Volume: 10 Issue: 05 | May 2023 www.irjet.net

Volume: 10 Issue: 05 | May 2023 www.irjet.net

Jessline Jebahena A 1,Thai Subha2

Abstract- This project proposes a stochastic model predictive controller (MPC). The modified MPC minimizes the oscillation which provides a rapid search method to track global maximum power point (GMPP) in a lesser period. The MPC based maximum power point tracking (MPPT) technique provides tracking of MPC with zero oscillations and high PV power tracking under rapid weather fluctuations. The MPC technique acquires MPC andprovidessofttuningofparameterstoachievehigh PV power tracking with zero oscillations around GMPP. Finallyprovides optimalPV power trackingwith accurate efficiency, fast convergence velocity, and less computational period. This topology is modelled and its response is manifested through simulation studies using MATLAB/Simulink under different atmospheric conditions. Rule-based control approach and the MPC optimization algorithm are used to allocate power in a hybrid energy storage system (HESS) in a reasonable manner. Finally, the findings reveal greater efficiency in tracking the solar power and the suggested Energy Management system (EMS) has a lower energy consumptionrateandbatterydeteriorationrate.

Keywords: Model Predictive Control (MPC),Maximum Power Point Tracking (MPPT), Global Maximum Power Point (GMPP), Photovoltaic (PV), Electric Vehicle

Photovoltaic (PV)/ Battery hybrid energy storage systems have been thoroughly tested in electric vehicles (EVs), as this method of optimization can fulfil the needs of an EV, including high power /energy capacity, long battery life. The Energy Management strategiesprovideaneffectivebutnon-flexibleapproach to the issue of energy management, which basically applies the specified control principles through that of the given rules according to the operating modes of the converter which are used. The PV system behaviour is basedonthePVchargingprocedure,whichworksunder maximum power point (MPP) and generates PV power that can be transferred to load. The maximum power transfer theorem thus operates with the principle of

maximum power transfer only when the internal resistances should be equalized so as to load the resistance. Therefore, a maximum power point tracking (MPPT) is needed to solve the PV system’s non-linear behaviour and the injection of maximum PV power into the load through a DC-DC converter, which is controlled by regulating duty ratio through maximum power point tracking(MPPT)algorithms.

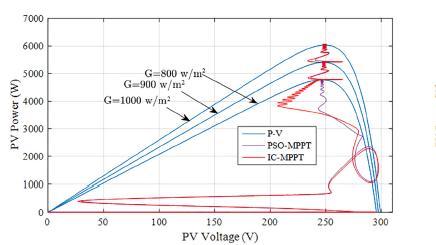

Many research studies examined other MPPT methods. In this work, the PSO-MPPT method was used in more than one application. The procedure of this methodisshown.AftersettingthePSOconfiguration,the algorithmwillthenstartsearchingforthebestdutycycle corresponding to the global best position of the i^th particle.

So, with the first particle, we will apply the corresponding duty cycle which is randomly chosen in this case. Then, the measured output PV voltage and current will be thus used for calculating the related PV power output. This value will be stored and nominated. With the same strategy, the algorithm will compare the obtained power value to the global best power value. If this new one is better, it will be then be affected by the newglobalbestpositionvalue.Thisactionwillnotfinish unlessalltheparticlesaretested.Then,eachparticlewill change its position and velocity, and these steps will be repeateduntiltheconvergencecriterionisobtained

Analytical expressions for power losses (converter losses and cell losses) were used to produce variations in component failure rates thatdependontheoperatingstateofthesystem.

Theoverallcostofthesystemishigh

1.3.

