STUDY ON TRIBOLOGICAL POPERTIES OF AZ91D MAGNESIUM COMPOSITE REINFORCED WITH B4C AND ZrO2

Rangubhotla Teja*, Dr. Prasanna Prattipati**, Singaiah Gali****(M.Tech, Department of Mechanical Engineering, JNTUH University College of Engineering Hyderabad, India, **(Assistant Professor, Department of Mechanical Engineering, JNTUH. Hyderabad, India, ***(Research Scholar, Department of Mechanical Engineering, JNTUH. Hyderabad, India. ***

Abstract:

Inpresentstudy,thetribologicalbehaviorofAZ91DMagnesiumalloymatrixreinforcedwith3wt.%ofB4Cand2wt.%ofZrO2 wasinvestigated.ThecompositeswereproducedbytheBottomPouringStirCastingProcess.Thetribologicalpropertieswere studiedusingPinonDiscapparatusasperASTMG99standards.Percentageofreinforcement,slidingvelocityandappliedload have been taken as the factors/variables for evaluating wear rate and friction coefficient. The test conditions taken for conductingthetestfortribological responsesisdesignedusingdesignofexperiment. Theweartestwascarriedoutusingan experiment design based on the Taguchi method. The influence of each individual element on the performance of composite wear was evaluated using the variance analysis (ANOVA). The weight percentage of reinforcements, load, and speed were foundtosignificantlyaffectthewearcharacteristics.Amathematicalmodelforwearandcoefficientoffrictionwasdeveloped usingtheresponsesurfacemethodology,anditwasconfirmedbyconductinganexperimentattheideallevel.

Keyword: AZ91D/B4C/ZrO2, Pin On Disc Apparatus, ANOVA, Taguchi method, Response Surface Methodology

I. INTRODUCTION

Low-density composites based on magnesium have attracted attention on the automotive and aerospace industries' for theongoing research onlighter materials. Magnesium has many benefits, including low density, increased specific strength, effective dampening, and superior dimensional stability. Magnesium's usage in piston-cylinderlinersandotherreal-timeapplicationshas been constrained, however, by its poor wear resistance, inherent brittleness, and poor temperature stability. In order to boost the wear resistance of the magnesium matrix, reinforcing particles, especially those of nanoscales, are sought. Due to the fact that a material's wear resistance is determined by its capacity for plastic deformation, nanoparticles can get stronger and harder, increasingwearresistance.Zirconiareinforcedcomposites offer significantly improved refractoriness, chemical resistance, and abrasion resistance when compared to composites with conventional reinforcements. In the majority of magnesium composites, plastic deformation is notpossible.Nano-scalereinforcementscanbeusedtoget around this restriction. And by the addition of Boron Carbide, hardness and melting point of the composite will be increased. Hamid Raza studied that, by the addition of B4C the hardness value of Al20%Mg2Si was increased [1].

With respect to Zirconia, Ke Qiao et al observed that, on the addition of Zirconia, the brittleness of the composite was increased and the elongation was decreased [2]. It is observed that, by the addition of ZrO2, the hardness and strengthofthematerial wereincreased[3-4]. RaviKumar studied that, on the addition of Tungsten Carbide as a reinforcement, the density of the AZ91D alloy was increased and elongation was decreased [5]. Nishita Anandan observed that, on the addition of small sized reinforcement to the AZ91D alloy, the particulate fracture and voids due to particulate debonding was not observed extensively [6]. Fareeha Ubaid et al fabricated the alloy of Aluminium and B4C using Microwave sintering method and followed by hot extrusion. She observed that, on the addition of B4C nanoparticles the yield strength and the ultimate strength were increased but the ductility behavior was opposite to the ductility of the pure Aluminium[7].J.UdayaPrakashetal.(2018)usedtaguchibasedgreyrelationanalysisapproachtooptimisethewear parameters of 413 Aluminium Alloy reinforced with 3%, 6%, and 9% B4C. For the creation of composite, the stir casting method was used. Using pin-on-disc testing equipment, a dry sliding wear test was conducted. The most crucial elements in determining the friction

