ANALYSIS OF SHRINKAGE AND WARPAGE DISPLACEMENT USING CONFORMAL COOLING

Shani Singh1, Dr. Satnam Singh2Abstract

This research paper presents a comprehensive comparison between conformal and conventional cooling channels in injection molding, focusing on geometric conformity, cooling performance, and part quality. The study demonstrates that conformal cooling channels offer a more compact design, with lower displacements in all directions. This enhanced geometric conformity leads to improved space utilization and better adaptation to complex part geometries. The cooling performance of conformal channels is found to be superior to conventional channels, with shorter cooling times and higher cooling efficiency. This results in increased productivity and reduced cycle times. Moreover, conformal cooling channels exhibit better thermal management, lower volumetric shrinkage, and improved flatness, contributing to higher part quality and reduced warpage. The research findings underline the potential of conformal cooling technology as a valuable solution for optimizing the injectionmoldingprocess.

Keywords: conformal cooling channels, conventional cooling channels, cooling efficiency, flatness and volumetricshrinkage

Introduction

The article titled "Analysis of shrinkage and warpage displacementusingconformalcooling"discussestheuseof conformalcoolingininjectionmoldingprocessestoreduce shrinkage and warpage displacement. Shrinkage and warpage are common issues in injection molding, which can lead to dimensional inaccuracies and other defects in themoldedproducts.

The article describes the methodology used to simulatetheeffectsofconformalcoolingonshrinkageand warpage displacement. The authors create a 3D model of themoldandsimulatetheinjectionmoldingprocessusing finite elementanalysissoftware.Theycomparethe results of simulations using conventional cooling channels versus simulationsusingconformalcoolingchannels.

The results of the study show that conformal cooling can significantly reduce the shrinkage and warpage displacement in injection-molded parts. The authors

***

concludethattheuseofconformalcoolingcanimprovethe dimensional accuracy and quality of injection-molded parts,resultingincostsavingsformanufacturers.

Overall, this article highlights the importance of controlling shrinkage and warpage displacement in injection molding processes and the potential benefits of usingconformalcoolingtoachievethis.Italsounderscores the value of simulation techniques in understanding the effects of process parameters on the quality of manufacturedproducts.

Literature Review

Injection molding is a widely used manufacturing process for producing parts with complex shapes. However, the production process is often associated with challenges such as shrinkage and warpage. These issues can cause dimensional inaccuracies, reduced mechanical properties, andproductdefects[1].Studieshaveinvestigateddifferent methodstomitigatetheseproblems,andonesolutionthat has been explored is the use of conformal cooling. Conformal cooling is a technique that involves designing and manufacturing molds with cooling channels that conformtotheshapeofthepartbeingproduced,allowing for more uniform cooling[2]. It has been shown that shrinkage and warpage defects in injection-molded parts are significantly influenced by factors such as injection pressure,holdspressure,andcoolingtime[3]Studiessuch as Liao et al have investigated optimal process conditions for shrinkage and warpage in thin-wall parts. Other research, such as that by Doerffel et al, has studied the deformation of injection molded parts and validated the quality of plastic parts based on laminated sheet parts [4].Further research by Mlekusch has compared the corner-warpage of short fiber reinforced injection moldings versus non-reinforced systems, showing that fiber alignment can result in orthotropic effects that contributetoincreasedwarpage[5]

According to Hu et al, FE modeling of the mapmolding process was carried out for a map mold encapsulated with the epoxy system and the warpage [6] caused by the curing process and the subsequent cooling down stage was investigated. Additionally, studies have

shown that the surface temperature of the mold is an essentialfactorindeterminingwarpage[7]

Researchers, such as Yang et al, have evaluated the effectiveness of conformal cooling in reducing warpage and dimensional inaccuracies. Their results showed that conformal cooling can significantly improve the quality of injection-molded parts by reducing shrinkage and warpage[8]

