Automated Aeroponic Farming

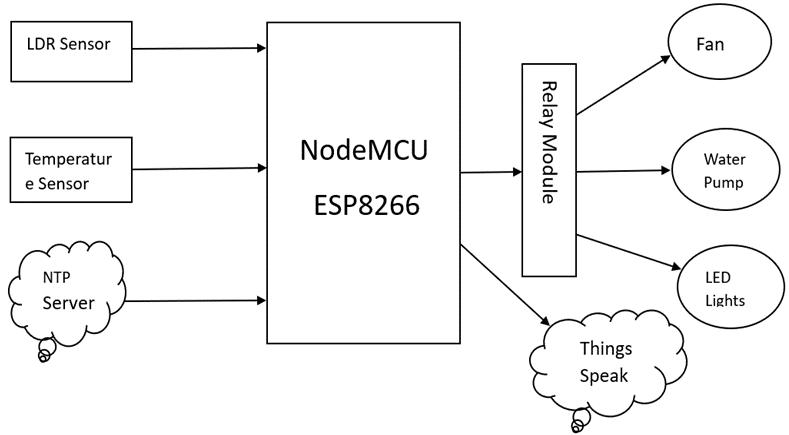

Abstract - Aeroponic farming offers numerous advantages over traditional farming, focusing on enhancing agricultural efficiency while minimizing environmental impact. This innovative approach involves the utilization of an automatic system to closely monitor plant growth. The automated aeroponic system operates on the principles of the Internet of Things (IoT). Temperature measurementsoftherootchamber and the required light intensity for the shoot system are captured using sensors. Actuators are managed by a control system. The sensor data is transmitted through the internet to a server, enabling convenient monitoring for users. The system's prototype has been successfully implemented, and it effectively provides access to all sensor data on the cloud.

Key Words: Aeroponics, growing chamber, monitoring system, control system, sensors

1. INTRODUCTION

Aeroponicsisaninnovativetechniqueusedinbothresearch and commercial crop production, where plant roots are suspendedintheairandperiodicallysprayedwithanutrient solution. This method offers numerous advantages over traditionalagriculture,includingreducedwaterandnutrient consumption,enhancedgrowthrate,increasedplantdensity, andimprovedirrigationsystemquality.

Itiscrucial tocontinuously monitor the consumption and levelofthenutrientsolution,aswellasensuretheproper functioningofpumps.Failuretodosocouldleadtocroploss duetoinsufficientnutrientsupply.Therefore,effectivedata transmissionisofutmostimportanceinthemonitoringand controlofaeroponicgrowingchambers.

This paper presents an alternative approach that utilizes sensorsandWi-Fitechnologyformonitoringandcontrolling aeroponicsystems.Byimplementingthismethod,itbecomes easiertoremotelymonitorandmanageaeroponicsystems from any location, reducing the risk of crop failure and ensuringoptimalplantgrowth.

2. Research Methodology

The base control unit microcontroller chosen for this aeroponic system is the Node MCU. This microcontroller offers efficient interfacing capabilities with the sensing devices and supports Wi-Fi connectivity for seamless data collectionandtransmissiontotheThingSpeakportal.

Thesetupoftheaeroponicgreenhouseboxincludesapump thatisconnectedtothebox,supplyingwaterspraythrough pipesinside.Thisarrangementensurestheadequatedelivery ofwaterandnutrientstothesuspendedplantroots.

Twotypesofsensorsareutilizedinthissystem.Thefirstis theDS18B20temperaturesensor,whichiswater-resistant andmeasurestheambienttemperatureinthesurrounding environment.Thisdataprovidescrucialinformationabout thetemperatureconditionswithintheaeroponicsetup.

The second sensor employed is the LDR (Light Dependent Resistor)sensor,whichmeasurestheintensityoflightinlux. Thissensorenablesmonitoringtheamountoflightreceived by the plants, which is crucial for their growth and development.

