REMOVAL OF CADMIUM FROM INDUSTRIAL WASTE WATER USING CILANTRO (Coriandrum Sativum) AS ADSORBENT

Anjali M Nair1 , Muhammad Fayis T2 ,1M.Tech student, Environmental Engineering, Dept. of Civil Engineering, M-Dasan Institute of Technology, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, M-Dasan Institute of Technology, Kerala, India ***

Abstract – The Laundry that produce waste water that contain cadmium which is a heavy metal and which contributes to pollution. This study investigates the adsorption of cadmium from the waste water by using cilantro as an adsorbent. The efficiency of the plant is tested by using batch study and column study. Study will research the effect of some primary operating parameters such as Adsorbent dosage, contact time and pH on the adsorption capacity of the plant. The column studies was performed by passing the waste water through a column setup having a diameter of 5cm and length 45 cm. The water sample will pass through the filter media through the column and the water was tested at different time interval and the removal efficiency of cadmium was calculated. Flow rate and bed depth are the two parameters used in column studies. The cadmium removal by the dry cilantro leaves was 69.3%.And the adsorption capacity of cadmium by the cilantro plant is 65 to 75% respectively.

Key Words: Cadmium, Cilantro plant, Batch study, Column Study, Adsorption capacity

1.INTRODUCTION

Cadmium is an extremely toxic industrial and environmentalpollutantclassifiedasahumancarcinogen. The textile wastewater contributes heavy metals like cadmium to the environment. This leads to the ability of the environment to foster life being reduced as human, animal, and plant health become threatened. This occurs duetobioaccumulationinthefoodchainsasaresultofthe non-degradable state of the heavy metals. Remediation of heavy metals requires special attention to protect soil quality, air quality, water quality, human health, animal health,andall spheresasa collection.Developed physical and chemical heavy metal remediation technologies are demanding costs which are not feasible, time-consuming, andreleaseadditionalwastetotheenvironment.

Heavymetalsanddyepigmentsused inthe production in the textile industries can exist in the structures of textile fabrics and can penetrate into fibers and these can be transferredtotheenvironmentwhicharehighintoxicand canbioaccumulateinthewaterlife,waterbodiesandalso traps in the soil. Developing research on a different

treatment methods for example; membrane processes, coagulation, precipitation, sedimentation, filtration, flotation, biological methods, chemical processes, electrochemical method ion exchange and adsorption; with various degree of successes leads to elevated dramatic outcomes inthescientific world.Adsorptionis a surface process in which multi-component fluids are attached to the surface of a solid adsorbent, forming chemicalorphysicalbonds.Itisbeingrecognizedasoneof the widely applied and most efficient fundamental approach in contaminated water treatment methods which mainly revolves on its technical feasibility, economical viability, socially acceptable and simplicity. Although,manymoretechniquescanbeusedintreatment of inorganic wastes, the best method should not only be appropriate, suitable and applicable locally, but also be of the maximum contaminant standards. Activated carbon, an adsorbent with controllable pore structure, thermally stable, low base/acid reactivity, large and porous surface areausehasbeenwitnessed,intermsofitsapplicabilityin eliminating of different types of chemical waste dissolved in water and in gaseous products. Despite the prolific application in adsorption processes, the major disadvantage of its use in the industries lies in the high cost and difficulties related on how to regenerate it. As a result of the above complications, more research to evaluate suitable and feasible renewable low cost natural materials like peat, bamboo waste, fungi, lignite, bark, moss, husks, coir piths, tea leaves, maize cobs, rice husks, and sago wastes as an alternative adsorbents for heavy metalsdecontaminationhasbeenintensified.

Adsorption utilizes nonliving biomasses to eliminate heavymetalsionsfromwater,isa biologicalphenomenon that can be explained by different types of physical and chemical relations among the heavy metals ions and different functional groups that are on the cellular wall. Theactivesitesoncellwallcanvaryaccordingtothetype ofthebiosorbentmaterial.Thisstudyinvestigatedcilantro plant as potential adsorbent to eliminate cadmium and leadionsfromsimulatedcontaminatedwater.

1.1 Objective of study

(1) To study and analyses the difference between adsorptioncapacityoffresh and dry cilantro leaves.

(2) Tofindouttheoptimumeff1iciencyoftheplant.

2. METHODOLOGY

2.1 Sample collection

The waste water is collected from the laundry situated near Eranhipalam bypass junction Calicut. Five liters of waste water sample was collected for the project. The wastewateriscollectedfromhugewashingmachineused for the dry cleaning processes. Mainly detergents and chemicalthatareusedforcleaningpurposepresentinthe wastewater. While there are numerous other domestic sourcesofheavymetalsinwastewater,detergentsarethe major source of cadmium. Therefore the presence of cadmium from detergents is particularly undesirable, so there is a need for constant monitoring and re-evaluation of metals concentration in all detergents, including those usedindishwasher.