However, while there have been many studies on the shrinkage and warpage of injection-molded parts, some aspects remain unexplored. For example, there is a lack of detailed research on the correlation optimization betweenvolumeshrinkageandwarpage.Additionally,few studies have investigated the warpage of large-sized orthogonalstiffenedplasticplates.Moreresearchisneeded to fully understand and address these issues in injection molding. Nevertheless, current findings suggest that conformalcoolingcanbeaneffectivesolutionforreducing shrinkage and warpage in injection-molded parts. By optimizing process parameters such as pressure, temperature,andcoolingtimewhileutilizingconform

Methodology

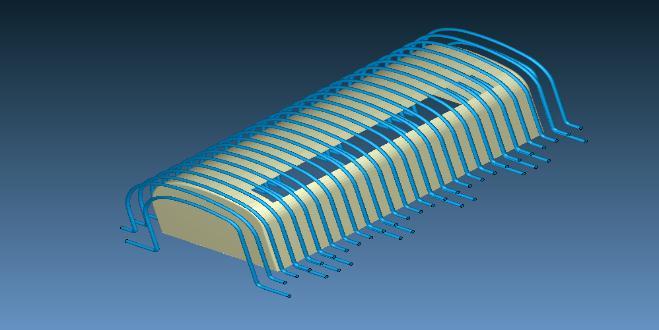

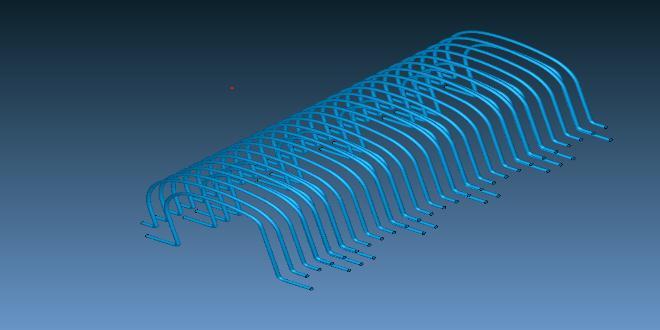

CAD Modelling

Creation of CAD Model by using CAD modelling tools in solidworksforcreatingthegeometryofthepart/assembly.

Governing Equation

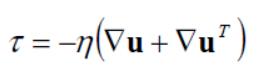

In this study, the fluids are considered to be incompressible, Newtonian (for water) or generalized Newtonian (for polymer melt). The governing equations for3Dtransientnon-isothermalmotionare:

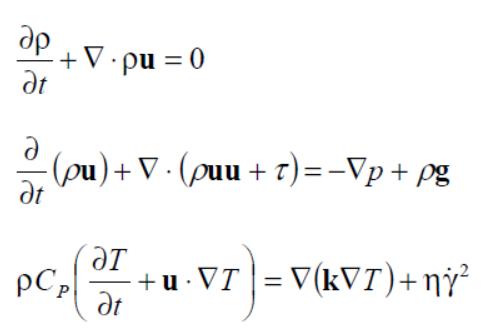

The modified-Cross model with Arrhenius temperature dependence is employed to describe the viscosity of polymermelt:

where u is velocity vector, T is temperature, t is time, p is pressure, τ is stress tensor, ρ is density, η is viscosity, k is thermalconductivity,Cpisspecificheat&isshearrate.For thepolymermelt,thestresstensorcanbeexpressedas:

wherenisthepowerlawindex,isthezeroshearviscosity,* is the parameter that describes the transition region between zero shear rate and the power law region of the viscositycurve.

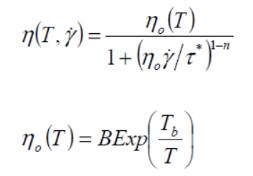

Thetotalelementnumberisfromtothenumerical schemes,Moldex3Dusesahybridfinite-difference/control volume/finite elementmethod.Timestepselectionhas an important effect on accuracy and calculating speed. An internal parameter was carefully chosen to have a good balanceonaccuracyandefficiency”.

