Review of Modified Vapor Absorption Refrigeration Cycles

Ayush Supe, Sameer Atole, Harsh Mulik , Param Varade. ***

Abstract:

This paper presents a thorough investigation of various vapor absorption refrigeration cycles, including both simple and complex designs, with the goal of achieving a comprehensive understanding of their performance characteristics. The study evaluates the current state of the art in vapor absorption refrigeration and highlights any recent advancements in this field. A theoretical analysis of different vapor absorption cycles with modifications such as an ejector, generator absorberheatexchanger,andboostercompressorhasbeenconducted.Thesemodificationsaimtoreducethrottlinglosses and require different mechanical hardware of varying levels of complexity and cost. The optimization of operating temperatures in the cycles is crucial for achieving maximum coefficient of performance (COP) and minimum gas requirements in the evaporator, absorber, and main condenser. Hybrid vapor compression absorption refrigeration systems have significantly higher COP compared to conventional vapor compression refrigeration, triple effect, and GAX systems.ThetripleeffectcycledemonstratesamaximumCOPof1.955,whichis132%higherthanthesingleeffectcycle, with a gas requirement reduction of approximately 122% under the same conditions. Compared to the GAX cycle, the HGAXcycleshowsbetterperformanceintermsofthefirstandsecondlawsofthermodynamics,althoughitincursahigher unit product cost. The ejector cycle has a COP that is 30% higher than the conventional single-effect absorption refrigerationcycleandacoolingcapacityforwasteheatwithlargetemperatureglidethatisabout20%higher.Ingeneral, alternative cycles offer many benefits to vapor absorption refrigeration systems, such as reduced losses, increased performance,anddecreasedenergyconsumption.

Keywords

Hybrid,Compression,Temperatureglide,Heatexchanger,Ejector,Configuration

Nomenclature

COP coefficientofperformance

GAX generator-absorber-heatexchanger

Tv throttlevalve

SHX suctionheatexchanger

AB absorber

pr Pressureratio

P pressure

Tg,i Temperatureatgeneratorinlet

G generator

T temperature(K)

PH preheater

C condensor

A absorber

EV expansionvalve

LPLT A lowpressurelowtemperatureabsorber

LPHT A lowpressurehightemperatureabsorber

HPA highpressureabsorber

LPE lowpressureevaporator

HPE highpressureevaporator

ṁ massflowrate

ω coolingcapacityperunitmassofexhaustgas

Subscripts

i inlet

o outlet

Introduction

Theworldiscurrentlyfacingtwomajorchallenges:anenergycrisisandglobalwarming.Theenergycrisisiscausedbythe continueduseoffossilfuelsandtheincreasingdemandforenergy.Itisestimatedthatglobalenergydemandwillincrease by around 71% from 2003 to 2030. Global warming is largely caused by the emission of greenhouse gases from various sources, including conventional vapor compression refrigeration (VCR) systems, which also use electricity that further exacerbatesthepressureonprimaryenergysources.Inaddition,thestrictregulationsonchlorofluorocarbonrefrigerants have driven research towards more environmentally friendly alternatives, such as water. Effective methods for reducing CO2 emissions include reducing fossil fuel consumption, improving the efficiency of heat pumps and refrigerators, and usinglow-gradeenergy.

Absorptionsystemscanbeoperatedusingrenewableenergysourcessuchassolar,geothermal,biomassenergy,andwaste heatfrom industrial and locomotive processes, which have no global warming effect.Moreover,absorption systems have the potential to be improved among the various heat-powered cycles. While the absorption cycle has lower efficiency compared to the vapor compression cycle, the priority is to develop refrigerators and heat pumps that do not harm the environment.Researchersarecurrentlyexploringbetterwaystoimprovethethermodynamicperformanceofabsorption systems,withthefocusonfindingsuitableconfigurationsorhybridcycles,utilizingnovelrefrigerants,andenhancingheat andmasstransfers.

