FABRICATION AND ANALYSIS OF SELF CHARGING ELECTRIC CAR

1Assistant Professor, Mechanical Engineering Department, School of Management Sciences Lucknow, Uttar Pradesh, India

2B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

3B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

4B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

5B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

6B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India ***

Abstract - Electric vehicles (EVs) have emerged as a promising alternative to gasoline-powered vehicles, owing to their environmental friendliness and lower operating costs. However, one of the major challenges faced by EV owners is the need for frequent charging, which limits their range and convenience. In recent years, self-charging electric cars have been developed as a potential solution to this problem, which can help to extend the range of EVs and reduce the dependency on external charging infrastructure.

This research paper explores the concept of self-charging electric cars, their working principles, and potential benefits for sustainable transportation. The paper also provides an overview of various self-charging technologies, such as solar panels, regenerative braking, and thermoelectric generators, which can be integrated into EVs to generate electricity on-the-go. The paper analyzes the feasibility and limitations of self-charging electric cars, and presents case studies of successful self-charging EV models. Additionally, the paper examines the potential environmental and economic impacts of self-charging EVs, such as reduced greenhouse gas emissions and lower cost of ownership. The findings of this research paper suggest that self-charging electric cars have the potential to revolutionize the EV market and significantly contribute towards sustainable transportation. However, further research and development are needed to improve the efficiency and reliability of selfcharging technologies and to address their limitations

Key Words: Electric Car, Self charging, EVs, Charging technologies, Solar panels etc

1. INTRODUCTION

The growing concern over climate change and the depletion of fossil fuel resources has driven the world towards sustainable transportation solutions, and electric vehicles (EVs) have emerged asa promisingalternativeto gasoline-powered vehicles. EVs offer several benefits such as lower carbon emissions, reduced noise pollution, and lower operating costs. However, one of the major

challenges faced by EV owners is the need for frequent charging, which limits their range and convenience. To overcome this limitation, self-charging electric cars have beendevelopedasapotentialsolution,whichcangenerate electricity on-the-go and reduce the dependency on externalcharginginfrastructure.Self-chargingtechnologies such as solar panels, regenerative braking, and thermoelectric generators can be integrated into EVs to generateelectricityfromrenewablesourcesandprovidea continuoussupplyofenergy.

This research paper aims to explore the concept of selfcharging electric cars, their working principles, and potential benefits for sustainable transportation. The paper will analyze the feasibility and limitations of selfcharging technologies and provide an overview of successful self-charging EV models. The paper will also examine the potential environmental and economic impacts of self-charging EVs and their contribution towards achieving sustainable transportation. The findings of this research paper will provide insights into thepotential ofself-chargingelectriccarstorevolutionize the EV market and contribute towards sustainable transportation

2. LITERATURE REVIEW

1) Kannan Shrinivasa Using two auxiliary power sources, Jeyakanthan, Sudharshan (2017) "Design and Fabrication Of Self-Charging Electric Vehicle" has created a selfcharging electric vehicle that produces the electricity needed to power it while it is operating. Two power sourcesareusedbythecar:ahorizontalwindmillsituated infrontofitandadynamothatisdirectlyconnectedtothe driving motor. A current regulator is used to control the power source so that the battery can be charged concurrently.

2)SuhasV,SukeerthCalastawad,PhaneeshM,andSwarajS (2015) "Performance Of A Battery Electric Vehicle With Self Charging Capacity For Its Own Propulsion" In this

work, they designed and built a selfchargingsystem for2 passengers and for weight up to 250 kg. They created an electricvehiclesimilartoreadilyavailablegolfcartsonthe market.

3) "Constant Electricity Generation From Self Charging Inverter" by Abatan O.A., Adewale A.O., and Alibi A.A. (2008)focusesontheselfcharginginverter,acheap,silent, emission-free,anduninterruptedalternativesource.

4) "Battery Electric Vehicles Performance, CO2 Emissions, Lifecycle Costs And Advanced Battery Technology Development"byDaanBakker(August2010).