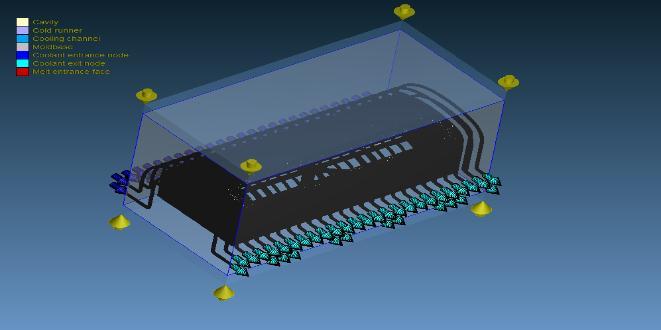

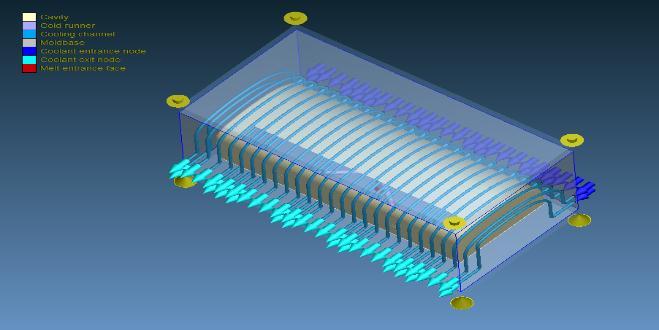

Pre-Processing

Import part/ insert geometry: import a CAD modelformouldanalysis.

Meshing: Cross section is a basic operation in molding process. In this operation, the CAD geometry is discretized into expansive quantities oflittleElement andhubs. Thegame planof hubs and component in space in a legitimate way is called network. The examination exactness and term relies on upon the cross section size and introductions.Withtheexpansionincrosssection size (expanding no. of component) the CFD examination speed diminish however the precisionincrement.

Type of Wizard:

1. Gate wizard: choose best gate location forfillingofmaterial

2. Runner wizard: choose the type of runnerformouldingprocess

Boundary Condition: Define the desired boundary condition for the problem by choose moldbasewizard

Cooling Channel: design the cooling channel for coolingthepartinmouldingprocess

Selection of inlet and outlet section in cooling channel: Selecting the section from where the fluidisenterandexitincoolingchannel.

Generate meshing: bygeneratingmeshthefileis readytoexecute.

Post Processing

Material Property:Choose theMaterial property formoldingprocess

Processing: For viewing and interpretation of Result. The result can be viewed in various formats:graph,value,animationetc.