There are several reasons for modifying vapor absorption refrigeration cycles, including improving the coefficient of performance (COP), increasing the capacity for a given system and component size, adapting the heat rejection temperature profile to specific requirements, and keeping the temperature of the generator within limits. The GAX absorptionrefrigerationcycleandmultipleeffectabsorptionrefrigerationcyclessuchasthedouble-effectandtriple-effect absorption refrigeration cycles have been proposed to improve the performance of the absorption refrigeration cycle. Integration of a hybrid compressor or an ejector is also considered an attractive method to enhance the performance of absorptionrefrigerationcycles.Theabsorptionrefrigerationcyclethatcanutilizewasteheatandsolarthermalenergyasa drivingforcehasgarneredincreasingattentioninrecentyears

Ejector-absorption combined refrigeration cycle

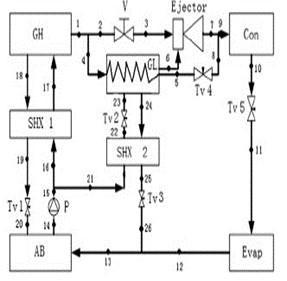

ThevaporabsorptionrefrigerationcycleusinganejectorisanovelapproachtoimprovetheCOPofthesystem.Thesystem usestheH2O/LiBrpairasaworkingfluid.Thewatervaporleavingthegeneratorisdividedintotwostreams.Onestream isdirectedtothelowpressuregeneratorwhereitiscondensedtosaturatedliquid, whiletheotherstreamisinjectedinto theejector.Thepressureofliquidwaterisreducedbyathrottlevalvetothecondensingpressure,andtheremainingvapor inthelow-pressuregeneratorisalsodirectedtothe ejector.Themixtureofvaporleaving theejectoriscondensedinthe condenser,andtheliquid exitingthecondenserisdepressurizedtotheevaporating pressurebya throttlevalve andthen further vaporized in the evaporator. The cycle between the high-pressure generator and the absorber is identical to the standardvaporabsorptioncycle.

Researchers have investigated ejector-absorption refrigeration cycles to improve system performance. Simulation results of the proposed cycle by Hong et al. showed that the COP was 30% higher than that of the conventional single-effect absorptionrefrigerationcycleundercertainworkingconditions.AnexergyanalysisbyAlexisshowedthattheejectorhad the maximum exergy loss of approximately 38%. Shi et al. proposed a half-effect ejector-absorption cycle to elevate the half-effectcycle.Kumaretal.combinedadouble-stageejectorcyclewithasingle-effectabsorptioncycle.Pourjahanetal. conducted a thermodynamic and cost-effective analysis for a double-effect absorption-ejector refrigeration cycle and predicted an overall reduction of 16% in the annual cost after optimizing the cycle. Farshi et al. performed a

thermodynamic analysis on a single-stage effect cycle and compared it with a modified cycle using an ejector to recover pressurefromtheabsorberandincreasemixingoftheweaksolutionandrefrigerantvapor.Veredaetal.projectedseveral ejector-absorptioncycleswithanadiabaticabsorbertoimproveperformance.

Hybrid absorption with an integrated low pressure compressor booster

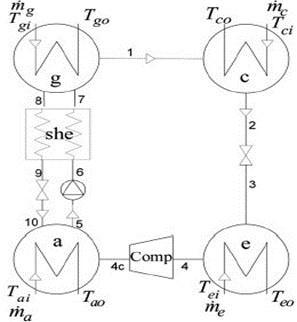

Thevaporabsorptionrefrigerationcycle'sefficiencycanbeenhancedbyutilizinganintegratedlowpressurecompressor booster. The proposed cycle arrangement, as depicted in Fig. 2, involves the high concentration refrigerant solution departingfromtheabsorber(5)andbeingpumped(6)viathesolutionheatexchangertothegenerator,whereitabsorbs heatfromtheweaksolutionreturningfromthegenerator.Ammoniaisseparatedfromthestrongsolutioninthegenerator (7), with the ammonia vapor exiting the generator (1), while the weak solution returns to the absorber via the solution heat exchanger (8-9) and is depressurized using the solution expansion valve. The ammonia vapor is condensed in the condenser(1-2)atarelativelyhighpressure(P1)andthendepressurizedusingarefrigerantexpansionvalve(2-3).Liquid ammonia then vaporizes in the evaporator, producing cooling. The ammonia vapor ispressurized in the compressor and passed to the absorber (4-4c). This modified cycle has three levels of pressure, with the high-density compressed vapor (4c)increasingtheabsorptionrate.

