Sewage water Treatment Using Moving Bed Bio-Film Reactor over SBR

Aditya Jagdhani1 and Nitin Sawalkar21MTech, VIIT, Pune, Maharashtra, India.

2Asst. Prof., VIIT, Pune, Maharashtra, India. ***

Abstract - Biofilms are a key feature of the Moving Bed Biofilm Reactor (MBBR) system, which combines both the Activated Sludge Process (ASP) and the Bio-filter Process, being able to make use of both suspended biomass and attached biomass. Moving Bed Biofilm Reactor (MBBR) media have been used in this study as an attached media to evaluate organic matter removal efficiency. A study was conducted to investigate the effect of factors such as Aeration Time on the performance of a reactor in order to remove Organic Matter. This study investigated the performance of the MBBR and SBR at a lab-scale during batch operation while changing Aeration time of 30min,60min and 90min.MBBR shows best result with aeration time of 90min allowing removal efficiency of 97% for Bod and 95% for COD while comparing both the SBR and the MBBR.

Key Words: MBBR,AERATIONTIME,BOD,COD,TSS

1. INTRODUCTION

Thesewagewastewatersareessentiallyproducedfromthe latrines, showers, showers, kitchen sinks, laundries and a few little ventures. The assessed sewage generation from ClassIandClassIItowns29129MLD.Currentsewageage from metropolitan regions in the nation is assessed at 72,368MLDagainstwhichsewagetreatmentlimitof31,841 MLD is accessible. Sewage water is portrayed by high biochemicaloxygeninterest(Body)andcompoundoxygen interest (COD) focuses, and by and large contains Disintegrated oxygen, Chlorine, Hardness along with cleansersanddisinfectingspecialists.Becauseofthegreat release of burden from the homes, shops, workplaces, limited scope processing plants, ranches, and so on Assuming the water from these sources is left untreated withoutappropriatetreatmentorbysomewhattreatingit might create a few serious natural issues. In addition, the Indiangovernmentandthe contaminationcontrol leading group of both focal government and state has forced extremelysevereguidelinesandGuidelinesfortheprofluent release to safeguard the climate. Consequently, it is importanttoproperlytakecareofthetreatmentstrategies which are required in order to fulfill the gushing release guidelinesbygovernment.

Sewage efflux contains solvent natural matter, suspended solids.Thesecom-ponentscontributegenerallytowardshigh natural oxygen interest (Body) and substance oxygen interest(COD).Theshadeofthenewsewageismarginally darkinvarietyandnormallyissomewhatantacidinnature

andbecomeacidicquicklysomeofthetime.Thesuspended matter in like protozoa, microbes and infections or rot of plantsorcreatures.Thecontaminationimpactofsewerage squanderisrequiringpromptandhighoxygeninterest.The attributes of sewage wastewater contain Temperature, Colour, pH 6.5-8.0, DO, Body, COD, Broke up solids, suspendedsolids,chlorides,sulphate.Itreliesgenerallyupon the amount of sewage created each day and the waste let intothechannels.Notwithstandingwaterfromthelocalarea watersupply,squanderwatercomprisesofhumanexcreta (dung and pee), water from the restrooms, and food arrangement squanders. It likewise contains nitrogen and phosphorusgotfromhumanwaste,aswellascleansersand sanitizers utilized in washing. It has high sodium content from the utilization of harsh soft drink for cleaning in ventures.MBBRmediaisdisplayedinfigure1.

Borghei et al., (2004) carried out the study on using MovingBedBiofilmReactorsintreatingdifferentdomestic andindustrialwastewaters.Currently,therearemorethan 400unitsoffullscaledwastewatertreatmentplantsbased onthisprocess.

JamesMcquarriecarriedoutthestudyonprocessincludes a submergedbiofilmreactorandliquid–solidseparation unit. The MBBR process shows Capacity to meet similar treatment objectives as activated sludge systems, with respect to carbon oxidation and nitrogen. Biomass retention is clarifier-independent. The MBBR is a continuous-flow process that does not require a special operational cycle for biofilm thickness control. Liquid–solid separation can be achieved with a variety of processes,includingconventionalandcompacthigh-rate processes.

1.2 Sub Heading 2

2. METHODOLOGY

2.1. Materials

Moving bed bio film reactor is a type of wastewater treatment process. It utilizes floating high-capacity microorganism Biochips media within the aeration and anoxic tanks. MBBR media is a free-floating media which houses huge quantity of active biomass. Within the bioreactor, the floating media serves as a non-clogging medium once submerged.Unlike other technologies,there arenochannelsordeadspots.Dependingonreactordesign and effluent requirements, movement is caused either by aerationormechanicalstirring.TheMBBRmediarepresents flexibility and new engineered potentials in waste water treatmentplantoperation.TechnicalspecificationsofMBBR mediaarementionedinTableno1.

material with a density close to the density of water (1 g/cm3). An example is high-density polyethylene (HDPE) whichhasadensitycloseto0.93g/cm3.Asthecarriersare mixedinthetankbytheaerationsystem,theywillhavegood contactwiththesubstrateintheinfluentwastewater.

