Maximizing energy efficiency in hotel HVAC systems: An energy modelling approach to comparing Chilled water and Variable Refrigerant Flow (VRF) systems

Mohammad

Furqan, Naveen, Priyanshu VermaMOHAMMAD FURQAN, B.tech (Mechanical engineering), Delhi Technological University, Delhi. NAVEEN, B.tech (Mechanical engineering), Delhi Technological University, Delhi.

PRIYANSHU VERMA, B.tech (Mechanical engineering), Delhi Technological University, Delhi. Under the guidance of Dr. Naushad Ahmad Ansari

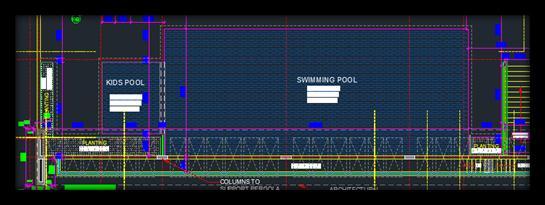

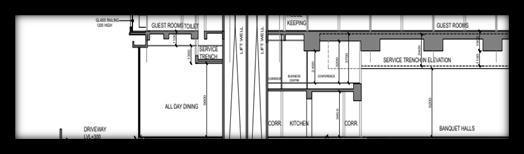

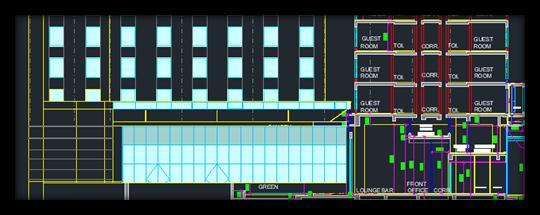

Abstract - The paper presents a five-star, four-story hotel project in Bangalore with 2 basement levels for parking and services, ground floor for public areas, and 95 guest rooms from the second to sixth floor. The design focuses on meeting functional requirements while avoiding over-sizing equipment, ensuring cost efficiency, and providing maximum comfort to occupants. Two HVAC systems (Chill water and VRF) have been considered for the project, based on international standards like LEED v4 and ASHRAE 62.1 for maximum cost efficiency and highest indoor air quality.

Key Words: HVAC, chilled water, energy efficiency, VRF systems,energymodelling

1.INTRODUCTION

The paper presents a five-star, four-story hotel project in Bangalorewith2basementlevelsforparkingandservices, groundfloorforpublicareas,and95guestroomsfromthe second to sixth floor. The design focuses on meeting functional requirements while avoiding over-sizing equipment,ensuringcostefficiency,andprovidingmaximum comforttooccupants.TwoHVACsystems(Chilledwaterand VRF) have been considered for the project, based on internationalstandardslikeLEEDv4andASHRAE62.1for maximumcostefficiencyandhighestindoorairquality.

Thenetuseofenergyhasbeenontherisethroughoutthe world,leadingtoclimatechangeandincreasinggreenhouse gasemissionsduetoincreasedenergygenerationfromfossil fuels. Even though mitigation measures have been implementedaroundtheworld,significanteffortsarestill requiredtolimittheriseintheglobaltemperaturetothe2 °CasstatedintheParisAgreement. Theamountofenergy thatcanbesavedinbuildingsthroughenergymodelingcan varydependingonthespecificbuildinganddesignoptions that are evaluated. Building sector accounts for approximately 40% of the total world final energy consumption and around one-third of the greenhouse emissions,therefore,itplaysanimportantroletoreducethe impact on the environment. However, studies have

shownthatenergymodelingcanleadtosignificantenergy savings in buildings. By and large, HVAC consumption in developed countries accounts for half the energy use in buildingsandonefifthofthetotalnationalenergyuse.[3]

2. Air conditioning systems

2.1 Chilled Water Systems:

Chilledwatersystemsaregenerallyusedinmediumand largesizebuildings.Thesesystemsactascentralizedcooling systems providing cooling to or even multiple buildings. Chilledwatersystemsprovidecoolingtofacilitiesbyusing chilledwatertoabsorbheatfromthebuilding’sspaces.

ThesystemutilizesamachineryknownasChiller,which consists of four primary components viz: Compressor, Evaporator,Condenser,andanExpansiondevice.Thesefour fundamental components are present in every chiller, irrespectiveofsize,shapeandtype.Also,therearethreemain circuitsassociatedwithachiller,whichareveryimportantto get desired cooling. The first, is the refrigeration circuit, which is the refrigeration cycle; the second, chilled water circuit,inwhichtheheatistransferredfromthebuildingto chillerviaheatedwaterandthenchilledwatersentbackto building, and the third, condenser circuit, in which heat is transferredtocoolingtower,actingasaheatejectionsource.

Thechilledwatersupply(CHWS)isthenamegiventothe waterthatexitsachiller,typicallyatatemperatureofaround 43°F(~6°C).ThisCHWSisthenpumpedthroughthechiller anddistributedtovariousairconditioningunitswithinthe building,suchasairhandlingunits(AHUs)andfancoilunits (FCUs).Asthechilledwaterpassesthroughaheatexchanging coilintheseunits,itcoolsthecoil,whichisthenblownwith airbya fantoprovidecoldairtothebuilding'sspace.The supplyairtemperatureforAHUsandFCUsistypicallyaround 55 °F (~12°C). After leaving the heat exchanging coil, the chilledwaterreturnstothechiller,whereitiscooledagain, andthecyclerepeats.Therearetwotypesofchilled-water systems:air-cooledandwater-cooled.

Air-cooled chillers are most often installed outside buildings and extract heat from chilled water by releasing heatdirectlyintothesurroundingair.Water-cooledchillers aremostofteninstalledinsidebuildings.TheydifferfromAircooledchillerinthefactthatitextractsheatfromthechilled waterbydissipatingitintoasecondisolatedwaterlinecalled thecondenserwaterline.Condenserwaterflowsthroughthe chiller and absorbs heat which is then ejected via cooling towerlocatedoutsidebuildings.

Duetocentralizedair-conditioning,itprovidesorganized configurationandsimplifiesthemaintenanceprocess.They provide better energy efficiency and cut down money on energyconsumptioninthelongrun.

2.2 Variable Refrigerant Systems:

It is a ductless, large system for HVAC, which uses refrigerant for both heating and cooling. VRF constantly controls the amount of refrigerant entering each zone to ensureoverallcomfortandenergyefficiency.AVRFsystemis based on the flow of refrigerant between an external condensingunitandmultipleinternalevaporators(usually fan coil units). Each internal evaporator serves a different heatzonewithinthebuildingandtherefrigerantflowtoeach evaporator is adjusted based on local requirements. This provides a high degree of flexibility, allowing the performanceoftheoutdoorcondensertoadapttotheoverall internaldemand,allowingtheoverallsystemtooperateat optimumefficiency.

VRF systems achieve high efficiency by making use of inverter compressors. An inverter system enables the compressor to ramp up or down as per requirements of individual space. In a system without an inverter, the compressor will always run at full capacity. Basically, it's eitheronoroff.Invertersystemsoperatingatlowspeedsand capacitiescanhavesignificantefficiencygains.

Broadly,aVRFsystemcanbeeitheratwo-pipeorthreepipesystem.

The2-pipesystemcancoolorheatallzones(heatpump system).The3-pipesystemcanheatandcoolsimultaneously by heating some zones and cooling others. Heat recovery allowsheatfromzonesrequiringcoolingtobeusedtoheat zonesrequiringheating.Thishasahighercapitalcost,but heatrecoveryallowsforveryefficientoperationandreduces runningcosts.