Inthiscycle,thecompressorissituatedbetweentheevaporatorandtheabsorber.Ventasetal.[8]developedanumerical modelofthiscyclewithammonia-lithiumnitratesolutionastheworkingpair,achievingaCOPmaxof0.645atTg,i=65°C andprof2.0,whilethesingle-effectabsorptioncyclereachesthemaximumatTg,i= 95°C,withCOPmaxof0.646.Banker et al. [9] investigated an adsorption cycle that integrated a booster compressor, demonstrating that around 40% energy could be saved with better performance when the temperature difference between the evaporator and condenser exceeded 40°C. Morawetz et al. [10] studied the layout and modifications of the resorption-compression cycle in detail, with the compressor operating in parallel with the basic single-effect absorption cycle in this configuration. The compressor augments the absorption pressure and temperature, decreasing the load on the absorber at a constant evaporationtemperature,whilealsodecreasingtheevaporationtemperatureataconstantabsorptiontemperature.Ifboth the temperatures, along with the generation temperatures, are maintained constant, the compressor boosts the cooling power. Boer et al. [11] explained the fundamentals of this layout in more detail. Herold et al. [12] examined the performance of several hybrid vapor compression-absorption cycles based on LiBrH2O, revealing the potential of hybrid cycles in improving the COP of the system. However, a highperformance steam compressor must be developed for the implementationofthesehybridcyclesinthenearfuture.

Generator- absorber- heat exchanger absorp- tion refrigeration system

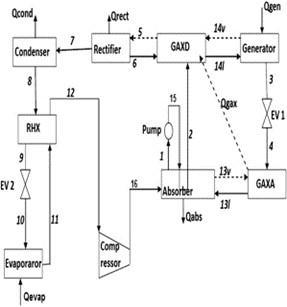

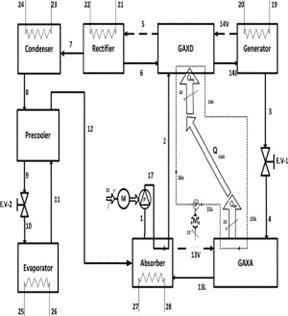

ThepassagedescribestheuseofaGenerator-Absorber-HeatExchanger(GAX)inanammonia-waterabsorption refrigerationcycletoreduceexpansionlossesandpotentiallyimprovetheCoefficientofPerformance(COP).Thesaturated strongsolutionfromtheabsorberispumpedandpassedontothe GAXdesorber whereit boilsandgenerates vapor withhigher refrigerant concentration. The weak solutionflowsback to the absorber via the expansion valve and the GAX absorber. The liberated heat raises the temperature of the solution passing through the GAXD. The ammonia vapor from the generator first enters the GAX desorber and then into the condenser through the rectifier where water vapor is condensed and returns to the generator. The ammonia vapor is convertedtoliquidammoniainthecondenserandthenfurthercooledinthepre-cooler.Thepressureofliquidammoniais reducedintheexpansionvalveanditvaporizesinthe evaporatorbyabsorbingheatfromthecooledproducts.Theweak solutionflowingintotheabsorberfromGAXAabsorbsammoniavaporcomingfromtheevaporatortocompletethecycle.

Mahmoudietal.[13]optimizedtheammonia-waterstandardGAX(SGAX)andhybridGAX(HGAX)absorptionrefrigeration cyclesusingparametricstudiesandgeneticalgorithm(GA)tomaximizeCOPandexergyefficiencywhileminimizingcost ofunitproduct.TheHGAXcycledemonstratedbetterperformancethantheGAXcyclewithaCOPmaxof0.98atTg,i=155 oC.OtherstudiesincludeawasteheatdrivenGAXcycle,athermaloiloperatedGAXprototypecoolingsystem,aSolar-GAX cycle, and a GAX heat pump for both heating and cooling modes. An ammonia GAX absorption cycle for simultaneous heating and cooling was also designed and developed by Park et al. [18] with novel multi-mode GAX cycles operating in threedifferentmodesofcoolingandhotwatersupplywithasinglehardware.

The HGAX absorption refrigeration cycle is a modification of the GAX cycle where a compressor is added between the condenser precooler and absorber. This allows the ammonia vapor from the evaporator to be compressed to a higher pressureandtemperaturebeforeenteringtheabsorber,whichresultsinincreasedheatrecovery.However,alimitationof theHGAXcycleisthatitrequiresacoolingmediumotherthanambientairduetothelowertemperatureintheabsorber.

