MECHANICAL CHARACTERISTICS OF RECYCLED AGGREGATE AND MINERALS ADMIXED HIGH-PERFORMANCE CONCRETE

Minakshi Tomar,M.tech student., Dept. of Civil Engineering, Radha Govind engineering college, Dr A.P.J. Abdul kalam technical university, Uttar Pradesh, India

Abstract - In this research paper, we have studied the effect of recycled aggregates and minerals in physical characteristics on high-performance concrete (HPC) when mixed in it. The present study consists of and considered the effect of many properties of concrete components which are not taken into account by the traditional mix design method. The suggested mix design process follows the rule and regulations of the (BIS) Bureau of Indian Standards as well as the American Concrete Institute (ACI).

The analysis of recycled aggregate (mostly demolished concrete) as a substitute for natural aggregates admixed with minerals, “silica fume” has been done based on an experiment conducted on HPC. M60 mix design is used in this study. At first, different materials used for making HPC are identified and later then with the help of mix design code, proportional quantities of materials are to be found. The proportions of silica fume in HPC are taken as 0, 10, 12, 15, 17.5, and 20 percent with cement content as 0, 0.5, 0.75, 1, 1, 1.25, and 1.5 percent fume silica. Two different minerals silica fume and fumed silica were used in experiment.

Cube compressive strength test at different (w/b) ratios 0.28, 0.3, 0.32 at different ages, such as 3, 7, 14, 28, 56, and 90 days.

Key Words: High-Performance concrete, recycled aggregate, plasticizers, silica fume, fumed silica

1.INTRODUCTION:

Concrete is the main component used for infrastructure development,mostofthestructuresaremadebyreinforced concreteinIndia.Inmoderntimeswhenhighrisestructures areintrendaswellasinneed,toprovidemorelivingroom fortheincreasingworldpopulation,especiallyinIndia.High rise and heavy-duty structures can’t be constructed with standardconcretemix,forwhichdesignof HPC isrequired, highperformanceconcretehaveacompressivestrengthof 55MPa or more. More construction work requires more construction materials, and construction land for that purpose.In the nowadays skyscraperbuildingsandheavy transportation bridges, and high-rise water retaining structureslikedamsarebeenconstructed,becauseofthat thereisconsiderablefocusonresearchanddevelopmentof high-performanceconcrete.Furthermore,thereisaneedto findnewsourcesofaggregatesduetotheincreaseddemand and reduction in natural resources. Sustainable building

development principles and maximizing the recycling of construction waste through research and development is necessary. One potential outlet is the use of recycled aggregatesinconcreteconstruction.

Concreteistypicallymadebyusingalluvialriversandand chorusedcrushedgravel,whichareabundantandrelatively inexpensivetoprocess.Thesematerialsproducehigh-quality concrete due to their physical properties such as size and shape.However,thesedepositswereformedovermillionsof years and are not easily replenished. There is currently a shortageofsandandover-miningcancauseenvironmental problemsanddamagetogroundwaterreserves.Asaresult, some state governments have banned sand mining due to concernssuchasthedangerofexcessivediggingfromthe riverbed,theimpactongroundwaterlevelscausedbydeep pits,anderosionofsurroundinglandduetoexcessivesand lifting.Itisgenerallybelievedthatexcessiveliftingofsand aroundsub-constructionsendangersthesafetyofbridges, especiallythewellfoundation.

1.1 NEED OF HPC:

Sinceancienttimes,cementmaterialshavebeenusedin constructionworks.Duringpastfifty-fortyyears,materials have aged significantly and In present times, because of recurringnaturaldisastersandstructurefailures,amodern solution is needed to be found. To fulfill the purpose of improving the strength and durability of structures, Highperformanceconcretewasinventedbyuseofwater-reducing admixture,whichleadstohighstrength.High-performance concrete (HPC) is designed to have superior chemical and physicalcharacteristicscomparedtotraditionaldesignmix concrete.

High-performanceconcretenotonlyhashighcompressive strengthbutalsohasexcellentflexuralandtensilestrength,it has a high modulus of elasticity which means less deformationunderstressapplication.HPCstructuresareless susceptibletoliquid-like“chemicalandwater”penetration duetotheirlowpermeability.

1.2 ROLE OF MINERALS AND ADMIXTURES:

1. Mineral mix like calcium hydroxide (CH) of silica fume and fumed silica are used to alleviate the unwanted negative effects during the cement

hydration in concrete. These minerals produced a negligible amount more calcium hydroxide than ordinaryPortlandcement(OPC)andproducedahigh amount of additional compressive strength comparatively.