AnimmediateadvantageofVRFsystemsisreducedenergy consumption.AccordingtoTranetechnologies,VRFsystems cansave30-40%energycomparedtohistraditionalHVAC systems.MostVRFsystemsareinherentlyscalableandcanbe builtcomponentbycomponentregardlessofthedesiredsize ofthefinalsystem.ThismakesVRFsystemsidealforlarge new buildings and older buildings undergoing major

renovationsandsincerequirementofductsisabsent,these systems can be implemented practically anywhere, regardlessofthetypeofexistingHVACsystem.

VRFsystemsareideal forbuildingswithmultipleareas, varyingheatingandcoolingrequirements,andwheregood local control is required, examples, range of commercial buildings,officespaces,banks,hotelswheresomeroomsmay bevacant,andothershaveveryhighheatdemands;etc

In India, these two air conditioning systems are widely utilized due to the abundance of materials and parts from numeroussuppliersandmanufacturers.Tochoosethemost efficientandcost-effectiveoptionforourbuildingproject,we willperformadetailedcomparisonofbothsystemsandmake aninformeddecision.

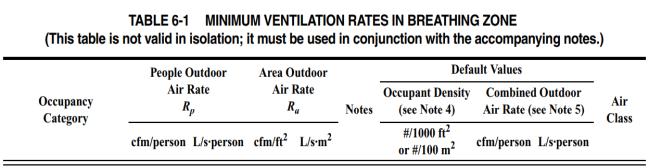

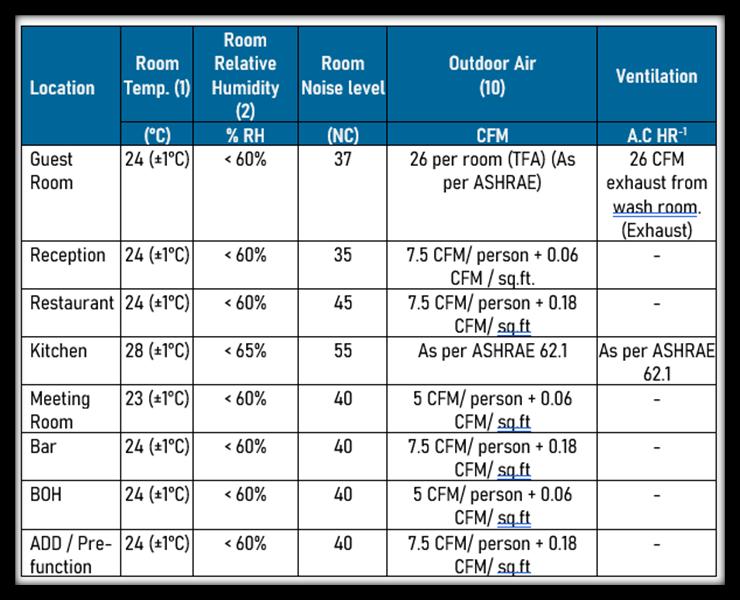

3. Occupancies & ventilation requirements

Itisextremelyimportanttoaccountfortheoccupantdensity and ventilation requirements of the occupants in order to accuratelydeterminetheActual HeatLoadofthebuilding. Following are the occupant density and Ventilation requirementsaspertheASHRAE62.

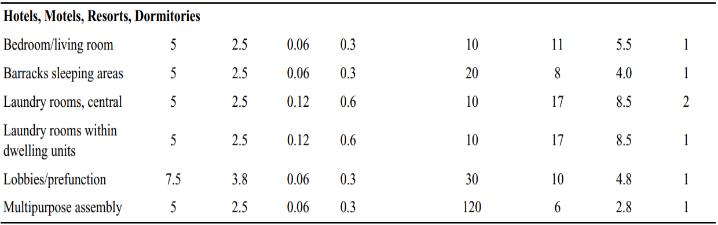

4. Breakdown of the energy use in buildings:

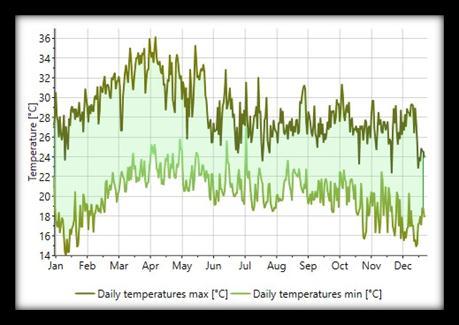

HVACsystemsaccountforasignificantportionoftheenergy consumptionincommercialandresidentialbuildings,with cooling and heating alone representing up to 50% of the totalenergyuse.ThismakesHVACsystemsaprimetarget forenergyefficiencyimprovements.[5]Theexactpercentage of HVAC's impact on building load depends on various factors such as the size and location of the building, the climate,thetypeofHVACsystemused,andtheefficiencyof thesystem.

Forexample,inahotandhumidclimate,theHVACsystem mayconsumeasmuchas70-80%ofabuilding'stotalenergy consumption due to the need for air conditioning. In a temperate climate, the HVAC system may consume less energy,accountingfor40-50%oftotalenergyconsumption.

Source: Guide to Best Practice Maintenance and Operation of HVAC Systems for Energy Efficiency (January 2012), Pages 36–37 http://ee.ret.gov.au/energy-efficiency/non-residentialbuildings/heating-ventilation-and-air-conditioning-hvac

Itcanbeeasilyunderstoodthatfromthetotalenergyinput ofabuilding,amajorandasignificantvalueistakenbythe HVAC systems. By having a control on this value, the performance of the building can be impacted. The US Department of Energy reports that energy modelling can leadtoenergysavingsofupto40%ormoreinsomecases [6].

A thorough energy audit and simulation can identify any operational and design anomalies and lead to improved performanceandreducedenergywaste,ultimatelysaving costovertime.Whendesigningorrenovatingabuilding,it's crucialtoconsiderthesignificantimpactoftheHVACsystem on building load. Implementing energy-efficient HVAC systemsandmaintainingthemproperlycanminimizetheir impact, lower energy expenses, and support a sustainable future.

5 Steps involved in energy modelling:

Therearevariousstepsinvolvedintheprocessofcreating an energy model in the trace software. These are general guidelines and the steps involved vary depending on the scale of the project and the specific process may vary dependingontheversionofTRACE3DPlusbeingusedand thecomplexityoftheHVACsystem.

1. TheusercreatesanewprojectbyopeningTRACE 3DPlus andselecting"NewProject"fromtheFile menu.Theuserinputsanamefortheprojectand selectsalocationtosavetheprojectfile.Theuser setsuptheproject'stimezone,weatherdata,and otherrelevantinformation.

2. The user defines the building by inputting the buildinggeometry,suchasthefloorplan,walls,and roof. The user specifies the type of construction, insulation, and other relevant information for the building envelope. The user may also import existingbuildinginformationfromaCADprogram orothersoftware.

3. Theusercanalsochoosewhichroomtypewillbe the default when a room is drawn. The room will automaticallybeassignedtheroomtypetemplate selectedasthedefault.Roomtypescanbeexpanded toviewtheconstruction,internalloads,andairflow templatesassignedtothem.Theassignmentscanbe alteredfromthedrop-downlist.