Dixit et al. [19] conducted an extensive analysis of aqua-ammonia generator-absorber-heat exchanger (GAX) and HGAX absorption refrigerationcyclesbasedon energyand exergy. TheycalculatedtheCOPandexergeticefficiencies atvarious operatingconditionstostudytheeffectofgeneratortemperature,condensertemperature,andevaporatortemperatureon them.ThemaximumCOPfortheGAXcyclevariesbetween0.7and1.1,whilefortheHGAXcycle,itliesbetween1and1.88. Kangetal.[20]proposedfourdifferentmodificationsfortheHGAXcyclesuitablefordifferentapplications.TheCOP value wasfoundtobealmost24%highercomparedtothestandardGAXcycle.RameshKumarandUdayakumar[21]simulateda hybridGAXcycleforairconditioningpurposesandfoundadegassingrangeof0.4correspondingtomaximumCOP.Yariet al.[22]investigatedtheHGAXabsorptionrefrigerationsystemfromtheperspectiveofthesecondlawofthermodynamics. They studied the effect of generator temperature on the COP and second law efficiency of GAX and HGAX cycles and establishedanoptimumvalueforthegeneratortemperaturetomaximizeperformance.

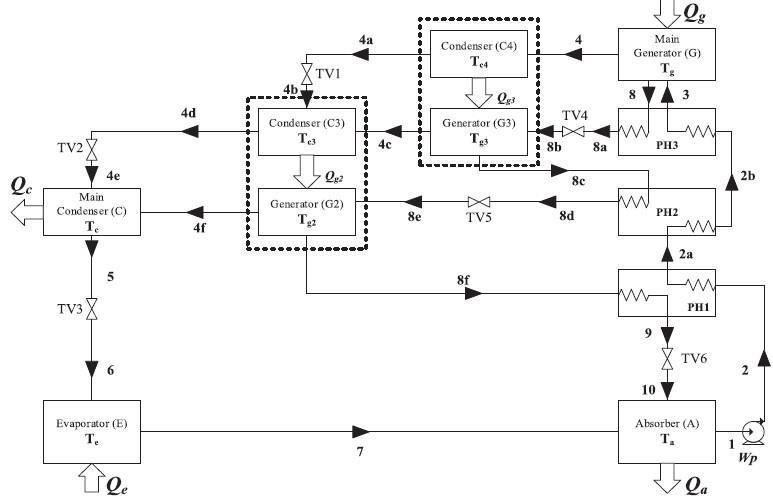

TripleEffectAbsorptionRefrigerationSystem

The efficiency of a vapor absorption refrigeration cycle can be significantly increased by employing a triple absorption refrigeration system. The triple effect vapor absorption system consists of three generators and three condensers, as depictedinFigure5.Theweaksolutionisheatedandpressurizedbeforeentering themaingenerator.Thestrongsolution is heated in the main generator to extract the ammonia vapors. The heat released during the condensation of ammonia vaporinthecondenserisutilizedbythegeneratorG3.ThestrongsolutionfromthegeneratorpassestothegeneratorG3 via preheater, and more refrigerant vaporizes in the generatorG3 and goes to thecondenser. Theweak solutionabsorbs heatfromthestrongsolution,andthestrongsolutionthenpassestogeneratorG2.Morevaporisboiledoffinthegenerator G2toenterthemaincondenser.Thetotalrefrigerantenteringthemaincondenserinthetripleeffectcyclewillbethesum of the refrigerants from all the generators. The liquefied refrigerant passes to the evaporator via a throttle valve and is vaporizedafterabsorptionofheatfromthecooledspace.Theammoniavaporsareabsorbedbythestrongestsolutionin theabsorber.

Azharetal.[23]conductedathermodynamicanalysisofLiBr-H2Osingle,double,andtripleeffectvaporabsorptioncycles usingLPGandCNGassourcesofenergy.Theoperatingtemperaturesinsingletotripleeffectcycleshavebeenoptimized formaximumCOPandminimumgasrequirementusinganiterativetechnique.ThemaximumCOPofthetripleeffectcycle goes up to 1.955, which is around 132% higher than that of the single effect cycle, with its gas requirement reduced to around 122% at the same conditions. Gomri [24] analyzed the first and second law for triple effect absorption cycles yieldingrefrigeratedwater.TheyfoundthatthehighestCOPofthetripleeffectcyclewasobtainedatcertaintemperature values.Ratlamwala etal.[25]determinedtheCOPand exergeticefficiencyofthetripleeffectammonia-waterabsorption refrigerationsystem.Theydemonstratedthe effectofdifferentoperatingvariablesontheCOPofthetripleeffectsystem. Gebreslassie et al. [26] evaluated the COP and exergy efficiency for various arrangements of water-LiBr absorption systems.Khaliqetal.[27]performedenergyandexergyanalysesforanovelsolar-driventriplestagedrefrigerationcycle. The cycle is a combination of ejector refrigeration cycle, absorption refrigeration cycle, and Joule-Thomson cryogenic cycles.

