STUDY ON THE MECHANICAL PROPERTIES OF HIGH STRENGTH CONCRETE USING G.G.B.S AND SILICA FUME AS PARTIAL REPLACEMENT OF CEMENT.

Vishvjeetsinh Dilipsinh Rana1, Aakash Rajeshkumar Suthar 2

1 Student Civil Engineering Department, L.J.I.E.T. Ahmadabad, Gujarat, India

2 Professor Civil Engineering Department, L.J.I.E.T. Ahmadabad, Gujarat, India ***

Abstract - The aim of this investigation is to assess how mineral admixtures can enhance the compressive and flexural properties of concrete by partially substituting cement. The research will involve conducting trial and error experiments to explore the impact of Silica fume and GGBS when partially replacing cement while maintaining a constant water-cement ratio to produce highstrength concrete. To achieve this, concrete samples of varying percentages of Silica Fume (5%, 8%, and 10%) and GGBS (25-50%) will be casted and evaluated, with partial substitution of cement, in sizes of 150mmx150mmx150mm (cube) and 500 X 100 X 100 mm (beam). The goal of the study is to identify the optimal percentage of Silica fume and GGBS that will provide the highest compressive strength (M65, M70, M75) and flexural strength. The research involves an analysis of how mineral admixtures such as Silica fume and GGBS can be effectively used in cement and concrete construction materials.

Key Words: Cement, Concrete, Construction Material, Mix Design, Silica Fume, GGBS

I.INTRODUCTION

Theutilizationoftripleblendedconcreteisamethodthatimprovesthestrengthcharacteristicsofconcretebyalteringits chemicalcomposition,particlesizedistribution,andfineness.Itinvolvesincorporatingadditiveslikepozzolana,granulated slag,orinertfillerstomodifytheconcrete'sproperties.Asaresult,thistechniquehasledtothedevelopmentofdifferent cementformulationsthatconformtobothnationalandinternationalstandards.Tripleblendedcementservesasapromising alternative to mineral admixtures such as flyash,silica fume, and granulated slag.This type of concrete, known as triple blendedconcrete,exhibitsexceptionalphysical,chemical,andmechanicalproperties,makingitparticularlyadvantageousin constructionapplications.

II. MATERIAL AND METHOD

General

In this chapter, you will find comprehensive details regarding the materials used. This includes information about the characteristicsofthematerials,thetypesofmaterialsemployed,andtheirrespectiveproportions.

Materials

ThematerialsutilizedforthestudyconsistofprocessedSilicaFumeandGGBSassourcematerials,ordinaryPortlandcement, aggregates,water,andanadmixture.

Cement:

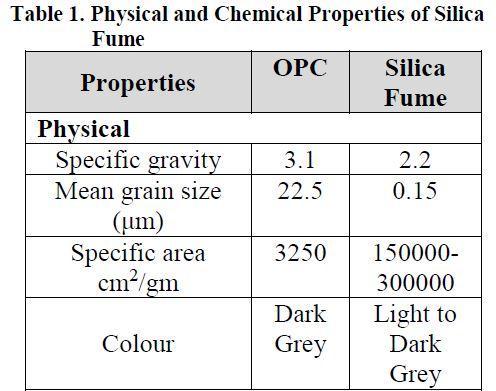

Theexperimentalworkutilizes53gradeordinaryPortlandcement.Thespecifictypeofcementemployedfortheexperiments canbeseeninFigure1.1.ThechemicalpropertiesofthecementareoutlinedinTable1.1.1,whileTable1.1.2presentsthe physicalpropertiesofthecement.

A. Ordinary Portland cement of 53 Grade

PurchasedfromultratechhavingsoundnesspropertyinlimitandallotherpropertiesaccordingtoIndianstandards

B. Aggregates of Pertaining Sieve Size (<20mm IS standard)

CollectedfromVadgam,AhmedabadGujarathavingspecificgravity2.6andallpropertiesaccordingtoIndianStandards

C. River Sand of Pertaining Sieve Size (<4.75mm IS standard)

CollectedfromVadgam,AhmedabadGujaratfollowingzone2andallpropertiesaccordingtoIndianStandards

D. Super Plasticiser

Amodifiedacrylicsuper-plasticizerwasutilizedinthestudy,whichhasalowwater/cementratio,longworkabilitytimes,and veryhighmechanicalstrength.