4. Theweathertabinthesiteandbuildingsectionwill allow the user to view or modify the design conditionsoftheselectedlocationaswellasview otherlocationsinthemaporthetreetheselected location will show on the top of the tree and the map will be zoomed in to the specific location markedwithastar.

5. Theuserwillnowproceedtothecreatebuildingtab todrawourbuildingwhenyouclickonthecreate buildingtabnoticethethreeoptionsthatshowg/b XML import draw building and building wizard. Uponselectingtheimagefile,youwillneedtoclick alocationontheimagethatwillbelinedupwiththe origin. The user can relocate the pictures origin simply use the origin tool and click a spot on the image where the new origin will be. The image is then scaled to match the true dimensions of the project.

6. Lengthandwidthvaluescanbeenteredwhenusing the drawing tools using these fields will create rooms or walls. They can also be used to add windowsandotherelementsintheproject.

7. Levels can be added above or below the original levelbysimplyclickingtheplussignoneitherside ofthecurrentlevelindicator.Theusercanswitch between levels by clicking on the number of the desired level levels of the building can also be reorderedordeleted.

8. TheuserdefinestheHVACsystembychoosingthe typeofHVACsystemtheywanttomodel,suchasa centralairsystem,aductlessmini-splitsystem,or others. The user inputs the system specifications, such as fan and pump sizes, coil sizes, duct sizes, andotherrelevantinformation.Theusermayalso importsysteminformationfromothersoftwareor equipmentmanufacturer'sdata.

9. Theuserdefinestheloadsbyinputtingtheheating andcoolingloadsforthebuilding,includinginternal loads from people, lights, and equipment, and externalloadsfromwindows,roof,andwalls.The usermayalsoimportloadinformationfromother softwareorusedefaultvaluesprovidedbyTRACE 3DPlus.

10. The user runs the simulation and analyzes the results. They can view air and water flow, air temperature and humidity, energy consumption, and other relevant information. They can also compare the performance of the HVAC system to industrystandardsorotherdesigncriteria.

11. The user optimizes the system based on the simulation results by making adjustments to the HVAC system to optimize its performance and energy efficiency. They can adjust the system components,suchasfans,pumps,coils,andducts, or change the building envelope or load information.

12. The user repeats the simulation and analysis process until they are satisfied with the results. Theycan makechangestothesystemor building information and repeat the simulation as many timesasneeded.

13. Theusersavestheprojectandexportstheresultsto share with othersorusein otherprograms.They can export results in various formats, such as graphs,tables,andreports,forfurtheranalysisor presentation.

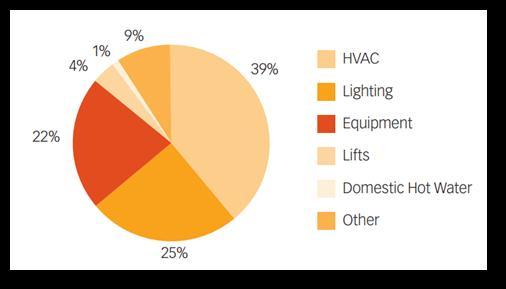

6 Project introduction:

Theselectedprojectisafive-starcategoryfourstoryhotel situated in the city of Bangalore and will comprise of 2 BasementsforParkingandServices,GroundfloorforPublic areasand95GuestRoomsfromSecondFloortoFourthFloor. The hotel name and brand have not been included for confidentiality purposes. The hotel plans and structural details were obtained from the architects. The rates of electricityandcostofequipmentwereobtainedfromHVAC vendorsandcontractors.ThehotelwasanalyzedonTRACE 3DPLUSandthetotalcostwascomparedforaperiodof20 years.

Thereportdescribestheprojectrequirementandoutlines thevariousmechanicalandelectricalsystemstobeadopted.

Thedesignphilosophyistoensurefulfillmentofallfunctional requirementsinaccordancewithnationalandinternational standardsandcodesaswellaslocalby-laws.Whilefulfilling

thefunctionalrequirements,specialeffortshavebeenmade towardsoptimizationwhileensuringadequacyofequipment andsystems.Throughthesecollectivemeasures,functional adequacy has been ensured while avoiding over sizing in equipmentandsystemasalloversizedsystems/equipment willcostmoretoowner,costmoretooperate(asoversized systemareinherentlyinefficient)andmostimportantly,over designedsystemisfunctionallyinferior.

We have considered 2 of the most readily available HVAC systemsavailableinIndia:

1. ChillwaterHVACsystem

2. VRFHVACsystem

Thedetailedanalysisisgivenbelow.

VariousinternationalstandardslikeLEEDv4,ASHRAE62.1 etc.havebeenconsideredwhiledesigningtheHVACsystem, toensuremaximumcostefficiency,alongwithensuringthe higheststandardofcomforttotheoccupants.Adequatefresh air quantity shall be provided to air-conditioned spacesto maintainIndoorAirQuality(IAQ)generallyasperASHRAE standard62.1-2010.

7. CODES AND REGULATIONS:

The following codes and standards have been used in the design:

- Accor(IBIS)EngineeringDesignGuidelines.

- NationalBuildingCodes:BuildingServices2016

- TheAmericanSocietyforHeating,Refrigeratingand AirConditioningEngineers(ASHRAE)standards:

• Ventilation foracceptable indoorairquality62.12010.

• Energystandardsforbuildings90.1-2007.

• ASHRAEhandbooks:

• 2018ASHRAEHandbook,Refrigeration.

• 2019ASHRAEHandbook,Applications.

• 2020ASHRAEHandbook,Systemsandapplications.

• 2021ASHRAEHandbook,Fundamentals.

- AirConditioning,HeatingandRefrigerationInstitute (AHRI).

- Sheet Metal and Air conditioning Contractors NationalAssociation(SMACNA):

- HVAC duct construction standards, metal and flexible,1995.

- EnergyConservationBuildingCode(ECBC2017)

- ASHRAE52.1-1992,52.2-2007.

- IMDWeatherData.

BUILDINGENVELOPE:

a) ‘U’-valueofexposedwall= 0.32

Btu/Hr/ft²/ºF

b) U’-valueofroof = 0.0951

Btu/Hr/ft²/ºF

c) Fenestration

i) Public area = ‘U’ value = 0.57

Btu/Hr/ft²/ºF &SHGC= 0.6

ii) Guest rooms = ‘U’ value =0.57

Btu/Hr/ft²/ºF &SHGC= 0.6

8. Hotel Specifications:

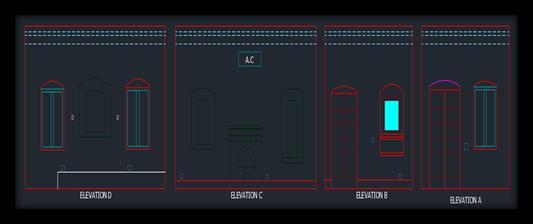

Thesiteandhoteldetailsaremadeavailabletousfromthe architects. They specify in detail the various elements, rooms,lobbies,areas,elevationsandgiveusinformationon theoccupiedandunoccupiedareasinthehotel.Theproject isafive-starcategoryfourstoryhotelsituatedinthecityof Bangaloreandwillcompriseof2BasementsforParkingand Services,GroundfloorforPublicareasand95GuestRooms fromSecondFloortoFourthFloor.

Details of the hotels structure and materials are obtained fromtheclientandcontractors,andtheyhelpusinentering the U – values and shading coefficients of the glass, partitions,slab,roofs,wallsetc.Thishelpsustogetamore detailed and accurate analysis, further increasing the accuracyoftheresults.