The MPC based MPPT technique provides tracking of GMPP with zero oscillations and high PV

Volume:

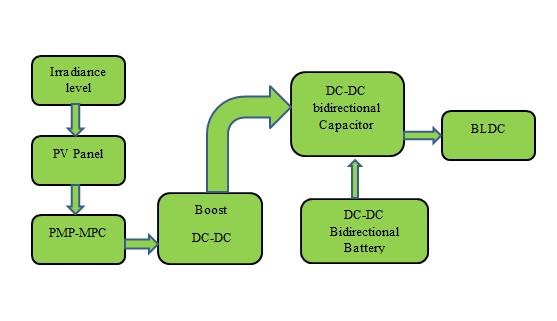

power tracking under rapid weather fluctuations. The MPC technique acquires GMPP and provides soft tuning of parameters to achieve high PV power tracking with zero oscillations around GMPP. Power electronically controlled (DC-DC converter), Ultra capacitor-battery energy storage system is proposed which supply power to the BLDC motor to drive a vehicle. Whole system is simulated in MATLAB Simulink with input as vehicle drivecycle.Speed,Torqueandthepowerrequirementof the vehicle are to be calculated using vehicle dynamics and drive cycle information. Based on the above calculation,theselectionofenergydevicewilltakeplace. Ultra capacitor is controlled through buck-boost converter to absorb/supply power from/to vehicle systemunderdeceleration/accelerationmode

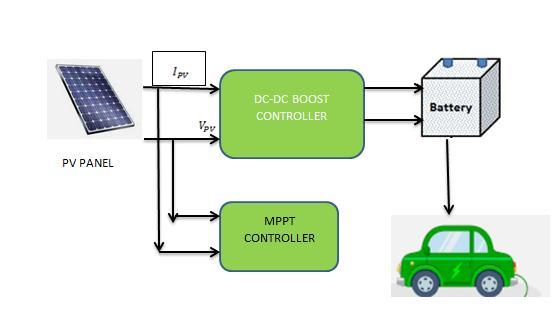

The proposed system is comprised of an input for the PV panel which is of irradiation and temperature. BasedupontheVoltageandCurrentfromthePVpanelit is thus analyzed with that of the algorithm to get the PWMpulse.ThisisthuspassedontotheBidirectionalDDCconverter.Thevoltageisthusimprovedandherecan be stored with that of Hybrid Energy storage system, whichusestheultra-capacitortostorethecharge.Which isthen,thepowerisutilizedbytheBLDCmotortodrive theElectricVehicle.

converterthatusestheMPPTalgorithm.PVmodulesare designed in system with 1500V and different ranges of Li-ion battery.The PV array gives the power to boost converter. This converter reduces the voltage of PV string to system volt for each system as required. This buck converter used the MPPT concept to get the best power and energy from the PV array and then give it to loadwhichistheelectricvehiclebatteryproposed.

The aim of MPC is to optimize power management over a moving horizon. Therefore, speed forecasting using Markov chain model can be leveraged to supply the preview power requirements. Reference SOCplanningdefinestheupperandlowerboundariesof the SOC values in each horizon for which the optimization algorithm, either DP or MPC, must be implemented, thus guiding when the battery discharges toachievebetterfueleconomy.Thismethodwaschosen, as it can be used to obtain the local solution of each horizon, yielding MPC, and can improve computational efficiency of MPC. Numerically, this type of MPC results in a two-point boundary value problem that can be solvedusingtheshootingmethod.

The MPC based MPPT technique provides tracking of GMPP with zero oscillations and high PV power tracking under rapid weather fluctuations. The MPC technique acquires GMPP and provides soft tuning of parameters to achieve high PV power tracking with zerooscillationsaroundGMPP.

Power electronically controlled (DC-DC converter), Ultra capacitor-battery energy storage system is proposed which supply power to the BLDC motor to drive a vehicle. Whole system is simulated in MATLAB Simulink with input as vehicle drive cycle. Speed, Torque and power requirement of vehicle are calculated using vehicle dynamics and drive cycle information. Based on above calculation, selection of energy device will take place. Ultra capacitor is controlled through buck-boost converter to absorb/supply power from/to vehicle system under deceleration/accelerationmode.