2. In 1952 first experimental testing of silica fume in OPCbasedconcretewascarriedout.Inearlytimes researchers used fumed silica made from silicon tetrachloridecombustioninhydrogenoxygenflames, while silica fume was a by-product of elemental ferrosilicon/silicon alloys in electric arc furnace production.

3. Fresh HPC has more cohesion means less prone to segregation,andlessconcretebleeding,itcanbeused at high fluidity compared to other concrete mixes withnosilicafume.

4. Using silica fume in HPC enhance its durability by three mechanisms: by increasing compressive strength, by reducing its permeability, and by its pozzolanicactivity.

5. As for chemical admixtures in concrete like superplasticizers when added to an almost solid mixture,dispersionoccursandthemixturebecomes more workable, more liquid as a result. Superplasticizers are high range water reducers (HRWR)of“ASTMC494typeFandTypeG”andare usedtoreducethemoisturecontentby12-30%.

2. NEED OF THE STUDY

1. Older buildings and structures are being demolished more frequently in metropolitan areas in construction industry because they are hazardous, required maintenance,andremodeling,orneedtobedemolished inordertomakenew,bigger,higherconstructions.Asa result,theyproduced,awholelotofinorganicwasteby demolishing concrete,and this demolished concrete is dampedinlandfillorusedtorestoreland.

2. Inpresentdaysnaturalresourcesarebeenreducingfast asaresultofurbanization,Asweknowbothconstruction materials(suchasaggregates,andsand)andlandcomes fromnaturewhichmeansthescarcityofbothbecamean issueforconstructionsocieties.

3. In order to overcome the depletion and shortage of natural course and fine aggregates there are many ongoing research and development works are taking place,isoneof.themistouserecycledaggregatesforthe concrete mix design. Recycled aggregate contains inorganic concrete waste like processed and crush concreteblocks,brick-bats,andrecycledsteelfiber.

Objective of study:

Wehavesixmainobjectivesforthisstudy.

1. TostudytheeffectoffumedsilicaonHPCcube compressivestrength.

2.TostudytheeffectoffumedsilicaonHPCsplittensile strength.

3.TostudytheeffectoffumedsilicaonHPCflexural strength.

4.TostudytheeffectofsilicafumeonHPCcube compressivestrength

5.TostudytheeffectofsilicafumeonHPCsplittensile strength.

6.TostudytheeffectofsilicafumeonHPCflexuralstrength.

3. LITERATURE REVIEW:

1. Viatceslav Konkov et. al (2013)[1]

Theauthorhasdonehisstudyontheprincipleapproaches to HPC concrete applications in construction field. In his article,hehasdiscussedthespecificrequirementofHPCin presenttimesfordifferenttypesofstructures.Optimization of HPC production and its application, design of HPC concretecompositions.AndconcludethatHPCisbecominga necessityofmoderntimestructuresapplication.

2. H. Van Damme (2018) [2]

The author studied the past, present and future innovationsoftheconcreteindustryandpossibilityofusing differentconcretematerialstoproduceintermsofquality andstrength-wiseenhancedconcrete,andconcludeInlong termuseofstructuresadmixingIngredientsthatcanbeused as cement and concrete additives include fly ash, slag, pozzolana cement, and silica fume. Mineral mixes may provide advantages like enhanced rheological characteristics.

3 Mohamed Amin, Yara Elsakhawy, Khaled Abu elHassan, Bassam Abdelsalam Abdelsalam (2022) [3]

Inthisstudy,HighStrengthGeopolymerConcrete(HSGC) wasmadeusingindustrialwastessuchflyash,metakaolin, andgranulatedblastfurnaceslag.Inordertocomparefour geopolymer concrete mixes with fifteen different high strengthconcrete(HSC)mixes,fourHSCmixescomprising Portlandcementwerecreated.Themixturesareallpoured, cured,andtested.sagmeasurementsaretakenforthefresh qualitiesofHSCandHSGCblends,aswellasaircontent.The

“Behavior evaluation of sustainable high strength geopolymerconcretebasedonflyash,metakaolin,andslag”

mechanicalparametersofthematerialwerealsotestedand analysed,includingitscompressivestrength,ultimatetensile strength,flexuralstrength,andelasticmodulusat3,7,28, and 91 days. Concrete combinations made of cement and geopolymer were examined for water permeability coefficient,anddurabilityduring3,7,14,21,28,56,and91 days, and tests temperature was kept between 100° and 700°.