9. Design Criteria:

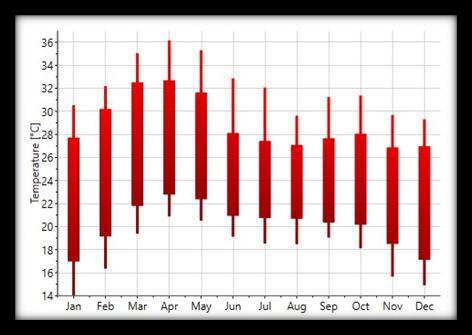

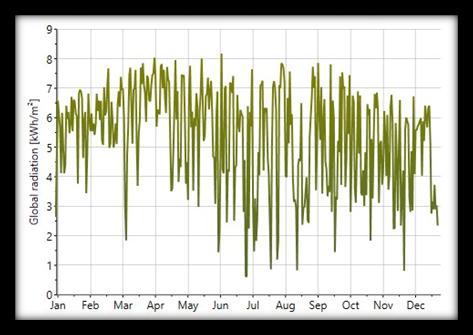

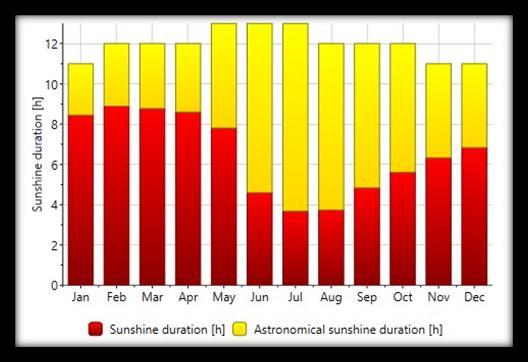

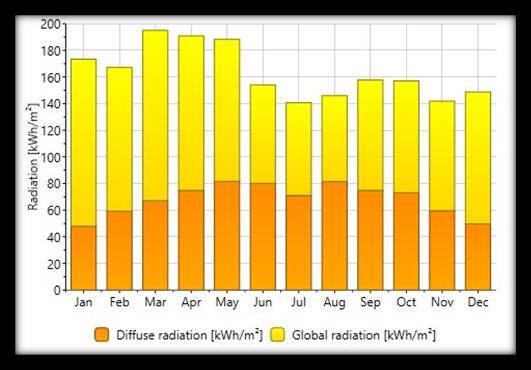

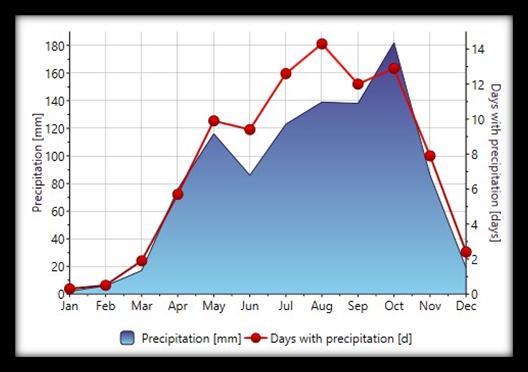

9.1 Climatic Design Conditions

The climatic design information as given by IMD/ASHRAE is used for design, sizing, selecting, installation,anddehumidificationequipment,aswellasfor otherenergy-relatedprocesses.8760hours(365x24)IMD weatherdatahasbeenusedfordetailedsimulationusingthe mostadvancedTRACE-3DPLUSsimulationsoftware.

Theexternalenvironmentalconditionsusedinthe mechanicaldesignareasfollows:

Location:Bangalore

Latitude:12.9716°N,77.5946°E

10. INDOOR DESIGN CONDITIONS:

Toreachcomfortconditionsandproperenvironment,itis necessary to maintain the design at a certain temperature andhumiditywithindifferentareastoacceptablelevels.

Assuch,theindoordesigntemperatureconditionsappliedin thedesignoftheprojectshallbeaccordingtoTable1below:

TABLE 1: Temperature,Humidity,ventilationandNCcriteria

Notes:

1. The tolerance levels shown indicate the range of temperatures due to the operation of the controls systems.

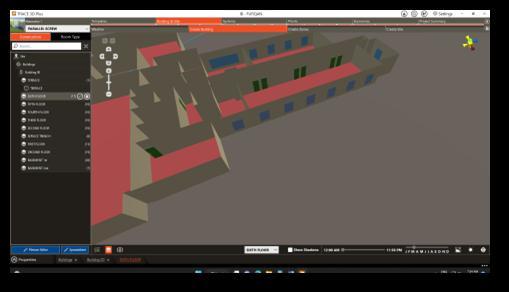

10.1 BUILDING DESING:

The hotel type was selected to be a standard hotel. This helpedinclassifyingthevariousroomtypesandoccupancies already available in the TRACE 3DPLUS library as per ASHRAEguidelines.

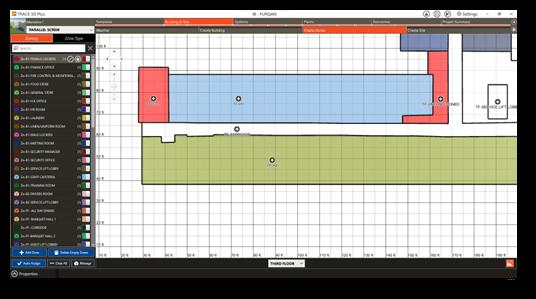

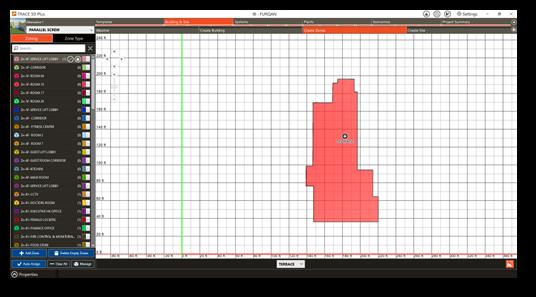

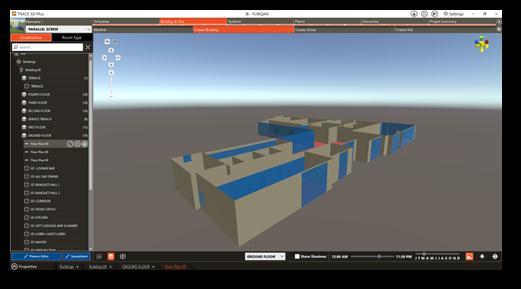

TheprojectAUTOCADorarchitecturallayoutsareobtained. ThesearetheninsertedintotheTRACE3DPLUSfiletoget reference points to draw the building on a floor-by-floor basis.Thiscanfurtherhelpusgainmuchmoredetailedand accuratemodelofthehotel.

Thedetailedplanshelpinclassifyingandbuildingeachroom accordingtospecifiedwidthsandhelptofurthersimplifythe designprocess.Thefinishedbuildingmatchestheimportant featuresofthebuildingperfectly.Asfarasenergymodelling isconsidered,itisahighlyaccuratematch.

(f) 10.2 ROOM TYPES:

Thenextprocessrequiresthevariousroomsgeneratedtobe dissociated in various room types. The pre-installed room typesareselectedfromthelibraryandthenassociatedwith each,andeveryspaceorroombuiltinthearea.

