustaskslike;

Removalofloose/nonstructurallayerssuchasCM plasterorPuttylayersetc.

CleaningforeigndepositsonthesurfaceLevelingthe undulationsinthesurfaceetc

2.1.2 Objective of Surface Preparation:

Thepreparedsurfacewillhavethefollowingadvantages,

It provides a leveled surface for FRP overlay becauseofwhichthevoidsduetoundulations canbeavoided.

ItprovidesapropercontactsurfacefortheFRP whileremovingforeigndepositsonthesurface.

It helps in bringing FRP composites direct in contact with the substrate material once removingnonstructurallayers.

Person working should wear all safety belongings andsafetyhazardswhileperformingatthesite

2.2 FORMING RADIUS AT CORNERS

2.2.1 General:

Formingradiusatcornersiscarriedoutformaintainingthe betterperformanceofthewrappingsystem.Itisnecessaryto removeallthesharpcornerswithagrinderandformatleast aminimumof20–25mmradiusforbetterconfinementin angularsections.

2.2.2 Objective for Forming Radius at Corners:

Roundedcornersurfaceswillhavethefollowingadvantages;

Rounding corners helps in making the composite actionmoreeffective.

TheefficiencyofFRPconfinementincreaseswhere thecornersoredgeshavebeenroundedbyforming aradius.

Figure1:Removalofforeigndepositsonthesubstrate surface

2.1.3 Tools Used:

Mild grinder machine with cub wheel providing sufficient abrasion to the surface to remove all kindsofforeigndepositsareused.

Sinceitisadrygrindingprocessablowermachine isusedtomakethesurfacefreefromdustparticles.

Toremoveplasterworksgentlechippermachineor manuallyoperatedhammerandchiselcanbeused.

2.1.4 Do’s and Don’ts of surface preparation:

Itisverynecessarytoensureandalsototakecareofcertain things in the process. The following are the factors to be ensured,

Ensurethesurfaceisfreefromdust

Ensure the surface is free from water, the surface shouldnotbewetincondition

Ensure possible minimum undulations (no undulationsintheidealcase)

2.2.3 Tools Used:

Mildgrindermachinewithcubwheelproviding sufficientabrasiontothesurfacetoremoveall kindsofforeigndepositsareused.

Since it is a dry grinding process a blower machineisusedtomakethesurfacefreefrom dustparticles.

Radiusgaugeisusedtochecktheformedradius atthecornersurfaceofthemembers.

2.2.4 Do’s and Don’ts on the finished surface:

Thefollowingarethefactorstobeconsidered;

Thesurfaceshouldbemadefreefromdust.

It should be overseen that there are minimal undulations.

2.3 MARKING ON THE SURFACE

2.3.1 General:

The marking should be done as per the design drawings provided.Beforemarkingthesurface,ensuringthesurfaceis clean and dust-free is a must. Sometimes it is performed beforesurfacepreparationwhereonlypartofthestructural memberparticipatesinstrengthening.

2.3.2

Objective for Marking on the Surface:

Markingonthesurfaceiscarriedouttomaintainaccuracy andavoiddiscrepanciesintheworkarea.

Sinceitisadrydrillingprocessablowermachineis to be used to make the surface free from dust particles.

2.4.3 Do’s and Don’ts while drilling holes:

Itisstronglyrecommendedtousesafetyequipment likesafetygoggles,nosemask&handgloveswhile carryingoutthework.

2.3.3 Do’s and Don’ts on the marked surface:

Centertocenterdistancebetweenthelaminatesis alsomarkedaccurately.

Followthedrawinggivenbytheengineertoensure the areas to be strengthened are measured and markedstraight.

Incaseofanyobstacles,allowableshifting/changein theplacementofFRPispre-decidedatthisstage

2.4 DRILLING FOR ANCHORS

2.4.1

General:

Thenextstepistogoforthedrilling,forwhichmarkinghas to be done at the center of the overlapping distance as specified(or)giveninthedrawing.Thedepthofthedrilling isasperthesizeoffiberanchorswhichisalmost50mmto 60mmlong.Thereafter,thefiberanchorisinsertedinsidethe drilledareaandthefiberisspreadinsuchawaythatitlocks thejointofoverlap.

2.4.2 Tools Used:

Drilling machine is used to drill holes for fiber anchors.

2.5 APPLYING R&M PRIMER COATING

2.5.1 General:

Primer is a resin-based material it is applied by brush or roller.Primerprovidesacompatiblesurfacefortheoverlay and thus improves the bonding of the strengthening material.

