REDUCTION OF STRENGTH OF DOMESTIC WASTEWATER USING NATURAL FIBROUS MATERIAL

Archana K U1 , Shika S2

1Pg student, Environmental Engineering in the Department of Civil Engineering, M-Dasan Institute of Technology Ulliyeri, Kerala, India

2Associate Professor, Department of Civil Engineering, M-Dasan Institute of Technology Ulliyeri, Kerala, India

***

Abstract - Wastewater is primarily created by manmade and natural processes. Following treatment, sewage may either be dumped into a body of water, such as a lake, stream, river, estuary, or ocean, or onto land. (Gulhane et al., 2014).The present work is intended to study the application of the comparative study between the Areca husk fibre and Agava sisalana(sisal fibre) as a fixed bed for treating domestic wastewater for different parameters such as turbidity, chloride, TSS, TDS and BOD. Column study was conducted. Sample was collected at 15, 30, 45, 60, 75 and 90 minutes at different depth 10, 20, 30, 40 and 45cm in different flow rate 10, 20, 30 and 40ml/min. The maximum removal efficiency was observed at a flow rate of 10ml/min and at an optimum time of 60 minutes at a bed depth of 40cm. And in the comparative study, Sisal fiber was observed to have maximum efficiency with removal efficiency of turbidity, chloride, TSS, TDS and BOD as 79.31%, 75.86%, 63.33%, 76.67% and 75% respectively. This work shows enhanced domestic wastewater treatment ability which iseconomicallyfeasible andreadilyavailable.

Key Words: Wastewatertreatment,Arecahuskfiber,Sisal fiber,Removalefficiency

1.INTRODUCTION

The primary source is thought to be water. The water cycle on earth involves the constant processes of evaporation, transpiration, condensation, precipitation, and runoff, with the goal of eventually reaching the sea. Wastewateristheliquidwastethatisdisposedofafteruse in home settings, commercial settings, industries, and agriculture. In order to establish a hygienic environment, wastewater obtained from various sources needs to be handled very well. If adequate plans are not made for the collection, treatment, and disposal of all municipal waste, it will continue to build up and create an unfavourable situation where buildings and roads will be damaged due towastewaterbuildupinthefoundations,endangeringthe safety of the structures. In general, the main goal of wastewater treatment is to enable human and industry. (Gulhaneetal., 2014).

The widening gap between readily accessible cleanwatersourcesandthe risingdemandbroughton by population growth and economic development over the

past few decades. A sustainable water management strategy necessitates that decision-makers view treated wastewater as a valuable resource rather than a waste product that needs to be expensively disposed of, which increases the focus on greywater utilisation. The water should be recycled or cleaned before being released to natural water sources like rivers or lakes or in open land as groundwater recharge due to the rising demand for groundwaterinmetropolitanareasandcities.Duetothis, the home wastewater has undergone little treatment that ismoreorlesssuccessful andcanbeutilised fora variety oftasks,including

Biobased fibres or fibres with vegetable and animal origins are examples of natural fibres. This definition covers all naturally occurring cellulosic fibres (such as cotton, jute, sisal, coir, flax, hemp, abaca, and ramie) as well as fibres made of protein, including wool and silk. Asbestos and other naturally occurring mineral fibres that are not bio-based are not included in this list (Lotfi et al., 2019).One such type of treatment procedure used is the weakening of residential wastewater utilising twodifferentbedmaterialsasfiltermedia:Agavasisalana and Areca husk fibre. Due to intrinsic benefits over suspended growth systems, the use of fixed films for wastewater treatment is being investigated more frequently. The goal of the current effort is to examine how the Areca fibre and Agava sisalana as a fixed bed for treating domestic wastewater to know the comparative removal efficiency of BOD, chloride, turbidity, TDS, TSS andanalysisofpHandcomparedwithWHOstandards.

2.MATERIALS AND METHODOLOGY

Sisal and areca husk fibre were the two natural fibres used in this investigation. The mesocarp tissue or husk of the areca fruit is where the versatile natural fibre known as areca husk fibre is found. Areca appears to be the most promising natural fibre due to its low cost, wide availability, and high promise as a perennial crop. The botanical name for sisal fibre is agave sisalana. Although commonlycultivatedinothernations,thiskindofagaveis endemic to southern Mexico. Rope and twine are made fromsisalfibre,whichisalsousedtomakepaper,textiles, footwear,headgear,bags,andcarpets(Vijayalakshmietal., 2019)

Agave sisalana has a rosette of 1.5–2 m (4.9–6.6 ft) tall sword-shaped leaves. A few tiny teeth may be present around the margins of young leaves, but they disappearastheyripen.Thesisalplanthasalifespanof7 to10yearsandnormallyyields200to250leavesthatcan be used for commerce. On average, there are about 1000 fibres per leaf. Only around 4% of the weight of the plant is made up of fibres. Given that its production benefits from temperatures over 250°C and sunlight, sisal is regarded as a plant native to the tropics and subtropics, showninFig-1(Kavinetal.,2019).

