Experimental investigate on the Influence of Sisal Fiber and Rice Husk Ash on Mechanical Properties of Self Compacting Concrete

Jayadeep K. P.1 , Anima P.21First Author Affiliation & Address

2Second Author Affiliation & Address Font size 11

3Example: Professor, Dept. of xyz Engineering, xyz college, state, country ***

Abstract - Concrete is an essential construction medium that is widely used throughout the world. Concrete is weak in tension. Several types of fibers are added to concrete in varying quantities to increase its tensile strength. The use of different synthetic fibers is common now a days. In this case we use a natural fiber. This study is to identify the effect of Sisal Fiber on concrete strength properties. Sisal Fiber is a natural fiber derived from the leaves of Sisal plant (Agava sisalana), which can be found in hot regions. Along with sisal fiber the cement is partially replaced with Rice Husk Ash (RHA) which is a waste material. The silica content available in them make it suitable supplementary cementitious material. This work aims to investigation of the use of sisal fibres and rice husk ash as partial replacement in SCC. The mix ratio is M30 and Sisal Fiber was added to concrete at 0,0.5%,1%,1.5%,2.0% by the volume of concrete and replacement of Rice Husk Ash by 5%. The specimens were subjected to tests and aimed to check the compression and tensile strength. After 7 days and 28 days of curing, the specimens' compressive and split tensile strengths were evaluated.

Key Words: Self- compacting Concrete, sisal fibres, Superplasticizer, Mix Design, RHA, Compressive strength, Split tensile strength

1.INTRODUCTION

Self-compactingconcrete(SCC)isaverymalleableconcretethatfillstheformworkbyitselfwithouttheneedforvibration.The necessityofself-compactingconcretecanberecognizedbyseeingthegrowingissueofatrainedlabourshortageinthebuilding sector.Self-compactingconcretecanfillthemouldwithouttheneedformechanicalvibration.Itcanbeappliedinsituations wherecompactingfreshlylaidconcretewouldbelaborious,suchasunderwaterconcreting,pilefoundations,andwallswith congestedreinforcement.SCC'sstrengthanddurabilitycanbeincreasedbyaddingmorecementitiousmaterials,suchasfly ash, pulverised granulated blast furnace slag, silica fume, and rice husk ash (RHA). RHA is a highly reactive pozzolanic substanceproducedbycarefullyburningricehusksattempsbelow7000C.Anotherfocusofthisprojectistoincorporatingsisal fiberintotheoptimumpercentageofRHAindifferentpercentagesandtocheckitsstrengthproperties.Byincludingfibersin concrete,toughness,reducedcreepstrain,flexuralstrength,andshrinkagecanallbeincreased.Cracksduetoplasticshrinkage anddryshrinkagecanalsobecontrolled.

SisalfibersinconcreteisstudiedbyvariousresearcherslikeBijuC.ThomasandY.StalinJose[3]studiedthecharacteristicsof usingsisalfiberinconcreteandit’sperformance.S.SureshKumaret.al[5]investigatedthepropertiesofsisalfiberinconcrete whenitistreatedwithNaOH.S.SolaiMathiet.al[2]usedsisalfiberinself-compactingconcretetoenhancethepropertiesofthe concreteusingthefiber.TheuseofRiceHuskAshbycertainpercentageprovedtobeaneffectivematerialforthereplacement ofcement.EliasMolaeiRaisiet.al[7]examinedtheeffectofRHAinself-compactingconcreteandstudiedit’sfreshconcrete propertiesandmechanicalproperties.DeshmukhSDet.al[10]studiedthepropertiesofconcreteusingRiceHuskashandsteel fibersanditshowsthatincorporatingsteelfiberinconcretewillincrease thetensilestrengthbutreducesit’sworkability. AnandarajSet.al[1]studiedstrengthpropertiesofluffafiberinRiceHuskAshcontainingconcretebytheweightofM25grade concrete.SaiERet.al[9]demonstratedthattheadditionofsugarcanebaggaseash(0%,2.5%,and5%)andRHA(0%,2.5%, and 5%) either separately or in blended mixes increased compressive strength for a period of time exceeding 28 days. SabarinathanMet.al[6]highlightedthattosolvetheproblemsofwastedisposal,minimise globalwarming,andraisethe strengthofconcrete,theyinvestigatedtheeffectsofsilicafumeandsisalfibreorientationonperformanceofconcrete.