2.5.2 Objective of application of Primer:

Topromoteadhesionandpreventthesurfacefromdrawing resinfromtheFRP,alow-viscosityepoxyprimercompatible withthesubstrateisappliedwitharolleruntilthesubstrate islocallysaturated.Italsohelpsinfillingthosesmallvoids onthesubstratesurface.

2.5.3 Tools Used:

Stirrer Machine is used to mix the base and hardenerofthePrimer.

Primerisappliedonthemarkedsurfaceofthearea tobestrengthenedwithabrush.

2.5.4 Do’s and Don’ts while applying Primer:

ThePRIMERisachemicalproductandcareshould be taken during its handling. It is strongly recommendedtousesafetyequipmentlikesafety goggles, nose mask & hand gloves while handling andusingthespecificproduct.

Anycontactwiththebareskinshouldbeavoided.If thepastedoescomeincontactwiththebareskin,it can be easily treated with splashes of water and cleaned.

2.5.5 Conclusion:

Afterapplicationof Primer allowthelayuptocure generallyrecommendedfor12hrsmayvarydependingon theenvironmentalconditions.

2.6 APPLICATION OF R&M RESIN PUTTY

2.6.1 General:

Thesurfaceiswellpreparedwithputty/levelingmortarto filltheundulationsorunevenness.Itshouldbeoverseenthat the surface of the member to be strengthened is smooth, even,andfreefromundulationsfortheefficientworkingof theCFRPcomposite.

2.6.2

Application of putty or leveling mortar is carried out to maintain uniform surfaces without any voids and undulations.

2.6.3 Tools Used:

Putty should be applied using a spatula to cover the unevennessandanyundulations.

2.6.4 Do’s and Don’ts while applying putty/leveling mortar:

Itisstronglyrecommendedtousesafetyequipment likesafetygoggles,nosemask&handgloveswhile carryingoutthework.

Resin putty is a non-structural element hence its thicknessislimited.Generallysuggested5mm

2.7

CUTTING FIBER TO THE REQUIRED LENGTH

2.7.1 General:

In a clean area away from the resins, the fabric (R&M Carbon Fiber) is carefully measured and cut by the specifications.Careshouldbetakensothatthereisn’tany damagetothecarbonfabric.

2.7.2 Dos and don’ts while handling the fabric:

Fabricshouldbecutinacleanplacefreefromdust.

Fibreshouldnotbedamagedbyanymeansbefore andafteritsapplication.

Fibreshouldbestoredatambienttemperatureat thesite.

2.8

2.8.1 General:

R&M SATURANT isabondingagentforthefibersanditisa 2-component-basedmaterial.Base:3.7kg-Hardener:1.3kg. These2componentsrequirepropermixingwiththehelpof a Stirrer machine for at least 2-3 minutes for accurate merging which gives an output of superior bonding. Immediatelyafterstirringitshouldbeappliedonthesurface without any time gap with the help of brush application.

Apply R&M Fiber immediately after applying the R&M SATURANT layer. We must start doing fiber wrapping aroundthesurfaceaspertheguidelinesofthemanufacturer concerning the design given. While wrapping roller applicationwithnominalhandpressureisamustsothatthe fiber should get properly embedded in the epoxy for superiorbondingwithconcretewhichresultsindeveloping betterstrength.AftertheapplicationofCarbonfiber,sealit withanotherlayerofsaturant.

Laying up additional CFRP L-wrap on the four edges of columnforabsoluteconfinement.

Note: Refer drawing for CFRP specification and detailing.

2.8.2 Objective of fiber wrap:

They serve as additional reinforcement in the structural memberswhenappliedwithsuitablebondingresin.Hence, theycanbeusedinshearstrengtheningofbeams,confining columns for their axial capacity, strengthening horizontal members for their flexural capacity in passive mode, and also improving resistance towards uni-axial/bi-axial momentsincolumns.

2.8.3 Do’s and Don’ts while applying fiber wrap:

Itisstronglyrecommendedtousesafetyequipment likesafetygoggles,nosemask&handgloveswhile carryingoutthework.

Avoid creases and air pockets while applying the carbon fiber wrap to the area marked to be strengthened.

Use a Teflon roller to expel entrapped air in the fiber.

2.9.1 General:

After completing the wrapping work fiber anchors are applied at specified spacing on columns. The anchor is insertedinthedrilledholeasshowninthefigureandthen protrudingfibersaremanuallyspreadinacircularshapeso thatitshouldgivealockingeffectfromall360°.

2.9.2 Reason for fixing fiber anchors:

Thepurposeofplacingafiberanchoristoholdtheends& jointsofthewrap.ItalsohelpsinbringingFRPcompositesin contactwithcoreconcrete/substrate.