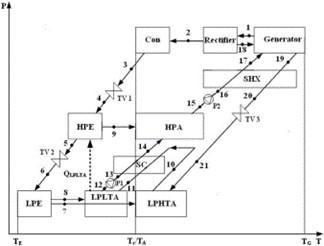

Novelabsorptionrefrigerationcycleusedforwasteheatwithlargetemperatureglide

Fig.6.Schematicdiagramofabsorptionrefrigerationcycleusedforwasteheatwithlargetemperature. glide[28]

Utilizingwasteheatwithlargetemperatureglidecanimprovetheperformanceofvaporabsorptionrefrigerationcyclebya few percentages. In this proposed cycle, an ammonia-water mixture serves as an absorbent while ammonia acts as the workingfluid. Thecycle worksasfollows:thevaporflowsintorectifierafterleavingthegenerator,andinthecondenser, ammonia vapor is converted to liquid ammonia by rejecting heat to the atmosphere. The low temperature absorber in high-pressureevaporatoriscooledbythevaporizingliquidammoniacomingfromthethrottlevalve.Theammoniavapors leaving the high-pressure evaporator proceed towards high-pressure absorber and are subsequently absorbed by the solutionabsorbent.Theunsaturatedammoniavaporoutfromthrottlevalveentersthelowpressureevaporatorandfully evaporates.Onestreamofthesaturatedvaporflowsintothehightemperatureabsorberandisabsorbedbytheammoniawatersolutionapproachingfromthegenerator,whiletheotherstreamisabsorbedbytheabsorbentsolutioncomingfrom hightemperatureabsorberinlowtemperatureabsorber.Thesolutionfromlowtemperatureabsorberispumpedtohighpressureabsorberbypumpviasubcooler.Thesolutionabsorbsammoniavaporfromlow-pressureevaporatorinhighand low temperature absorbers, moves to the high-pressure absorber and further absorbs ammonia vapors. The highly concentratedammoniamixtureinthesolutionprovidesmorecoolingeffecttotheexhaustgas/waterincomparisontothe conventionalsingle-effectcycle.Theoreticalsimulationresultsshowthatthecoolingcapacityperunitmassofexhaustgas of the proposed cycle is about 20% higher than that of a single-effect absorption cycle, especially for the situation that temperatureofsuppliedwasteheatislowerand/orrefrigerationtemperatureislower.Otherproposedcyclesincludethe double-lift absorption refrigeration system, the combination of a single-effect absorption refrigeration cycle with a twostage absorption refrigeration cycle, and the integration of a single-effect cycle and a double-effect cycle with a common evaporator and absorber, which all utilize waste heat recovered from exhaust and cooling water to improve the performance of the combined cycle. A simulation model for analyzing the performance of a CO2/propylene based transcritical cascaderefrigeration-heatpumpsystem wasalsoproposed, whichpredicted an increase of about 6%inthe COP of the system for the given range of operating variables by utilizing a vortex tube instead of an expansion valve for recoveryofexpansionwork.

Conclusion

Thisstudyextensivelyevaluatesvariousmodificationstovaporabsorptionrefrigerationcycles,includingtheuseofan ejector,generatorabsorberheatexchanger,boostercompressor,andmultistagesystems.Basedontheresultsofthisstudy, severalconclusionscanbedrawn.

Firstly, for absorption temperatures and condensing temperatures of 40°C and an evaporation temperature of 5°C, an ejectorcycleyieldsa30%higherCOPthantheconventionalsingle-effectcyclewhentheheatsourcetemperatureexceeds 122.5°C.

Secondly,theboostercompressorcycleenablesareductioninthehotwaterinlettemperature(Tg,i)by24°C,providedthat pressureratios(pr)arenothigherthan2.0.TheCOPandcoolingcapacityremainunchanged.