FromtheabovestudieswecanseethatmanyexperimentwereconductedusingRiceHuskAshandSisalfiberbutthereisno studyonincorporationOfSisalfiberinconcretewhenthecementisreplacedbyRHA.Thegoalofthisstudyistothoroughly examinehowRHAandSisalfiberaffectsthemechanicalperformanceandfreshqualitiesofSCC.Forthisexperiment,cement was partially replaced by RHA in three dosages i.e 5%,10%,15% and the optimum is found by conducting mechanical properties. After finding the optimum percentage, keeping the optimum constant sisal fibers was added in different percentages0.5%,1.0%.1.5%.2.0%.V-funnelflowtime,L-box,andslumpflowdiameterandtimetestswerecarriedoutto

ascertain the fresh properties of SCC. Also, many hardened concrete specimens were formed to examine the mechanical performanceofSCC.

2 MATERILAS AND MIX RATIO

2.1 Materials

Cement

PortlandPozzolanacementofUltratechbrandwasusedforthisstudy.Tostudythepropertiesofcementvariousexperiment weredoneaccordingtotheIScodespecifications.

Fine Aggregate

Duetothescarcityofnaturalsand,M-sandwasusedforthisstudyasitisabestalternativefornaturalsand.M-sandisaproduct formedfromcrushedhardgranitestone.IS:383-1970definesthefineaggregatesas7.25particles,whichwillpassthrough 4.75mmISsieveandretainedon150micron.

Coarse Aggregate

Anaggregatethatismostlyretainedona4.75mmISsieveisreferredtoascoarseaggregate.Coarseaggregateofsize12mmwas usedinthisstudyandcompliedwithIS383:1970.

Rice Husk Ash (RHA)

Asanagriculturalwasteproduct,ricehuskiswidelyavailableandaccountsfor20%oftheworld'syearlyriceproductionof 649,7milliontonnes.Thisprocedure,whichalsoaddstopollution,usesthemillingplantbyproduct,whichishuskthathas beenpartiallyburned,asfuel.RHAwascreatedbyburningatareasonablyhightemperatureofaround7000Cwhileheatingata rateof100C/min[7].TheRHAwaspreferredforthepartialreplacementofcementafterpassingthroughasievewithan

openingof75μm.Thismethodyields25%ofRHA.Thisashisverypozzolanicandcontains85%to90%amorphoussilicaand 5% alumina, which makes it highly pozzolanic. Use of RHA minimise the need for cement and lowers the overall cost of producingconcrete.

Sisalplantcanbeseeninhotanddryareaswhichareunsuitableformostofotherplantstogrow.Themostpopulartechnique forobtainingsisalfiberisdecortication.Thefleshypulpisseparatedfromthefiberbycrushingtheleavesbetweenbluntblades andwetnessinthisprocess.Debrisfoundintheleavesiscleanedwithwater.Thesisalfiberisharvestedandcuredinthe scorchingsun.ThefiberistreatedwithNaOHanddriedbeforeincorporatinginconcrete.

Admixture

TheadmixtureusedhereisMasterRheobuild1126nd.Itisspecificallycreatedtoallowforasignificantreductioninmixingwater whilekeepingcontrolovertheextentofsetretardation.Itisusedintheproportionof6mlperkgofcement.,Someofthe benefits of Master Rheobuild are reduced permeability, high workability for longer periods, improved durability, reduced shrinkageandcreepetc.

2.2 Mix ratio

M30mixwasusedforthestudyandthedesignwasdoneasperIS10262.Themixproportionobtainedwas1:2.1:3.4.Thewater percementratiowas0.45.Thetotalmaterialsrequiredforperm3ofconcretewere400kgofcement,127Lofwater,843kgof fineaggregateand1234kgofcoarseaggregate.Afterconductingallthefreshpropertiesofconcreteweconcludedthatthis proportionofconcreteissuitableforcasting.

