Fabrication of Foot Operated Paper Plate Making Machine

PANKAJ KUMAR YADAV1 , AKASH KUMAR SINGH2, ADARSH SINGH3, ANURAG KUSHWAHA4, UDIT NARAYAN SINGH5

1Assistant Professor, Mechanical Engineering Department, School of Management Sciences Lucknow, Uttar Pradesh, India

2B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

3B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

4B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India

5B.Tech Mechanical Engineering Scholar, School of Management Sciences Lucknow, Uttar Pradesh, India ***

Abstract- A paper plate is a plate made of paper that is frequently lined with plastic to stop liquid from seeping through the paper or leaking out. Kraft paper is the type of paper used to make paper plates. This Kraft has a tiny layer of silver film applied to it. The paper is then coiled on a roller after passing through a series of rolling processes. Then it is cut to the necessary measurements, in this case 14x28 inches. The press machine is then given this paper with the necessary dimensions to give the plate the proper form. Our goal is to automate the laborious processes involved in removing the coated paper roller, cutting it to the necessary dimensions, and then transferring it to the press machine. The goal of this project is to automate the aforementioned function of the manually operated paper plate maker that is located at "School of Management Sciences Lucknow."

Keywords-Paper plates, Kraft, rolling silver film, press machine, automation.

1. INTRODUCTION

In home settings, paper plates are frequently used in place of metal plates. The fact that these plates can be thrown away makes them helpful. These plates can be producedforverylittlemoney.Makingplasticplatesisa tiny business that may be easily financed with the least amountofcapital.

1.1. Press machines:

A press machine is a type of machine tool that uses pressuretoaltertheshapeofaworkpiece.

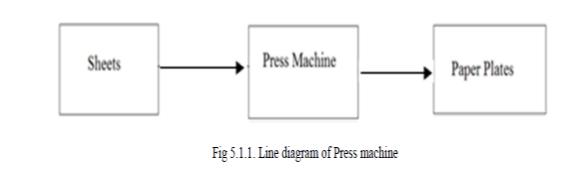

The line diagram of the press machine used in our industryisshownintheimagebelow.

Therearedifferenttypesofpressmachines

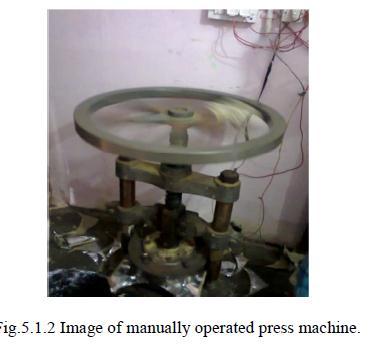

i)Manuallyoperatedpressmachine:

One person is needed to operate this machine. Figure depictsamanuallyoperatedpressmachinewithawheel that must be rotated by one person in order to apply pressure to the sheets in order to produce paper plates. Onetonofpressureisneededtohandpresstensheets.

1.2. Types of Paper Cutters:

1.2.1. RotaryPapercutters:

Inrotarypapercutters,the cuttingheadissomekind of circularblade,sometimesjustaplainrazorblade.Paper isslicedbyacuttingheadthatslidesbackandforthona track. Rotary paper cutters are well renowned for their utmostaccuracyandarewidelyusedtocutphotographs.

1.2.2 Guillotine paper cutters are excellent multipurpose tools. They are also known as arm or lever cutters.

Inmostcases,theyhaveacuttingbladeandalongblade armthatcanbeloweredtocutmaterial.

These cutters can be used to cut paper, card stock, and othermaterials,andtheyaretypicallyhighlyaccurate.

1.2.3.StackPaperCutters:

Papercuttersthatcancuthundredsofsheetsofpaperat once are known as stack paper cutters, and they are monstrous machines. In print shops, these cutters are frequentlyusedtotrimprints andothermaterials.They are also widely used to cut larger sheets of paper into paper of a specific size. Stack cutters have a wide range of industrial and commercial applications. Typically, these are offered in manual, semi-automatic, and fully automaticversions.

1.2.4 Hydraulic paper cutters are arguably the strongestandmostdurablepapercuttersonthemarket. Thesecuttersareprimarilyusedforhigh-volumecutting throughoutthedayandhaveastackpapercutterdesign. Thesearefrequentlyutilizedin factories, print facilities, papermills,andotherestablishmentsthatdealwithtens ofthousandsofsheetsofpaperperday.