In PV panels, PV cells convert sunlight into electricalenergy,whichisoneofthebestapproachesfor achieving electrical power for long duration. The conversion from sun light to electrical power greatly depends on various factors such as the insolation level and cell efficiency. Solar PV systems are used today in many applications such as lighting, battery charging, water pumping, and satellite power systems etc. This articleproposesaPVsystemtochargeEVsusingaboost

The principle of the model predictive control is to determine the optimal behaviour of a system over a time horizon that we will call the whole horizon T. To find the input (or control) trajectory and the state trajectoryofthesystem,aniterativealgorithmisapplied in the following way. At each time step, the control trajectory is computed by solving an optimization problem over a finite prediction horizon P that can be differentfromthewholehorizonT..Oncethisproblemis solvedatthetimestept,onlythefirststepofthecontrol

International Research Journal of Engineering and Technology (IRJET)

Volume: 10 Issue: 05 | May 2023 www.irjet.net

trajectoryisappliedtogetthestate ofthesystematthe timestept+1.Then,anotheroptimalcontrolproblemis solved based on the new state of the system and with a shifted prediction horizon. This iterative procedure is repeateduntilthelasttimestepofthewholehorizonT

More formally, the optimal control problem (OCP)solvedateachtimestept oftheMPC algorithmis thefollowing:

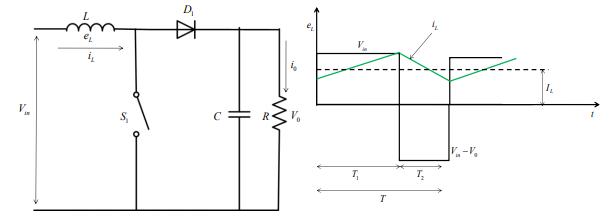

A boost converter is a DC-to-DC power converter which steps up voltage (while stepping down the current) from its input to its output. It is a class of switched-mode power supply (SMPS) that containing at leasttwosemiconductorsthatisadiodeandatransistor, and at least one energy storage element: a capacitor, inductor, or the two in combination. To reduce voltage ripple, filters made of capacitors are normally added to suchaconverter'soutputandinput.

x is the vector that gathers all the state variables of the systemfromtimek=0tok=Pand u theonewithallthe control variables from time k = 0 to k = P − 1. In model predictive control, the control variables are also called manipulatedvariables. g( )isthecostateachtimek and l is the terminal reduction. The meaning of each constraintoftheOCPisthefollowing:

•Theconstraintenforcesthecurrentstateofthesystem , to be the initial state x0 of the system for the optimalcontrolproblem.

• The constraint makes sure that the state variables satisfythedynamicsofthesystem.

• The constraint represents the set of constraints imposed on the state variables and the manipulated variablesateachtimek.

Fort=0,..,T−1:

(1) Set = , where is the current state of the system.

(2) Solve the optimal control problem for = to obtaintheoptimalcontrolsequence u∗

(3)DefinetheMPCcontrollawvalueμP( ):= u∗(0).

(4)Applythecontrolvalue ( )tothesystem,t=t+1 andgoto(1).

TheMPCisusedtooptimallydeterminethedeployment ofminimizingtheoscillationswiththatofpredicting the maximumpowerpointtrackingatvarioushorizonssoas togetthemaximumPVpowerwhichcouldbefedtothat ofthe batteryfor energystorage systems whichcan run therequiredload.

The key principle that drives the boost converter is that the tendency of an inductor to resist changes in current by creating and destroying a magnetic field. In a boost converter, the output voltage is always higher than that of the input voltage. When the switch is closed, current flows through the inductor in clockwise direction and the inductor stores some energy by generating a magnetic field. The polarity of the left side of the inductor is positive. When the switch is opened, current will then be reduced as the impedance is higher. The magnetic field created will be destroyed to maintain the current to that of the load. Thus the polarity will get reversed (means left side of inductor will be negative now). As a result of this, two sources will be in series whichwillcauseahighervoltagetochargethecapacitor through that of the diode D. If the switch is cycled fast enough, then the inductor will not discharge fully in between charging stages, and thus the load will always seea voltage greaterthanthatoftheinputsourcealone whentheswitchisinopenstate.Alsowhentheswitchis opened, the capacitor in parallel with the load is thus charged to this combined voltage. When the switch is thenclosedandtherightsideisshortedoutfromtheleft side,thecapacitoristhenabletoprovidethevoltageand energy to the load. At this time, the blocking diode prevents the capacitor from discharging through the switch. The switch must be opened again fast enough to preventthecapacitorfromdischargingtoomuch.

