PRODUCTIVITY IMPROVEMENT USING LEAN TOOLS IN PUMP INDUSTRY

1,2 Lecturer, Dept. of Mechanical Engineering, PSG Polytechnic College, Tamil Nadu, India

3,4,5,6 Students, Dept. of Mechanical Engineering, PSG Polytechnic College, Tamil Nadu, India

Abstract - In its most basic form, lean manufacturing is the systematic elimination of waste from all aspects of an organization's operations, where waste is viewed as any use or loss of resources that does not lead directly to creating the product or service a customer wants when they want it. In many industrial processes, such non-value-added activity can comprise more than 90 percent of a factory's total activity. Nationwide, numerous companies of varying size across multiple industry sectors, primarily in the manufacturing and service sectors are implementing such lean production systems, and experts report that the rate of lean adoption is accelerating. Companies primarily choose to engage in lean manufacturing for three reasons: to reduce production resource requirements and costs; to increase customer responsiveness; and to improve product quality, all which combine to boost company profits and competitiveness.

Key Words: Waste, Industry sector, Productivity improvement

1.INTRODUCTION

The Toyota Production System (TPS), pioneered by a Japanese automobile corporation, Toyota, has been adopted by practically every country in the world due to its global superiority in cost, quality, flexibility, and quick response. Lean is a manufacturing practise that tries to reduce waste across whole value streams in order to provide greater value to consumers. It is a customercentric strategy that focuses on the value stream and its optimisation. The utilisation of resources that do not provide customer value is a target for reform or eliminationunderleanprinciples.

The primary goal of implementing lean manufacturing is to increase production, reduce lead time and cost, and improvequalityinordertoprovidethemaximumvalueto customers. There are numerous descriptions regrading leanmanufacturingintheindustries

1.1 Implementation of lean manufacturing steps

1. Waste identification in the system:Many organisations must be aware that their systems contain severalhiddenandunhiddenwastes.

2. Wastes in the organisation might be of various types: The types of trash and their causes must be identified. Lean manufacturing believes in addressing the root causes of problems and permanently resolving them. Therearenumeroustoolsandtechniquesthatcanbeused toreduceoreliminatethisformofwaste.

3. The next stage is to identify and address the underlying causes:- Stick to core lean concepts and look for root reasons. Looking at causes may not be sufficient, hence it is necessary to discover the effects of the causes solutionontheentiresystem..

4. The final step in the lean implementation process is to identify and test solutions:- After testing, solutions shouldbeimplemented.Trainingandfollow-uparecritical in each of the steps outlined above. It is necessary to be patient because the implementation process may take sometime.

1.2 Waste Types

Thefollowingaretheseventypesofwaste:

(1) Overproduction: It is unnecessary to manufacture more than the consumer requires, or to make it too soon before it is required. This increases the chances of obsolescence and creating the wrong thing. It frequently resultsinhighleadandstoragedurations.

(2) Defects: In addition to physical flaws that directly contribute to the Costs of goods sold, which may include documentation errors, late delivery, production to inaccurate specifications, the use of excessive raw materials,orthedevelopmentofunneededscrap.Rework may be required if a flaw arises; otherwise, the product would be discarded. Defects not only waste material and human resources, but they also cause material shortages, interfere with achieving deadlines, create idle time at

succeeding workstations, and lengthen the manufacturing leadtime.

(3) Inventory: Having excessive levels of raw materials, works-in-process, and finished products. Extra inventory increases inventory finance costs, storage costs, and failure rates. It tends to lengthen lead times, prevents early problem identification, and increases space requirements. It is especially important to remove inventory due to inaccurate lead times in order to undertakesuccessfulpurchasing.

(4) Transportation: This covers any material movement thataddsnovaluetotheproduct,suchasmovingsupplies between workstations. Transportation between processing stages lengthens production cycle times and makes wasteful use of labour and space. Any movement within the firms could be considered waste. With the distance of communication between processes, double handlingandexcessivemotionsarelikelytocausedamage anddeterioration.

(5) Waiting: Idletimeforworkersormachinesasaresult ofonthefactoryfloor, thereare bottlenecksor inefficient production flows. It includes minor delays in unit processing. The waste of waiting happens when time is employedinefficiently.Thiswasteoccurswhilethingsare not being moved or worked on. This waste affects both commodities and workers, who both waste time waiting. Waitingtime forworkerscanbe employedfortraining or maintenance purposes, but it should not lead to overproduction.

(6) Motion: Any needlessphysical motionsor walking by workers that diverts them from genuine processing work is included in this category. This could include walking around the manufacturing floor looking for a tool, or it could be superfluous or uncomfortable physical movements caused by poorly designed ergonomics that slow down the workers. It entails inadequate production ergonomics, in which operators must extend, bend, and pickupwhensuchactivitiesmaybeavoided.

(7) Over processing: It is conducting more processing work than the consumer requires in terms of product qualityorfeaturessuchaspolishingorputtingfinishingin regions of the product that the customer will not see. Over-processinghappenswhenunnecessarilycomplicated solutionstosimpletasksarediscovered.

1.3 The Objective of the Paper

To study the current state of the pump manufacturing industry and the causes of lean wastes.