Thefibersadjoiningtheinnerlayerareirregularly lignified group of cells called hard fibers and the portions ofthemiddlelayercontainsoftfibers(Kavinetal.,2019)

2.3

The manufacture is normally done on a large scale,andtheleavesarebroughttoacentraldecortication plant where the waste parts of the leaf are washed away using water. Following that, the fibre is dried, brushed, and baled for export. The quality of the fibres depends heavily on moisture content, hence proper drying is crucial.Comparedtosundrying,artificialdryinghasbeen showntogeneratetypicallysuperiorfibregrades,butitis not always practical in developing nations where sisal is grown(Kavinetal.,2019).

2.2 Areca husk fiber

It originates in the Malaya Peninsula, East India, and is a member of the palmecea family as the species Areca catechu L. East India and other Asian nations are where most industrial farming is done. The hard, fibrous partofthearecanutthatprotectstheendospermiscalled the husk. It makes up between 30 and 45 percent of the fruit'soverallvolume.Arecafibrescontain13to24.6%of lignin,35to64.8%ofhemicelluloses,4.4%ofashcontent, and the remaining 8 to 25% of water content, as opposed to the cellulose depicted in Fig.3.3 above. (Kavin et al., 2019)

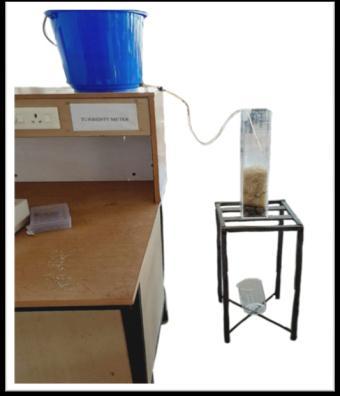

A mesh is placed at bottom from height of 5cm.It wasthenfilledwithfiberforaknowndepthof10,20, 30, 40 and 45cm. It is fabricated for down flow mode and for columnoperation process. Collectionof effluent wasfrom bottom of the setup. Sample was collected through outlet pipein15,30,45,60,75and90minutestounderstandthe variation in parameters for different time period. Also, sincethis isa column study, the flow rate wasalsovaried as10,20,30and40ml/min.

3. RESULTS AND DISCUSSIONS

In the present study sisal fibre and areca husk fibre was used. Different depth 10,20,30,40 and 45cm at different flow rate 10, 20, 30 and 40ml/minutes was adopted. Higher removal efficiency was found at depth 40cmat10ml/minutesflowrateforbothfibres.

10ml/min

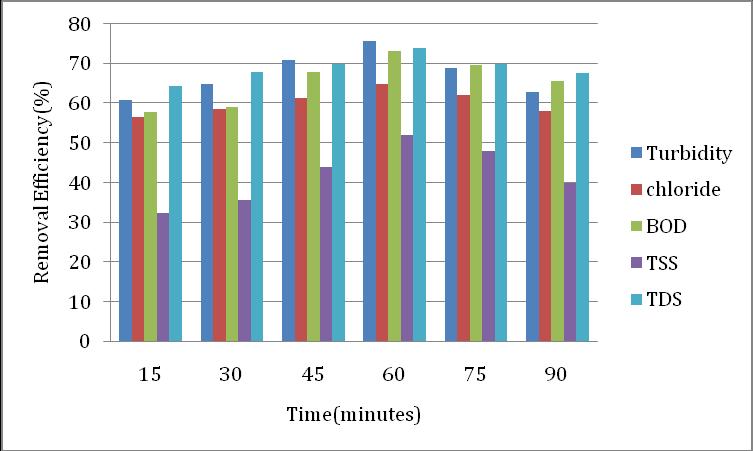

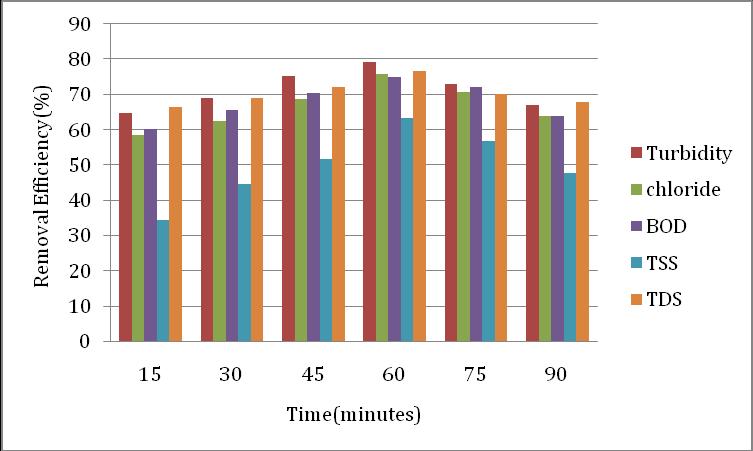

From this chart indicates removal efficiency of parameters using sisal fiber. At different flow rate maximum removal efficiency was observed at flow rate 10ml/minutes.

