Analysis of Different Types of Batteries In Electric Vehicle

Vishal S Chavan1 , Atharva S Gadkari 2 , Nikhil N Hanpude 3, Tushar S Pawar 41Professor, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

2Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

3Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

4Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India ***

Abstract - In the modern automotive industry, Battery powered Electric Vehicles are beginning to play an important role. The construction of today's electricvehiclesusesavariety of batteries, making it difficult to select one that best satisfies all the key requirements from various perspectives, including energy storage effectiveness, constructive qualities,costprice, safety, and utilisation life. The battery is the main part of an EV. This report provides a succinct overview of the various battery types utilised in electric vehicles. Electric vehicles mostly use lithium-ion, nickel metal hydride, and lead acid batteries. In this review paper, the fundamental characteristics of several batteries are compared. In light of this, lithium-ion batteries are the most significant option for electric vehicles.

Key Words: Electric Vehicle, Battery, Performance, Specific Power, Specific Energy, Life Cycles

1. INTRODUCTION

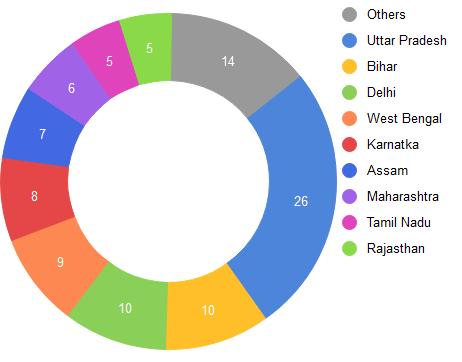

India'smarketforelectricvehiclesisslowlyexpanding.The IndianEVmarketenvironmentatthemoment isshownin Fig.1

market share. Given that a total of 995,319 EVs across all vehicle segments were sold in 2022, a significant 509% increaseoverthe163,458EVssoldin2019,ayearbeforeto the launch of COVID, and a 208% rise year over year (allIndiaEVsalesin2021:322,871units).

Main Components of EV’s are:

1. Charger

2. convertor

3. Battery

4. Motor

About50%ofthecostofelectricvehiclesisrelatedtothe battery.Reducingthepriceofthebatterypackiscrucialto boostEVsales.Soit'scrucialtochooseabatterypackthat's bothaffordableandefficient

2. TYPES OF BATTERIES:

There are different types of batteries available in market. Slectionofbatterytypeisbaedonenergystoragecapacity, constructiondetails,safety,costpriceandefficiency.

There are mainly four types of batteries available in the market:

1.Leadacidbattery

2.Nickelmetalhydridebattery

3.Lithiumionbattery

4.Otherbatteries

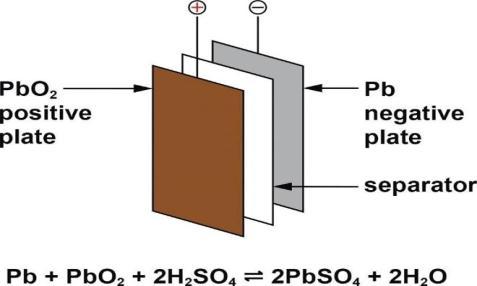

2.1 Lead acid battery:

GastonPlante,aFrenchchemist,createdthefirstleadacid battery in 1860. It is a battery that can be recharged. The least expensive battery option is flooded lead-acid, which wasalsothemostpopularpowersourceinthepast.

Twotypesoffloodedlead-acidbatteriescanbedistinguished asfollows:

Research on EV technology progress, focusing mostly on battery electric vehicles, is ongoing in many parts of the worldduetolimited energy resourcesandenvironmental impact.Only450unitsweresoldbyIndianmanufacturersin 2016.ThroughgovernmentsubsidiesandincentivesforEV adoption, India has a significant opportunity to grow its

1.enginestarterbatteries

2. deepcyclebatteries.

Whenanenginestarteroperatesandischargedbythecar's alternator, an engine starter battery produces a brief but

powerful surge current. EVs like "forklifts or golf carts" employ "deep cycle batteries" which are made to be periodicallydeeplydischarged.Ithasapositiveplatemade of brown lead dioxide and a negative plate made of lead metal, both of which are submerged in an electrolyte of diluted sulfuric acid. A lead-acid battery stores electrical energy that can be transformed from chemical energy to electricalenergy

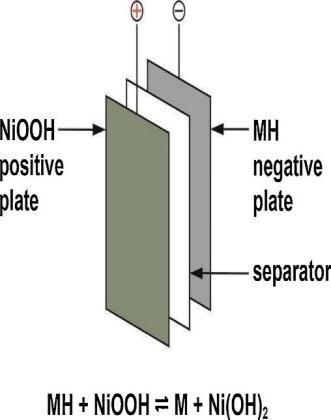

Fig-3:Anickel-metalhydridebattery'schemistryand mainparts.