3. Experimental Setup

The reactor was setup at the Sewage treatment plant lab Deagoan Solapur. A rectangular shaped tank built of glass with0.45mlength,0.25mwidthand0.30mdepth.Thelab scalereactor(Model)preparedforconductingtestsonwater isinfigure2. Tomixthecarriersandsupplyoxygentothe microbialmass,airdiffuserswereinstalledatthebottomof thereactorataconstantflowrateof2.5l/min.

Thelaboratoryscalebasinisfabricatedusing5mmthick glassmaterial.Thereistank model comprising ofbasin. A volumeofwastewatertreatedin27Lit.tankinwhich12Lit wastewater is treated. Valves are provided at different sectionsandatdifferentdepthsforsamplingpurpose.Inlet valveisprovidedatthetoptocontroltheinfluentflowrates andtheoutletvalvesareprovidedforcleaningandsludge wastage. Decanting is done using a pipe and is controlled with a valve. The readings are taken for three different intervalsofCODandBOD.

It consists of an aeration tank (similar to an activated sludge tank) with special plastic carriers that provide a surfaceforbiofilmstogrowon.Thecarriersaremadeofa

4. RESULT AND DISCUSSION

Effect of Aeration Time on the performances of reactor in termsoforganicmatter

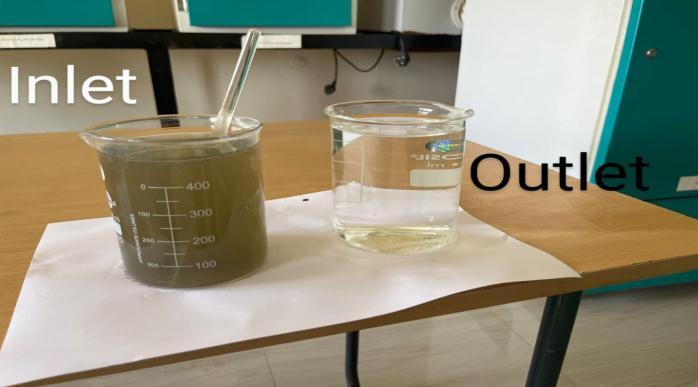

Aerationtimeisanimportantoperationalvariablewhichcan be easily con-trolled. It is calculated by dividing the tank volume by daily average flow without regard to return sludge. Figure no 3 shows the wastewater before the treatmentandafterthetreatment.Thewateraftertreatment islessturbidity.

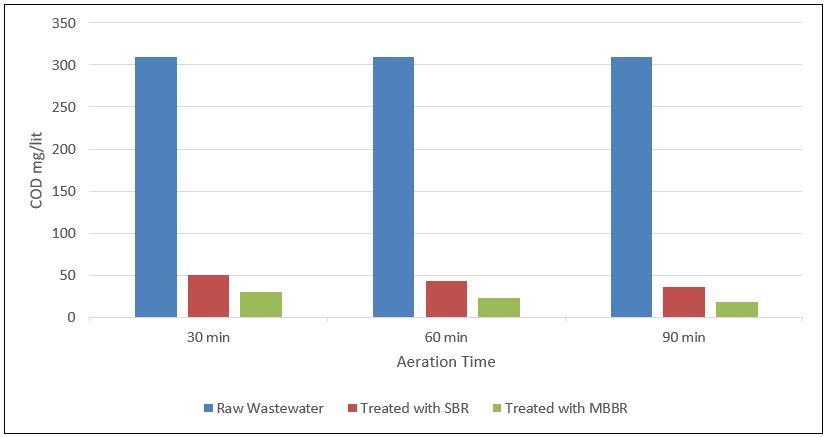

TheCODremovalobtainedforAerationtimeof30min,for60 min,andfor90minisshownintable2

TheCODofWastewaterafterdifferentstagesofexperiment isshowninfig3.

The wastewater before the treatment and after the treatmentisshowninfig5thewateraftertreatmentisless inturbidity.