3. PRESENT WORK

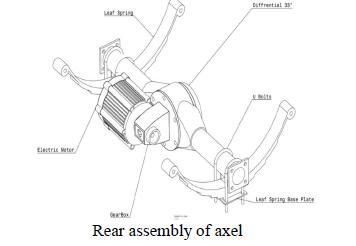

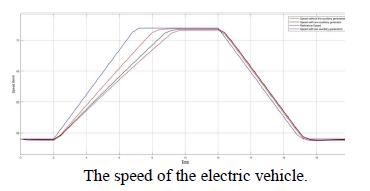

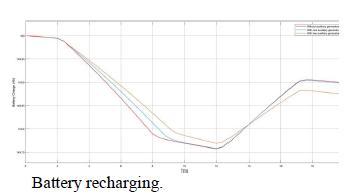

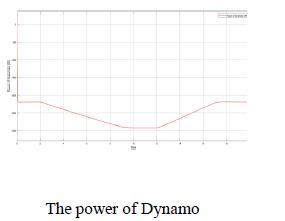

In our project, we utilized a 1000 watt dual shaft 48v DC motor. One of the shafts provides power to the back wheels while the other is connected to a dynamo via belt drive. The dynamo's output is directly linked to five 12v, 35Ahbatteries,whichareconnectedtoacontrollerrated at 48v - 72v. This controller governs all of the car's operations. With the use of five batteries, the car's speed canreachupto60kmphwithoutthedynamoand50kmph whenthedynamoisconnected.Thecarcanaccommodate four people under full load conditions. All of the componentshave beenassembled,and thecaris ready to move;onlysomefinishingworkremainstobecompleted

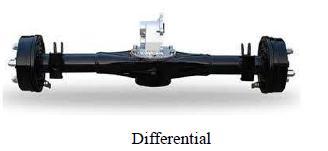

3.1. DIFFERENTIAL

AsoliddifferentialmakesuptheE-rickshawmodelthatis being proposed. The E-rickshaw's back axle is coupled to this differential. Heavy loads can be supported by this disparity. The differential supports the car in a variety of drivingcircumstancesandeasilyaccomodatesroadsways. Thevehicle'sabilitytoturnwithoutskiddingisduetothe differential. The motor uses the power produced by the batteries. The differential receives this power from the engine, which then divides it effectively into equal amountsandsendsittothewheels.

whenever it enters a magnetic field; this is the fundamentaloperationofaDCmotor.

3.2. A DC- An electrical device known as a DC motor transforms electrical energy into mechanical energy. A current-carrying wire encounters a mechanical force

Astraightforwardtypeofspringfrequentlyutilizedforthe suspension in wheeled vehicles is the leaf spring. One of theearliesttypesofvehiclesuspensionisthelaminatedor carriage spring, also known as a semi-elliptical spring, ellipticalspring,orcartspring.Aleafspringismadeupof one or more thin, arc-shaped, narrow plates that are fastenedtotheaxleandchassissotheycanbendvertically in reaction to imperfections in the road surface. Although transverse leaf springs are also widely employed, lateral leafspringsaremorefrequentlyusedastheytraversethe lengthofthevehicleandareinstalledperpendiculartothe wheelaxle.

Themostpopularbatterytypeinsolarsystemsisthelead acid battery. In contrast to other battery types, lead acid

batterieshavealonglifespanandinexpensivecostdespite having a low energy density, only modest efficiency, and high maintenance needs. Because lead acid batteries are the most often used type of battery for the majority of rechargeable battery applications (such as starting automobileengines),theyhaveawell-established,mature technology basis. This is one of the main benefits of lead acidbatteries.

alternator currently predominates in large-scale power generation.

Oneofthekeyelementsofabattery-poweredvehiclethat controls its overall operation is a controller. This controller is responsible for drawing electricity from the batteryandsupplyingittotheelectricdrivemotor.