Silicafumeisamaterialthatisobtainedasaby-productfromtheferrosiliconindustryandhashighpozzolanicpropertiesthat can improve the mechanical and durability characteristics of concrete. It can be added directly to concrete as a separate ingredientormixedwithPortlandcement.IntheUS,silicafumeismainlyutilizedtoproduceconcretewithhigherresistance againstchloridepenetrationinparkingstructures,bridges,andbridgedecks.

whichstandsforGroundGranulatedBlastFurnaceSlag,isaproductthatiseco-friendlyandderivedfromaby-productofthe ironmanufacturingprocess.ItisknownforitshighqualityandlowCO2emissioncharacteristics.DuetoitslowembodiedCO2, GGBSisanidealmaterialfordesigningsustainableconcretemixesforconstructionpurposes.

G. Admixture

Toachievethedesiredlevelofworkabilityinregularconcrete,Superplasticizerisemployed.MAPEIDynamonSX550 isutilizedtoimproveworkabilityanddecreasethewater-to-cementratioinfreshconcrete.

Table 2:- Properties of Admixture

Appearance: liquid

Colour: amber

pH: 7.0±1

Chemicalnameofactiveingredient Polycarboxylicether ensityaccordingtoISO758(g/m³): 1.110±0.03at+25°C

Mainaction: increaseworkabilityand/orreductionof mixing water

ClassificationaccordingtoEN934-2 highrangewaterreducingsuperplasticizer, tables3.1and3.2

ClassificationaccordingtoIS9103-1999 Superplasticizer,waterreducingClause3.6

ClassificationaccordingtoASTMC49 typeF

Water-solublechloridecontent accordingtoEN480-12(%): <0.1(absentaccordingtoEN934-2)

Alkalicontent(equivalentNa₂O) accordingtoEN480-12(%): <2.5

III. PROCEDURE

Thisresearchpaperincludesexperimentscarriedoutonseveralhighstrengthconcretegrades,inwhichapartialreplacement ofcementwasmadewithGGBSandsilicafumetodeterminethemostoptimalmixdesign.Allthemixdesignsusedinthisstudy wereincompliancewithIndianStandards.ThedifferentmixesincludedM65(withatargetstrengthof73N/mm2),M70(with atargetstrengthof79N/mm2),andM75(withatargetstrengthof783N/mm2)gradesofconcrete,withsilicafumeandGGBS beingreplacedbyvaryingpercentagesrangingfrom5to10%and25to50%,respectively.

Themainobjectivesofthisstudyare:-

•Theaimofthisstudyistoinvestigatetheeffectsofpartiallyreplacingcementwithpozzolanicmaterialslikesilicafumeand GGBSinconcrete.

•Thestudyaimstodeterminethecompressiveandflexuralstrengthofthetriple-blendedconcretewiththecombinedeffects ofsilicafumeandGGBS.

•Themainobjectiveistoidentifytheoptimalreplacementofcementwiththepozzolanicmaterials.

ThecompressivestrengthtestswereperformedfollowingtheguidelinesoutlinedinIS1489-199,andtheflexuralstrength testswereconductedinaccordancewithIS:516-1959.

Themixgroupsfor70Gradeswerecreatedasfollows:

GroupA

D1(withCement:70%,Silicafume:5%,GGBS:25%)

D2(withCement:65%,Silicafume:5%,GGBS:30%)

D3(withCement:60%,Silicafume:5%,GGBS:35%)

D4(withCement:55%,Silicafume:5%,GGBS:40%)

D5(withCement:50%,Silicafume:5%,GGBS:45%)

D6(withCement:45%,Silicafume:5%,GGBS:50%)

GroupBconsistedofthefollowingmixtures:

D7(with67%cement,8%silicafume,and25%GGBS)

D8(with62%cement,8%silicafume,and30%GGBS)