TheNodeMCUmicrocontrollergathersthedatafromboth thetemperaturesensorandtheLDRsensor.Itthentransfers thesedatapointstotheThingSpeakportalthroughitsWi-Fi capabilities. This allows for centralized storage and monitoringofthecollecteddata,providingvaluableinsights foranalysisandcontroloftheaeroponicsystem.

3. Components/ Software Used

3.1 ESP8266

The ESP8266 is an affordable Wi-Fi chip developed by EspressifSystems.Itcanbeusedasastandalonedeviceoras aUARTtoWi-Fiadaptor,enablingothermicrocontrollersto connecttoWi-Finetworks.Forinstance,itcanbeconnected toanArduinoboard,addingWi-FicapabilitiestotheArduino. Itspracticalapplicationisoftenasastandalonedevice.

With the ESP8266, you can control inputs and outputs similartoanArduino,butwithaddedWi-Ficapabilities.This featureallowsprojectstobebroughtonline,makingitideal for home automation and Internet of Things (IoT) applications. The ESP8266 has gained popularity due to severalkeyfactors:

1.Low-cost:ESP8266boardsareavailableatastartingprice of$3orevenless,dependingonthespecificmodel.

2. Low-power: The ESP8266 consumes minimal power comparedtoothermicrocontrollersandcanenterdeepsleep modetofurtherreducepowerconsumption.

3.Wi-Ficapabilities:TheESP8266cancreateitsownWi-Fi network(accesspoint)orconnecttoexistingWi-Finetworks (station)toaccesstheinternet.Thisallowsittointeractwith onlineservices,makeHTTPrequests,savedatatothecloud, and even act as a web server for remote control and monitoring.

4. Compatibility with the Arduino programming language: ThosefamiliarwithprogrammingArduinoboardscanusethe same programming style for the ESP8266, simplifying the transition.

5.CompatibilitywithMicroPython:TheESP8266canalsobe programmedwithMicroPythonfirmware,whichisaPython 3 implementation designed for microcontrollers and embeddedsystems.

Thesefeatures,coupledwiththeESP8266'saffordability and versatility, have contributed to its popularity in the makerandIoTcommunities.

3.3 LDR Sensor

The Light DependentResistor (LDR) isa unique typeof resistor that operates based on the photoconductivity principle,whichmeansitsresistancevariesinresponseto theintensityoflight.Asthenamesuggests,theresistanceof an LDR decreases as the light intensity increases. This characteristic makes it ideal for applications where light sensitivity is required, such as light sensors, light meters, automaticstreetlights,andotherlight-controlledsystems.

LDRs are commonly available in various dimensions, including 5mm, 8mm, 12mm, and 25mm sizes. These differentsizesprovideflexibilityinchoosingtheappropriate LDR for specific applications based on factors like space constraintsordesiredsensitivity.

3.2 DS18B20

The DS18B20 isa temperaturesensor manufacturedby MaximIntegrated.Itisdesignedtobecompatiblewithawide rangeofmicrocontrollersandcancommunicateusingthe1Wire protocol. By employing the 1-Wire interface, the microcontroller can establish communication with the DS18B20sensorandretrievetemperaturedata.

The 1-Wire bus, which is used to interface with the DS18B20,requiresminimalhardwarecomponents,makingit a simple and convenient solution. The data pin of the DS18B20sensorisconnectedtoanIO(input/output)portof the microcontroller. This direct connection enables the microcontrollertoexchangedatawiththesensorusingthe1Wireprotocol.

Through this straightforward hardware interface, the microcontroller can effectively communicate with the DS18B20 temperature sensor and retrieve accurate temperature readings for further processing and analysis. ThesimplicityandcompatibilityoftheDS18B20sensormake itapopularchoicefortemperaturesensingapplicationsin variousprojectsandsystems.

By utilizing the photoconductivity property of LDRs, engineersandhobbyistscanincorporatethesecomponents into their projects to enable light-based functionality. The versatilityandavailabilityofLDRsmakethemwidelyutilized in numerous fields, ranging from electronic circuits and automation systems to environmental monitoring and photographyequipment.