Removal efficiency of turbidity was 75.69% in 60 minute at 10ml/min flow rate. Flow rate decreases removalefficiencyincreases.

3.1

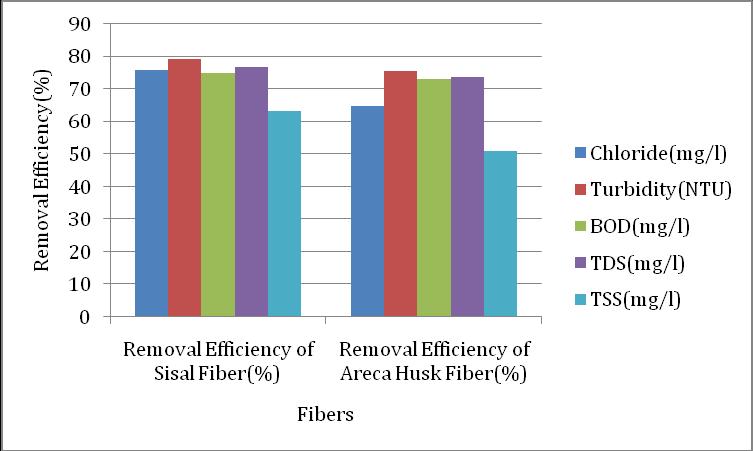

Thus in the overall experimental study the removal efficiency was maximum at a bed depth of 40cm and a flow rate of 10ml/min for both the fibers. The optimizedresultsareshowninTable-1

UtilityoffibrousmaterialssuchasSisalfiberandAreca huskfiberasfixedmediafortreatmentofwastewaterwith different depth and different flow rate has been successfullyestablishedinaboveresults.Fromthiswecan understandthatconsiderablereductioninparameterslike turbidity,chloride,BOD,TSSandTDS. Afterthetreatment of wastewater sample using Sisal fiber and Areca husk fiber, the pH was depicted to have no much variation throughout the treatment period in all depth. Removal efficiency was observed more for Sisal fiber compared to Arecahuskfiberandsteeplyincreasedat15minutesthen graduallyincreasesupto60minutes,thereafteritstarted decreasing.

4. CONCLUSIONS

Fromthisstudy,itwasobservedthatreductionin turbidity, chloride, TSS, TDS and BOD was achieved from sisal fiber and areca husk fiber at different depth 10, 20, 30, 40 and 45cmat different flow rate 10, 20, 30 and 40ml/min.Theremovalefficiencyofturbiditywas79.31% at depth 40cm and for areca husk fiber was 75.69%.

Removal efficiency of BOD was 75% in 60 minutes at depth 40cm and 73.2% for areca husk fiber. Removal efficiency of TDS was 76.67% in at depth 40cm and for arecahuskfiberis73.82%. RemovalefficiencyofTSSwas 63.33%atdepth40cmandforarecahuskfiberis51.11%. Removalefficiencyofchloridewas75.86%atdepth40cm andforarecahuskfiberis64.82%.

Maximum removal efficiency occurred for turbidityandchloride.For bothSisalfiberand arecahusk fiber, the removal efficiency steeply increases upto15 minutes and then gradually increases up to 60 minutes, thereafter it starts decreasing. The maximum removal efficiencywasobservedata flowrateof10ml/minand at anoptimumtimeof60minutes.Itwasalsoobservedthat as the flow rate increases, the removal efficiency also decreases indicating that the removal efficiency will be higher for lower flow rate. Also the removal efficiency decreased after 60 minutes which is believed due to the decomposition of fibers. Removal efficiency was observed moreinsisal fibercompare toareca husk fiberand water quality parameters reached the standard value as per Central Pollution Control Board(CPCB). This work shows enhanced domestic wastewater treatment ability which is economically feasible and readily available. The treated wastewater can be used for gardening and domestic purposes like washing and cleaning. This method is ecofriendly and can be used as pre-treatment process for wastewatertreatment.

REFERENCES

[1] Gowda, R. M. and Vinod, A. R, “Studies on natural fibrous materials as submerged aerated beds for wastewater treatment”, Elixir International Journal, Volume51,2012,Page10759-10762.

[2] Gulhane, M. L. and Yadav, P.G, “Performance of the modifiedmulti–mediafilterfordomesticwastewater treatment”, Proceedings of 3rd IRF International Journal,ISBN:978-93-84209,2014,Page15-50.

[3] Kavin,T.andJanagan,S.S, “Studiesonnaturalfiberous as fixed beds for domestic wastewater treatment, International Research Journal of Engineering and Technology”, eISSN: 2395-0056, Volume: 06, 2019, Issue:04/April.

[4] Lotfi, A., Huaizhong, Dao,V,D. and Prusty, G, “Natural fiber-reinforcedcomposites, Journal of Environmental Engineering”, Volume11,2019,Page10-40

[5] Vijayalakshmi., Eshanthini., Vanitha., Kumar, S. and Vigneshwaran, “Reduction of strength of domestic wastewater using natural fibrous materials”, Rasayan Journal ofChemistry, Volume24,2019,Page15-30.