Analysis of Microstructural Behaviour of Rice Husk Ash Blended Cement Mortar

Sonu Sharma1 , Vaibhav Dubey2

1M. Tech Scholar, Construction Technology and Management, Faculty of Engineering & Technology, Rama University Uttar Pradesh, Kanpur, India.

2Assistant Professor, Faculty of Engineering & Technology, Rama University Uttar Pradesh, Kanpur, India. ***

Abstract- The stated work investigates the microstructural properties of Rice Husk Ash and the viability of replacing cement with it. Cement was replaced by Rice Husk Ash (0–25 percent at 5% intervals) to investigate its impact on cement mortar's mechanical and physical characteristics, including the evaluation of the microstructure. Samples used were tested after 3, 7, and 28 days of curing. It was noted that when a sample has a consistent water content, it produces a dry mix when more than 10% of the cement was replaced by RHA. owing to dry mix the mortars attempt to hydrate itself was unsuccessful, and the strength starts declining as the Rice Husk Ash percentage rises.

It was also noticed that consistency of cement was continuously increasing with increase in percentage of Rice Husk Ash when samples were prepared for checking consistency of cement at varied quantities of Rice Husk Ash. The compressive strength was seen to increase up to a 15% Rice Husk Ash, and results above this percentage were also superior to those of the similar samples with constant consistency.

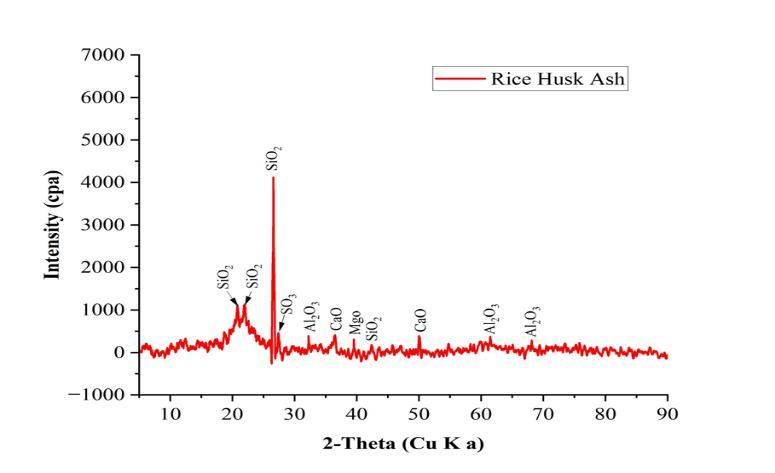

Peaks in the Rice Husk Ash 's XRD pattern revealed quartzite and coesite minerals, both of which have crystalline natures that signify silica concentration. The weight loss percentage of Rice Husk Ash was evaluated using thermal gravimetric analysis (TGA), and the phase transition was examined using differential scanning calorimetry (DSC) between 600 and 1000 C. As the Rice Husk Ash mixed cement mortar cured up to 3,7 and 28 days, the microstructures were also examined usingSEM and EDS analysis.

Keywords: XRD-X ray diffraction, TGA-Thermal Gravimetricanalysis,DSC-Differentialscanningcalorimetry.

1. INTRODUCTION

Any nation's economic development depends heavily on cement, and India's cement sector is the world's second-largest producer of cement after China. India uses 195 kg of cement per person annually. Currently, India's

installed cement capacity is 500 million tons per annum, producing 298 million tons of cement annually. India's cement production is anticipated to reach 500 million tons by 2021 and 800 million tons by 2030 due to the country's expandinginfrastructure.

Ash from the rice husk industry is a waste by-product. When utilized as fuel in boilers, rice husk produces Rice HuskAshasaby-product.InIndia,itiswidelyavailable.Rice Husk Ash has been discovered to have a significant level of reactivity toward cement and lime. In the study, it was discovered that Rice Husk Ash maintained if not improved the mechanical and durability qualities of concrete and mortarmadeofblendedcement.Asaresult,itcanbeutilized as a substitute material in concrete and mortar as partial cementreplacementforthesustainabledevelopment.