2.9.3 Do’s and Don’ts while fixing fiber anchors:

Itisstronglyrecommendedtousesafetyequipment likesafetygoggles,nosemask&handgloveswhile carryingoutthework.

Brushthethreadswellbeforeusing.

Spreadthefibersat360otogivealockingeffectall around.

Usesufficientsaturantduringitsapplication

2.10 PROTECTIVE COATING

2.10.1 General:

It is advised to provide fire protection coat post strengthening on the structural member to fire-proof the members.FireprotectivecoatalsohelpsasUVresistantfor thestructuralmemberafterstrengthening.

2.10.2

Materials for Application:

Cement,Vermiculitepowder,Sand,PlasteringAccessoriesMetal Lath, angle beads, special pieces for internal angles andcorners,Trialmix.

2.10. 3 Preparation:

Clean the surface and remove any dust, removing loose materialandsubstancesthatmayimpairthework.Formties andotherobstructionsshallberemovedortrimmedback evenwiththesurfaceofthesolidbase.

Before vermiculite plastering starts, dampen, by spraying water on concrete dash coat surfaces that are to receive plasterwithcleanwater.

2.10.4

Material Mix Proportion of Plaster:

Thefirstcoatshallbeappliedwithsufficientmaterialand pressuretoensuretightcontactwithastrengthenedsurface of 12 mm thick. The surface of the second coat shall be brought to a true, even plane with a rod or straightedge, filling surface defects in place with plaster of thick 8mm. Makingatotalthicknessof20mm.

Applied plastershall be floatedassmoothlyaspossible andsteel-trowelled.Steeltrowellingshallbedelayedaslong aspossibleandusedonlytoeliminatetheunevenpointsand to force aggregate particles into the plaster surface. Each plaster coat shall be applied to an entire strengthening surfaceorceilingpanelwithoutinterruptiontoavoidcold joints and abrupt changes in the uniform appearance of succeedingcoats.

2.10.6 Curing:

Provide sufficient moisture in the plaster by spraying waterasfrequentlyasrequiredatleasttwiceperdayfor7 Days

3. RESULT:

Table -1: TestReportofConcreteCylinder (Plain)

TestReportofConcreteCylinder

CylinderID.Mark Cylinder WT(kg.)

Table -2: TestReportofConcreteCylinder (300GSM)

TestReportofConcreteCylinder CylinderID.Mark Cylinder

Cement1Part:Vermiculitepowder1part:Sand3part

2.10.5

Application of Plaster:

Plastershallbepreparedinmix1:1:3(1-partcement,1part vermiculite powder & 3-part sand) using sufficient water to produce a workable consistency. Plaster by first mixingwithwater(30%).Afteralltheingredientshavebeen added including the remaining mixing water, the plaster should be mixed for a further few minutes until uniform vermiculitedispersion.

Table -3: TestReportofConcreteCylinder (400GSM)

TestReportofConcreteCylinder

CylinderID.Mark Cylinder

Table -4: TestReportofConcreteCylinder (600GSM)

TestReportofConcreteCylinder

EXPERIMENTAL RESULTS

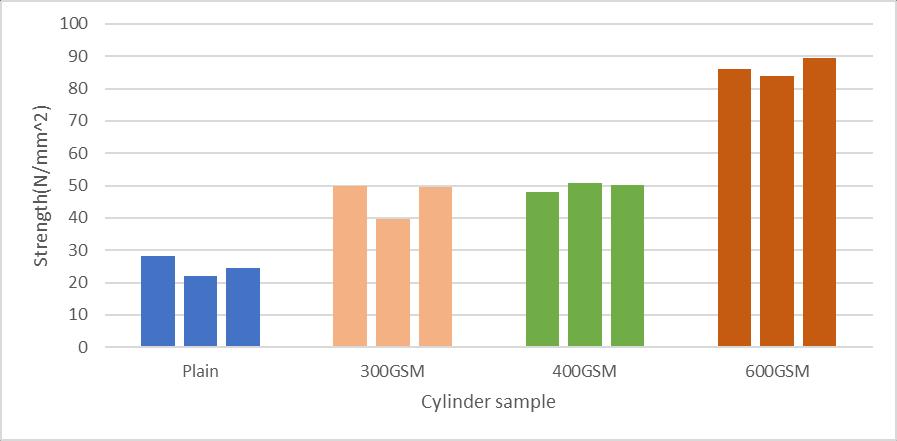

Chart.1.DifferentCylinderSample

Fromabovegraphitisseemsthat600GSMsamplegives maximumstrengthascomparetoanothersample.