DuetodifferentmaterialsusedasnegativeeletrodesNickel batteriesareclassifiedas:

1) Nickel-iron(Ni-Fe)batteries

2) Nickel-cadmium(Ni-Cd)batteries

3) Nickel-zinc(Ni-Zn)batteries

4) Ni-MHbatteries

Fig-2: Chemistryandmainlead-acidbatterycomponents.

Thelead-acidbatteryhasthefollowingreversiblereactions:

Positive electrode reaction:

PbSO4 + 2H2O↔PbO2 + 3H++HSO4- +2e-

Negative electrode reaction:

H+ +PbSO4+2e-↔Pb+HSO4-

Net reaction:

2PbSO4+2H2O↔PbO2+Pb+2H+ +2HSO4-

Advanatages:

1. Highavailability

2. Lowcost

3. Highreliability

Disadvantages:

1. Lowspecificenergy

2. Lowenergydensity

3. Maintainancecostishigh

4. Lesslifeofservice

Lead acid batteries store less energy per unit of mass or volumethanlithiumionbatteries,whichiswhytheyarenot frequentlyemployedinelectricvehicles.Theytypicallyride inslowelectricvehicles.

2.2 Nickel Metal Hydride batteries

Innickelmetalhydridebatteriesnickelhydroxideispresent at positive electrode, various materials as a negative electrodes and a potassium hydroxide solution as the electrolyte

5) Nickel-hydrogen(Ni-H2)batteries

Table -1. Advantages&DisadvantagesofNickelBatteries.

Material Advantages Disadvantages

Ni-Fe Better for traction applications Lowspecificenergy,power and energy density; high selfdischarge, hydrogen evolution, high purchase andmaintenancecost

Ni-Zn Highspecificenergy Highcost,shortservicelife

Ni-Cd Highspecificenergy High cost cadmium toxicity, recyclingissues

Ni-MH High specific energy, safety,longservicelife Highcost,highself-discharge, memoryeffect

Ni-H2 Extreme long-life cycle and tolerance to overcharge or overdischarge without damage

Expensive, low volumetric energy density, selfdischarge proportional to H2pressure

FromabovetypesNi-MHbatteriesispopularchoiceforEV. ElectrochemicalreactionsinNi-MHbattery:

X+2NiO(OH)+2H2O↔2Ni(OH)2+X(OH)2

M(H)+2NiO(OH)↔M+Ni(OH)2

H2+NiO(OH)↔Ni(OH)2

ThepatentencumbranceofNi-MHbatteriesforheavy-duty vehicles has caused a stagnation in the usage of Ni-MH batteriesinelectricvehicles(EVs)inrecentyears.

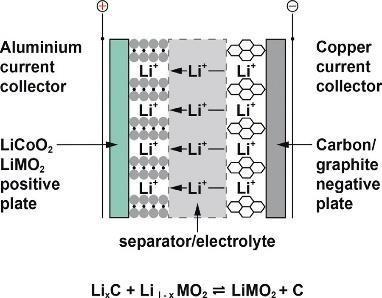

2.3 Lithium-ion Batteries

Afterbeingmanufacturedforthefirsttimeinacommercial settingbytheSonyCompanyin1991,lithium-ionbatteries dominated the market for energy storage and portable electricdevices.Theyarelightweight,tiny,andhavealotof powerstoragecapacityallatonce.Thelithium-ionbattery has considerable benefits over other batteries in terms of specificenergyandenergydensity.