The use of Rice Husk Ash as an additional cementitious material or non-reactive filler might lessen the adverse effects on the environment (such as air pollution and soil pollution). Due to CO2 emissions, cement production severely harms the environment. Pozzolanic materials can be used in place of cement to lessen the environmental impact. Because pozzolanic material lacks cementing properties and reacts in the presence of free lime and moisture to generate C-S-H gel, a complete substitution of cement by Rice Husk Ash is not feasible. Using RICE HUSK ASH as a mineral additive, 10 to 15 percent of the cement might be replaced. The solid mixture's packing state has a major impact on the physical qualities, Surface area, morphology, particle size, and specific gravity are the main variableslinkedtothephysicalfeatureofRiceHuskAsh.The amount of amorphous silica, which combines with free lime [Ca(OH)2]inthepresenceofwaterduring hydration,hasan impactonthechemicalcharacter.

The observation of the calcium silicates hydrate phase is of primary concern. The calcium silicate hydrate mineral structure changes weak crystal from fibres to a net-like structure. According to previous research on the use of fly ash in cement mortar, the mechanical strength increased

when cement was replaced by fly ash up to 20% and declined once this limit of cement-fly ash mortar was reached (after curing for up to 28 days). Additionally, they had examined the XRD patterns of several fly ashcement mixtures that had been cured for up to 28 days, and they had determined the phases of Ca(OH)2, CaCO3, Ca2Al(OH)2xH2O,Ca2SiO4,ettringite,andSiO2.

The need of partial replacement of cement aroused duetovariousfactorslike

• Withincreaseintherateofconstructionandpricing Thehighcostofcementusedasbinderhasledtoasearch foralternative.

• Inordertoreducethedepletionofnaturallimestone depositsusedupformanufacturingcement.

• To lower the energy demand and emission of CO2 responsibleforglobalwarmingrelatedtocementusage.

• In order to ensure a safe and effective solution to deal with industrial and agro waste byproducts such as flyash,ricehuskash,sugarcanebagasse.

It was found that some of these waste products contain amorphous silica and hence act as pozzolanic materials which enhance properties of concrete and mortar.Flyashhasbeenusedasapozzolanicmaterialin mostresearchprojects,accordingtotheliterature.There waslittleactivityinusingRiceHuskAshforconstruction. Microstructural characterization of Rice Husk Ash has received little attention, and the cause of strength increases,anddecreasesarenotwellunderstood.

As a result, an effort has been made to research on microstructural characterization of Rice Husk Ash, and Rice Husk Ash-blended cement mortar. The analysis is crucial in understanding Rice Husk Ash's characteristics as well as how this waste might be applied to constructionprojectsforsustainabledevelopment.

2. MATERIALS AND METHODOLOGY

2.1 Materials used and their properties

Cement acts as the binding material in concrete used in construction, the basic property of cement is that it first setsandthenultimatelyhardensandadherestotheother materialsbindingallofthemtogether.Thecementfroma single batch used throughout for this study is Ordinary Portland Cement 43 Grade selling under the name CONCRECEM, The Manufacture of the cement is Birla

Waterimpartsworkability whenthe mortar isinpaste form and then it is required for the process of hydration whichultimatelyleadstostrengthdevelopment.Tocreatea robust and usable cement mortar, water is mixed to cement and sand. The hydration reaction of cement cannot occur withoutwater.Additionally,watermustbeaddedtocreatea paste that may be used on both overhead and vertical surfaces. The excessive workability brought on by too much waterwillresultinthemortardrippingoffinadditiontothe mortarlosingstrength.Thebestwaytodeterminethewater to cement ratio primarily depends on conditions existing at site.

Sand is used as a filler material in the mortar and comprises maximum percentage of volume of mortar, Sand isnottypicallyaddedtomortartobooststrength.Instead,it is primarily utilized as an inert substance to enhance the amountofmortarforeconomicreasons.Sandcanbeusedin the proper quantity to create inexpensive mortar without compromising mortar strength. The fundamental idea behindusingallcementingingredientsisthatsandsplitsthe paste of the cementing components into a thin film. Sand provides the necessary amount of surface area for the cementingmaterialfilmtoadhereandspread,alsoitaidsin keepingmortarfromshrinking.Additionally,itstopsmortar from breaking when setting. The density of mortar is increased by using well- graded sand. Additionally, it is assertedthatachemicalreactionoccurstocreateahardened massbetween thecomponentsofthecementingingredients andthesilica(SiO2)foundinsandgrains.