2.2 Initial parameters of wastewater

The initial parameters such as pH, Turbidity, TSS, BOD, Alkalinity, Chloride, Hardness and Cadmium were determinedbtstandardmethodprocedures.

-1: Initialcharacteristicsofwastewater

Fresh cilantro stems and leaves were sun dried and then coverttofinepowderusing a mixer.Freshplantsleafand stemwerechoppedto1cmandthengroundedtoincrease the surface area for the adsorption The cilantro plant is nowadayscultivatedwidelyinmostpartsoftheworldasa spices, for essential oils production and production of seeds.

2.4 Batch Study

Batch study is conducted in order to study the effects of various parameters like adsorbent dosage, contact time and variation in pH on the removal capacity of cilantro plant. The batch experiments were conducted using 100 ml of waste water sample for each adsorption run having aninitialconcentrationof0.32mg/ltrofcadmium.

2.3 Adsorbent Preparation

The cilantro plant was collected and washed properly for removingthesoilfromtherootoftheplant. Theplantwas thenseparatedasleafandstemandasectionwasdriedin sunlightforremovingtheexcessmoisturecontent.

Various studies were conducted using dry leaf, dry stem, freshleaf,freshstem.Thefouradsorbentsuchasdryleaf, dry stem, fresh leaf and fresh stem was taken as 0.5, 1, 1.5,2and2.5gramsrespectively.Andfivedifferentcontact time was selected as 30, 60, 90,120 and 150 minutes and pH values from 5 to 9 was considered. Here we have to find the maximum removal efficiency of the different adsorbentandchoosingthebestadsorbentfromtheplant having the highest removal efficiency among them. And removescadmiuminhigherlevelfromthewastewater.

2.5 Column Study

Columnexperimentsonlaboratoryscaleswerecarriedout at steady state in a duplicate sets of column with the dimensions and arrangements given in the figure 3.9. From the batch study we get the optimum value that the dry leaf powder has the highest removal efficiency than the other adsorbent. So that the column study chosen the dry leaf adsorbent and the parameters taken from the batch study. Since the highest optimum value obtained

from1.5gramoftheadsorbentfor100mlofwastewater sampleandheretaking15gramsofadsorbentforoneliter of waste water sample and considering the bed depth for the experiment . About 15 grams 30 grams and 45 grams of cilantro dry leafs are taken for the experiment by choosing the bed depth of 2.5cm ,5cm and 7.5 cm was packedseparatelyandbedwascoveredbypebbles. After Filling the column by the waste water by maintaining the head.Thewaterwasflowthroughthecolumncontinuously and by changing the flow rate of 2 ml/min, 4 ml/min, 6 ml/min. The water was collected by an interval of 30 minute,60minute,90minute,120minuteand180minute andtheremovalefficiencyweredetected.

3.1 Effect of adsorbent dosage

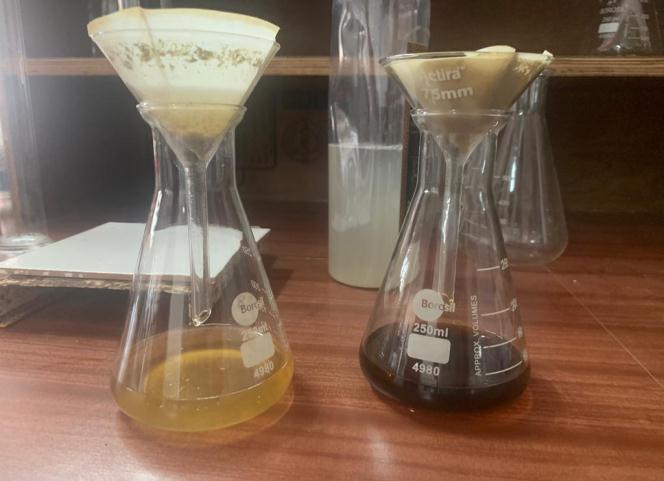

Here in figure shows the column set carried out for the study. Here the waste water sample was placed at the top portion of the column for the easy flow of water and a pipe was connected from the beaker to the column forthepassagewater.