1.2.5. Corner Cutters: To remove sharp edges from paper, use corner counters, also known as corner rounders. These practical devices can frequently round the corners of a stack of paper that contains more than 100 sheets at once. There are typically several various radiussizesavailable.

Formcutters,alsoknownaspaperslitters,aremachines that automatically feed paper and slit it to the desired size.

Inadditiontoslitting,many formcuttersalsogiveusers the option of scoring and perforating. These kinds of equipmentareexcellentforcreatingmarketingmaterials andcanfrequentlyperformmultiplecutsatonce.

2. LITERATURE REVIEW

Initially, the goal of the development of disposable food service goods was to improve industry procedures and hence, public health. The idea of PAPER PLATES was bornasa resultofthisdemand,theenvironmental peril that we were facing at the turn of the 20th century, and the necessity of making significant environmental conservationefforts.

When opposed to plates made of other materials, employing paper plates has a number of intrinsic advantages.

Apaper plateisa plate madeof paperthatisfrequently linedwithplastictostopliquidfromseepingthroughthe paperorleakingout.Kraftisthenameofthebasepaper used for paper plates. This Kraft has a small layer of silverfilmcoveringit.Thepaperisthencoiledonaroller after passing through a series of rolling processes. Then it is cut to the necessary measurements, in this case 14x28inches.Thepressmachineisthengiventhispaper with the necessary dimensions to give the plate the properform.Manual labor isusedtoremove the coated paper from the roller, cut it to the proper dimensions, and transfer it to the press machine. The goal of this project is to automate the aforementioned function of themanuallyoperatedpaperplatemakerthatislocated at"SchoolofManagementSciencesLucknow."

Foodisservedondisposableplatessincetheyaresimple to use and dispose of. In the past, India utilized disposable plates made of leaves. In various states, several plant species have been employed to make plates. But paper and expanded polystyrene (foam) plates make up the majority of the disposable plate market today. Areca (Areca catechu), Siali (Bauhiniavahlii), and Sal (Shorearobusta) are the three varietiesofleafplatesthatwereexamined.Thepurchase ofrawmaterialsandlaborcosts accountsformorethan halfofthecostofmakingleafplates.Thisshowsthatthe manufacturingofleafplatesisalabor-intensiveindustry that generates jobs in rural areas. Paper plates (Rs 0.5/plate)andarecaplates(Rs7/plate)havethehighest and lowest market prices, respectively. The production of Sal and Siali plates used about the same amount of energy as the production of paper plates, whereas the production of Areca leaf plates used the most energy. Nowadays,polythenesheetsareinsertedinSalandSiali plates. Therefore, when examining the designs that are currently on the market, it wasdiscovered that the only entirely biodegradable disposable plates were noncoatedpaperplatesandArecaleafplates.

Apaper plateisa plate madeof paperthatisfrequently linedwithplastictostopliquidfromseepingthroughthe paperorleakingout.Kraftisthenameofthebasepaper

used for paper plates. This Kraft has a small layer of silverfilmcoveringit.Thepaperisthencoiledonaroller after passing through a series of rolling processes. Then it is cut to the necessary measurements, in this case 14x28inches.Thepressmachineisthengiventhispaper with the necessary dimensions to give the plate the proper form. the steps involved in removing the coated paper roller, cutting it to the appropriate dimensions, andthentransferringittothepressmachine.

"Excellent Paper Plate Engineering Company" was foundedin1972andspecializesinproducing,supplying, and exporting Paper Plate Making Machine & Dies. Offering Paper Plate Machines, Paper Plate Making Machinery, Paper Plate Making Raw Materials, Paper ThaliMakingDies,andCoreThaliinthisfieldofwork.

2.1. Operating Theory:

Apaper plateisa plate madeof paperthatisfrequently linedwithplastictostopliquidfromseepingthroughthe paperorleaking out. In Indianvillages, paper platesare typicallymanufactured byhand;our goal istoautomate this time-consuming process and produce elegantly shaped paper plates. Kraft paper is the type of paper usedto make paperplates. ThisKrafthasa tiny layer of silver film applied to it. The paper is then coiled on a rollerafterpassingthroughaseriesofrollingprocesses. It is then cut to the necessary dimensions. The press machine is then given this paper with the necessary dimensions to give the plate the proper form. Manual laborisusedtoremovethecoatedpaperfromtheroller, cut it to the proper dimensions, and transfer it to the pressmachine.