In the investigation for preparing cement mortar sand usedwasstandardriversandhavingspecificgravity2.7and moisturecontent1.4%,respectively.Ricehuskashisanagro basedwasteby-productwhichiscollectedfromboilerfeeds and is available abundantly in India, it constitutes of high amount of silica and behaves as pozzolanic material hence canbeusedasamaterialforpartiallyreplacingcementas supplementary cementitious material or non-reactive filler in mortar to decrease the cost of production as well as maintainorincreasethemechanicalordurabilityproperties ofmortaruptosomeextent.

Thericehuskashusedinthisinvestigationwasbought from Baba Traders, a Rice Husk Ash manufacturer and supplier situated in Kolkata, West Bengal. The manufacturers quoted that the supplied rice husk ash was generated by burning rice husk at a controlled temperature

from 700°C to 900°C and sieved through a 90-micron sieve to remove coarser unburnt remains of carbon particle.

The specific gravity of rice husk ash was determined using Le-Chatelier flask as apparatus and kerosene oil as medium having density 0.71gm/cc according to IS 1727:2004andthespecificgravitywasfoundtobe2.1.

2.2 Microstructural testing methods.

In this thesis microstructural characteristics of Rice Husk Ash and accordingly the feasibility of partial replacementofcementwithRiceHuskAshinmortarhas been investigated, also effect of this replacement on mechanicalandphysicalpropertiesofcementmortarhas also been studied. Various types of testing and analysis have been performed on cement, rice husk ash, grinded mortar to know microstructural behavior and elemental compositionlike-

1) Thermal Gravimetric Analysis to observe weight change variation with temperature of rice husk and ordinaryPortlandcement.

2) Differential Scanning Calorimetry to observe the chemicalchangewithtemperatureofRiceHuskAsh andOrdinaryPortlandCement.

3) X-Ray Fluorescence analysis to determine the elementalcompositionofincineratedricehuskash.

4) X-Ray Diffraction technique to determine the chemical composition of Rice Husk Ash and OrdinaryPortlandCement.

5) Scanning Electron Microscopy and EnergyDispersive Spectroscopy for analyzing the chemical composition and microstructure of finely grinded blendedcementmortar.

There are various analysis software present in the market for refinement and analysis of these raw data files. For this investigation the software used is X'Pert High Score Plus which provides various features and has ahugeelementaldatabaseforphaseidentification.Toget refined results, determine phase and obtain chemical composition information a specific set of procedures needtobeperformedintherespectivesoftware-

1) Background Correction- To see the XRD signal in a two-dimensional (2D) XRD measurement, the backgroundmustbeeliminated,whichismadeupof

scatteringfromtheapparatusandthemainX-raybeam ratherthanthesample.

2) Stripping K alpha 2- X-ray diffraction requires monochromatic X-rays, as Bragg's law makes clear. CopperK-alpha,whichismoreintensethanK-betaand provides superior resolution, is employed in the procedure because it is used to identify and examine material structures. The composite link model is used toextendthemodelandremovetheKdoublet.Thedata areconsequentlysplitintotwosmoothcomponents,K1andK-2.Theappliedpenalty'sweightisautomatically tailoredforbothsmoothingandK2removal.

3) Identifying the peaks-The peak intensities in an XRD experiment will vary since intensity is proportional to the number of scatterers per unit area of a certain atomic plane. Typically, the peak's strength decreases with increasing plane indices (greater angles in the pattern). We must examine the nature of the Bragg's peaksthatemergeintheXRDpatterninordertouseit to determine the nature of the materials. If the peak is quite broad, the substance is amorphous with short range ordering. The material is crystalline if the XRD patternshowssharppeaks.

4) Executing Search and Match- To determine phase and obtainchemicalcompositioninformation.

3. RESULTS AND DISCUSSION

Forinvestigatingthemicrostructuralbehaviorofricehusk ash blended cement mortar and determining optimum cementreplacementbyricehuskashinrespecttostrength and durability several tests had been conducted whose resultsareasrepresentedbelow

3.1 Effect of Rice Husk Ash replacement on standard consistency

for compressive strength testing irrespective of the partial replacementofcementbyRiceHuskAsh.

Group 2- (V Group) In this group samples the standard consistencycorrespondingtoeachpartial replacement was first calculated and the water requirement for compressive strength testing was calculated accordingly for each partial replacement.