3. RESULTS AND DISCUSSION

This section deals with the batch study done by using DL, DS,FLandFSbyusingadsorbentdosage,contacttimeand pHasinitialparameters

Chart -1:EffectonadsorbentdosageforDL,DS,FLandFS

The removal efficiency of cadmium for the adsorbent dosage of 1.5gram are 69.37%, 65.31%, 74.06% and 71.87%Figure5.1showstheeffectofadsorbentdosageon the removal of cadmium by different adsorbent. Here we cansee thatthevalueincreasesgraduallywhenweight of theadsorbentincreasesand decreases when reached at2 grams. The 1.5 gram of dry leafs having an optimum removal efficiency of 74.06% than the other adsorbents. And then decreases to 62.62% by adding 2 grams of adsorbent and also decreases to 65.31% when adding of 2.5gramsofadsorbent.Drystemhasaremovalefficiency of71%freshleafhaving69%andfreshstem65.3%.From these it is clear that dry leafs having the highest removal efficiencythantheotheradsorbents.

3.2 Effect of contact time

The study of contact time was conducted such as taking 1.5gramofeachadsorbentandthecontacttimewastaken as 30 minutes, 60 minutes, 120 minutes and 150 minutes ataninitialconcentrationof0.32mg/l.

Here the value gradually increasing when contact time increases and the optimum value are obtained at 120 minutes and gradually decreases. Figure shows the effect of contact time of various adsorbent such as fresh leaf, freshstem,dryleafanddrystem.Thetimeof120minutes havingaoptimumvalueoftheremovalefficiencyandalso dry leaf has higher value than the other adsorbent. The graph it is clear that when time increases the removal efficiency also increases. At last when the contact time increase up to 120 minutes the removal efficiency is optimumanddecreases.

3.3 Effect of pH

The effect of pH was determined by taking 100 ml of solutionofpH5,6,7,8and9 bykeepingotherfactorssuch as adsorbent dosage, initial concentration as constant. Providingtheadsorbentdosageof1.5gramanda contact timeof120minutes.

15 grams of dry leaf powder for one liter of waste water sample.Ithasalengthof2.5cmsochoosingthebeddepth as 2.5 cm .15 grams of dry leaf powder was packed in 2.5 cmheight,30gwerepackedas5cmheightand45gwere packedas7.5cmheight.andefficiencywerecalculatedin various flow rate. The optimum time obtained from the batch study was 120 minutes so here taking the constant. From this the maximum removal efficiency of cadmium from the waste water is about 5cm bed depth at the flow rateof2ml/minandcontacttime120minutes.

3.6 Effect on flow rate

Here three flow rates are considered, 2ml/min, 4ml/min and 6ml/min. when flow rate decreases the removal capacityoftheadsorbentincreases

From this analysis it is clear that removal efficiency increases when flow rate decreases. Figure shows the effect on bed depth of 2.5 cm of flow rate 2ml/min, 4ml/min and 6ml/min and effluent are collect at three different time interval 30min, 60 min, 120 min and 150 minutes.

Chart -3:EffectoncontacttimeforDL,DS,FLandFS

Here the removal efficiency gradually increases when pH varies up to 8 dry leaves. And then gradually deceases FigureshowstheeffectofpHofvariousadsorbentsuchas dry leaf, dry stem, fresh leaf and fresh stem. Dry leaf has higher removal efficiency when pH 8. The efficiency gradually increases when pH increases. The optimum value shows in pH-8 in adsorbents. The variation in pH shows a gradually increases in the value of removal capacity of adsorbent from the waste water. The dry leaf hasthehighestof71.25%atpH8anddeceasesto65.48% atpH9.

3. 5 Effect on bed depth

For this experimental setup the bed depth were taken as 2.5 cm, 5 cm and 7.5 cm.1 liter of waste water is pass though the column and head is maintained. Samples was collectedatanintervalof30min,60min,120minand150 min.With a rate of flow of 2ml/min, 4ml/min and 6ml/min. We get the optimum removal efficiency at the adsorbentdosage1.5gramsfor100mlofwatersotaking

Chart -4: Effectonbeddepth2.5cmon2ml,4mland6ml

Herewecanseethattheremovalcapacityincreaseswhen the time increases to 60 minutes and the optimum value obtained at the sample collected at 120 minutes. The maximum removal capacitywas 67.5 at the flow rate of 2 ml/min and decreases when sample tested after 150 minutes. Flow rate on 4ml and 6ml has almost the same removal efficiency when sample tested at 120 minutes is 63%.Anddecreasesto60%whentestedat150minutes.