4. Y.N. Chana et . al (2000) [4].

Afterbeingexposedtohightemperaturesofupto80°C,the author evaluated the compressive strength and pore structureofhigh-performanceconcrete.High-performance concrete (HPC) and normal-strength concrete were subjected to an experimental programto investigate the mechanical characteristics and pore water of concrete elementfollowingexposuretohightemperature.Afterthe concrete samples had undergone a specific temperature. Their residual compressive strength was calculated at an 80°Ctemperature.Mercuryintrusionporosimetrywasused to examine the concrete's porosity and pore size distribution.Accordingtotestresults,HPCexhibitedmore residualstrength,afterbeingexposedtohightemperatures, its strength declined more quickly than that of normalstrengthconcrete.Changesinporesizecouldbeutilisedto showhowHPC'smechanicalpropertieshavedegradedasa resultofexposure.

5 J. J. Chena et. al. (2017) [5].

Theproductionofhigh-performanceconcreteusingflyash microspheresandcondensedsilicafumewasthesubjectof the author's research. Regarding the concrete materials' packingmodel,theadditionofflyashmicrospheres(FAM)to fillthespacesbetweencementgrains,

Inordertoobtainthedesiredflowability,thewatercontent wouldbereduced,thencondensedsilicafume(CSF)would be added to further fill the spaces between the FAM. This might make it possible to use less water to make HighPerformanceConcrete(HPC)byreducing theW/CMratio. ThepurposeofthisstudywastoassesshowFAMandCSF affected cementitious material packing density as well as cement paste flowability and strength. The outcomes demonstratedthatFAMandCSFcanconsiderablyimprove 2019JETIRJune2019,Volume

This paper aims to assess the information gathered from overview,70%ofrespondentshavegiventhereasonswhy theydo notsupport reusing construction waste,andfrom this examination it is very likely to be assumed that 25% RCAsquarehavingmorequalitythanregular,yethalfRCA square quality too adequate. (3) This paper compares the performanceofrecycledaggregateinconcrete.

“Characteristicsofhigh-performancesteelfiberreinforced recycled aggregate concrete utilizing mineral filler”Nowadays,alotofbuildingsaredemolishedtomake room for new ones. As this trash is useless, recycled aggregates are employed in this paper along with mineral fillerforconstructionpurposes.Usingrecycledmaterialscan helpreducepollutionbecausedemolishedstructuresproduce garbageandtheamountofpollutantsintheglobeisrising. Thisstudyintendstomakeuseofandassesstheutilisationof steel fibres and recycled aggregates to improve the performanceofhighperformanceconcrete.Inthisstudy,15 distinctgeopolymerconcretemixeswereusedtocreatefour high strength mixes using Portland cement. Mechanical properties such as compressive strength, tensile strength, flexuralstrength,andelasticmodulusat3,7,28,and91days weremeasuredandexamined,andthedurabilityandwater permeabilitycoefficient also.

5. Prashant Dodiya, Varsha Yadav (2023) [8].

The authorstudied the performance analysis of HPCusing MetakaolinandsilicafumeeffectonHPCconcretestrength andconcludetheresultcompressivestrengthofmixhaving 10% silica and 10% metakaolin has its highest strength achievedbyday28ofcasting.

4. METHODOLOGY OF STUDY:

ToUnderstandtheinteractionsofdifferentmaterialswith respecttotheselectionofappropriateingredients,evaluation of their properties and Optimal use is essential for the developahighperformanceconcretemixbyusingtheright Cement material for this test, such as fine aggregate (FA), recycled concrete aggregate (RCA), coarse aggregate (CA), water,chemical,andmineralmix.

ForEffectiveproductioncarefullyselectalltheingredientsof HPC, which should be controlled, and used proportionally obtained. To achieve HPC, cement content, overall quality, and copy ratio, given the mixed paste interaction, mixing type,dose,andcharacteristicsofmeticulouscareinmixing andhandling,theoptimumratioshouldbeselected.

4.1 Ingredients Used:

Listofingredientsusedinstudyisgivenbelow

1. OPC,conformingtoBIS53grade:12269-1987.

2. Drydenseformofsilicafumeobtainedfrom ELKEMIndia(P)Ltd.Propertiesaregivenintable 2.1.

3. DrydenseformoffumedsilicafromCABOT SANMARLMT.Propertiesaregivenintable2.2.

4. Superplasticizer(chemicaladmixture)CONPLAST SP430compliantwithBPS:9103-1999andASTM C494-1992thepropertiesaregivenintable2.3.