Model Details

Table 1: Modeldetails

S. No. Parameter

1 Material ABS(CYCOLACBDT5510)

2 PartThickness 1.8mm

3 Length 820mm

4 Breadth 299mm

5 Hieght 250mm

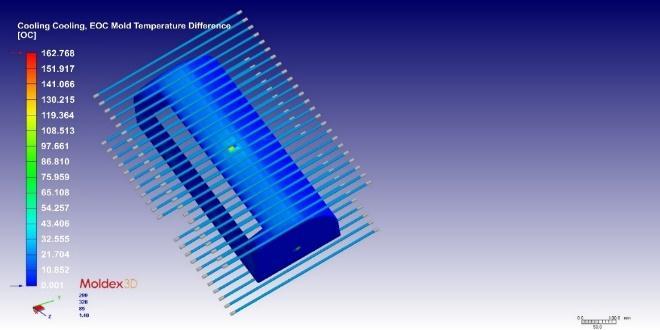

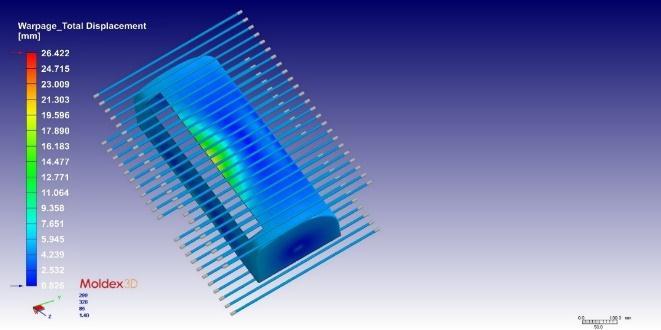

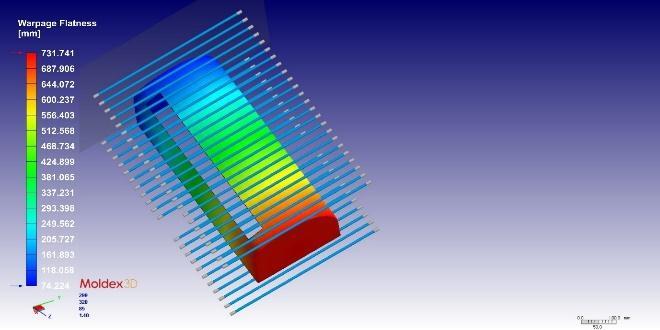

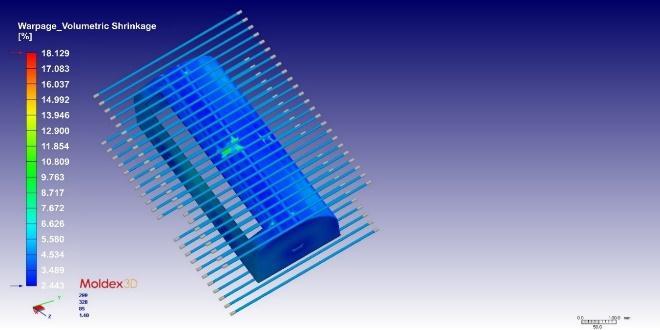

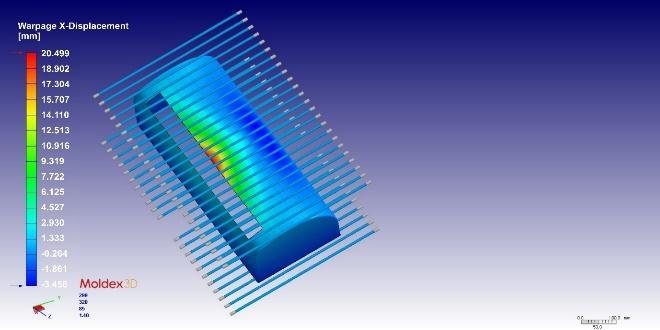

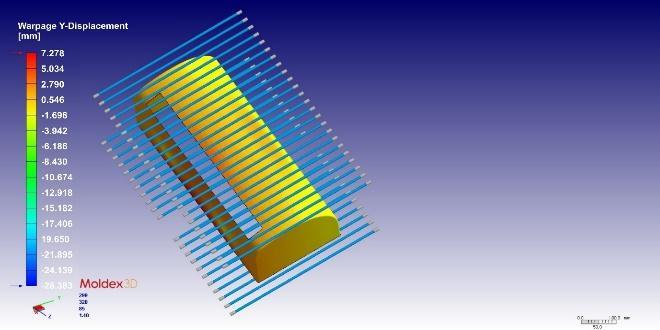

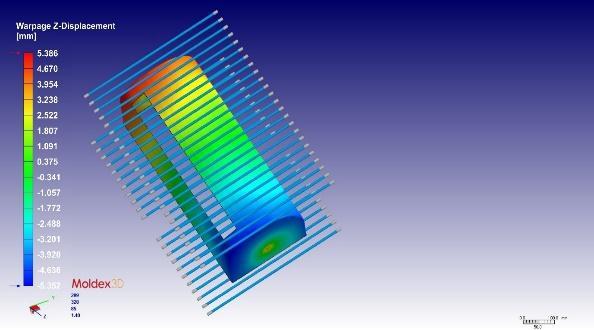

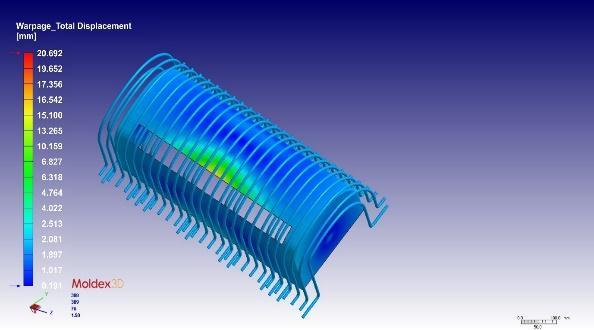

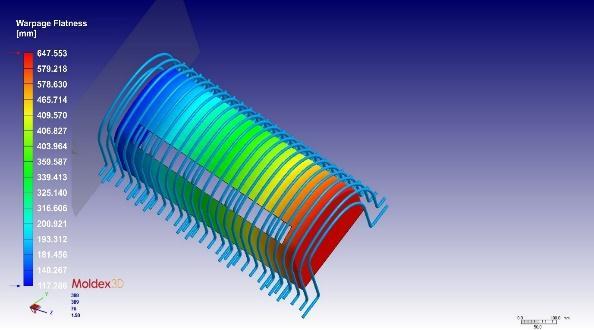

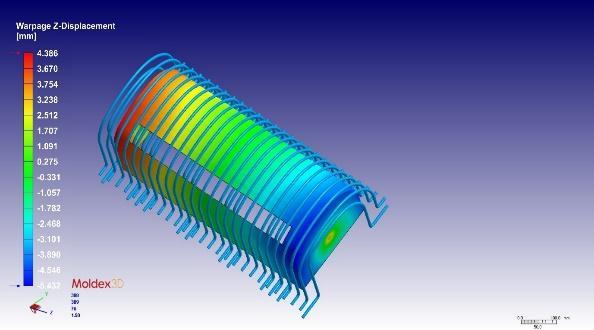

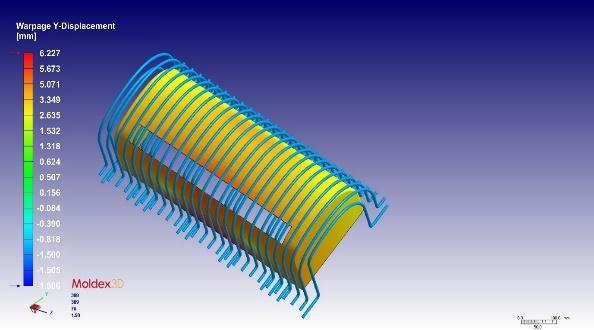

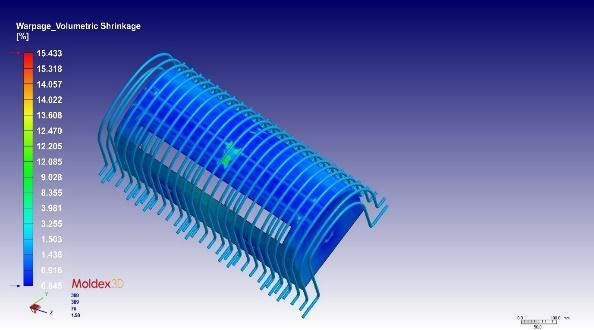

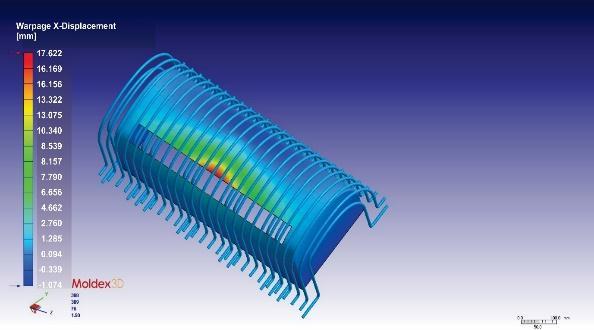

conformal cooling channels have a more compact design, with lower displacements in the X, Y, and Z directions (17.622, 6.227, and 4.386, respectively) compared to conventional cooling channels (20.499, 7.278, and 5.386, respectively). The total displacement is also lower for conformal cooling channels at 20.692, as opposed to 26.422 for conventional channels. This indicates that conformal cooling channels can provide better geometric conformity and space utilization. Moreover, conformal cooling channels showcase lower volumetric shrinkage (15.433)thanconventionalchannels(18.129),whichcould potentially lead to better dimensional accuracy and reduced warpage. The flatness value is also lower for conformal channels (647.553) compared to conventional channels(731.741),suggestingimprovedsurfacequality.