Battery orsolarinpowersystemsstackcellsin series to achieve higher voltage. However, sufficient stacking of the cells is not possible in many of high voltage applications due to lack of space. Boost converters can also increase the voltage and reduce the numberofcells.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 05 | May 2023 www.irjet.net p-ISSN:2395-0072

The battery is hybridized with ultra-capacitor withaDC-DCconverter.Thiswillthusincreasethelifeof the battery which will reduce the maintenance cost of the vehicle like of Battery replacement. It will also improve the vehicles performance during higher accelerationanddecelerationandprovidebettervoltage regulation in the system. In dynamic conditions, that is during higher acceleration or deceleration periods, the Ultra Capacitor will thus act as the charging and discharging device due to its ability to act faster and while in normal working mode the battery will then supplytheloadmakingthesystemoptimized.

An ultra-capacitor, which is also called as super capacitor, is an electrical component which capable of holding hundreds of times more electricalcharge quantity than a standardcapacitor. This characteristic wouldmakeultra-capacitorsmoreuseful indevicesthat would require relatively less currentand low voltage. In some situations, an ultra-capacitor can take the place of rechargeable low-voltage electrochemical battery. The principal disadvantage of the ultra-capacitor, compared with the older capacitor designs, is that the ultracapacitor cannot withstand high voltage. Whereas, an electrolytic capacitor might be rated at several hundred DC volts, ultra capacitors which will have maximum ratings of about 5 DC volts. In order to use ultracapacitorsathighervoltages,multiplecomponentsmust be connected in series. Then their voltage ratings will add up, just as battery voltages add in a series connection.

A brushless DC motor whichisalsoknownasa BLDC motor is an electronically commuted DC motor which does not have any brushes. The controller thus providespulsesofcurrenttothatofthemotorwindings which will control the speed and torque of the synchronous machine .These types of motors are highly efficient in producing a larger amount of torque over a large speed range. In brushless motors, the permanent magnets rotate around a fixed armature and can overcome the problem of connecting current to that of thearmature.Commutationwithelectronicshavealarge scopeofcapabilitiesandflexibilities.Theyareknownfor smooth operation and holding the torque when stationary

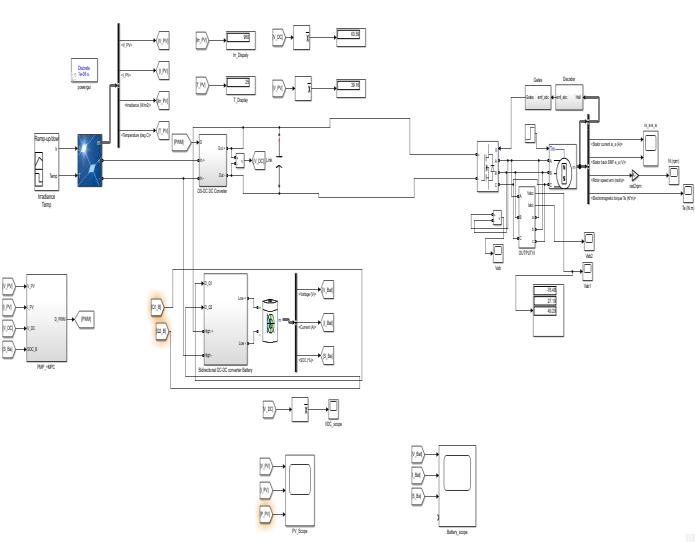

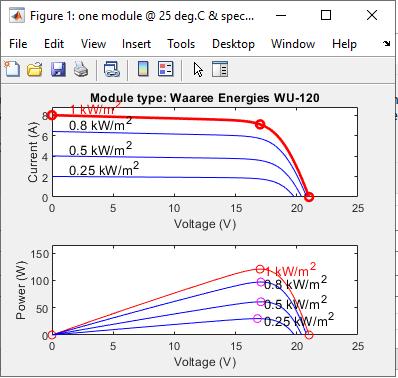

The Mat lab simulation is thus designed of an input for the PV panel which is of irradiation and temperature. Based upon the Voltage and Current from