There are various room types to select from including kitchen,guestroom,lobby,corridor,etc.thishelpstospecify the room occupancy, ventilation requirement, heating requirement, heat load etc. This further allows us to accurately predict and room heating and cooling requirements,inturnallowingustocalculatetheroomtotal electricityconsumptionbytheHVACequipment.

10.3 Zone types:

A"zone"istobeacollectionofroomswhichshareasingleair diffuserand/orterminaldevice(s).Forexample,ifaunitor ACunitisappliedtoazone,alloftheroomsinthezoneshare thesinglefancoilterminalunit.Allroomswithininazone sharetheparametersinthezone'srespectivezonetype.The purposeofzonetypesistoestablishtheheatingandcooling setpoints, drift points, supply path, return path, and ASHRAE62.1effectivenessratiosatatemplatelevelrather thanzonebyzone.

Thus, establishing zones allows us to further simplify calculations,andinsertaspecificzonetypeorparameterfor a largenumberofsimilarrooms.Fore.g.,a hotel with500 roomscanbemadeasinglezoneoneachfloor.Then,ifany changes are required, we only need to edit the individual floorlevelzones,ratherthanallthe500rooms.

(b)

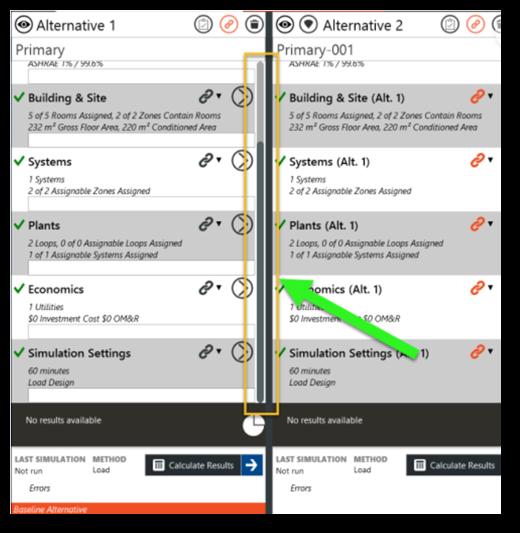

11. HVAC System Alternatives:

TRACE3DPLUSallowstheusertocreatemultiplescenarios andtestingconditions.Thepurposeofacomputermodelisto test scenarios prior toconstruction. To facilitate in testing scenarios,TRACE3DPlusallowstheusertohaveupto16 alternatives. The alternatives may be linked, copied, made

new,oranycombinationofthese.Forexample,Thebuilding may be linked, the systems may be copied for small changes,theplantsmaybelinkedtoadifferentalternative, and the simulation settings may be completely different.Alternative 1, is elevated as the main or "base" alternativethroughoutmanyreports. Thesealternativescanthenbeusedtogeneratereportsand comparisons between various scenarios. We create 2 alternativesinthiscase:

1. Screwchiller

2. VRFsystem

BoththesesystemsareextremelycommoninIndiaandare economicalunderdifferentconditions.

volumesystemscanbeeasytocontrolandreduceoncapital costs.

Variable volume systems involve extra control and equipment.Themostimportantisthemodulatingdampers andpressuresensorswhichareneededtobeinstalledatthe various rooms. This increases capital costs in the form of increased first costs. Furthermore, this also needs more complexcontrollingmechanisms.

Wehavechosenthefollowingconstantvolumesystem.

11.1 SYSTEMS:

Therearevarioustypesofairconditioningsystemswecan choose from in trace. These can be classified into various types.Thesemustfirstbeaccessedfromthesystemlibrary. Thesystemlibraryhasseveraloptionstochoosefrom.

1. Variablevolumeunits

2. Constantvolumeunits

3. Heatingonlyunits

4. Doubleduct

5. Chilledbeam

Andmanymoresuchsystems.Forourconsideration,weuse the constantairvolumesystems. Thisisbecause,constant

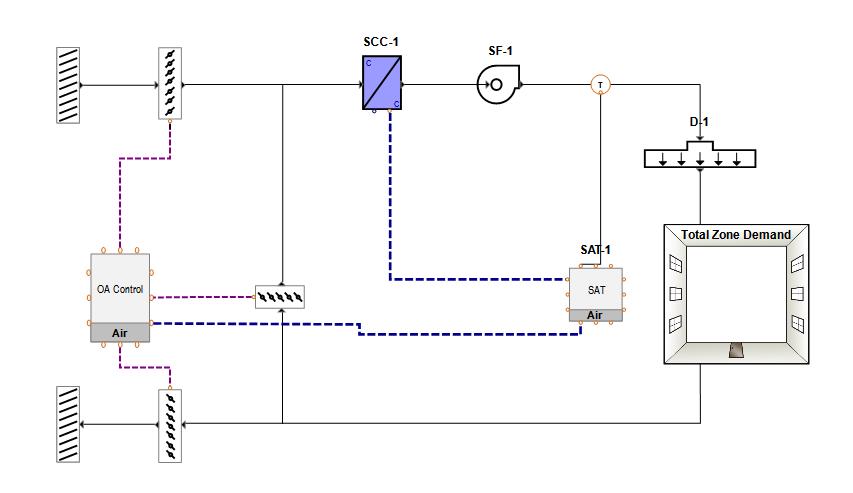

Theselectedsystemconsistsofvariouscomponentslikean Outdoor air control and dampers for outdoor and room return air. The outdoor air is required for ventilation. We thenhavethecoolingcoilbythenameSCC-1.Theairpasses throughthiscoolingcoilandthenreachestheroomthrough the supply damper named D1. SAT 1 refers to the temperaturesensorpresentintheroom.

11.2 Configuring systems:

Inordertoconfiguresystems,wegototheconfiguresystems tab. Since the project is a hotel the setpoints are taken accordingtoASHRAEstandardsforinternalcomfort.

Assigningzonestosystems:

Once a system has been designed, it needs zones to be assignedtoit.Thisisdoneeasilyintheassignzonestabofthe program. Separate systems are applied for areas with separate zones. We have the following zones made in the project.

1. Lobby

2. Basement-1

3. Basement–2

4. Firstfloor

5. Secondfloor

6. Thirdfloor

7. Fourthfloor

8. Fifthfloor

9. Sixthfloor

10. Groundfloor

11. Banquet

12. Alldaydining.

All these systems have their individual setpoints and ventilation conditions based on ASHRAE ventilation and indoor air quality comfort guidelines. The zones can be assignedtoeachsystemeasilybytheassignzonestab.

Eachandeveryzonecanbeassignedtovarioussystemby clickingonthesystemandthenonthezone.Spaceswhichare unconditionedcanalsobementionedheretoalloweasein theselection.

Thenextistheconfigurezoneequipmenttab.Thisallowsthe settingupandadjustingoftheequipmentorFancoilunitin therespectiveroomsorzones.Mostly,1.5TRfancoilunits areusedinthehotelroomsandthesamehavebeenusedin theaboveproject.