3. EXPERIMENTAL STUDY

3.1 Specimen details

Forfindingthemechanicalpropertiesofcontrolspecimenatotalof6cubesand3cylinderswerecasted.Atotalof18cubesand 9cylinderswerecastedfortheinitialstagesofexperimentforfindingtheoptimumpercentageofRiceHuskAshinconcrete. Afterfindingtheoptimumpercentage,atotalof24cubesand12cylinderwascastedkeepingtheoptimumpercentageofRHA constantandchangingthepercentagesofsisalfiber.

3.2 Preparation of specimen

For the control specimens, the necessary amounts of cement, fine aggregate, coarse aggregate, super plasticizers, mineral admixture,andwaterwerecollected.RicehuskashandSisalwasalsocombinedwiththecomponents.Machinemixingwasdone forconcretemixing.Coarseaggregatealongwithsuperplasticiserismixedduringinitialstagesandmixedwithfineaggregate andcement.Waterisaddedtoconcreteduringvariousintervals.Boththecubeandcylindermouldhavetobeoiledandscrewed tightlybeforepouringtheconcreteintoit.BythisprocesscontrolspecimenaswellasSCCincorporatingRHAismade.After findingtheoptimumpercentageofRHA,keepingitconstantcastingofconcreteisdonebyaddingsisalfiberindifferentratiosby thevolumeofconcrete.

3.3 Testing of Specimen.

FreshpropertiesofconcretelikeSlumptest,Lboxtest,Vfunneltestweredoneduringinitialstagesforthecontrolspecimen. MechanicalpropertieslikecompressiontestandtensilestrengthtestwereconductedforbothSCCwithRHAandSCCmixwith RHAandSisalFiber

4. RESULT AND DISCUSSION

4.1 Effect of RHA on Tensile and Compressive strength

Inthisfirstpartoftheexperiment6numberofcubesand3numberofcylinderswerecastedascontrolspecimenand18cubes and9cylindersforthethreepercentagesofRiceHuskAsh5%.10%,15%whichhasbeenpartiallyreplacedbythecement.Allthe specimenswerecastedaccordingtotheM30mixratio.Thespecimenisthentestedformechanicalpropertiesafter28daysof curing.Thetestresultsofspecimensareasfollows

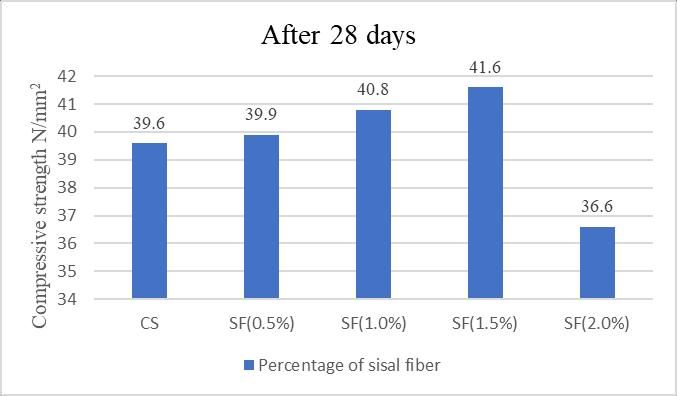

4.2 Effect of Sisal fiber and RHA on Compressive Strength of Concrete

FromtheboxaboveweseethatcementcanbereplacedbyRiceHushAshby5%inconcrete.BykeepingtheRHAconstant thenwecast24cubesincorporatingsisalfiberindifferentpercentage0.5%,1.0%,1.5%,2.0%.Thespecimensarecastedfor compressivetest

4.3 Effect of Sisal fiber and RHA on Split Tensile Strength of Concrete

ForfindingtheSplittensilestrengthofconcreteatotalof12cylinderwerecastedandtestedafter28daysofcuring

After 28 days

Percentage of sisal fiber

Chart -2:SplitTensileStrengthofConcrete

5. CONCLUSIONS

Themainfindingsofthisinvestigationare

• For M30 mix of concrete the replacement of cement with Rice husk ash by 5%,10%,15% was done. It was found that comparedtoconventionalconcretereplacementofcementbyRHAat10%foundtobemoreeffective.