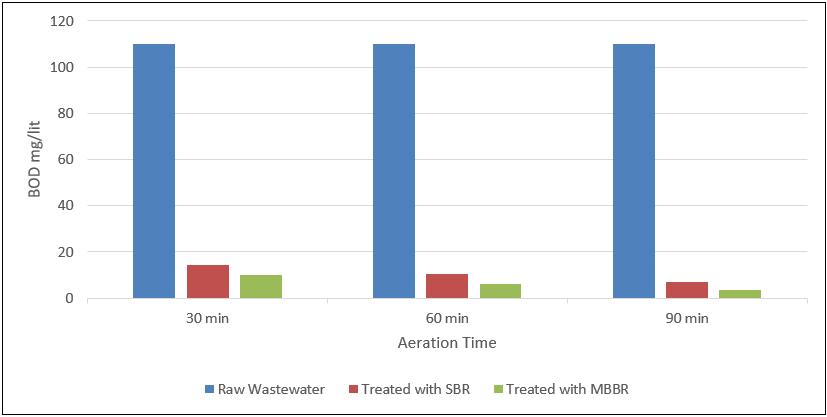

TheBODremovalobtainedforAerationtimeof30min,for 60min,andfor90minisshowninTableno3.

4. CONCLUSIONS

1. TheMBBRshowstohaveagoodperformancetotreat sewage wastewater, reaching a removal efficiency of 95%forCODand97%forBODfor90minofaeration.

2. Afterthetestscarriedoutalongthiswork,itispossible toconcludethat,theCODefficiencyis95%for90min from the other two cycles of 60 min and 30 min of aerationforMBBR.

3. Afterthetestscarriedoutalongthiswork,itispossible toconcludethat,theBODefficiencyis97%for90min from the other two cycles of 60 min and 30 min of aerationforMBBR.

TheBODofWastewaterafterdifferentstagesofexperiment isshowninfig4.

4. ThecyclesofBOD60minand30minofaerationfailsto reachthepermissiblelimitofBODinSBR.

5. TheMBBRhasshowngoodresultsthantheSBRwhile carryingoutthetests.

6. TheHRTrequiredforMBBRislessthanthatoftheSBR soitisenergysaving.

7. SampleparagraphDefineabbreviationsandacronyms thefirsttimetheyareusedinthetext,evenafterthey havebeendefinedintheabstract.Abbreviationssuchas IEEE, SI, MKS, CGS, sc, dc, and rms do not have to be defined.Donotuseabbreviationsinthetitleorheads unlesstheyareunavoidable.

REFERENCES

[1.] Ahl.,R.M.,Leiknes.,T.&Odegaard.,H.(2006),“Tracking particle size distributions in a moving bed biofilm membrane reactor for treatment of municipal wastewater.”,WaterSci.Technol.,53:33-42.

[2.] Andreottola., G., Foladori., P., & Ragazzi., M. (2000), “Upgradingofasmallwastewatertreatmentplantina coldclimateregionusingamovingbedbiofilmreactor (MBBR)sys-tem”,WaterSci.Technol.41,177-185.

[3.] AygunAhmet,etal.,(2008)“InfluenceofHighOrganic LoadingRatesonCODRemov-alandSludgeProduction in Moving Bed Biofilm Reactor”, Environmental EngineeringScience,Volume25,Number9,2008.

[4.] BrinkleyJohn,“movingbedbiofilmreactortechnology–afull-scaleinstallationfortreatmentofpharmaceutical wastewater.”

[5.] Hosseini., K.E., et al. (2011), “Comparison of overall performance between moving-bed and conventional sequencingbatchreactor.”Iran.J.Environ.Health.Sci. Eng.,2011,Vol.8,No.3,pp.235-244.

[6.] Rusten.,B.,etal(2006),“Designandoperationsofthe Kaldnesmovingbedbiofilmre-actors.”AquacultEng., 34:322–331.

[7.] Ødegaard.,H.,Rusten.,B.,&Westrum.,T.(1994)“ANew MovingBedBiofilmReactorApplicationsandResults,” WaterScienceandTechnology,29,157-165

[8.] Maurer M., et al (2001), “Moving-bed biological treatment (MBBT) of municipal wastewater: denitrification”,WaterScienceandTechnologyVol43 No11pp337–344.

[9.] MarquesJ.J.,etal.,(2008),“AttachedBiomassGrowth andSubstrateUtilizationRateinaMovingBedBiofilm Reactor”,BrazilianJournalofChemicalEngineering,Vol. 25,No.04,pp.665-670,October-December,2008

[10.] Makowska M., et al., (2009), “Treatment of Septic TankEffluentinMovingBedBiolog-icalReactorswith IntermittentAeration”,PolishJ.ofEnviron.Stud.Vol.18, No.6(2009),1051-1057.

[11.] Kermani., M., Bina., B., et al (2009), “Biological phosphorus and nitrogen removal from wastewater using moving bed biofilm process,” Iranian Journal of Biotechnology,Vol.7,No.1,January2009.