Material Advantages Disadvantages

LiCoO2 In common use, high power density,highenergy density

LiMn2O4 High power density, very goodthermalstability

LiFePO4 Very good thermal stability and cycle life, goodpowercapabilityno memory effect, lighter andsmaller

LiNiMnCoO2 Highpowerdensity,high energy density, high energy efficiency, good cyclelife

Low self-discharge, lowsafety,highcost

Moderate cycle life, lowerenergy

Lowenergydensity

Structural/chemical instabilities during repeatedcycling

2.4 Other types of energy storage systems

1. SodiumNickelChloridebatteries

2. Metal–airbatteries

Different materials are used in positive electrodes, accordinglylithiumionbatteriesinclude:

1. Lithiumcobaltoxide(LiCoO2)batteries

2. Lithiummanganeseoxide(LiMn2O4)batteries

3. Lithiumironphosphate(LiFePO4)batteries

4. Lithium nickel-manganese-cobalt oxide (LiNiMnCoO2orNMC)batteries

5. Lithiumnickel-aluminum-cobaltoxide(LiNiCoAlO2 orNCA)batteries

6. Lithiumtitanate(Li4Ti5O12)batteries

Asmentionedabove,LiFePO4batteriesarefrequentlyused inelectricvehiclesbecausetheyoffersuperiorchemicaland thermalstabilityatareasonableprice.

Advantagesoflithiumionbatteries:

1. Highenergyefficiency

2. Lifecycleislong

3. Powerdensityisbetter

3. Sodium-betabatteries

4. Fuelcells(FCs)

5. Ultracapacitors

Fromabove Sodium Nickel Chloride batteryiscommonly used

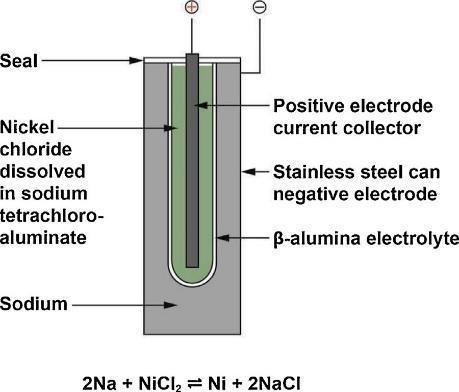

2.4.1 Sodium nickel chloride battery:

Batteries made on sodium nickel chloride are known as Zebra batteries. The "Zero Emission Battery Research Activity" (ZEBRA) project is where the name "Zebra" originated.AmoltensaltelectrolytefoundinZebrabatteries can only remain liquid at temperatures between 300 and 350C.

Thenormalcellreactionsareasfollows:

Positiveelectrode:NiCl2+2Na++2e−→Ni+2NaCl

Negativeelectrode:Na→Na++e−

TheNetreactionisNiCl2+2Na→2NaCl+Ni

Advantages:

1. Highenergydensity

2. Lowcorrosion

3. Highsafety

4. Longlife-cycle

5. Lowestprice

Disadvatages:

1. Lowspecificpower

2. Self-dischargeproblem

Otherapplicationsforthese batteriesincludesubmarines, militaryhardware,telecommunicationssystems,andpower storage.

3.Results:

Table-3: VariousParametersforBatteries

4. CONCLUSIONS

Thebatteriesusedinelectricvehiclesareillustratedinthis article. Choosing the right battery is a crucial factor. Nowadays, batteries with high specific energy and high energy density, including Zebra batteries and lithium-ion batteries,areusedasthepowersourceofEVsinsteadofthe conventionalleadacidbatteries.Lithiumionbatterieshave the highest specific energy (about 150 Wh/kg), energy density(250Wh/L),andnumberoflifecycles(4000).Less advantageous for electric vehicles are lead acid batteries with1000lifecyclesand100Wh/LenergydensityandNiMH hydride batteries with 3000 cycles and 140 Wh/L energydensity.

REFERENCES

1) J. Brady, M. O'Mahony, 2011, Travel to work in Dublin.Thepotentialimpactsofelectricvehicles (Elsevier: Transportation Research Part D: Transportandenvironment,vol16,issue2)p.188

2) T.R. Hawkins, B. Singh, 2012, Comparative Environmental Life Cycle Assessment of ConventionalandElectricVehicles

3) Pelegov, D.; Pontes, J. Main Drivers of Battery Industry Changes: Electric Vehicles A Market Overview.Batteries2018,4,65

4) Nykvist, B.; Nilsson, M. Rapidly falling costs of batterypacksforelectricvehicles.Nat.Clim.Chang. 2015,5,329–332.

5) Reddy,T.B.Linden’sHandbookofBatteries;McGrawHill:NewYork,NY,USA,2011;pp.167–201.

6) ToyotatoMakeOver10BatteryEVModelsinEarly 2020s. Available online: https://www.cnbc.com/2017/12/18/toyota-tomake-over-10-battery-ev-models-in-early2020s.html(accessedon18December2017).