IdentificationofLeantoolsthatcanbeusedinthe industrytoassistreducedefectsandwaste.

Observing productivity increases as a result of toolimplementation.

Validationusingpreviousinformation

2. LITERATURE REVIEW

In recent years, the Indian manufacturing industry has seen unrelenting rivalry in terms of cheap costs, higher quality, and various goods with greater performance. To confront the challenges given by the competitive climate, Indian entrepreneurs have realised that manufacturing organisations must incorporate quality and maintenance improvement programmes into all elements of their processesinordertoimprovetheircompetitiveness.

Lean is a manufacturing concept that believes that any activitythatusesresourcesbutdoesnotprovidevaluefor the end consumer is wasteful and should be removed. Antony,2011;ShahandWard,2007)

lean production eliminates unnecessary processes, align processes in continuous flow and solve problems through continuous improvements. At operational level lean manufacturing is carried out through a set of lean practices. By implementing these tools and techniques lean manufacturing targets to identify and eliminate numerous wastes exist inside the factory or along the supplychainSohal(1996),

Applytheleantoolbymethodtimemeasurementandline balance efficiency and reduce the cycle time in a truck bodyassemblylineandimproveefficiencyinthatproduct line. Also says that lean manufacturing is a business philosophy that continuously improves the process involveinmanufacturing.

Santoshkumaret,al.(2014)Companies recognize that consistent and disciplined application of lean manufacturing strategies with the emphasis on waste elimination and process streamlining can lead to business excellence (Mejabi, 2003; Taj. 2008; Rahmanetal.,2010).

Lean is a manufacturing paradigm based on the fundamental goals of Toyota Production System (TPS), which is aimed at continuously minimizing waste to maximizeflow(Vinodhetal.,2010),

Applied VSM in a biscuit manufacturing plant and found thatapplicationofleanmanufacturingresultedinincrease in quality, decrease in inventory,increase in timely deliveries better utilization of space and equipments and reductioninleadtime.Upadhyeetal.[2010][24]

3. METHODOLOGY

Theintendedtechniquewasusedtocreatethefuturestate value stream map from the present state value stream map.Byadoptingkaizen,manytoolsandtechniquesfrom the Lean Production System were applied to generate a continuous flow in the line. Several continuous improvements have been achieved to reduce cycle time, lead time, worker count, work in progress inventory, and nonvalueaddedtime.

4. TAKT TIME

Takt time is the maximum amount of time required to develop a product in order to meet client demand. The word"aks"isderivedfromtheGermanword"pure."Takt, whichisdeterminedbyconsumerdemand,establishesthe pulse throughout all processes in a firm to maintain continuous flow and capacity unification. The takt time is the amount of time that must elapse between two consecutiveunitcompletionsinordertomeetdemandifa product is manufactured one unit at a time at a constant rate within the net available work time. The amount of timeavailableforworkisreferredtoasnetavailabletime.

Example The takt time for the following this to be calculated.

The monthhas22 working days with2 shifts per day

8hourspershift.

Breaksaddupto1hourpershift.

TheOEEis78%

Expectedcustomerdemand20.000parts.

WorkableproductionHours

TaktTime= UnitRequired(customerdemand) 720 = 1000 =44min/day

5. OVERALL EFFICIENCY OF EQUIPMENT

Overall Equipment Effectiveness (OEE) is a method of measuring and improving manufacturing process efficiency. OEE has gained acceptance as a management technique for measuring and evaluating machine productivity.

Before

A=Runtime/Totaltime=78.09%

P=Totalcomponentsdividedbytargetcount=78.09%

Q=98.47%ofgoodcomponents/totalparts

OEE=A*P*Q=60.04%

After

A=Runtime/Totaltime=89.28%

P=Totalpartsdividedbytargetcount=89.28%

Q=Goodpartsdividedbytotalparts=98.66%

OEE=A*P*Q=78.64%

6. SMED (Single Minute Exchange of Die)

SMED(SingleMinuteExchangeofDie)is asystemusedto dissectandreducesetuptimes.TheinnovatoroftheSMED system is the Japanese mastermind Shigeo Shingo. He showed that setups that took hours could be reduced to twinkles SMED methodology operation consists of four distinct stages primary Stage Internal and external setup notdiscerned;

•Stage1–Separateinternalandexternalsetup

•Stage2–Convertinternalintoexternalsetup

•Stage3–explaintheinternalandexternalsetup.

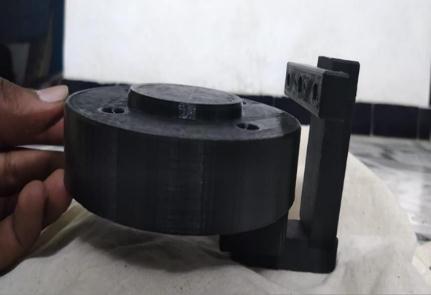

Inthiswehavecreatedanylon3Dprintedjig,becausethe oldmetaljigwasheavyandhightimeconsuming.