•Compressiveandsplittensilestrengthofthisconcreteat28daysisfoundouttobe36.4N/mm2 and3.05N/mm2 .

•For M30 mix of concrete keeping the RHA mix constant Sisal fiber is added to concrete by volume at proportions of 0.5%,1.0%,1.5%,2.0%andcomparedwithcontrolspecimenafter28days.

•Compressiveandsplittensilestrengthofconcreteismaximumat10%RHAand1.5%additionofsisalfiberintoconcreteand itsvalueis37.8N/mm2and3.32N/mm2

Fromthisexperimentwecanconcludethatbyadding1.5%ofsisalfiberwith10%ofRHAgivesoptimummechanicalstrength comparedtootherproportions.

ACKNOWLEDGEMENT

I wish to thank the Management, Principal and Head of Civil Engineering Department of Universal Engineering College, Thrissur,affiliatedbyAllIndiaCouncilforTechnicalEducationNewDelhiandtheAPJAbdulKalamTechnologicalUniversity for their support. This paper is based on the wok carried out by me (Jayadeep K. P.), as part of my PG course, under the guidanceofAnimaP.(Associateprofessor,CivilDepartment,UniversalEngineeringCollege,Thrissur,Kerala).Iexpressmy gratitudetowardshimforvaluableguidance

REFERENCES

[1] AnandarajS,RajeshkumarV,PreethyRL,DhivyaK,GaneshkumarS,AnushaG,KanmaniS.Strengthpropertiesofluffafibre reinforcedconcretecontainingRHAascementreplacement.MaterialsToday:Proceedings.2022Jan1;52:1817-20

[2] Mathi,S.Solai,S.Karthikeyan,V.Johnpaul,P.R.Riyas,N.Chidambaram,andM.Vegumathi."WITHDRAWN:Experimental investigationonselfcompactingconcretewithsisalfibre."(2021).

[3] ThomasBC,JoseYS.Astudyoncharacteristicsofsisalfiberanditsperformanceinfiberreinforcedconcrete.Materials Today:Proceedings.2022Jan1;51:1238-42.

[4] SabarishKV,PaulP,JonesJ.Anexperimentalinvestigationonpropertiesofsisalfiberusedintheconcrete.Materials Today:Proceedings.2020Jan1;22:439-43.

[5] S.SureshKumaret.alExperimentalStudyandBehaviourofConcretewithSisalFibre,Volume10IssueNo.32020

[6] Sabarinathan,M.,S.Mohanraj,andV.Murugesh."ExperimentalStudiesofSilicaFumeandSisalFibreonPerformanceof Concrete."(2020).

[7] Raisi EM, Amiri JV, Davoodi MR. Mechanical performance of self-compacting concrete incorporating rice husk ash. ConstructionandBuildingMaterials.2018Jul20;177:148-57.

[8] Vikram AV, Arivalagan S. Engineering properties on the sugar cane bagasse with sisal fibre reinforced concrete. InternationalJournalofAppliedEngineeringResearch.2017;12(24):15142-6.

[9] SaiER,JumaA,PrakashDV,HaiderS,RaoSK.AnexperimentalstudyonsynergiceffectofsugarcanebagasseashwithRice huskashonselfcompactionconcrete.Pan.2012;90(9):55.

[10] DeshmukhSD,DomkePV,KeneSD,DeotaleRS.ExperimentalStudyonStrengthofConcretebyUsingArtificialFiberswith RiceHuskAsh.InternationalJournalofEngineeringResearchandApplications.2011;1(3):571-81.

[11] IndianStandardCodeofPracticeforPlainandReinforcedConcrete(FourthRevision),IS:456-2000,BureauofIndian Standards,NewDelhi.

[12] IndianStandardCodeofRecommendedGuideLinesforConcreteMixDesign,IS:10262-2019,BureauofIndianStandards, NewDelhi