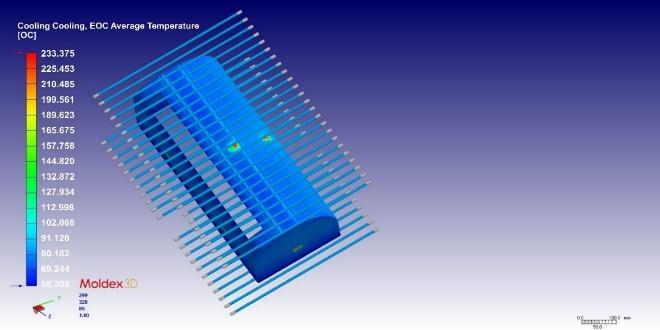

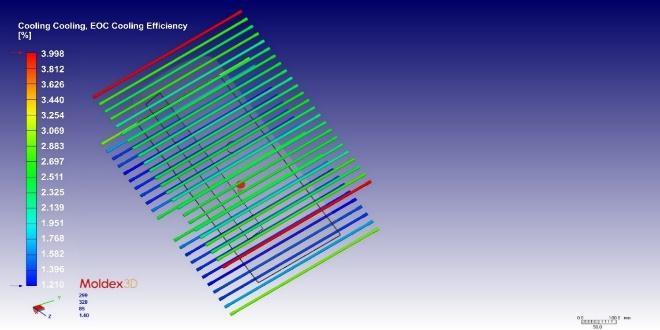

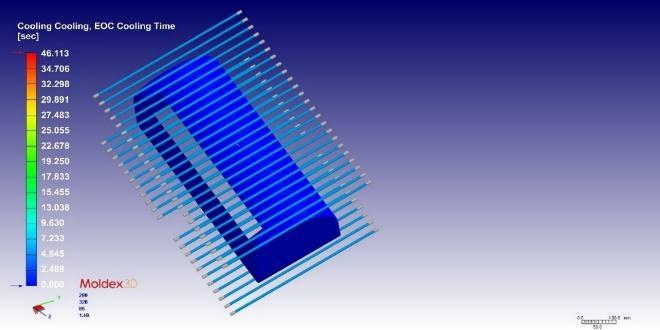

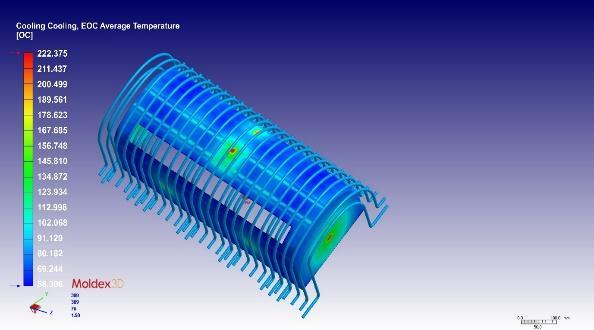

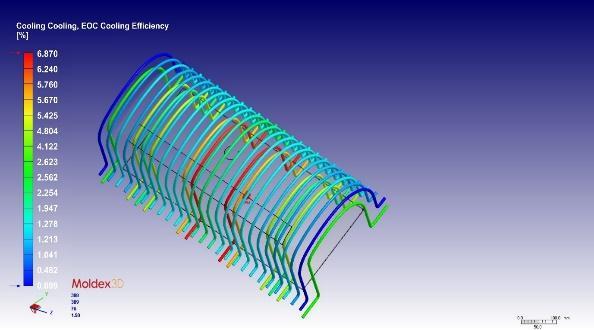

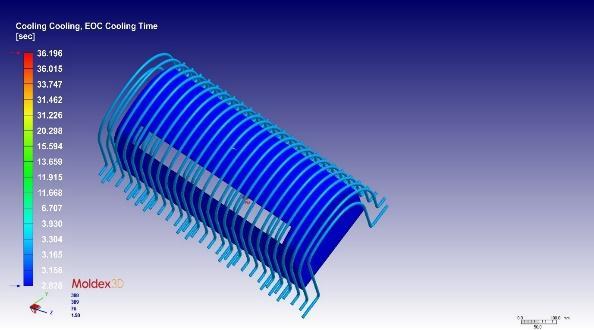

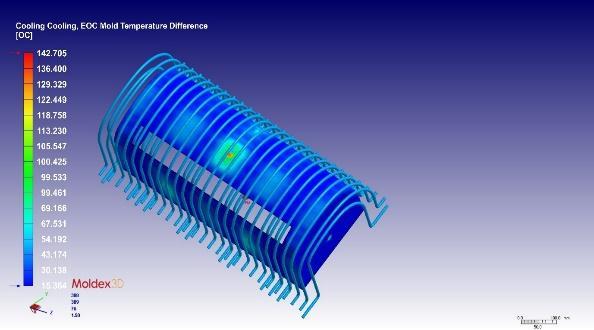

In terms of cooling performance, conformal cooling channels significantly outperform conventional channels with a shorter cooling time (36.19 vs. 46.113) and higher cooling efficiency (6.870 vs. 3.998). This implies that conformal cooling channels can reduce cycle time and improve productivity. Additionally, conformal channels exhibit a lower mold temperature difference (142.705) comparedtoconventionalchannels(162.768),whichcould lead to more uniform cooling and reduced thermal stresses. The average temperature (Avg temp0) is also

lowerforconformalcoolingchannels(222.375)compared to conventional cooling channels (233.375), indicating better thermal management. Overall, conformal cooling channels offer several advantages over conventional coolingchannels,includingenhancedcoolingperformance, reducedcycletimes,andimprovedpartquality.

References

[1]. P.LinandC. Lee."Process Parameters Optimization for an Injection-Molded Plastic Wheel by Uniform Design of Experiment and Kriging Interpolation". Destech Transactions on Engineering and Technology Research. no. apetc. Jun. 2017. 10.12783/dtetr/apetc2017/10884.