coefficient and wear rate were the sliding distance and speed.Inthiswork,theTaguchiL27orthogonalarraywas employed.ToanalysetheGreyRelationGrade,ANOVAwas utilised. The size of the matrix grain decreased as the weight % of reinforcement increased. The material's hardness was raised by the addition of carbides [8]. Sandeep Singh Kharb studied that the COF reduced over time, and it was discovered that base fluid containing nanoparticles significantly altered the antifrictional characteristic. The coefficient of friction (COF) value was lowest in 2wt% SiC/soluble oil nanofluids and greatest in dry sliding conditions (0.33). The wear of the AZ91D-5SiC compositepinwith2weightpercentSiC/solubleoilNanofluids Lubrication was reduced by 70.75% and 59.21% compared with dry condition and oil condition, respectively, at load of 40N and sliding for 180s [9]. The conditions for clustering of nanoparticles make it difficult to fabricate nanocomposite. Despite the fact that powder metallurgy is more popular, porosity is the main problem with the finished product. Spray casting and in-situ salt routemethodsarealsofrequentlyemployed.Stircastingis becoming more and more standardised because of its adaptability, simplicity, and tremendous production capacity.Thisentailsmeltingtheactual metal ina furnace and combining it with the heated reinforcements. After that, the liquid slurry is poured into the desired shape. The wear qualities of AZ91Dalloy are insufficient, despite itsimprovedsuperiorcastability,andstiffness.Toincrease wear resistance, this alloy includes nanoparticles of zirconia and boron carbide. Few publications have been made on enhancing the wear properties of hybrid magnesiumnanocompositemadebystircasting,according toathoroughexaminationoftheliterature.Therefore,itis importanttooptimisethewearpropertiesofMg-ZrO2-B4C producedbystircasting.

II. EXPERIMENTAL DETAILS

A. Workpiecematerial

ThebasemetalusedinthisstudyisanAZ91Dmagnesium alloy, while the reinforcement elements used are nanosized zirconia (ZrO2) and boron carbide (B4C). The size of a nanoparticle is typically 100mm on average. The AZ91D magnesium alloy's composition is displayed in Table1.

Theprocedureofbottompourstircastingisusedtocreate thecomposite.TheAZ91Dmaterialisplacedinthefurnace and heated to a temperature of 750°C in a steel crucible. The reinforcement materials are currently being weighed beforebeingaddedtothesmallfurnacethatisattachedto the main furnace. The reinforcement material will be preheated for at least an hour at a temperature of 350 °C before being added to the molten AZ91D alloy in the furnace. The composite mixture will then continue to be stirred while the furnace is heated continuously to a temperatureof750oCtoensurethatthereinforcementand base alloy are well blended. The liquid will then be added toapermanentmould.ThreeweightpercentagesofB4C 0%, 3%, and 5% along with 2% of ZrO2 are used in this approach. The casting furnace is depicted in Figure 1. Table2providesinformationonthevariousreinforcement combinationsused.

B. DesignofExperiments

The design of experiments aims to produce the most conclusive knowledge from the least quantity of data. The statistical strategy prepares the details of the experiment in order for adequate data to be gathered, assessed, and a valid conclusion to be drawn. This technique assists in identifying the fewest parameter combinations and levels necessary to ascertain the primary and interaction effects of selected parameters on the outcome. There are numerous DOEs, including Taguchi, Grey Relational Analysis, Response Surface Approach, and others. Depending on the situation, researchers will choose an acceptable experiment design. In this work, the Taguchi method of experiment design was used. In this scenario, threeinputfactorsweretakenintoaccountatthreelevels. TheyaresummarisedinTable3. Table3

InputParametersandtheirlevels

the composite. The disc's wear was disregarded. A dead weightwasplacedonthepantoapplythedesiredload to thesample.