7) Horkos, P.G.; Yammine, E.; Karami, N. Review on differentchargingtechniquesoflead-acidbatteries. In Proceedings of the 2015 Third International ConferenceonTechnologicalAdvancesinElectrical, Electronics and Computer Engineering (TAEECE), Beirut,Lebanon,29April–1May2015;pp.27–32.

8) May,G.J.;Davidson,A.;Monahov,B.Leadbatteriesfor utility energy storage: A review. J. Energy Storage 2018,15,145–157.

9) Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies:Frompresentstatetofuturesystems. Renew.Sustain.EnergyRev.2015,51,1004–1012.

10)Ding,Y.;Cano,Z.P.;Yu,A.;Lu,J.;Chen,Z.Automotive Li-Ion Batteries: Current Status and Future Perspectives.Electrochem.EnergyRev.2019,2,1–28.

11)Bresser, D.; Hosoi, K.; Howell, D.; Li, H.; Zeisel, H.; Amine,K.;Passerini,S.Perspectivesofautomotive batteryR&DinChina,Germany,Japan,andtheUSA. J.PowerSources2018,382,176–178.

12)Lee,J.H.;Yoon,C.S.;Hwang,J.Y.;Kim,S.J.;Maglia,F.; Lamp,P.;Myung,S.T.;Sun,Y.K.High-energy-density lithium-ion battery using a carbon-nanotube-Si composite anode and a compositionally graded Li[Ni0.85Co0.05Mn0.10]O-2 cathode. Energy Environ.Sci.2016,9,2152–2158.

13)Akhil,A.A.;Hu_,G.;Currier,A.B.;Kaun,B.C.;Rastler, D.M.; Chen, S.B.; Cotter, A.L.; Bradshaw, D.T.; Gauntlett, W.D. DOE/EPRI 2013 Electricity Storage HandbookinCollaborationwithNRECA.InSandia Report, Sand; Sandia National Laboratories: Albuquerque,NM,USA,2013;pp.201–213.

14)Nazri,G.A.;Pistoia,G.LithiumBatteries:Scienceand Technology(Paperback);Springer:Berlin,Germany, 2009;pp.455–478.

15)Andwari, A.M.; Pesiridis, A.; Rajoo, S.; MartinezBotas,R.;Esfahanian,V.AreviewofBatteryElectric Vehicle technology and readiness levels. Renew. Sustain.EnergyRev.2017,78,414–430

16)Un-Noor,F.;Padmanaban,S.;Mihet-Popa,L.;Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle Components, Technologies,

Challenges, Impacts, and Future Direction of Development.Energies2017,10,1217.

17)Co_man, M.; Bernstein, P.; Wee, S. Electric vehicles revisited: A review of factors that a_ect adoption. Transp.Rev.2017,37,79–93.

18)Liao,F.;Molin,E.;vanWee,B.Consumerpreferences forelectricvehicles:Aliteraturereview.Transp.Rev. 2017,37,252–275.

19)Yong,J.Y.;Vigna,K.R.;Tan,K.M.;Mithulananthan,N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain.EnergyRev.2015,49,365–385.

20)Veneri, O.; Capasso, C.; Patalano, S. Experimental studyontheperformanceofaZebrabatterybased propulsionsystem forurbancommercialvehicles. Appl.Energy2017,185Pt2,2005–2018

21)The Sodium / Nickel chloride (ZEBRA) battery J.L. Sudworth Beta Research and Development Ltd.50 Goodsmoor Road Sinfin Derby DE24 9GN , UK (www.elsevier.com)

22)Analysisofelectricvehicletrends,developmentand policiesinIndia VedantSingha*,VirenderSinghb,S. Vaibhavb a State Project Implementation Unit, HimachalPradesh,India bCareerPointUniversity, Hamirpur, Himachal Pradesh, India (www.elsevier.com)

BIOGRAPHIES

Prof VishalChavan

ProfessorinMechanical EngineeringDepartmentofPVG’S COET,Pune

E-mail:vsc_mech@pvgcoetac.in

AtharvaGadkari

BEscholarinMechanical EngineeringDepartmentofPVG’S COET,Pune.

E-mail:atharvagadkari100@gmailcom

NikhilHanpude BEscholarinMechanical EngineeringDepartmentofPVG’S COET,Pune

E-mail:nikhilhanpude2020@gmailcom

TusharPawar

BEscholarinMechanical EngineeringDepartmentofPVG’S COET,Pune

E-mail:tusharpawar20113@gmailcom