ThefunctioningofaLightDependentResistor(LDR)relies ontheprincipleofphotoconductivity.Whenlightilluminates the photoconductive material of the LDR, the material absorbsitsenergy.Consequently,theelectronspresentinthe valencebandofthematerialbecomeexcitedandtransitionto theconductionband,resultinginanincreaseinthematerial's conductivityproportionaltothelightintensity.

Forthisprocesstooccur,theenergycarriedbytheincident lightmustexceedthebandgapenergyofthephotoconductive material.Onlythencantheelectronsbesufficientlyexcitedto movefromthevalencebandtotheconductionband.

In a dark environment, an LDR exhibits the highest resistance, typically around 10^12 Ohms. As the light intensityincreases,theresistanceoftheLDRdecreases.This change in resistance allows the LDR to function as a light sensor, with its resistance serving as an indication of the intensityoflightfallingonit.

TheinverserelationshipbetweentheresistanceoftheLDR and the intensity of light enables its use in various applications, including light-dependent circuits, automatic controlsystems,andlightmeasurementdevices.

Thetiminganddurationofwaterspraycontrolaremanaged using a timer, which synchronizes with an NTP (Network TimeProtocol)server.This allowsforprecisecontrol and divisionofthewateringcycles.

3.4 NTP Server

The NTP server, or Network Time Protocol server, is responsibleforrespondingtotimerequestsfromclientson the network. When a client requests the current time, the NTP server provides time samples that can be used to synchronizetheclient'slocalclock.

By synchronizing the local clock with the NTP server, clients can ensure that their timekeeping is accurate and consistent.Thisisparticularlyimportantinsystemswhere precisetimesynchronizationisrequired,suchasinnetwork infrastructure,distributedsystems,orapplicationsthatrely ontime-sensitiveoperations.

The default value for both domain members and standaloneclientsistypicallysetto1.Thisvaluerepresentsthe largesampleskewforlogging,measuredinseconds.Ithelps toidentifyanysignificantdiscrepanciesintimesamplesand allowsformonitoringandtroubleshootingpurposes.

ByutilizinganNTPserver,organizationsandindividuals can maintain synchronized and accurate time across their network, ensuring smooth operations and reliable timebasedfunctionalities.

4. Working

Inthisaeroponicsystem,thefanisprogrammedtoswitch ON when the temperature exceeds a certain threshold, helping to regulate the temperature within the growing environment. Additionally, an LED light is activated when the intensity of light, measured in lux, drops below a specified level. The relay is used to interface with AC components,enablingthecontrolofthesedevices.

Toprovideadequatelightingforplantgrowthwhennatural light is insufficient, programmable LED light strips are utilized. These LED lights fulfill the light requirements necessaryforplantgrowthbasedonthereadingsfromthe lightsensor.

For the nutrient solution used in this project, an organic nutrientbaseinliquidformisobtainedfromgeneralplant marketshops.Theseproductsarelabeledwithinstructions on the appropriate water-to-nutrient mixing ratios for gardening purposes. Alternatively, individuals can create their own nutrient solution by accurately mixing specific chemical compounds in proper measurements. Chemical stores typically carry solid crystalline forms of essential elementssuchasphosphorus,nitrogen,calcium,andother necessary macronutrients and micronutrients. These nutrient salts serve as the foundation for creating a customizedfertilizersolution.