the PV panel it is thus analysed with that of the MPC to get the PWM pulse. This is then passed on to the Bidirectional DC-DC converter which is connected. The voltage is thus improved and here can be stored with that of Hybrid Energy storage system, which uses the ultra-capacitor to store the charge. Which is then, the powerisutilizedbytheBLDCmotortodrivetheElectric Vehicle.

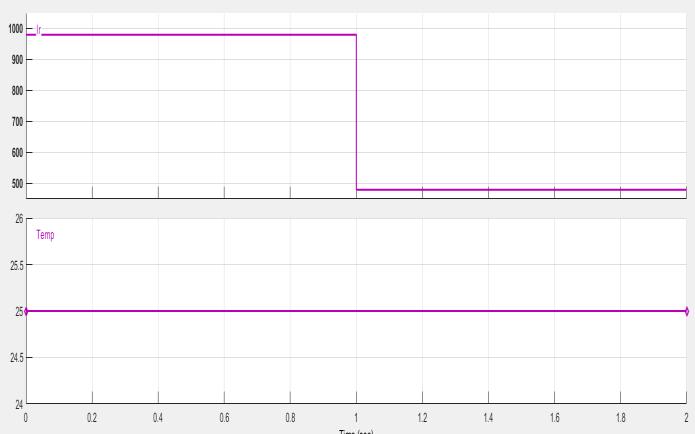

The solar power is thus tracked with the solar panel and its been estimated the irradiance and the temperature in which its power is been utilized. The estimatedirradianceiscalculatedtobeof980w/m2and 25degreeCelsius of Solarpower whichis been givenas input.

The below is the comparison of existing PSO algorithm in tracking the solar power in which the MPC algorithm attains 1 k w/m 2, which when compared to thatofPSOalgorithmwhichreachesof800w/m2.Hence the MPC MPPT could track higher efficient power from PV.

The hardware output rule-based control approach and the MPC optimization algorithm are used to allocate power in a hybrid energy storage system (HESS) in a reasonable manner. Finally, the findings reveal that the suggested EMS has a lower energy consumptionrateandbatterydeteriorationratethanthe rule-basedmethod.

ThestateofchargingprofilesyieldedfromtheMPC method based on four preview horizons (5s, 10s, 15s, and 20s).. The quantitative results are thus summarized in the final SOC levels almost which reached the boundary value in each case, suggesting that the four horizonsconsumea similar amountof electricity.Asthe prediction horizon increases, the total cost is thus slightly reduced. It can be observed that as the preview horizon increases,computational time persecond of the drivingcyclesignificantlyincreases.Thismaybebecause ofthetimerequiredforMPCcalculationsoverthelonger horizons, which involves speed prediction, iterative calculation of the State of charge (SOC) and co-state variables and interpolations for obtaining battery internal resistance and that of the open circuit voltage from look-up tables, which are more time-consuming over longer horizons. Hence, the case (horizon = 5s) looks to be a preferable solution with a very good balance between optimality and computational efficiency.

The reliability of the system is balanced is balanced such that the tracking of solar has increase in efficiency with this MPC methodology and therefore gives a high performance of the battery and the other energymanagementsystem.

The performance of the proposed MPC ALGORITHM method has been compared experimentally using the dSPACE platform with conventional MPC ALGORITHM based MPPT. Thus, the proposedPVpowersystemhasbeenused.

The presented control strategy shows a higher quality in the injected current into the electrical system, by making it possible the connection of solar arrays at various points, without causing problems to the control algorithmandtothequalityofthepowersupply.Thisis thereforecanbeobservedthattheproposedalgorithmis able to track better PV energy so as to provide better powertothesystemandtotheconnectedloadi.e.,tothe electricvehicleprovidingbetterefficiencytothebattery.