C. ExperimentalSetup

A Pin-on-Disk type triboteter was used to conduct a dry slidingweartestoftheproducedMg-B4C-ZrO2 composites at room temperature. (JNTU UCESTH ,Hyderabad). The Pin-on-Disk tribotester is shown in working order in Figure 2. On samples measuring 12 mm in diameter and 120 mm in length, a wear test was performed. To guarantee that the experiments were carried out in a dry atmosphere, the samples were painstakingly cleaned. A steel disc serves as the test's counter surface because the disc's substance has a far higher degree of hardness than

III. RESULTS AND DISCUSSIONS

ThetestswerecarriedoutinaccordancewiththeTaguchi technique's specified Design of tests. Each experiment's time frame was wear track radius was also maintained at 0.070metresandkeptconstantat15minutes.Theaverage linear wear was 0.51, 0.33, and 0.28 microns for B4C concentrationsof0%,3%,and5%,respectively.Whilethe average COF for B4C concentrations of 0%, 3%, and 5% was 0.532, 0.47, and 0.389. When compared to AZ91D magnesium alloy, the average linear wear improved by 46.95%,andthecoefficientoffrictionincreasedby26.9%.

OBSERVATION(L9ORTHOGONALARRAY)

D. AnalysisofVariance

ANOVA is used to statistically analyse the results of the experiment and create a useful regression model. In this experiment, ANOVA was performed using MINITAB 19. Table5presentsthefindingsoftheANOVAanalysis.

TABLE5

ANALYSISOFVARIANCE

E. Development of Mathematical Models Using ResponseSurfaceMethod

RSM examines the system objectively by using statistical and regression techniques. It then analyses and optimises the quantitative data acquired from a limited number of tests. Utilising statistics, this approach looks at how input and output elements relate to one another. This experimental method is frequently used to statistically analyse data across several academic disciplines. The response surface approach was developed largely to increase output accuracy around a target value and provide robust designs that are resistant to component fluctuation. When building a regression model, either a first order model or a second order model is taken into account. In cases when a small area is selected, the first orderpolynomialisemployed.Twoindependentvariables areincludedwhenanacordermodelisproduced.

Y = β0 +∑

According to the analysis of variance, reinforcement and load have a greater impact on wear and coefficient of friction,respectively.Errorwasverylow.

TABLE6 MODELSUMMARY

It is to be noted that the predicted R2 of 0.6890 is in reasonable agreement with the adjusted R2 of 0.8472 i.e., thedifferenceislessthan0.2

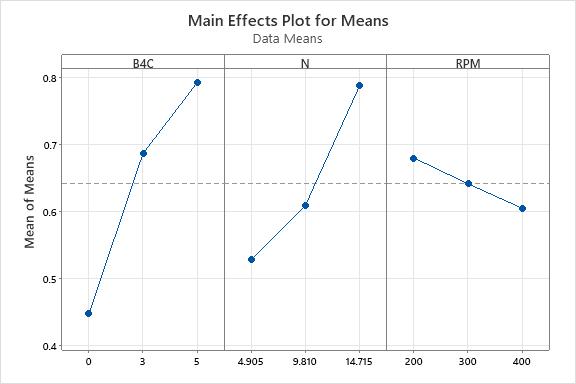

The highest values produce the best results in the main effect plot for means. As a result, the ideal level is reinforcement at 5 weight percent, load at 14.715 N, and speedat200RPM.

wear rate = +0.030072-0.003039*B4C-3.39789E06*Load+1.00000E-05*Speed

COF = +0.955220-0.028019*B4C-0.039755 *Load0.000090*Speed

Accordingtotheoptimallevelofparameters,confirmation experiment was conducted at 5% of B4C, 14.715 N Load, and 200 RPM Speed. The Coefficient of friction was found to be 0.2228, and Wear rate was found to be 0.01805 microns/min.Thepredictedvalueforcoefficientoffriction was 0.2125 while the Wear rate was 0.017245 microns/minrespectively,whichwerecalculatedfromthe corresponding mathematical models developed using ResponseSurfaceMethodologyinDesignExpertSoftware.