The automotive steering column is a piece of equipment designed primarily to transmit the driver's input torque fromthesteeringwheeltothesteeringmechanism.

Originally another name for an electrical generator, dynamo (from the Greek word dynamis; meaning power) mainly refers to a generator that produces direct current by using a commutator. The rotary converter, electric motor, alternating-current alternator, and other later electric-power conversion devices were all based on dynamos, which were the first electrical generators capable of supplying power for industry. Because of its efficiency, dependability, and low cost, the simpler

Thecontrollerreceivesasignalfromtheacceleratorpedal and changes the frequency of the AC power from the inverter to the motor to change the speed of the vehicle. Through a cog, the motor is connected to and rotates the wheels.

3.9. SPEEDOMETER

A speedometer, often known as a speed meter, is a gauge that calculates and shows the current speed of a moving object.Theybegantobeofferedaschoicesintheearly20th century and became standard equipment starting around 1910. Today, they are fitted to all motor vehicles. Other vehicles may utilize speedometer-like instruments with other methods of measuring speed, such as pit logs for boatsandairspeedindicatorsforaircraft.

occurs. The mechanical latch, which is a part of this system's mechanism, provides the signal and enables it to stopthecircuitflow.

Anelectricswitchthathasfourterminalscapableofbeing connected in pairs in two different ways so as to reverse thedirectionofcurrentflow

4. CALCULATION

Area=Length*Width

A=1.67m2

TotalweightofVehicle=180kg

Weightofmotorandgenerator=10kg

Weightofchassis=60kg

WeightinNewton=180*9.81=1765.8N

WeightofBattery=40kg

4.1. Calculation of rolling Resistance

Whenasystemfault,suchasanoverloadcondition,occurs, the MCB shuts down the entire electrical circuit. Mechanical latches are the components of MCB bimetallic stripsthatassistinswitchingthecircuitwhenanoverload occurs because the bimetallic strip moves and comes into contact with the mechanical latches when deflection

Rollingresistance, RR=weightofVehicle*coefficientofRR, RRinConcretefair=0.015

Grossvehicleweightis180kg=1765.8N

RR=1765.8*0.015RR=26.487N

4.2.

Graderesistance=Grossvehicleweight*sinθ

GradeofinclinationAngleθ=0Degree(sincethe surfaceisflat)

GR=1765.8*sin(0)

GR=0N

4.3.

FA=m*a

m=Grossvehicleweight/g

FA=AccelerationForce

m=massofthevehicle

g=AccelerationduetoGravity(9.81m/sec2)

a=RequiredAcceleration

m=1765.8/9.81

m=180kg

a=finalvelocity-initialvelocity/time

finalvelocity40kmph=11.11m/sec

Initialvelocity=0m/s

Time=60sec

a=(11.11-0)/60

a=0.1851m/sec2

FA=180*0.1851

FA=33.31N

4.4.

TTE=RollingResistance+Graderesistance+ AccelerationForce

TTE=26.48+0+33.31TTE=59.79N

4.5. Calculation to Torque Required on the drive wheel

Torque=Rf*TTE*r(wheel)

Rf=FrictionalResistance=0.7

R(wheel)=Radiusofthedrivewheel=0.18m

Torque=0.7*59.79*0.18

Torque=20Nm

5.

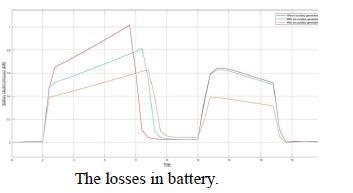

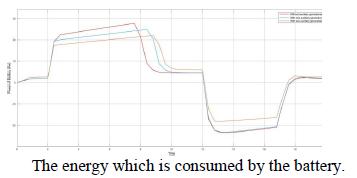

Electrical and mechanical energy are converted by chemicalenergy,andelectricalenergyisthenconvertedby

mechanical energyonceagain.Byapplyinga fewtechnical principles, we can convert kinetic energy into electrical energy.Finally,dynamosgenerateelectricity,whichisthen stored in batteries. The dynamo's output voltage is 24 volts.