D9(with57%cement,8%silicafume,and35%GGBS)

D10(with52%cement,8%silicafume,and40%GGBS)

D11(with47%cement,8%silicafume,and45%GGBS)

D12(with42%cement,8%silicafume,and50%GGBS)

C.GroupC

D13(Cement:65%,Silicafume:10%,GGBS:25%)

D14(Cement:60%,Silicafume:10%,GGBS:30%)

D15(Cement:55%,Silicafume:10%,GGBS:35%)

D16(Cement:50%,Silicafume:10%,GGBS:40%)

D17(Cement:45%,Silicafume:10%,GGBS:45%)

D18(Cement:40%,Silicafume:10%,GGBS:50%)

Mixgroupswerepreparedforthe65Gradesasfollows:

"D.GroupD

J1(Cement:70%,Silicafume:5%,GGBS:25%)

J2(Cement:65%,Silicafume:5%,GGBS:30%),

J3(Cement:60%,Silicafume:5%,GGBS:35%),

J4(Cement:67%,Silicafume:8%,GGBS:25%),

J5(Cement:62%,Silicafume:8%,GGBS:30%),

J6(Cement:57%,Silicafume:8%,GGBS:35%)

J7(Cement:65%,Silicafume:10%,GGBS:25%),

J8(Cement:60%,Silicafume:10%,GGBS:30%),

J9(Cement:555%,Silicafume:10%,GGBS:35%)

Forthe75grades,thefollowingmixturegroupswerecreated"

E.GroupE

K1(Cement:70%,Silicafume:5%,GGBS:25%)

K2(Cement:65%,Silicafume:5%,GGBS:30%)

K3(Cement:60%,Silicafume:5%,GGBS:35%)

K4(Cement:67%,Silicafume:8%,GGBS:25%)

K5(Cement:62%,Silicafume:8%,GGBS:30%)

K6(Cement:57%,Silicafume:8%,GGBS:35%)

K7(Cement:65%,Silicafume:10%,GGBS:25%)

K8(Cement:60%,Silicafume:10%,GGBS:30%)

J9(Cement:555%,Silicafume:10%,GGBS:35%)

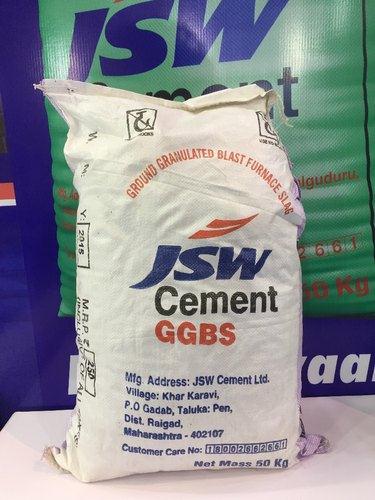

IV. RESULT AND DISCUSSION

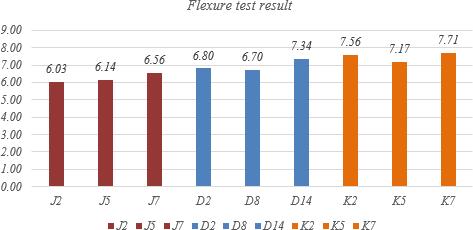

ItwasobservedthatthecompressivestrengthdecreaseswhentheGGBSquantityexceeds35%.AmongthemixesforM70 grade,D8(Cement:62%,Silicafume:8%,GGBS:30%),forM65grade,J5(Cement:57%,Silicafume:8%,GGBS:35%),andfor M75grade,K5(Cement:62%,Silicafume:8%,GGBS:30%)werefoundtobetheoptimalmixes.Nosignificantchangewas observedinflexuralstrengthforanyofthetrialmixes,exceptforaslightincreasewith10%Silicafume.

V. CONCLUSIONS

ThestudyconcludesthatincreasingtheamountofGGBSinthemixleadstoadecreaseincompressivestrength.

After56days,thereisaslightincreaseinstrengthofabout4-10%.

Theworkabilityoftheconcreteislowduetothelowwater-to-cementratio,resultinginanaverageslumpvalueof30 to35cm.