9. REFERENCE:

[1]. S.Gomathy, M.Sabarimuthu, S.KrithikaSree, J.Radha, R.Vennila, M.P.Krishna, “Photovoltaic - Battery Operated Electric Vehicle with an Energy Management Strategy” IOP Conf. Series: Materials Science and Engineering2023

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 05 | May 2023 www.irjet.net p-ISSN:2395-0072

[2] *Lalit Kumar Narwat and Javed Dhillon “Design and Operation of Fuzzy Logic Based MPPT Controller under Uncertain Condition” Journal of Physics: Conference Series (2021) 012035 IOP Publishing doi:10.1088/1742-6596/1854/1/012035

[3] Alex Omar Topa Gavilema 1 , Juan D. Gil 1 , José Domingo Álvarez Hervás 1,* , José Luis Torres Moreno and Manuel Pérez García “Modeling and Energy Management of a Microgrid Based on Predictive Control Strategies” Solar 2023, 3,62–73.https://doi.org/10.3390/solar3010005

[4] Gangadhar Mahalingappa Akki1, Srivani S. G2 “MaximumPowerPointTrackingusingmodifiedParticle SwarmOptimizationTechnique”Volume10IssueVMay 2022-Availableatwww.ijraset.com

[5] M. M. Shehu, M. Dong and J. Hu, “Optimization of Particle Swarm based MPPT under Partial Shading Conditions in Photovoltaic Systems,’’2021 IEEE 16th Conference on Industrial Electronics and Applications (ICIEA),2021,pp.267-272.

[6] Neeraj Priyadarshi M. S. Bhaskar P. Sanjeevikumar Farooque Azam Baseem Khan “High-power DC-DC converter with proposed HSFNA MPPT for photovoltaic basedultra-fastchargingsystemofelectricvehicles”IET RenewablePowerGenerationDOI:10.1049/rpg2.12513

[7]Kumar,M.,Tyagi,B.:Arobustadaptivedecentralized inverter voltage control approach for solar pv and storage basedislanded microgrid. IEEETrans.Ind. Appl. 57(5),5356–5371(2021)

[8]. Habib Kariem, Ezzedine Touti1,and Tamer Fetouh “The efficiency of PSO-based MPPT technique of an electric vehicle within the city” Measurement and Control 2020, Vol. 53(3-4) 461–473 DOI: 10.1177/0020294019882973

[9].Technosun.RECPEPeakEnergySeriesSolarPanelsModelREC260PE.TechnicalReport,2022.

[10] Gil, J.D.; Topa, A.O.; Álvarez, J.D.; Torres, J.L.; Pérez, M. A review from design to control of solar systems for supplyingheatinindustrialprocessapplications.Renew. Sustain.EnergyRev.2022,163,112461.

[11] Yan, Q.; Zhang, B.; Kezunovic, M. Optimized Operational Cost Reduction for an EV Charging Station IntegratedWith Battery Energy Storage and PV Generation. IEEE Trans. Smart Grid 2020, 10, 2096–2106.

[12]Moya,F.D.;Torres-Moreno,J.L.;Álvarez,J.D.Optimal Model for Energy Management Strategy in Smart Building with Energy Storage Systems and Electric Vehicles.Energies2020,13,3605.

[13] Ma´slak, G.; Orłowski, P. Microgrid Operation Optimization Using Hybrid System Modeling and Switched Model Predictive Control. Energies 2022, 15, 833.

[14]. Wang, X.; Atkin, J.; Bazmohammadi, N.; Bozhko, S.; Guerrero, J.M. Optimal Load and Energy Management of Aircraft Microgrids Using Multi-Objective Model PredictiveControl.Sustainability2021,13,13907.

[15] Zhang, J.; Li, J.; Wang, N.; Wu, B. An enhanced predictive hierarchical power management framework for islanded microgrids. IET Gener. Transm. Distrib. 2022,16,503–516