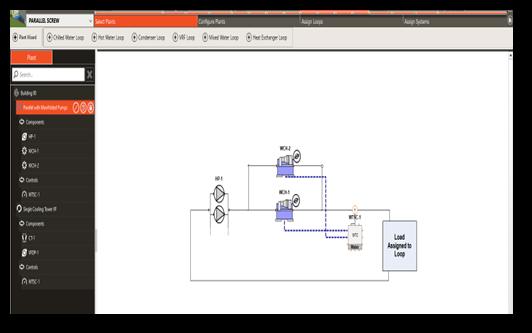

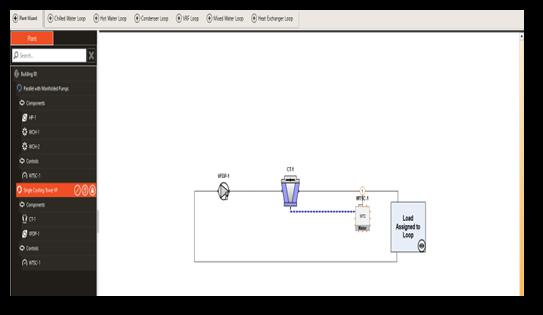

11.2 Plant Configuration:

There are prebuilt plant systems in TRACE 3D PLUS. The program gives the option of automatic plant selection, however depending on the two systems and the Indian subcontinent,weselectdifferentunitsandplants.

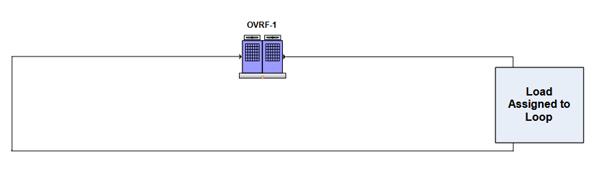

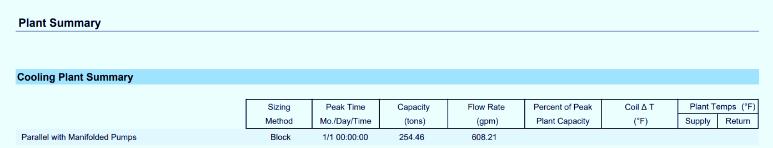

Inthechillwatersystem,therearetwoloopsselected:

1. The chiller loop including two chillers with manifoldedpumps.

2. Thecoolingtowerloop.

Here,watercooledchillersareusedastheplantislocatedin Bangalore, where the conditions allow the installation of coolingtowers.

IntheVRFsystem,onlyoneloopisconsideredastheindoor units are connected to larger outdoor VRF units.

Thegivenequipmentandloopsarethebasisoftheanalysisof the two alternatives. We now run analysis on both the systemsandgettheresultsintheprojectsummarytabsof bothalternatives.

12 Calculations and Results:

Theprojectsummarytabcontainsthetabfortheanalysis anddisplayingtheresults.Theloadreportiscalculatedon both the selected alternatives. The System Component Summaryreportisthemainloaddesignreportforpopulating specificationsandequipmentschedules.Thisreportprovides the heating/cooling rate, airflow, air conditions and water conditions of eachcoil. The system airflows are calculated based on the heating and cooling airflows required by the rooms and zones, plus any systemlevel overridesapplied. Systemrulesarethenappliedtodecidehowtheheatingand coolingairflowsshouldrelate.

The program generates therequired load design report.It consistsof:

1.TitlePage

2.RoomCoolingLoadsbyComponent

3.RoomHeatingLoadsbyComponent

4.ZoneCoolingLoadsbyComponent

5.ZoneHeatingLoadsbyComponent

6.SystemComponentSummary

7.DesignPsychometrics

8.OutsideAirandASHRAE62.1Analysis

9.PlantSummary

10.SystemCoolingChecksums

11.SystemHeatingChecksums

The program generates the reports based on the various parametersenteredandtheroomsdesigned.

13 Reports:

13.1 Project Summary:

TheprojectsummaryiscreatedbytheTRACEsoftware.The total ventilated or conditioned area is 73,344 ft^2. This is almost 49.1% of the building area. The weather location conformstoBangalore.

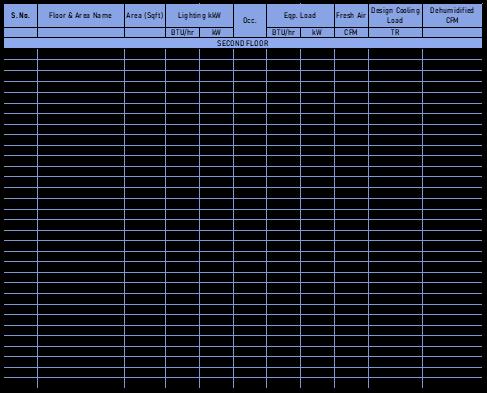

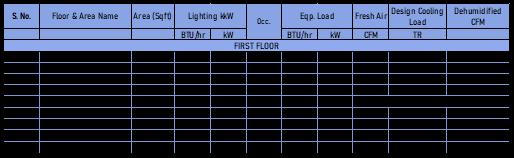

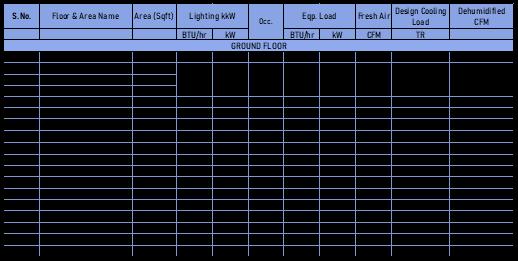

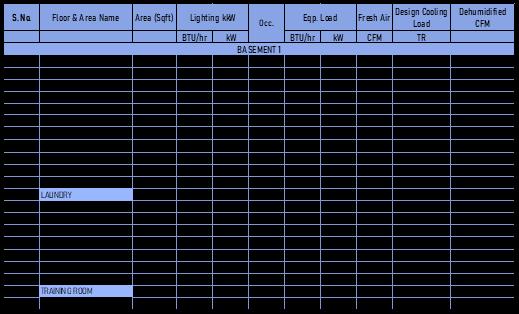

13.2 Heat Load Summary:

TABLE 2: Heat Load Summary

TOTAL TONNAGE FOR GROUND FLOOR = 110 TR

TOTAL TONNAGE FOR BASEMENT 2 = 5 TR

TOTAL TONNAGE FOR FIRST FLOOR = 5 TR TFA

TOTAL TONNAGE FOR BASEMENT 1 = 35 TR

TOTAL TONNAGE FOR SECOND FLOOR = 34.4 TR

TOTAL TONNAGE FOR THIRD FLOOR = 37 TR

13.3 Cost Breakdown:

“When selecting an HVAC system, it is important to weigh the upfront costs (CAPEX) against the long-termsavings (OPEX) to determine the most cost-effective option.[7]”

ThecostofachilledwatersystemandaVRFsystemcanvary depending on several factors, including the size of the building,thecomplexityofthesystem,andthelocation.Both typesofsystemscanbeexpensivetoinstall,butlong-term costs, such as energy consumption, can be lower for more efficientsystems.

Chillwatersystemstypicallyhaveahigherinitialcostdueto the need for a central chiller and a network of pipes. However,theycanbemorecost-effectiveinlargerbuildings wherethecostofthecentralchillercanbespreadoutovera largerarea.VRFsystems,ontheotherhand,tendtohavea lowerinitialcostastheyuseindividualoutdoorandindoor units. However, they can be more expensive to install in smallerbuildingsduetotheneedformultipleoutdoorand indoor units. In addition, VRF systems tend to have lower energycostsinthelongrun,astheyaremoreefficientand offermoreprecisetemperaturecontrol.

Overall,thecostofachillwatersystemandaVRFsystemcan varydependingonthespecificneedsofthebuildingandthe location,aswellasthecostofinstallationandmaintenance. It'srecommendedtoconsultwithanHVACprofessionalto determine which system would be the best fit for your buildingandbudget.