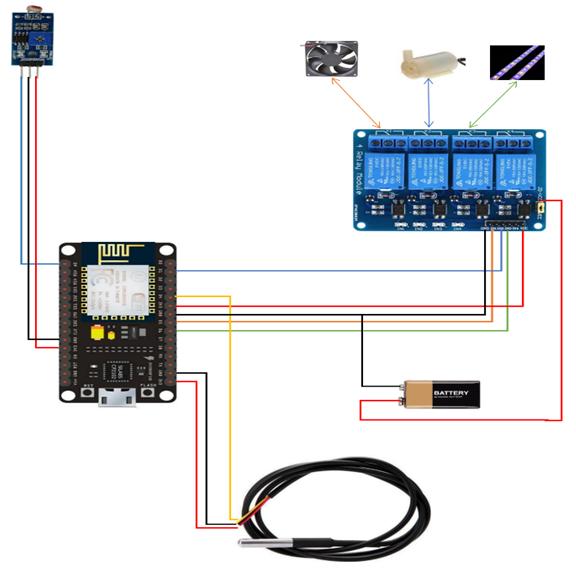

In this circuit the grounds of esp8266, Relay and 9-volt battery has been connected together to provide separate power supply to relay since this relay requires 5 volt to operateandmaximumoutputofvoltagefromesp8266pins is 3.3 volt only. The positive side of battery has been connectedtotheJD-VCCpinoftherelayafterremovingits jumpercap.

The NTP Server is a networking protocol for clock synchronizationbetweenembeddedsystemsorcomputers. We have used NTP Client library to get timing of spray solution.ItbelongstoTCP/IPsuite.TheNTPclientinitializes requestfortiming.Tocontrolthetimeintervalofspraying solutionwehaveusedArduino-timerlibrary.Wecansetthe timerusingthislibrarytoswitchthemotoronandoffafter fixedintervals.Thus,NTPshowstimingatwhichthemotor isonornot.

4.1 Monitoring Growth of eggplant

Eggplant, also known as brinjal, is a purple-colored vegetablecommonlyfoundinIndianhouseholds.Itrequires a light intensity of approximately 2000 lux for optimal growth. We maintained the root chamber temperature between 22 to 30 degrees Celsius to provide the ideal conditionsfortheplant'sdevelopment.Insufficientlightcan leadtoreducedfruitweightineggplants.

Thefirstpictureshowcasesthestemoftheplantreceiving lightfromadjustableLEDstrips.TheintensityoftheseLEDs canbecontrolledbyadjustingthesuppliedvoltage.While we used white light in this setup, specialized RGB lights designedforindoorplantgrowthareavailableinthemarket. Eggplantscangrowwellevenwithwhitelight,butcertain otherplantsrequirecoloredlights,particularlyredandblue, foroptimalgrowth.

Inthesecondpicture,weobservetheplant'srootsbeing nourishedwithawaternutrientsolutionthroughsprinklers. The number of sprinklers can be adjusted according to specificrequirements.Foroursetup,weemployedaregular DCwatermotorcapableofhandlingtwosprinklers.TheDC motorisconnectedviaarelayswitchforeffectivecontrol. Thewaterusedcontainsanorganicnutrientliquidsolution that encompasses all the essential elements necessary for plantgrowth.Thecompositionofthissolutioncanbealtered inthefuturebasedonspecificneeds.Ourorganicsolution comprisesbothmicroandmacronutrients,withapHrange of 6.0 to 8.0. Additionally, the solution incorporates bio enzymes,whichcanbeadjustedtoachieveoptimalgrowth conditions.

Intheprovidedimage,wecanobservetheindoorsetupof an aeroponic plant chamber. To monitor the root temperature, a water-resistant temperature sensor, specificallytheDS18B20,hasbeenincorporated.Thissensor isdesignedtowithstandexposuretowaterasitcontinuously senses the temperature of the root chamber, which is constantlysprayedwithawatersolution.

To regulate the temperature within the chamber, a DC coolingfanisemployed.Whenthetemperaturesurpasses30 degrees Celsius, the fan is activated. ThisDC cooling fanis readilyavailableinthemarketandisconnectedtoarelayfor switchingpurposes.Duringthenightwhenthetemperature naturallydrops,thefantypicallyremainsinactive.

By leveraging software solutions, this system has been cost-effective, reducing the need for additional hardware

components. The esp8266, a Wi-Fi module, serves as the main controller, eliminating the necessity for a separate controller and thereby saving on hardware costs. Additionally, instead of using a Real-Time Clock (RTC) modulefortimedisplay,thesystemutilizesanNTPserverto obtainaccuratetimeinformation.