[2]. M. Göktaş and A. Güldaş. "Production of Plastic InjectionMoldswithConformalCoolingChannelsby LaminatedBrazingMethod".GaziUniversityJournal of Science. vol. 33. no. 3. pp. 780-789. Sep. 2020. 10.35378/gujs.621930.

[3]. T. Bhirud and R. M. Metkar. "Experimentation and Optimization of Shrinkage in Plastic Injection Molded GPPS Part". Jan. 2017. 10.2991/iccasp16.2017.18.

[4]. T.JachowiczandV.Moravskyi."NumericalModeling of Cooling Conditions of Thermoplastic InjectionMolded Parts". Acta Mechanica Slovaca. vol. 20. no. 1.pp.42-51.Mar.2016.10.21496/ams.2016.007.

[5]. F. Tan. "Experimental Investigation of the Mechanical Properties of Injection-Molded PA66+PA6I/6TCompositeusingRSMandGreyWolf Optimization".El-CezeriFenVeMühendislikDergisi. May.2020.10.31202/ecjse.705212.

[6]. J. Wang, C. Hopmann, M. Röbig, T. Hohlweck, C. Kahve and J. Alms. "Continuous Two-Domain Equations of State for the Description of the Pressure-Specific Volume-Temperature Behavior of Polymers". Polymers. vol. 12. no. 2. pp. 409. Feb. 2020.10.3390/polym12020409.

[7]. Y. Li, N. Gong, Q. Wang, Y. Chen, B. Wang and X. Li. "Advances in Polymer Technology: Application of Pareto-Based Genetic Algorithm in Determining LayoutofHeatingRodsforaPlasticInjectionMold". AdvancesinPolymerTechnology.vol.2020.pp.1-7. Mar.2020.10.1155/2020/7573693.

[8]. "Experimental Investigation of the Mechanical Properties of Injection-Molded PA66+PA6I/6T CompositeusingRSMandGreyWolfOptimization".