In conclusion, the development of self-charging electriccarshasthepotentialtorevolutionizethe EV market and contribute significantly towards sustainable transportation. Self-charging technologies such as solar panels, regenerative braking, and thermoelectric generators can provide a continuous supply of energy, reducing the dependency on external charging infrastructureandextendingtherangeofEVs.

Thisresearchpaperhasprovidedinsightsintothe concept of self-charging electric cars, their working principles, and potential benefits for sustainable transportation. The paper has analyzed the feasibility and limitations of selfcharging technologies, provided an overview of successfulself-chargingEVmodels,andexamined the potential environmental and economic impactsofself-chargingEVs.

The findings of this research paper suggest that self-charging electric cars have the potential to significantly reduce carbon emissions, lower the costofownership,andprovideamoreconvenient and sustainable transportation option. However, further research and development are needed to improve the efficiency and reliability of selfcharging technologies and address their limitations.

In conclusion, the adoption of self-charging electric cars can contribute to the transition towards a more sustainable transportation system, providing several environmental, social, and economic benefits. This research is crucial in guiding policymakers, manufacturers, and consumers towards making informed decisions about the adoption of self-charging EVs and

driving the transition towards a sustainable future.

7. FUTURE SCOPE

The future scope of self-charging electric cars includes advancements in technology, integration with smart grid technology, expansion of charging infrastructure, collaboration between manufacturers, and adoption by fleets, all of which can contribute towards a more sustainabletransportationsystem

REFERENCES

[1]K.Vignesh,P.Sakthi,A.Pugazhenthi,V.Karthikeyan,C. Vinothkumar (2015), Free Energy Bicycle’, International journal of Innovative science Engineering & Technology, Vol.2Issue4,April2015.

[2] Prof. Kuseker S.K (Guide), Bandgar P.M , Andhale P.S, Adlinge G.H, Gaikawad V.V, Dhekale S.P (2015), ‘Design And Development of Electrical Car’, International journal ofEmergingTechnologyandAdvancedEngineering,Vol.5, Issue4,April2015.

[3] Awash Tekle (2014), ‘Renewable Energy Use for Continuous Electric Vehicles Battery Charging Capacity in Mobile’,InnovativeSystemsDesignandEngineering,Vol.5, Issue10,2014.

[4] Patel Vijaykumar V, Prof. R.I. Patel (2012), ‘Structural Analysis of Automotive Chassis Frame and Design Modification for Weight Reduction’, International journal of scientific & Technology Research, Vol. 1, Issue 3, May 2012.

[5]T.AllenPrasad,Lokesh Ramesh(2012),‘Powering the Electric Cars with Dynamos’, IOSR Journal of Mechanical andCivilEngineering,Vol.3,Issue2,September2012.

[6] S.M Ferdous, Walid Bin Khaled, Benzoir Ahmed, Sayedus Salehin, Enaiyat Ghani Ovy (2011), ‘Electric Vehicle With Charging Facility in Motion using Wind Energy’,WorldRenewableEnergyCongress2011-Sweden.

[7] A text book of ‘Automobile Engineering’ by Dr. Kirpal Singh.

[8] Saurabh Chauhan (2015), ‘Motor Torque Calculations For Electric Vehicle’, International journal of scientific & TechnologyResearch,Vol.4,Issue08,August2015.

[9]V.M.Prajapati,K.H.Thakkar(2015),‘Determinationof Energy produced by Wind Mill on Running vehicle’, International journal of Engineering Research and Applications, Vol. 3, Issue 1, January-February 2013, pp.106-110

[10]D.Cundev, Z.Cerovsky,P.Mindl (2009),‘Modeling of the Hybrid Electric Drive with an Electric Power Splitter and Simulation of the Fuel Efficiency’, EPE2009 13th European Conference on Power Electronics and Application,Barcelona,Spain,Sep2009.