4.2 Circuit Description

Topowerthedifferentcomponentsofthecircuit,atotalof four batteries are utilized. Additionally, a power supply is provided to the esp8266 module through USB. Among the batteries, a single 9-volt battery is dedicated to supplying externalpowertotherelay,accomplishedbyconnectingitto theJD-VCCpin.Toestablishacommongroundconnection, theesp8266,relay,andbatterygroundsareinterconnected.

Fortheswitchingfunctionality,threerelaychannelsare employed, and they are connected to digital pins on the esp8266module.Thisconfigurationallowsforcontroland operationbasedontheproject'sspecificrequirementsand desiredfunctionality.

thedevicesonoroffbasedonspecificconditionsorprogram logic.

AnNTP(NetworkTimeProtocol)serverservesasacloudbasedsystemthatprovidesaccuratetiminginformation.It offers libraries that can be utilized freely in projects, eliminatingtheneedforaseparateRTC(Real-TimeClock) moduleandreducingcircuitcomplexity.Sincethecircuitis continuously connected to Wi-Fi, it can easily establish a connectionwiththeNTPserveratalltimes.Byleveraging theNTPserver'sresources,thecircuitcanobtainpreciseand synchronized time data, ensuring accurate timing functionalitywithouttheneedforadditionalhardware.

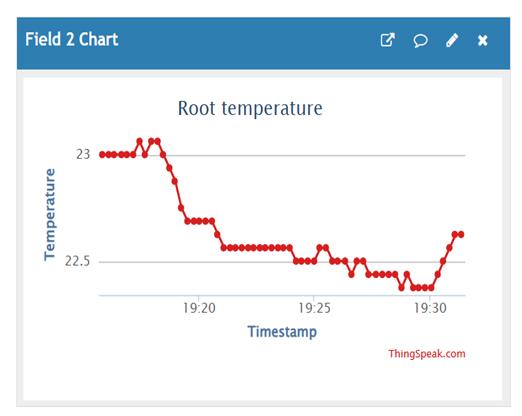

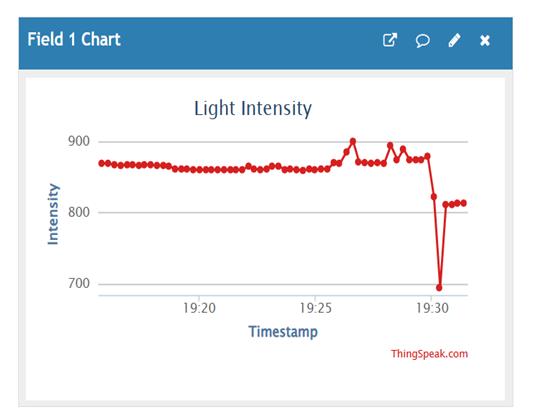

4.3 ThingSpeak data collection

Wehaveimplementedtwodatafieldsinouraeroponic farmingchannel:LightIntensityandRootTemperature.Our objectiveistocollectdatacontinuouslyuntilthefruitsreach theirfullsize,enablingustodeterminethemostfavourable growing conditions for our plants in future cycles. Additionally, this data will be invaluable for conducting comparativestudiesbetweeneggplantsgrowninaeroponic chambersandtraditionalsoil-basedmethods.

Inthecircuitsetup,separatebatteriesareallocatedto powertheLEDlights,DCwaterpump,andDCfan,ensuring eachcomponenthasitsdedicatedpowersource.TheLDR sensor is responsible for detecting light intensity and communicateswiththemicrocontrollerthroughananalog pin(A0),allowingthemicrocontrollertoreadthesensor's output. Similarly, the DS18B20 sensor, which measures temperature,utilizesoneoftheavailablePWMpinsonthe microcontrollertotransmittemperaturedata.

To control the various devices in the circuit, a relay is employed and connected to digital pins on the microcontroller.Thisenablesthemicrocontrollertoswitch

Intoday'sdata-drivenera,thecloud-basedcollectionof this data proves exceptionally advantageous for analysis purposes. Moreover, it presents opportunities for AI/ML projectstoderiveinsightsonoptimizingroottemperature, lightintensity,andnutrient contentto enhancethehealth andweightoftheeggplantfruits.