Total 18 cube specimens were made for each case of partial replacement out of which 9 cubes were made accordingtoCGroupandtheother9weremadeaccording to V group, out of these 9 specimens 3 specimens were tested after 72 hours for calculating 3 days Strength, the next 3 specimens were tested after 168 hours for calculating 7 days strength and the remaining 3 specimens were tested after 672 hours for calculating 28 days strength.

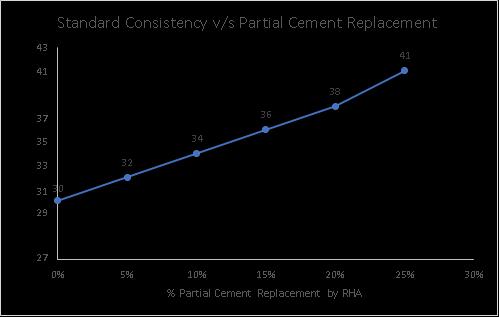

On performing the test to obtain the standard consistency corresponding to different partial replacements of cement by pozzolanic material Rice Husk Ash, the following results were obtained. The graph illustrates initially a nearly linear increase in the standard consistency as we increase the percentage replacement of Rice Husk Ash and also it indicates that at higher replacements the rate of increase of standard consistencyalsoincreases.

This above observation indicates towards the hygroscopic nature of the rice husk ash by the virtue of which it absorbs more water in comparison to the cement hence increase the water demand, this can be due to high specific surface of Rice Husk Ash in comparisontocementandshouldbekeptinmindwhile determining water requirement for cement mortar in field.

3.2 Compressive strength test results

While performing compressive strength testing the samples were divided into two groups on the basis of theirstandardconsistency-

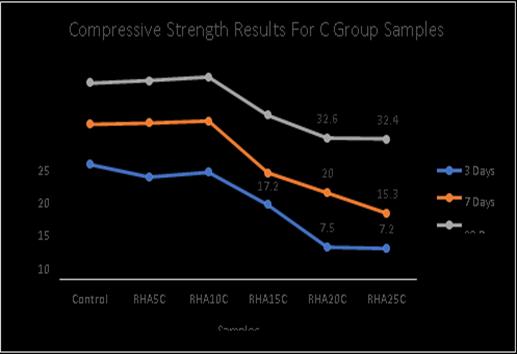

Group 1- (C group) In this group samples the standard consistency was assumed as constant and equal to the standard consistency of unblended Ordinary Portland Cement (30%) while calculating the water requirement

On analyzing the Compressive strength results it was observed that the 3 days compressive strength of blended cement mortar irrespective of partial replacement percentage is always lesser than the 3 days compressive strength of control sample, this observation indicates toward the slow nature of pozzolanic reaction that is occurring in blended cement mortar and is responsible for latestrengthdevelopmentofcompressivestrength.

Further on investigating it was observed that the 28 days compressive strength is increasing on increasing the percentage partial replacement up to partial replacement of 10% after which it shows a down fall pointing towards the conclusion that optimum level of partial replacement in the case of constant standard consistency is 10% to achieve highest compressive strength.

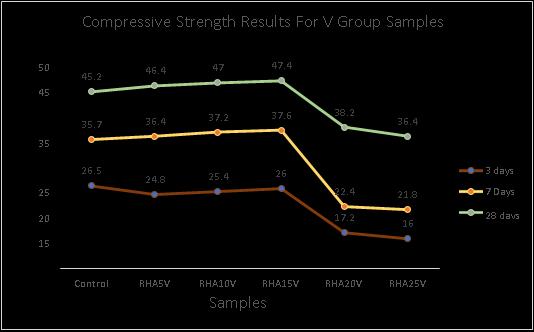

On analyzing the Compressive strength results it was observed that the 3 days compressive strength of blended cement mortar irrespective of partial replacement percentage isalways lesser than the 3 days compressivestrengthofcontrolsample,thisobservation again indicates toward the slow nature of pozzolanic reaction that is occurring inblended cement mortar and is responsible for late strength development of compressivestrength.

Further on investigating it was observed that the 28dayscompressivestrengthisincreasingonincreasing the percentage partial replacement up to partial replacement of 15% after which it shows a down fall pointing towards the conclusion that optimum level of partial replacement in the case of variable standard consistency is 15% to achieve highest compressive strength.