PlainsampleofM30gradeat70dayswithvarious

4. CONCLUSIONS

We From experimental work and testing of specimen followingconclusionshavebeenconcluded:

i. After 70 day concrete attaining highest compressive strength when 600GSM carbon fibre rapping increase compressivestrengthof61.57N/mm2ascomparetoplain concretecolumncasting.

ii. After 70 day concrete concrete attaining highest compressive strength when 600GSM carbon fibre rapping increasecompressivestrengthof40.09N/mm2ascompare to300GSMcolumncylinder.

iii. After 70 day concrete concrete attaining highest compressive strength when 600GSM carbon fibre rapping increasecompressivestrengthof36.82N/mm2ascompare to400GSMcolumncylinder

iv.FurtherIconcludethat600GSMisgivingmaximum strengthascomparetoallothertypeofcasting.

ACKNOWLEDGEMENT

Thispaperwassupportedbycivilengineeringdepartment andourcolleaguesfromDr.DYPatilSchoolofEngineering and Technology, Pune. who provide insight and expertise that greatly assisted the research. I also like to show our gratitudetothecollegeforsharingtheirpearlsofwisdom withmeduringthecourseofthisresearch.

REFERENCES

[1] D. Kornack and P. Rakic, “Cell Proliferation without NeurogenesisinAdultPrimateNeocortex,”Science,vol. 294, Dec. 2001, pp. 2127-2130, doi:10.1126/science.1065467.

[2] M.Young,TheTechnicalWriter’sHandbook.MillValley, CA:UniversityScience,1989.

[3] R. Nicole, “Title of paper with only first word capitalized,”J.NameStand.Abbrev.,inpress.

[4] K.Elissa,“Titleofpaperifknown,”unpublished.

[5] MIAKHIL,S.Uet.al.“RetrofittingofReinforcedConcrete beams using CFRP Sheets a Review”. International Research Journal of Engineering and Technology (IRJET),2020.

[6] T.S.VISHNUKUMARet.al.‘FiniteElementModellingof RCCbeamusingABAQUS”Dept.ofCivilEngineering,SV University College of Engineering, Tirupati. IJCRT | Volume8,Issue7July2020|ISSN:2320-28822020.

[7] ANKIT DASGUPTA “Retrofitting of Concrete Structure with Fibre Reinforced Polymer”, M. Tech. Scholar Department of Civil Engineering KIIT University, Bhubaneswar,Odisha,India.2018

[8] PROF.SHIBIVARGHESEet.al.“StudyonthePerformance of Retrofitting Techniques in RCC Beams” Associate. Professor, Dept. of Civil Engineering, A. College of Engineering, Kothamangalam, Kerala, India 2B.Tech. Students, Dept of Civil Engineering, M. A. College of Engineering, Kothamangalam, Kerala, India,

International Research Journal of Engineering and Technology (IRJET)

International Research Journal of Engineering and Technology(IRJET)Volume:03Issue:06.2016

[9] CHARU GUPTA et.al. “Review Paper on Retrofitting of RCC Beam Column Joint Using Ferro cement” International Research Journal of Engineering and TechnologyVolume:03Issue:03.(2016),

[10] J.O. AFOLAYAN, “Numerical Modelling of Retrofitted Reinforced Concrete Building Frames” Department of Civil Engineering, Federal University of Technology, Akure, Nigeria Research Journal of Applied Sciences, Engineering and Technology 12(2): 206-213, 2016

ISSN:2040-7459;e-ISSN:2040-7467,2016

[11] NIKHIL L. JAGTAP et.al. “Study on Retrofitted R.C.C. Building by Different NDT Methods” IOSR Journal of MechanicalandCivilEngineering(IOSR-JMCE)e-ISSN: 2278-1684,p-ISSN:2320-334X,Volume12,Issue3Ver. I.2015.

[12] J. GOPI KRISHNA, et.al. “Retrofitting of Reinforced ConcreteBeamwithExternallyBondedCFRP”M.Tech Student Department of Civil Engineering Universal College of Engineering Technology, Guntur, InternationalJournalforInnovativeResearchinScience &Technology|Volume2|Issue07.2015

[13] T. TEJASWINI et.al. “Analysis of RCC Beams using ABAQUS” PG Student, Dept. of Civil Engineering CBIT, Hyderabad,Telangana,IndiaDr.M.V.RamaRajuAssoc. Professor,Dept.OfCivilEngineeringCBIT,Hyderabad, Telangana,India,InternationalJournalofInnovationsin EngineeringandTechnology2015.

[14] PRAVIN B. “Materials and Jacketing Technique for Retrofitting of Structures” Waghmare International Journal of Advanced Engineering ResearchandStudies.2015

© 2023, IRJET | Impact Factor value: 8.226 |