5. Recycledaggregatewithaspecificgravityof2.5 andafinenessmodulusof6.45.

6. Nominalsize,locallyavailablebasedonBIStable2 12.5MMcorrespondtogradedaggregate:3831970withs.pof2.65and6.7coarseaggregate. Table -4.1: Physicalpropertiesofsilicafume

Butrevisedmeantargetstrengthfor40%RCAreplacement ofnaturalaggregatesforM60gradeofconcretetocalculate Quantities:

84+1.65*5=92.25MPa

Step3.Withtheobtainedsetofmaterialsbyvarioustrialsit hasconcludedthatOPC440kg/m3

silicafume44kg/m3and w/c + SF ratio of .28 gives 28 days average compressive strengthas71.27MPa.

Step4.Thecalculateddensityofconcretemix;

=10X2.65(100-1.5)+{440[1-(2.65/3.15)]+44[1(2.65/2.20)]}-120(2.65-1)=2610.25+57.842-198 =2470.1kg/m3

step5.Quantityofaggregates=2470.1-440-44-118=1868.1 kg/m3

Physicalpropertiesof fumedsilica

1 type Sulphonatednaphthalene formaldehydeCondensate

3 Recommendeddose 00.6-01.5lit/100kgof cement

4.2 Mix design Calculation for HPC:

GradeDesignation:M60asHPCconcrete.

Inthiscase40%partialreplacementofnaturalfine aggregatebyrecycledaggregateistaken

Step1.Targetmainstrengthfck

fck=fck+(txs) ….. (1.1)

= 60x1.4 =84MPa

Step2.ForM60Gradeofconcretedesignmeantarget strengthat28daysforcalculations.

Designmeantargetstrengthfor M60=60+1.65*5=68.25MPa

step6. RecycledAggregates=1868.1x0.4=7747.2kg/m3 Sand=1868.1x0.25=467kg/m3

12.5mmaggregates=1868.1x0.35=653.8kg/m3

Nowwehavetheestimatedquantityofmixdesignas follows:

Waterrequired=118kg/m3

Cementrequired=440kg/m3

Silicafume=44kg/m3

Recycledaggregate=378kg/m3

Sand=661.5kg/m3

12.5mmaggregate=850.5kg/m3

Superplasticizer=4.41kg/m3

5. RESULTS AND DISCUSSION

5.1Cube Comp. Str.

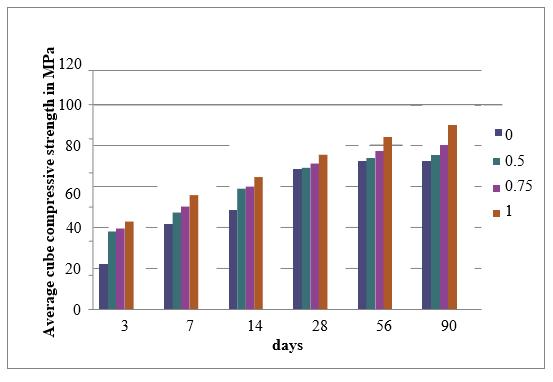

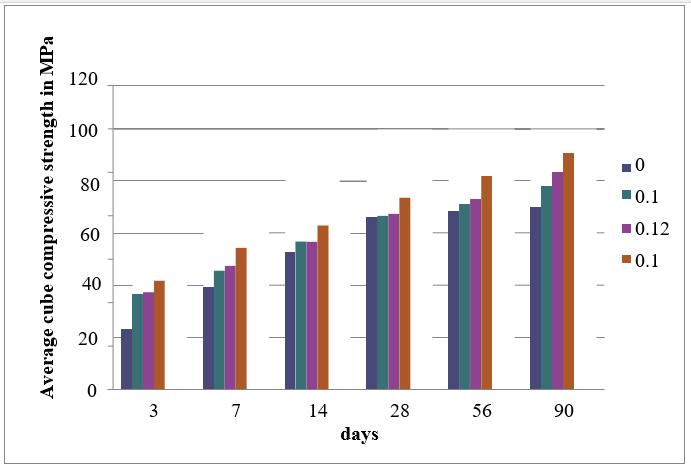

Cube compressive strength results in water-binder ratios suchas0.28fordifferentages,suchas3,7,14,28,56,and90 days,andatreplacementlevelssuchas 0%,10%,12.5%,and 15%of silicafumeand0.%,0.5%,0.75%,1%,fumedsilica arepresentedinTables5.1.1to5.1.2andplottedinthegraph.