13.4 Operational Cost:

TOTAL TONNAGE FOR FOURTH FLOOR = 40 TR

Thetotalpeakloadforthehotelis 266.4 TR. However,since thecoolingrequiredbydifferentzonesofthebuildingvaries throughouttheday,itisnotadvisabletoselectthechillersat peakloadcapacity.

Wehavecarriedoutadetailedsimulationfor8760hoursto provide the block cooling load for the entire hotel, which comesouttobe 254 TR approx.

Intermsofenergyefficiency,VRFsystemstendtobemore efficientthanchillwatersystemsinsmallerbuildingsbecause they can adjust the amount of refrigerant flowing to each indoorunitbasedonthecooling/heatingneedsofthatarea. Chill watersystems onthe other handare more suitedfor largerbuildingsandcanbemorecosteffectiveforthesame. Todeterminewhichsystemisbettersuitedforourneeds,we need to deeply analyze the reports and data which weget from the program. The program analyzes the heating load generatedbythebuildingduringvariousmonthsoftheyear. Basedontheorientationofthesun,theheatingloadchanges throughout the year. However, the system must be sized

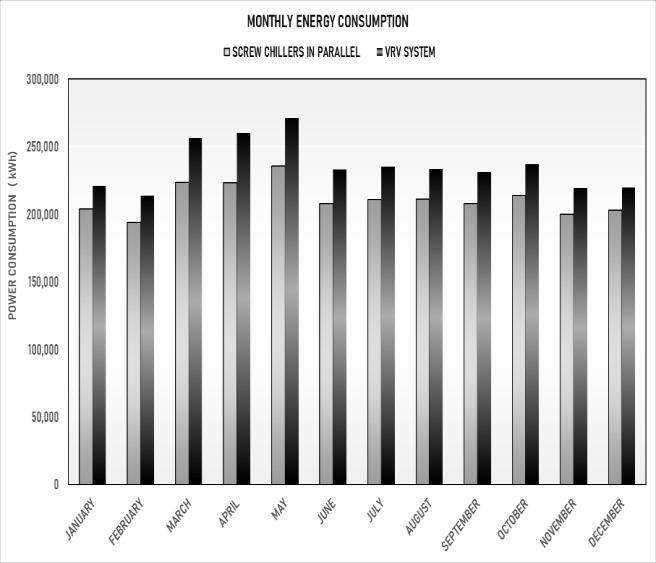

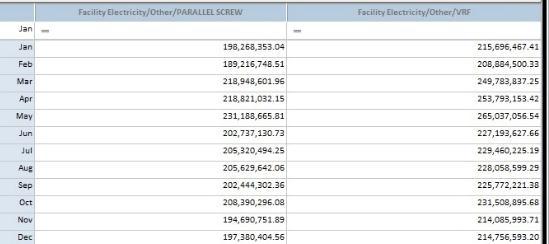

basedonthepeakload,asthesystemmustbeabletohandle peak capacity generated by the building. The electricity consumptionpermonthisgivenbelowasgeneratedbythe software.

TABLE

Here,weseethattheelectricityconsumptionisconsistently lessinthecaseofchillwatersystem,ascomparedtotheVRF system.Thesummationforthewholeyeariscalculated.This difference in kWh is summarized below. The per unit commercialelectricitycostforBangaloreis₹10/unit.

muchlesserthantheoperatingcostoftheVRFsystem.The costofcommercialelectricityconsumptionforthewholeyear is₹2,53,28,533and₹2,83,14,681inthecaseofchillwater and VRF systems.The difference in costis ₹29,86,148 per year,asignificantnumberwhenconsideredduringalifespan of30–60years.Moreover,asthecostsofelectricitycontinue torise,thisgapwillfurtherwiden.

13.5 Capital/Installation Cost:

Acompletecomparisonisonlypossibleonceallthevarious aspectsofinstallingthesystemsareanalyzedseparately.This alsoincludesthecostofpurchasingandinstallingthevarious systems. Only then can the various costs be compared accurately.

The initial cost for installing the various systems can be providedbythemanufacturersof variousequipmentonce theheatloadhasbeencalculated.Theheatloadis255TRin the case of our hotel complex. Hence, we size the various systemsaccordingtothetonnagerequired.

Different manufacturers and suppliers provide equipment such as chillers and VRF units. Prices for certain common itemsarecomparableacrossallcompanies,andtheselection ofappropriatepricingisbasedonquotationsfrommultiple suppliers.Wehavecompiledasummaryofthecostsinvolved inthesystems.

Theresultsoftheanalysisaresummarizedinthetablegiven above.TheannualoperatingcostoftheChillwatersystemis

The initial and installation cost can be summarized in the above table. We see that the chilled water system costs ₹4,12,00,000andtheVRFsystemcosts₹3,33,50,000.This differenceincostisapproximately₹7,850,000.Thisisquitea significant amount and must be taken into consideration whilecomparingbothsystems.Tomakeafaircomparison between the two systems, we need to consider both the upfront cost and the ongoing cost over the length of the evaluationperiod.

*Thecostsgivenhereareaveragesofcostsandquotations fromvariouschillerandVRFmanufacturersandsuppliers, obtainedaftersendingourcustomrequirements.Thesecosts cannotbeusedasreferencetoobtainquotationsfromany manufacturersorsuppliers.

13.6

Tosummarize,chilledwatersystemsandVRFsystemsare both types of HVAC (heating, ventilation, and air conditioning) systems used for temperature control in buildings. The chilled water system operates by a central chillerthatcoolswateranddistributesitviapipestodifferent air handling units for cooling the air in the building. In contrast, the VRF system consists of independent outdoor and indoor units connected by refrigerant lines, providing greatertemperaturecontrolflexibilityinspecificareasofthe building.

Buildingshavealimitedlifespan,with5-starhotelstypically lastingbetween25and50years.5-starhotelshavealifespan of25-50years.Whenchoosingbetweenoptions,long-term costsmustbeconsidered,notjustinitialcost.Bothoptions wereevaluatedover20years,thetypicallifespanofaVRF system.Resultsaretabulatedbelow.

thantheVRFsystemfortheoperationaltime.Thissignificant costsavingsisamajorfactorthatallowsustosaythatthe chilled water system is a better alternative for the hotel project.

Inadditiontothecostsavings,thechilledwatersystemalso offersotherbenefits.Forexample,itistypicallysimplerand easiertoinstall,itrequireslessmaintenanceandit'smore energyefficient.Thesebenefitscanleadtoevenmorecost savingsovertime.Thisisanimportantconsiderationwhen looking to reduce the impact of the hotel complex on the environment.Inconclusion,thechilledwatersystemoffersa combination of cost savings, ease of installation, lower maintenancerequirementsandbetterenergyefficiency.Due tothesebenefits,thechilledwatersystemhasbeenselected asthepreferredoptionforthehotelproject.

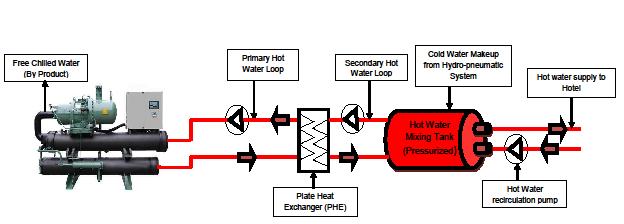

13.7 Further Savings:

BasedonabovecomparisonitcanbeconcludedthatWater cooledScrewChillersinparallelisthebetteroptionforour hotelcomplex.Tofurtherreduceelectricityconsumption,we canalsopairitwithheatexchangerandusetheadditional heattogeneratesimultaneous hotwater fordomestic use. Thiswillallowustousetheheatgivenoffbythechillwater system and utilize it for thebuilding. This configuration is alsousedinsomehotels,butitisnotfeasibleduringwinter months,whenthechillwatersystemisswitchedoff.