An error of 4.28% was observed for COF while 3.08% error was observed for wear rate for experimental

responses compared to the predicted parameters. This error might have been attributed due to the wobbling of disk, vibrations in the equipment, aging of the linear and frictionalforcesensors

IV. CONCLUSIONS

The hybrid metal matrix composite of AZ91D/B4C/ZrO2 wasproducedviastircasting.Forthreetestspecimens,the proportion of ZrO2 was changed while the percentage of B4Cremainedconstant.Theresultsoftheexperimentwere used to derive the following conclusions. The ideal set of wear test settings is reinforcement at 5 weight percent, load at 14.715 N, and speed at 200 RPM. When compared to AZ91D magnesium alloy, The wear rate decreased by 74.85% for sample with 2% ZrO2 + 5% B4C [0.0187 microns/min] reinforced composite compared to that of base alloy [0.0327 microns/min] and The Coefficient of friction has slightly reduced (i.e. 6.14%) with increase in Speed

The composite with 5% B4C and 2% ZrO2 reinforcements showed superior wear resistance. The constructed mathematicalmodelswereoptimallytested,andtheylittle deviatedfromtheexperimentalfindings.

ACKNOWLEDGMENT

Without the help of my department, it would not have been feasible to complete the research for this work. We alsooweadebtofgratitudetoalltribologyscholarswhose research abstracts inspired us and helped us to finish our project.

REFERENCES

[1].GhandvarH,JabbarMA,KoloorSS,PetrůM,BahadorA, BakarTA,KondohK.Roleb4c additiononmicrostructure, mechanical, and wear characteristics of al-20% mg2si hybrid metal matrix composite. Applied Sciences. 2021 Mar29;11(7):3047.

[2] Qiao K, Zhang T, Wang K, Yuan S, Zhang S, Wang L, Wang Z, Peng P, Cai J, Liu C, Wang W. Mg/ZrO2 metal matrix nanocomposites fabricated by friction stir processing: microstructure, mechanical properties, and corrosion behavior. Frontiers in Bioengineering and Biotechnology.2021Mar25;9:605171.

[3]RaviKiranR,GhanarajaS.FABRICATIONOFSTUDYOF MECHANICAL PROPERTIES OF ALUMINIUM ALLOY 6061 REINFORCEDWITHNANOZIRCONIA.

[4] Rahmani K, Majzoobi GH, Sadooghi A, Kashfi M. Mechanical and physical characterization of Mg-TiO2 and Mg-ZrO2 nanocomposites produced by hot-pressing. MaterialsChemistryandPhysics.2020May1;246:122844.

[5] Kumar KR. Characterization, mechanical and wear behaviour of magnesium (AZ91D)/graphite/tungsten carbide hybrid composites fabricated by powder metallurgy. Transactions of the Indian Institute of Metals. 2020Oct;73:2539-48.

[6] Anandan N, Ramulu M. Study of machining induced surface defects and its effect on fatigue performance of AZ91/15% SiCp metal matrix composite. Journal of MagnesiumandAlloys.2020Jun1;8(2):387-95.

[7] Ubaid F, Reddy Matli P, Shakoor RA, Parande G, Manakari V, Amer Mohamed AM, Gupta M. Using B4C nanoparticles to enhance thermal and mechanical responseofaluminum.Materials.2017Jun6;10(6):621.

[8]PrakashJU,AnanthS,SivakumarG,MoorthyTV.Multiobjective optimization of wear parameters for aluminium matrix composites (413/B4C) using grey relational analysis. Materials Today: Proceedings. 2018 Jan 1;5(2):7207-16.

[9]KharbSS,KhatkarSK,CharakA,ThakurA.Tribological investigation of AZ91/SiC magnesium hybrid composite under dry, oil and nanofluids lubricating conditions. Silicon.2021May;13:1313-23.