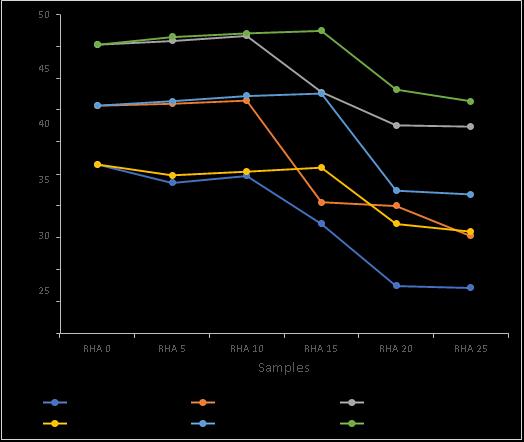

Chart -4:GraphforCompressivestrengthtestresults comparisonforVgroupsamplesandCgroupsamples

On comparing the results of compressive strength tests corresponding to both groups it was observed that the maximum 28 days compressive strength for group C sampleshavingconstantstandardconsistencywasobtained for10%replacementandhada valueof46.6MPawhereas the maximum 28 days compressive strength for group V sampleshavingvariablestandardconsistencywasobtained for15%replacementandhadavalueof47.4MPaandafter it in both cases there was a downfall in compressive strengths with respect to control sample, The main cause can be that there wasn't enough water for hydration. At replacement levels of 20 and 25 percent, the materials had verylittlebonding,whichmadethemlessworkable.

In addition to this, all samples with variable water contentproducedhighercompressivestrengthresultsthan equivalent samples made with constant water content. It canbesincethereisenoughwaterinthemixturestofinish hydrationofthecementitiouspaste.Theproductionofextra C-S-Hgelbecauseofthereactionbetweenfreelimepresent incementpasteandactivesilicapresentinRiceHuskAshis anotherfactorcontributingtotheincreasedstrengthgain.

3.4 XRD analysis results

SamplesofOrdinaryPortlandCementandRiceHuskAsh were investigated by XRD technique in order to determine

their chemical composition and raw data files were obtained, Then the results obtained from XRD machine in the form of raw data images were refined in X'Pert High Score Plus Software and plotted in graphical form inOriginProsoftware.

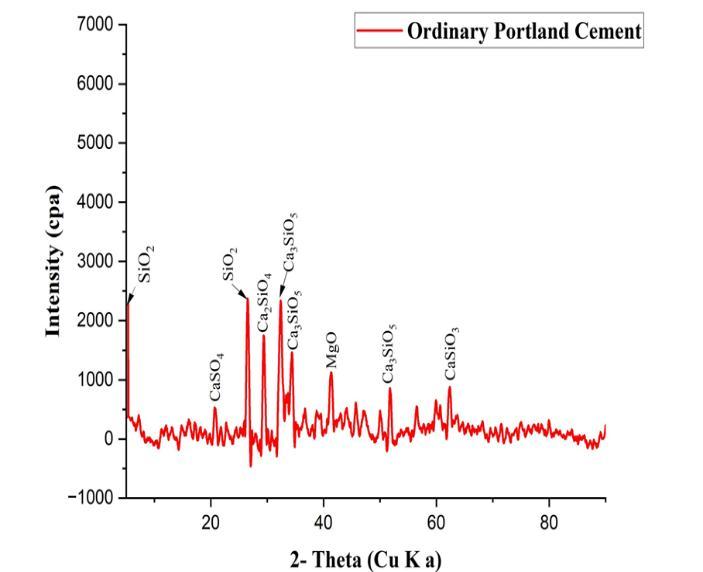

To analyze the chemical structure of materials, XRD Patterns of OPC were plotted. The pointed peaks of graph indicate towards the crystalline nature of OPC. The main peaks of Tricalcium Silicate C3S (Ca3SiO5) Dicalcium Silicate C2S (Ca2Sio4) and Silica (SiO2) were observed, along with it peaks of Gypsum (CaSO4), Magnesia(MgO)werealsoobserved.