Table -5.1.1: cube compressive strength result mixes with silica fume at w/b ratio of 0.28

5.2

Itispreviouslyknownthatcompressionisdirectlyrelated totheflexuralstrengthofconcreteanddependsonthe compressivestrength.ButforHPCthereisalowrateof

increaseintheflexuralstrength,whichisapproximately9 to10%ofitscompressionstrength.

Table 5.21 Flexural strength results of HPC mixes with silica fume at 28 days at w/b 0.28

Silica fume % Flexural strength (MPa) w/b = 0.28

Table 5.21 Flexural strength results of HPC mixes with fumed silica at 28 days at w/b 0.28

Fumed Silica % Flexural strength (MPa) w/b = 0.28

5.3 Splitting Tensile Strength

The spilt tensile strength result of HPC are taken for w/b ratioof0.28atdifferentsubstitutionlevelofsilicafumesuch as0%,10%, 12.5%,15%and for fumedsilica substitution levelarekeptas0%,0.5%,0.75%,1%at28daysofageare giveninthetables5.3.1and5.3.2below.

Table 5.21 split tensile strength results of HPC mixes with silica fume at 28 days at w/b 0.28

3. CONCLUSIONS

The concrete mix design procedure outlined here is more logical since it takes into account the effects of numerous concretecomponentqualities,whichareoftenoverlookedin standard mix design techniques. Superplasticizer and a mineralmixturearecoupledtocreateastraightforwardmix design procedure for HPC that complies with BIS and ACI coderequirements.TocreateaffordableHPCmixtures,this proposed method of mix design, proportionally uses superplasticizersandconcretecomponentsalongwithRCA inplaceofnaturalaggregates.Targetstrengthisappliedto thedesignmixaftercastingthetrialmix.Therefore,HPCcan bedesignedemployingmineralcombinationssuchassilica fumeandfumesilicausingtheindicatedmixdesignprocess.

TheHPCMix'scompressivestrengthat7and14dayswas60 to78and85to92percent,respective,ofthestrengthat28 days.Thisshowsthatsilicafumeandfumedsilicagainearly strengthwhencementispartiallysubstituted.

The optimal replacement of silica fume and fumed silica werefoundtobe15and1present.

Ontheotherhandtheoptimalamountofrecycledconcrete tobereplacedbynaturalaggregateswasfoundtobe40% maximum.

REFERENCES

[1] Viatceslav Konkov, “Principle Approaches to HighPerformance Concrete Application in Construction” ProcediaEngineering57,(2013),PP.589–596

[2] Henry van Damme,” Concrete material science: Past, present,andfutureinnovations”,Volume112,October (2018),PP5-24.

[3] MohamedAmin,YaraElsakhawy,KhaledAbuel-Hassan, BassamAbdelsalamAbdelsalam“Behaviorevaluationof sustainablehighstrengthgeopolymerconcretebasedon fly ash, metakaolin, and slag”. Case Studies in ConstructionMaterials16(2022)

[4] Y.N.Chana,X.Luob,W.Sunb,“Compressivestrengthand pore structure of high-performance concrete after exposuretohightemperatureupto800c”Cementand ConcreteResearch30(2000),PP.247–251.

[5] J.J.Chena,P.L.Ng,L.G.Lid,A.K.H.Kwan,“Productionof high-performance concrete by addition of fly ash microsphere and condensed silica fume”, Procedia Engineering172(2017),PP.165–171

[6] Ali Mohd, “Comparative Analysis of Concrete Using Recycled Aggregate”, International Journal of EngineeringResearchandManagement.

[7] Osama Zaid, Faisal M. Mukhtar, Rebeca M-García, Mohammad G. El Sherbiny, Abdeliazim M. Mohamed, “Characteristics of high-performance steel fiber reinforcedrecycledaggregateconcreteutilizingmineral filler”.CaseStudiesinConstructionMaterials16(2022)

[8] PrashantDodiya,VarshaYadav“StudyandAnalysisof High-PerformanceConcreteUsingMetakaolinandSilica Fume”casestudiedinconstructionmaterialsvolume10, Issue4 (2023).