Thecostofachilledwatersystemissignificantlylesswhen comparedtotheVRFalternativewhenanalyzedovera20yearlifecycle.Thisdifferenceincostissubstantial,withthe chilledwatersystemcostingapproximately₹5,18,72,960less

13.8 CONCLUSION:

Energymodellingandanalysishasallowedustoanalyzein detailthetwomostusedalternativesinordertochoosethe most appropriate system for our hotel. Deciding upon the HVAC system is a big part of project planning as the MEP rooms, chillers and cooling towers take up a lot of the valuablespaceofthehotel.Thismaycauseproblemsifthey aredecidedafterthehotelstructureismade.Furthermore, thespaceforductingandchillwaterpipingisquitedifferent thanthespacerequirementfortherefrigerantpipinginVRF systems, causing structural changes to be made in the building.Hence,decidingontheHVACsystembeforehandis essential.

Sinceourhotelisalarge-scaleproject,theTRACE3DPLUS data shows thata chill water system is best suited for our needs.Furthermore,basedonthefindingsofthisproject,we conclude that energy modelling is a critical step in determiningthemostefficientandcost-effectivesystemsfor buildings.Byconductingenergymodelling,buildingowners and operators can gain a deeper understanding of their energy usage and identify opportunities for improvement. This approach can help to reduce energy consumption, decrease operational costs, and improve the overall sustainabilityofthebuilding.Therefore,werecommendthat allbuildingprojectsshouldconsiderenergymodellingasa standardpracticetoensurethattheyareimplementingthe mostefficientsystemsfortheirspecificneeds.

14 Inference:

LCCorLifeCycleCostingisamethodologyusedtoevaluate thetotalcostofaproductorassetoveritsentirelifespan.The goalofLCCistoassessthecostsassociatedwithdesigning, manufacturing, operating, maintaining, and disposing of a productorasset,inordertomakeinformeddecisionsabout itsacquisitionordevelopment.LCCtakesintoaccountallof thecostsassociatedwithaproductorassetoveritslifecycle, includingbothdirectandindirectcosts.Directcostsinclude theinitialpurchaseprice,installation,andmaintenancecosts, while indirect costs may include costs associated with downtime,energyconsumption,andenvironmentalimpact. We have done the life cycle cost analysis which has successfully allowed us to determine the most optimum optionforthehotel.

Thispaperalsoteachestheimportanceofenergymodelling toensurebuildingefficiency.“Buildingenergymodelingisan essential step in designing and operating energy-efficient buildings. Without energy modeling, building systems and componentsmaybesizedincorrectly,leadingtoinefficiencies andhigherenergyuse.”[8]

Thereareseveral differenttypesofBEM,includingwholebuildingenergysimulation,envelopeandsystemssimulation, and daylighting and lighting simulation. Envelope and systems simulation focuses on specific components of a building,suchasthewalls,roof,andwindows,andisusedto optimizetheirthermalperformance.

Becauseeverybuildingandprojectisunique,itiscrucialto conductenergymodelingforeachindividualproject,rather than trying to apply a one-size-fits-all solution. Through energy modeling, we can evaluate various options and determinewhichsystemswillbemosteffectiveforaspecific project.Themodelingwillprovideadetailedreportthatcan beusedtoinformthedesignandconstructionofthebuilding.

It allows for the simulation of a building's energy performance before it is built, enabling the comparison of

differentdesignoptionsandtheselectionofthemostcosteffective and energy-efficient solution. Through energy modeling, we can identify opportunities to reduce energy consumptionandcosts,aswellasdemonstratecompliance with energy codes and regulations. Additionally, energy modeling can help to reduce a building's environmental impactandimprovetheindoorenvironment.Furthermore, energy modeling can also be used to monitor a building's energy performance after it is constructed and identify opportunitiesforfurtherenergysavingsandimprovements. Overall, energy modeling plays a crucial role in the design and operation of sustainable, comfortable, and energyefficientbuildings.

Theamountofenergythatcanbesavedinbuildingsthrough energymodelingcanvarydependingonthespecificbuilding anddesignoptionsthatareevaluated.However,studieshave shownthatenergymodelingcanleadtosignificantenergy savings in buildings. For example, a study by the National RenewableEnergyLaboratoryfoundthatenergymodeling canleadtoenergysavingsof20-30%ormoreincommercial buildings.[9] Another study by the American Institute of Architects found that energy modeling can lead to energy savings of 15-25%or morein residential buildings.[10]In addition,theUSDepartmentofEnergyreportsthatenergy modelingcanleadtoenergysavingsofupto40%ormorein somecases.

Indiangovernmentmustalsostartintroducingregulationto ensureallbuildingsarecompliantwiththelateststandards, andthatenergymodellingisdonetoensurethemostefficient andeconomicalsystemsareinstalledtoreduceourimpacton theenvironment.

15 References:

[1] United Nations. "The Paris Agreement on Climate Change,"UnitedNations,Rome,Italy,2015.

[2]Anderson,J.E.;Wulfhorst,G.;Lang,W."Energyanalysisof the built environment A review and outlook," Renew. Sustain.EnergyRev.,vol.44,pp.149-158,2015.

[3] Pérez-Lombard, L.; Ortiz, J.; Pout, C. "A review on buildings energy consumption information," Energy and Buildings,vol.40,no.3,pp.394-398,2008.

[4] Zuo, W.; Zhao, R. "Building energy performance assessment forsustainabledevelopment inChina,"Energy and Buildings, vol. 68, pp. 518-526, 2014. (Case study on buildingenergyperformanceassessment)

[5] EIA. "Energy use in commercial buildings," U.S. Energy Information Administration, 2019. [Online]. Available: https://www.eia.gov/energyexplained/energy-use-incommercial-buildings/.

[6]Cheung,T.;Zhang,J.;Hong,T."Tenquestionsconcerning occupantbehaviorinbuildings:Thebigpicture,"Buildingand Environment, vol. 128, pp. 284-295, 2018. (Impact of occupantbehavioronbuildingenergyperformance)

[7] National Institute of Building Sciences."Life Cycle Cost Analysis for HVAC Systems," National Institute of Building Sciences. [Online]. Available: https://www.nibs.org/lifecycle-cost-analysis-for-hvac-systems/.

[8]Garg,V.;Sharma,A.;Nagpal,G."Buildingenergymodeling for energy conservation in buildings: A review," Energy Reports, vol. 6, pp. 947-957, 2020. doi: 10.1016/j.egyr.2020.02.004

[9]NationalRenewableEnergyLaboratory(NREL)."Energy modeling for energy efficiency in commercial buildings," National Renewable Energy Laboratory (NREL), 2012. [Online]. Available: https://www.nrel.gov/docs/fy12osti/54183.pdf.

[10] American Institute of Architects (AIA). "The role of energy modeling in architectural practice," American Institute of Architects (AIA), 2017. [Online]. Available: https://www.aia.org/resources/93606-the-role-of-energymodeling-in-architectural.