To analyze the chemical structure of materials, XRD Patterns of Rice Husk Ash were plotted. The pointed peaks of graph indicate towards the crystalline nature of Rice Husk Ash. The main peak of Silica (SiO2) was observedshowingthatintensityofsilica isveryhigh in comparisontootherconstituents,alongwithitpeaksof Lime (CaO), Magnesia (MgO), Alumina (Al2O3) were also observed. The silica was observed at different diffractedanglesandwasmainlyobservedintheforms ofcoesite,quartz,andtridymitemineral.

3.5 TGA-DSC Analysis Results

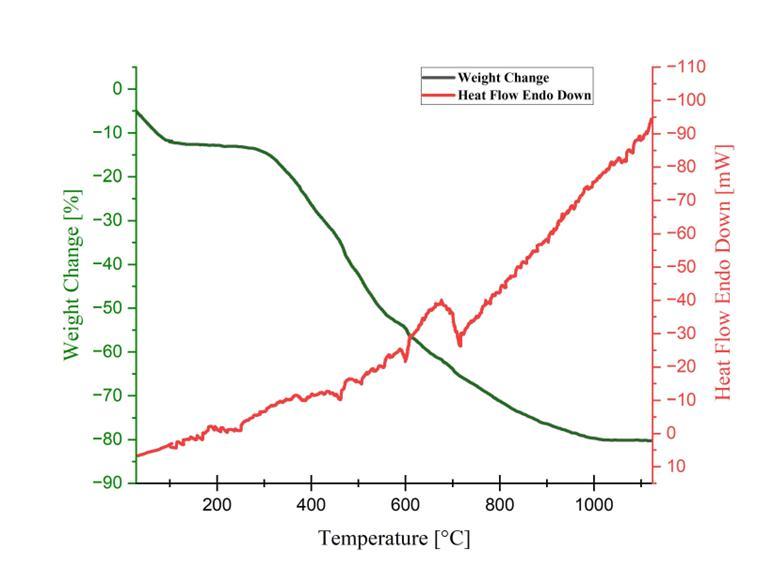

In the Fig. 7 below, the rice husk thermograms are displayed. Three peaks that can be identified as stages in the decomposition are demonstrated. An exothermic shift occurs after a brief endothermic curve (first peak) at 200°C.At500°C,thesecondpeakshiftsfromexothermicto endothermic. 650°C marks the third peak, which was followedbyanexothermicshift.

The first weight loss of 10% below 110°C and the subsequent rapid weight loss of 56% that began above 400°C. The weight loss exceeds 83 percent at 900°C. The firstpeakisfollowedbya5%weightloss,whichisseento represent absorbed water loss. The degradation of cellulose is indicated by the second peak, which is exothermic and i followed by fast weight loss. The breakdown of cellulose and lignin occur at the same time. At the third peak, the weight of rice husk continued to decrease, which was due to the continuous degradation of ligninandanotherorganiccomponent.

4. CONCLUSION

After detailed investigation following conclusions are drawnfromthisstudy-

InthecalcinationofRiceHuskinordertoobtaintherice husk Ash, silica content was increased from 28.12% to 92.30%asnotedbyX-RayFlorescenceTechnique.

A study of Rice Husk Ash’s morphology was also conductedanditwasfoundtobeporousandsoftinnature. The main peaks as obtained in X-Ray Diffraction analysis wereSiO2,Al2O3 andCaO.

Ca, Si and O were noted as the primary components of OPC,whereasSiandOaretheprimarycomponentsofRice HuskAshinEDSanalysis.

On performing Thermo Gravimetric analysis of Rice Husk from 200 to 350°C, a sudden decrease in weight change percentage was seen, and from 350°C to 400°C, it waspracticallylinear.Between600and800°C,exothermic to endothermic transitions were seen in the Differential ScanningCalorimetry.

The maximum compressive strength was discovered at 10% substitution with mortar made from Rice Husk Ash mix with the same consistency in contrast to 15% replacement level with mortar made from Rice Husk Ash mixinthevariousconsistencyblends.Allblendedmixesof different consistency had greater compressive strength thanthecorrespondingblendedmixesmadewithconstant water content. As Rice Husk Ash level rose in blended mixtures, EDS analysis revealed decreasing Ca peaks and increasingsilicacontentpeaks.