Instead of using a manual, labor-intensive craft, this project work uses a mechanically operated machine to makepaperplates.Thesearereasonablypriced,takeup lesstime,andoffergooddimensionalstability.

A foot-operated controller for discrete inputs to a machine to be controlled is described. It consists of a base,afoot-receivingmemberforreceivingauser'sfoot, which is movably secured to the base according to at least one degree of freedom and extends substantially within a plane, and at least two switches, each of which is located at a different location between the base and the foot-receiving member and each of which can be activatedupon.

2. SELECTION & DESIGN CRITERIA

Generalrequirementsofmachinedesign:-

Simplicityofdesign

Safetyandeasytocontrol

Lowcost

Lightweight

Compactinsize

3. DESIGN PROCEDURE

It is important to understand the project design before moving on to the production process. Before beginning production,itiscrucialtodesigntheprojecttoavoidany negativeimpacts;thefinishedproductcontainsof

Productdesign;

Functionaldesign

Technicaldesign

3.1 Design procedure for a product:

Adesignermaytakethefollowingstepswhencreatinga newproductoritscomponents:

Create a thorough description of the issue; it should be as clear as possible. Include information about the machine'sintendeduse.

Choose a potential mechanism that will move thedesiredobject.

Calculate the energy delivered and the forces operatingoneachcomponentofthemachine.

Choosethematerialthatfitseachcomponentof themachinethebest.

Calculatethepermissibleordesignstresstaking into account all the elements that have an impactonthemachinepart'sstrength.

Definethemachine'ssignificance,necessity,and use.

Issues with the demand and productivity of the machineasitisnowused.

Determinethedimensionsofeachcomponentin order to avoid excessive deformation or breakageowingtotheappliedload.

Modify the machine part(s) to facilitate manufacture and to be consistent with prior experienceandjudgment.

Make assembly and detail drawings of the machine with detailed material and manufacturing procedure specifications, includingaccuracy,surfacequality,etc.

3.2. ADVANTAGES

This product can be used in place of plastic platesandmugs.

Aproductthatdecomposesquickly.

Theuseofmorereadilyavailableandaffordable materials.

Eco-friendlygoods.

Rapidresponseisaccomplished

Thedesignisuncomplicated.

Simpletomaintainandfix.

Theunitcostsless.

Overloadingpresentsnofirethreat.

Thecostofoperatingislowerincomparison.

It is possible to operate continuously without pausing.

Itlessensmanuallabor.

Itcutsdownonproductiontime.

Takesuplessroomonthefloor.

Alessexperiencedoperatorisadequate

3.3. DISADVANTAGES

Itaddsmoremanuallabor.

Nohightorquemaybeachieved.

Highinitialcost.

Thelengthierproductionperiod

3.3. Where it can be used / it’s Application

Restaurants,hawkerswhosellfoodproductsontheside oftheroad,caterers(whoarehiredtoprovidemealsfor weddings and celebrations) who utilize paper plates, cups, and glasses, and manufacturers of ornamental thingsthatusepaperplates,Householduses.

3.4. MAIN COMPONENTS

Punch

Die

Bottomplate

TopPlate

Rod

3.5. MATERIAL USED:-

3.5.1. MILD STEEL: -

Reasons:-

Mildsteeliswidelyaccessibleinthemarket.

It comes in common sizes and is affordable to use.

It has outstanding mechanical characteristics, makingitsimpletomachine.

It has a moderate factor of safety since a high factor of safety leads to excessive selection and unnecessary material waste. Low safety factor leadstounnecessaryfailurerisk.

Ithasahightensilestrengthandasmallthermal expansioncoefficient.

Properties of Mild Steel:

M.S. contains 0.15% to 0.30% carbon. They can only be toughened because they can be easily welded. With regard to characteristics, they resemble wrought iron. With increasing carbon content, these steels' ultimate tensile and compressive strengths rise. They are easily arc, electric, or gas welded. Welding ability reduces as carbon content rises. Mild steel serves the function, henceitwaschosenfortheaforementionedreason.

3.5.2. BRIGHT MATERIAL:

It is a drowned machine. Mild steel plates and bars are forgedintheforgingmachineusingaprocessthatisnot forged, which is the primary fundamental difference between mild steel and brilliant metal. However, the materialsaretakenfromthedieswhilestillbeingplastic. For extrusion and creation of engineering materials, the materialhasagoodsurfacefinishcomparedtomildsteel and has no carbon deposits on its surface, giving such materials a good surface finish and preserving their metallicqualities.