The removal efficiency of water sample at three different flowratesuchas2ml/min,4ml/minand6ml/min.onbed depth of 7.5 cm. The removal efficiency increases when flowdeceases. Theoptimumvalueisat 2ml/min havinga removal capacity of 69.3% when is at 120 minutes, and thendecreasesgradually.

min,120 min and 150 min. and pH varies 5-9 . And taken different adsorbents as dry leaf, dry stem, fresh leaf and freshstem.Thepercentageremovalefficiencyofthefresh adsorbents gives about 60%. The maximum removal efficiency was obtained in dry leaf as 73% at 1.5 g of adsorbentin120mintscontacttimeinbatchstudy.

Columnexperimentswasperformedusing5.5cmdiameter and 35 cm height pipe is used for the experiments. In column study taking two parameters such as bed depth and flow rate. In the previous batch study we get the optimum removal efficiency for 100 ml of sample is 1.5grams of dry leaf as adsorbent Dry leaf which is grounded is taken for the study. Choosing three different bed depth as 2.5cm, 5 cm and 7.5 cm and three different flow as 2 ml/min, 4ml/min and 6ml/min.15 grams of dry leaf powder is taken for one liter of water. Removal efficiency is 67.5% at the flow rate of 2ml/min, 63.1 % at the flow rate of 4ml/min and 63% at the flow rate 6ml/min at the bed depth of 2.5cm bed depth. Removal efficiencyat5cmbeddepthis69.35%at2ml/min,67.5% at 4ml/min and 67.1% at 6ml/min as flow rate. And the removalefficiencyat7.5cmbeddepthis68.3%attheflow rate of 2ml/min, 66.8% at the flow rate of 4ml/min and 67.8%attheflowrateof6ml/min.Themaximumremoval efficiencyobtainedinthecolumnexperimentsis69.3%at abeddepthof5cmofflowrate2ml/min.

Here we can conclude that cilantro plant has about 60% of removal efficiency of cadmium from the waste water Thecilantroplantcanusedasaorganicadsorbentforthe removal of cadmium from the waste water is naturally occurring material easily available is possesses some medicalvalueandmoreoverwithhighcadmiumremoval.

REFERENCES

The removal efficiency of water sample at three different flowratessuchas2ml/min,4ml/minand6ml/min.onbed depth of 7.5 cm. The removal efficiency increases when flowdeceases. Theoptimumvalueisat 2ml/min havinga removal capacity of 68.3% when is at 120 minutes, and then decreases to 65 % gradually. The optimum value is obtained at5cm bed depth on2 ml/min.Inthis studythe removalefficiencyobtainedfrom58to69%.

4. CONCLUSIONS

This study leads to prove the removal efficiency of the cilantroplantwithdifferentadsorbentspreparedfromthe plant and the optimum value obtained from the dry leaf. Study conducted with a batch study and column study. In batchconsideredparameterssuchasadsorbentdosageas 0.5g, 1.5g, 2g and 2.5g. Contact time as 30min,60 min, 90

[1] Bhattacharjee, A., and Ahmaruzzaman, M. (2015). Facile synthesis of SnO2 quantum dots and its photocatalytic activity in the degradation of eosin Y dye: A green approach. Materials Letters, 139, 418421.

[2] Chaturvedi, D and Sahu, O. (2014). Adsorption of Heavy Metal Ions from Wastewater.Global Journal of Environmental Science and Technology, 2(3), 020-028.

[3] Chaturvedi, D and Sahu, O. (2014). Adsorption of Heavy Metal Ions from Wastewater.Global Journal of EnvironmentalScienceandTechnology

[4] Dessalew. B and Yonas. S (2017). Assessment of the physicochemical and heavy metal concentration from effluentsofpaintindustryinAddisAbaba,Ethiopia

[5] Dey, B. K., Hashim, M. A., Hasan, S., and Gupta, B. S. (2004). Microfiltration of water-based paint effluents. AdvancesinEnvironmentalResearch

[6] Dursun,D.,andSengul,F.(2006).Wasteminimization study in a solvent-based paint manufacturing plant. Resources,conservationandrecycling

[7] Fomina, M., and Gadd, G. M. (2014). Biosorption: current perspectives on concept, definition and application.Bioresourcetechnology

[8] Gezahegn. L. (2013). Chemical fractionation of selected metals in the soil of waste disposal sites of Dire Dawa Textile Factory and their contents in the sweet potato Leaves. MSc. Graduate research project, HaramayaUniversity,Haramaya,

[9] Gupta,V.K.,andRastogi,A.(2008).Biosorptionoflead from aqueous solutions by green algae Spirogyra species: kinetics and equilibrium studies. Journal of HazardousMaterials

[10] Khatoon,H.,andRai,J.P.N.(2016).AgriculturalWaste Materials As Biosorbents For The Removal Of Heavy Metals And Synthetic Dyes-A Review. Octal Journal of EnvironmentalResearch