Thirdly,theGAXandhybridGAXcyclesachievetheirmaximumCOPvalues(0.9-1.3and1.3-1.88,respectively)atgenerator temperaturesrangingfrom160°C to175°C.Astheapproachtemperatureincreasesfrom0°Cto14°C,theCOPoftheGAX cycledecreasesbyupto30%,andthatoftheHGAXcycledecreasesbyupto45%.

Fourthly,thetripleeffectcyclehasthehighestCOP(132%)andrequiresalowvolumeflowrateofgases,makingitmore efficient and economical. The salt concentration in the main generator is lower in the double and triple effect cycles, resultinginalowergeneratortemperaturevalue.

Lastly,theabsorptionrefrigerationcycleusedfor wasteheatwithalargetemperatureglidealwayshasalowerCOPthan theconventionalsingle-effectcycle.Thisisbecausetheammoniaconcentrationofthesolutioninthegeneratorofthenew cycle is much higher than that of the conventional single-effect cycle, allowing the projected cycle to fully use low-grade heatintheexhaustgas.Thisincreasestheωofthenovelcycleupto20%comparedtotheconventionalsingleeffectcycle.

Therefore, the triple effect absorption cycle has the highest COP, followed by the hybrid GAX and standard GAX cycles. However,thevaporabsorptioncyclewithalargetemperatureglidehasthelowestCOP.

References

1. Hong, D., G. Chen, L. Tang and Y. He. 2011. “A novel ejector-absorption combined refrigeration cycle”. International Journal of Refrigeration 34:1596-1603.

2. Alexis,G.K.2014.“Thermodynamicanalysisofejector-absorptionrefrigerationcycleusingthesecondthermodynamic law”. International Journal of Exergy 14:179-190.

3. Shi, Y., D. Hong, G. Chen, L. Tang, Y. He and Y. Zou. 2015. “A two-stage absorption refrigertion cycle with an ejector”. Taiyangneng Xuebao/Acta Energiae Solaris Sinica 36:599-603.

4. Kumar,A.andR.Kumar.2014.“Thermodynamicanalysisofanovelcompactpowergenerationandwasteheatoperated absorption,ejector-jetpumprefrigerationcycle”. Journal of Mechanical Science and Technology 28: 3895-3902.

5. Pourjahan, R., A. Behbahaninia and R. Bahrampoury. 2015. “Exergy analysis and thermoeconomic optimisation of double-effectejector-absorptionrefrigerationcycleusinggeneticalgorithm”. International Journal Of Exergy :18,423442.

6. Farshi,L.G.,A.H.Mosaffa,C.A.I.FerreiraandM.A.Rosen.2014.“Thermodynamicanalysisandcomparisonofcombined ejector-absorptionandsingleeffectabsorptionrefrigerationsystems”. Applied Energy 133:335-346.

7. Vereda, C., R. Ventas, A. Lecuona and R. Lopez.2014. “Single-effect absorption refriger-ation cycle boosted with an ejector-adiabaticabsorberusingasinglesolutionpump”. International Journal of Refrigeration 38:22-29.

8. Ventas, R., A. Lecuona, A. Zacarías and M. Venegas.2010. “Ammonia-lithium nitrate absorption chiller with an integrated low-pressure compression booster cycle for low driving temperatures”. Applied Thermal Engineering 30: 1351-1359.

9. Banker, N.D., P. Dutta, M. Prasad and K. Srinivasan.2008. “Performance studies on mechanical+ adsorption hybrid compressionrefrigerationcycleswithHFC134a”. International Journal of Refrigeration 31:1398-1406.

10. Morawetz,E.1989.“Sorption-compressionheatpumps.International”. Journal of Energy Research 13:83102.

11. Boer, D., M. Valles and A. Coronas.1988. “Performance of double effect absorption compression cycles for airconditioning using methanol-TEGDME and TFETEGDME systems as working pairs”. International Journal of Refrigeration 21(7):542-555.

12. Herold, K.E., L.A. Howe and R. Radermacher.1991. “Analysis of a hybrid compression absorption cycle using lithium bromideandwaterastheworkingfluid”. International Journal of Refrigeration 14:264-272.