Thequalityandyieldofeggplantareheavilyinfluencedby these critical factors. Through careful analysis of the collecteddata,wecangainvaluableknowledgeonhowto manipulate and optimize these variables to ensure the productionofhealthierandmorerobustfruits.

5. Future Enhancement

A water quality meter is a valuable tool for optimizing nutrient solutions in plant cultivation. It enables measurement of important parameters such as Total DissolvedSolids(TDS),pHlevel,ElectricalConductivity(EC), and the availability of various nutrients in the water. By monitoringandanalyzingthesevalues,adjustmentscanbe madetocreatecustomizednutrientsolutionsthatpromote optimalplantgrowthandproductivity.

Image processing techniques combined with AI/ML algorithms offer additional benefits in plant health management. By analyzing images of plant leaves, AI algorithmscanassesstheirqualityandprovideinsightson improvingplanthealth.Itcandetectandidentifydiseasesor deficienciesbasedonleafcolor,pigmentation,and overall appearance. This information can guide farmers in taking appropriate actions to address these issues, such as adjustingnutrientlevelsorapplyingtargetedtreatments.

In the field of biopharmaceutical farming, the aeroponic systemholdspromise.Ongoingresearchfocusesonutilizing aeroponic systems for cultivating medicinal plants, especially in space environments. The controlled environment provided by aeroponics allows for precise nutrientdeliveryandoptimalgrowingconditions,ensuring theproductionofhigh-qualitymedicinalplants.

Vertical farming techniques can be effectively integrated withaeroponicsystemstomaximizeproductivityinlimited spaces.Byimplementingaeroponicsystemsintalltowers, multipleplantscanbegrowninacompactarea,significantly increasingtheoverallyield.Thisapproach,knownasvertical farming, has gained popularity for its ability to utilize vertical space efficiently and produce large quantities of crops.

Implementing aeroponics and advanced technologies like AI/MLinagricultureopensupopportunitiesforsustainable andhigh-yieldfarmingpractices.Itallowsforprecisecontrol overnutrientsolutions,earlydetectionofplantdiseases,and efficient use of space. As research and development continue,thesesystemshavethepotentialtorevolutionize farmingandcontributetotheproductionofawiderangeof crops in a cost-effective and environmentally friendly manner.

6. CONCLUSIONS

The implementation of indoor aeroponic farming indeed offers numerous advantages. It allows for efficient

cultivationofplantswithouttheneedforlargelandareas, makingitaviablesolutionforincreasingfoodproductivity tomeetthedemandsofagrowingpopulation.Moreover,it provides a cost-effective approach to farming, as the investmentrequiredforsettingupsuchasystemisrelatively low, with an estimated cost of around INR 2000. This affordability makes it feasible to implement aeroponic farming in households, enabling individuals to grow their ownfreshproduce.

One significant benefit of indoor aeroponic farming is the reduced risk of plant diseases and pests commonly associatedwithsoil-basedcultivation.Byeliminatingtheuse ofsoil,thespreadofsoil-bornepathogensandpestscanbe mitigated, resulting in healthier plants. This method also offers resilience during drought conditions, as the plants receiveacontrolledsupplyofwaterandnutrients,reducing dependenceontraditionalirrigationsystems.

Aeroponic farming contributes to environmental sustainabilitybyminimizingfertilizerrunoffintowaterways. Intraditionalfarming,excessfertilizerscanwashawayinto rivers and streams, causing water pollution. However, in aeroponicsystems,thenutrientsolutioniscontainedwithin thechamber,allowingforefficientrecyclingandminimizing wastage. Additionally, the system conserves water by collectingandreusingthewaterthatdripsfromtheroots, reducingoverallwaterconsumption.