REFERENCES

[1] Antiohos, S. K., Papadakis, V. G., & Tsimas, S. (2014). Cement and Concrete Research Rice husk ash ( RHA ) effectiveness in cement and concrete as a function of reactive silica and fi neness. Cement and Concrete Research, 61– 62, 20–27.

https://doi.org/10.1016/j.cemconres.2014.04.001

[2] Ash,B.,Materials,C.,Xu,Q., Ji,T.,Gao,S., Yang,Z.,& Wu, N.(2018).

[3] Characteristics and Applications of Sugar Cane. 1–19.

https://doi.org/10.3390/ma12010039

[4] Askaruly, K., Azat, S., Sartova, Z., Yeleuov, M., Kerimkulova, A., & Bekseitova, K. (2020). OBTAINING AND CHARACTERIZATION OF AMORPHOUS SILICA FROMRICEHUSK.88–97.

[5] Bahurudeen, A., Kanraj, D., Dev, V. G., & Santhanam, M. (2015). Cement & Concrete Composites Performance evaluation of sugarcane bagasse ash blended cement in concrete. CEMENT AND CONCRETE COMPOSITES, 59, 77–88.

https://doi.org/10.1016/j.cemconcomp.2015.03.004

[6] Bui,L.A.,Chen,C.,Hwang,C.,&Wu,W.(2012).Effectof silica forms in rice husk ash on the properties of concrete. 19(3), 6–7. https://doi.org/10.1007/s12613012-0547-9

[7] Chindaprasirt, P., & Rukzon, S. (2008). Strength , porosity and corrosion resistance of ternary blend Portland cement , rice husk ash and fly ash mortar. 22, 1601–1606.

https://doi.org/10.1016/j.conbuildmat.2007.06.010

[8] Demir, I. (2019). Optimization of fly ash particle size distribution for cementitious systems with high compactness. 195, 104–114.

https://doi.org/10.1016/j.conbuildmat.2018.11.080

[9] Gautam, A., Batra, R., & Singh, N. (2019). Engineering HeritageJournal(GWK).3(1),1–4.

[10] Hu, L., He, Z., & Zhang, S. (2020). Sustainable use of rice husk ash in cement-based materials : Environmental evaluation and performance improvement. Journal of Cleaner Production, 264, 121744.

https://doi.org/10.1016/j.jclepro.2020.121744

[11] Madandoust,R.,Mohammad,M.,&Ahmadi,H.(2011). Mechanical properties and durability assessment of rice husk ash concrete. Biosystems Engineering, 110(2), 144–152. https://doi.org/10.1016/j.biosystemseng.2011.07.00 9

[12] Modani, P. O., & Vyawahare, M. R. (2013). Utilization of Bagasse Ash as a Partial Replacement of Fine Aggregate in Concrete. Procedia Engineering, 51(NUiCONE 2012), 25–29. https://doi.org/10.1016/j.proeng.2013.01.007

[13] Morales, E. V, Villar-cociña, E., Frías, M., Santos, S. F., &Jr,H.S.(2009).

[14] Cement & Concrete Composites Effects of calcining conditionsonthemicrostructureofsugarcanewaste ashes(SCWA):Influenceinthepozzolanicactivation. Cement and Concrete Composites, 31(1), 22–28.

https://doi.org/10.1016/j.cemconcomp.2008.10.004

[15] Mosaberpanah,M.A.,&Umar,S.A.(2020).Materials Today Sustainability Utilizing Rice Husk Ash as Supplement to Cementitious Materials on Performance of Ultra High Performance Concrete : e A review. Materials Today Sustainability, 7–8, 100030.

https://doi.org/10.1016/j.mtsust.2019.100030

[16] Nasiru, S., Jiang, L., Yu, L., Chu, H., Huang, Y., Pei, C., Gu,Y.,Jin,W.,Eyram,E.,&Guo,M.(2021).Properties ofcementmortarcontaining

[17] recycled glass and rice husk ash. Construction and Building Materials, 299, 123900.

https://doi.org/10.1016/j.conbuildmat.2021.123900

BIOGRAPHIES

Mr. Sonu Sharma after Graduating in Technical Education as a Civil Engineer in 2012 has been working as Senior Engineer in Metro Construction Projects Since the past one Decade and holds a vast range of working Knowledge & experience in Metro Construction. Currently He is a Scholar of Masters in Technology, Construction Technology and Management, Faculty of Engineering & Technology, Rama University Uttar Pradesh,Kanpur,India