13. Mehr,A.S., V.Zareand S.M.S.Mahmoudi.2013.“StandardGAXversus hybridGAXabsorptionrefrigerationcycle: From theviewpointofthermoeconomics”. Energy Conversion and Management 76:68-82.

14. Kang, Y.T., A. Akisawa and T. Kashiwagi.1999. “An advanced GAX cycle for waste heat recovery: WGAX cycle”. Applied Thermal Engineering 19:933-947.

15. Gomez,V.H.,A.Vida,R.Best,O.GarciaandN.Velazquez.2008.“Theoreticalandexperimentalevaluationofanindirect efiredGAXcyclecoolingsystem”. Applied Thermal Engineering 28:975-987.

16. Velazquez, N. and R. Best.2002. “Methodology for the energy analysis of an air cooled GAX absorption heat pump operatedbynaturalgasandsolarenergy”. Applied Thermal Engineering 22:1089-103.

17. Garimella,S.,R.N.ChristensenandD.Lacy.1996.“Performanceevaluationofagenerator-absorberheatexchangeheat pump”. Applied Thermal Engineering 16(7):591-604.

18. Park, C. W, J. Koo and Y.T. Kang.2008. “Performance analysis of ammonia absorption GAX cycle for combined cooling andhotwatersupplymodes”. International Journal of Refrigeration 31:727-33.

19. Dixit, M.2015. “Thermodynamic analysis of GAX and hybrid GAX aqua-ammonia vapor absorption refrigeration systems”. International Journal of Hydrogen Energy 40(46):16256-16265.

20. Kang, Y.T., H. Hong and K. S. Park.2004. “Performance analysis of advanced hybrid GAX cycles: HGAX”. International Journal of Refrigeration 27(4):442–448.

21. Yari, M., A. Zarin and S.M.S. Mahmoudi. 2011. “Energy and exergy analyses of GAX and GAX hybrid absorption refrigerationcycles”. Renewable Energy 36:2011–2020.

22. Ramesh Kumar, A. and M. Udaya kumar.2007. “Simulation studies on absorption compression cooler”. Energy Conversion and Management 48:2604-10.

23. Azhar,M.andM. A. Siddiqui.2017. “Optimization of operating temperaturesin the gasoperated single to triple effect vaporabsorptionrefrigerationcycles”. International Journal of Refrigeration 82:401-425.

24. Gomri, R.2008. “Thermodynamic evaluation of triple effect absorption chiller”. Second International Conference on ThermalIssuesinEmergingTechnologies245-250.

25. Ratlamwala, T. A. H., I., Dincer and M. A. Gadalla.2013. “Performance analysis and evaluation of a triple-effect ammonia-waterabsorption-refrigerationsystem”. International Journal of Energy Research 37:475-483.

26. Gebreslassie,B.H.,M.MedranoandD.Boer.2010.“Exergyanalysisofmulti-effectwater-LiBrabsorptionsystems:From halftotripleeffect”. Renewable Energy 35:1773–82.

27. Khaliq, A., R. Kumar, I. Dincer and F. Khalid.2014. “Energy and Exergy Analyses of a New Triple-Staged Refrigeration CycleUsingSolarHeatSources”. Journal of Solar Energy Engineering 136(1):011004.

28. Shi, Y.,G. Chenand D.Hong.2016.“The performanceanalysisofa novel absorption refrigeration cycleusedfor waste heatwithlargetemperatureglide”. Applied Thermal Engineering 93:692–696.

29. Kalinowski, P., Y. Hwang, R. Radermacher, S.A. Hashimi and P. Rodgers.2009. “Application of waste heat powered absorptionrefrigerationsystemtotheLNGrecoveryprocess”. International Journal of Refrigeration 32:687-694.

30. Zhu, Y.1998. “A single-effect/double-lift cycle-a new absorption cycle for low temperature applications”. Cryogenics and refrigeration proceedings of ICCR 98:167–173.

31. Longo, G.A., A. Gasparell and C. Zilio.2005. “Analysis of an absorption machine driven by the heat recovery on an I.C. reciprocatingengine”. International Journal of Energy Research 29:711–722.

32. Dubey, A.M., G.D. Agrawal and S. Kumar.2016. “Performance evaluation and optimal configuration analysis of a transcriticalcarbondioxide/propylenecascadesystemwithvortextubeexpanderinhightemperaturecycle”. Clean Technology and Environmental Policy 18:105-122.