Commercial-scaleaeroponicfarminghasprovensuccessful in several countries, and entrepreneurs in India can also explore the potential of this method for large-scale production. By implementing aeroponics, farmers can achieve higher yields in shorter durations compared to traditionalfarmingmethods.Thisacceleratedgrowthrate, coupled with the ability to control growing conditions, presentsanattractiveopportunityforenhancingagricultural productivity.

In conclusion, indoor aeroponic farming offers a range of benefits, including increased food productivity, reduced waterandfertilizerwastage,improvedplanthealth,andthe ability to cultivate crops in areas with limited space or adverse environmental conditions. With its low cost, scalability,andpotentialforhighyields,thismethodholds promiseforrevolutionizingagricultureandmeetingthefood requirementsofagrowingpopulationinasustainableand economicalmanner.

REFERENCES

[1] L.Lucero,D.Lucero,E.Ormeno-MejiaandG.Collaguazo, "Automatedaeroponicsvegetablegrowingsystem.Case studyLettuce,"2020IEEEANDESCON,Quito,Ecuador, 2020, pp. 1-6, doi: 10.1109/ANDESCON50619.2020.9272180.

[2] S. Ruengittinun, S. Phongsamsuan and P. Sureeratanakorn, "Applied internet of thing for smart hydroponic farming ecosystem (HFE)," 2017 10th InternationalConferenceonUbi-mediaComputingand Workshops(Ubi-Media),Pattaya,Thailand,2017,pp.14,doi:10.1109/UMEDIA.2017.8074148.R.Nicole,“Title ofpaperwithonlyfirstwordcapitalized,”J.NameStand. Abbrev.,inpress.

[3] H. Andrianto, Suhardi and A. Faizal, "Development of SmartGreenhouseSystemforHydroponicAgriculture," 2020 International Conference on Information TechnologySystemsandInnovation(ICITSI),Bandung, Indonesia, 2020, pp. 335-340, doi: 10.1109/ICITSI50517.2020.9264917.

[4] N. P. Mohanty, D. Singh, A. Hota and S. Kumar, "CultivationofCashCropsunderAutomatedGreenhouse using Internet of Things (IoT)," 2019 International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 2019, pp. 0235-0239, doi: 10.1109/ICCSP.2019.8697930.

[5] A.Yahaya,Y.A.AbassandS.A.Adeshina,"Greenhouse Monitoring and Control System with an Arduino System," 2019 15th International Conference on Electronics, Computer and Computation (ICECCO), Abuja, Nigeria, 2019, pp. 1-6, doi: 10.1109/ICECCO48375.2019.9043188.

[6] Ethirajan, Lakshmiprabha & Govindaraju, C.. (2019). Hydroponic-based smart irrigation system using Internet of Things. International Journal of CommunicationSystems.e4071.10.1002/dac.4071.

[7] D. Saraswathi, P. Manibharathy, R. Gokulnath, E. Sureshkumar and K. Karthikeyan, "Automation of Hydroponics Green House Farming using IOT," 2018 IEEEInternationalConferenceonSystem,Computation, Automation and Networking (ICSCA), Pondicherry, India, 2018, pp. 1-4, doi: 10.1109/ICSCAN.2018.8541251.

[8] C.A.Jamhari,W.K.Wibowo,A.R.AnnisaandT.M.Roffi, "Design and Implementation of IoT System for Aeroponic Chamber Temperature Monitoring," 2020 ThirdInternationalConferenceonVocationalEducation andElectricalEngineering(ICVEE),Surabaya,Indonesia, 2020,pp.1-4,doi:10.1109/ICVEE50212.2020.9243213.

[9] M.R.M.Kassim,"IoTApplicationsinSmartAgriculture: IssuesandChallenges,"2020IEEEConferenceonOpen Systems(ICOS),KotaKinabalu,Malaysia,2020,pp.1924,doi:10.1109/ICOS50156.2020.9293672.

[10] Dutta, Abhay & Tamang, Pawan & Dahal, Prayukti & Prajapati, Rabina & K.C., Saban. (2018). IoT based AquaponicsMonitoringSystem.