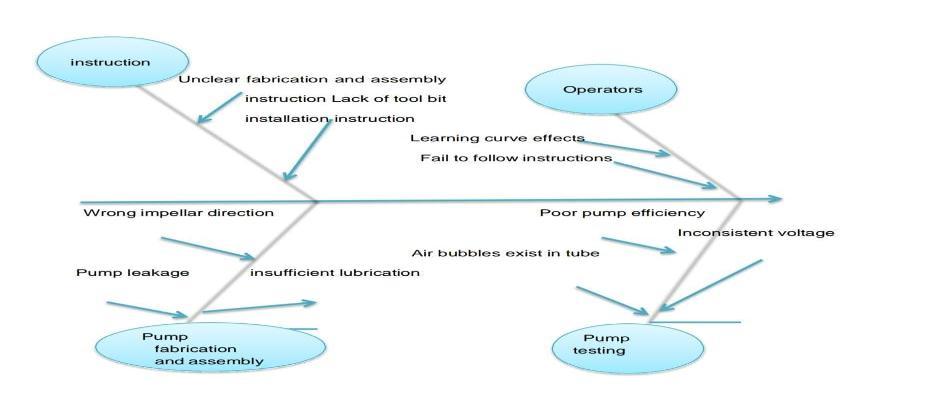

7. FISH BONE

A fishbone diagram is a cause-and-effect discovery tool that aids in determining the causes of flaws, variances, or failures in a process. In other words, it aids in the breakdown. Root factors that may contribute to an effect are identified in successive layers. A fishbone diagram, also known as an anlshikawa diagram or cause-and-effect analysis, is one of the primary techniques used in root causeanalysis.Afishbonediagram,asthenameimplies,is a representation of a fish skeleton. The underlying problem is represented by the fish's head, and the causes arerepresentedbytheskeleton'sbonestotheleft:theribs branchoffthebackandrepresentmajorcauses,whilesubbranches branch off of the cause and represent root causes.Thesecausesresemblethefishskeleton'sbones.

Productivityimprovesto7.7%.

For practitioners in the pump manufacturing industries, thiscasestudyprovidesuswiththeprivilegetolearnalot fromthespecificcasestudyproblemanditalsoprovidesa scopeforfurtherresearch.

9. REFERENCES

[1].Ramesh V, Sreenivasa Prasad KV, Srinivas TR (2011) Implementation of a lean model for carrying out value stream mapping in a manufacturing industry. J Ind Syst Eng 2(3):180–196.

[2].Aniket B. Pawar, C. A. Waghmare. Improving Productivity By Reducing Cycle Time Through Value Stream Mapping In Pump Manufacturing Industry, Proceedings of 7th IRF International Conference, 27th April-2014, Pune, India,ISBN: 978-93-84209-09-4.

[3].Mulla M. L.,Bhatwadekar S.G, PanditS.V,2014, ―ImplementationofLeanManufacturingThrough The Technique of Single Minute Exchange Of Die (SMED) to Reduce Change Over Time‖

.International Journal of Innovative Research in Science,EngineeringandTechnology,ISSN:23198753.

[4].Prof.Rahul.R.Joshi1, Mr.Rahul, Patil, Prof.G.R.Naik, Prof.M.V.Kharade.―Through Put Time Reduction

Lean Manufacturing‖, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) ISSN: 22781684,PP:40-45.

8. CONCLUSION

Thefollowingaresomeofthesalient conclusionsthatare drawnbasedonthepresentstudies:Itwasobservedfrom the current state map that the total lead time for the product is more than value added time. After the improvementsbeenmade,Processleadtimereducesfrom 24.4daysto16.14days

Inventoryreducesto8.26days

Continuousflowbeencreatedwhereverpossible

Operators reduced from 7 to 3 in the machine shopby

Balancingtheworkcontent.

Achievedsinglepieceflowinsubassembly

[5].Hudli Mohd, Rameez, K.H.Inamdar. ―Areas of Lean Manufacturing for Productivity Improvement in a Manufacturing Unit‖, World Academyof Science,EngineeringandTechnology, Vol:42010-09-20.

[6].BharathR,DrGSPrakash,―Leadtime Reduction UsingLeanManufacturing PrinciplesForDelivery Valve Production‖,Global Journal of Finance and Management. ISSN 0975-6477Volume6, Number 1(2014),pp.35-40.

[7].Ramamoorthy.C. Dr. V. Selladurai Dr. S.Venkatachalam (2008),―Efficiency Enhancement of Centrifugal Monoblock Pump throughLeanManufacturingSystemusingKaizen Techniques.,‖IJAEA,Volume1,Issue2,pp38-44.

[8].Martín Tanco , Javier Santos Jose Luis Rodriguez :Applyingleantechniquestonougatfabrication:a

seasonal case study, Int J Adv Manuf Technol (2013)68:1639–1654.

[9]. Karthik .T, Senthilkumar.M, ―Improvisation of Productivity Through Layout Optimization In Pump Industry‖, International Journal of Lean ThinkingVolume3,Issue2(December2012).

[10]. Rahani AR, Muhammad al - Ashraf,―Production Flow Analysis through Value Stream Mapping: A Lean Manufacturing Process Case Study‖, ProcediaEngineering,41(2012)1727–1734.