Silicafumeisareactivepozzolanicmaterialinconcreteduetoitshighcontentofamorphoussilicondioxide.Itreacts withthecalciumhydroxidereleasedbythePortlandcementtoformadditionalbindermaterialcalledcalciumsilica hydrate,whichimprovesthehardenedpropertiesoftheconcrete.

Silicafumeparticlesareabout80timessmallerthancementparticles,sotheyfillthevoidsbetweencoarseaggregate particlesandcementgrains,providingamicro-fillereffectthatsignificantlyincreasesthestrengthoftheconcrete.

TheuseofGGBSasasubstitutematerialforconcretecanreduceCO2emissionsduringproductionandactasanecofriendlymaterial,reducingthegreenhouseeffect.

Theexperimentalresultsshowthat8%silicafumeand30-35%GGBSprovideoptimalresultsinmostcases.

The flexure strength of the concrete does not differ significantly, but a slight increase in flexure strength can be observedwiththepresenceof10%silicafume.

In summary, increasing the amount of GGBS results in a decrease in compressive strength but an increase in workability.Theinitialincreaseincompressivestrengthisduetothemicro-fillereffectcausedbythesmallgrainsize ofsilicafumecomparedtocementparticles.

ACKNOWLEDGMENT

I would like to take this opportunity to express my gratitude to everyone who helped and guided me throughout the completionofthisprojectwithinthegiventimeframe.IamdeeplythankfultomyInternalProjectGuide,AakashRajeshkumar Suthar,AssistantProfessor,LJInstituteofEngineeringandTechnology(LJIET).Ahmadabad,forhisassistance, invaluable support,motivationandguidancethroughouttheprojectduration.Hisguidanceandadvicewerealwaysavailable,andhis dedicationandassistanceprovedhelpfulevenwithpracticalaspectsoftheproject.

REFERENCES

Thefollowingsourceshavebeencitedinthisstudy:

Basic

1. Villasmil,Fischer,andWorlitschek(2019)provideanevaluationofthermalinsulationmaterials andmethodsfor thermalenergystoragesystems.

2. Khoukhi (2018) investigates the combined effect of heat and moisture transfer on the thermal conductivity of polystyreneinsulationmaterialanditsimpactonbuildingenergyperformance.

3. Ciecierskaetal.(2016)examinetheflammability,mechanicalproperties,andstructureofrigidpolyurethanefoams withdifferenttypesofcarbonreinforcingmaterials.

4. Wang,Jiang,andSun(2017)exploretheflameretardancyandmechanicalpropertiesofexpandedpolystyrenefoams containingammoniumpolyphosphateandnano-zirconia.

5. Jiang et al. (2014) investigate the correlation between flammability and the width of organic thermal insulation materialsforbuildingexteriorwalls.

6. Zhouetal.(2017)examinetheeffectivenessofverticalbarriersinpreventinglateralflamespreadoverexposedEPS insulationwalls.

7. Li,Zeng,andXu(2017)studytheeffectofporeshapeonthethermalconductivityofpartiallysaturatedcement-based porouscomposites.

8. ParmarandPatel(2013)investigatethepropertiesofhigh-performanceconcreteusingAlccofineandflyash.

IS CODES

IS456-2000:Indianstandardspecificationsforplainandreinforcedconcrete.

IS516-1959:Indianstandardmethodsoftestsforstrengthofconcrete.

BOOK

Shetty(2006)providesacomprehensivebookonconcretetechnology.

BIOGRAPHIES

MR. Vishvjeetsinh Dilipsinh Rana

Student,Structuralengineeringdepartment,L.J.I.E.T.Ahmadabad,Gujarat,India

Mr. Aakash Rajeshkumar Suthar iscurrentlyworkingasanAssistantProfessoratLJInstitutesof EngineeringandTechnology..HegraduatedwithaBachelorofCivilEngineeringfromLJInstituteof EngineeringandTechnology.HehasalsocompletedMastersofTechnologyinForensicStructural EngineeringfromGujaratForensicSciencesUniversity.