3.5.3. LIST OF COMPONENT

3.5.4. MANUFACTURING PROCESS

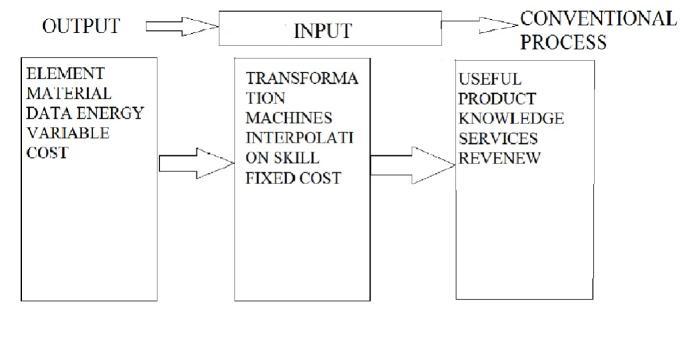

The procedure of turning raw materials into finished goods employing the three resources of people, machines,andfinishedcomponents.

Manufacturing refers to the process of transforming resources into useful items and services. Manufacturing is another term for the deliberate act of creating something useful. Below is a diagram of the transformationprocedure.

Itcomesafterthedesignphase.Hence,referencingthose idealsthatweintendtouphold thedifferentprocedures usethefollowingdevices:-

Power saws, drills, universal lathes, milling machines, grindingmachines,andelectricarcweldingequipment.

3.5.5. FABRICATION AND OPERATION SHEET:-

NAMEOFTHEPART:- PUNCH

MATERIAL :- MILDSTEEL

QUANTITY :- 1

FABRICATIONANDOPERATIONSHEET:-

NAMEOFTHEPART:- PUNCH

MATERIAL :- MILDSTEEL

QUANTITY :- 1

NAMEOFTHEPART:- PUNCH

MATERIAL :- MILDSTEEL

QUANTITY :- 1

Table 03- Punch sheet table

SR. NO. DETAIL OPER. M/C. USED TOOL USED ACCES MEA.INST.

1. Marking onrod - - - Scale

2. Cutting as per drawing

3. Facing bothside ofshaft

4. Turning as per drawing size

5. Filling on both end

Power hacksaw Hack saw blade

Lathe machine Single point cutting tool

Jig & fixture Scale

Chuck Vernier

- - - -

Flatfile Vice -

COMPONENT:-FRAME

MATERIAL:-MILDSTEELANGLE

QUANTITY:-1

Table 04- Frame table

SR. NO. DESCRIPTION OF OPERATION MACHIN EUSED CUTTIN G MEASURE MENT

1. Cutting the angle in to length as per dwg

2. Cutting the angle in to number of piece asperdwg

3. Filing operation can be performed on cutting side and bring it in perpendicularC.S.

4. Weld the angles to the required size as perthedrawing

5. Drillingtheframeat required points as perthedrawing

Gas cutting machine

Gas cutting machine

Gas cutter Steelrule

Gas cutter Steelrule

Bench vice File Trysquare

Electric arc welding machine

Radial drill machine

Trysquare

Twist drill Vernier calliper

4. RESULT ANALYSIS

Table05displaysthebowl'sdevelopmentafterapplying variouspedalforces.Therefore,itcanbeshownfromthe calculations above that bowls can form more effectively when moderate pressure is applied. The quality of the bowl improves as the pressure rises, but beyond a certainpoint,strongforcewillcausecrackstoappearin the bowl. The outcome is attained at the heating coil's 150°C

Table 05: Result Analysis

The project involves working with mechanical devices. Theprojectconfigurationis supported bya rectangularshaped frame. This pedal is located in the middle of the frame and is attached to the shaft by a spring-loaded crank slider mechanism. One fixed die that is fixed at a movablediemakesupthediepair,whichisattachedon theshaftbyarectangularplate.

Aswepressthepedal,pressureisappliedtoit,andasa result,thecrankslidermechanism,whichhasaV-shaped shaftwithloweranduppershaftsthatmoveupwardand downward respectively, attaches a movable die to the fixed die and shapes the product as the upper shaft movesupwardduetothespringextension.

The majority of the components of our machine are separate, making part replacement simple. In addition, another type of die may be used in place of the bowl's die. The hydraulic or pneumatic system might take the roleofthemanualsystem.

5. CONCLUSIONS

With the equipment at hand, paper plates may be produced quickly. Hydraulic press machines often need torunataveryhighspeedformanufacturing.However, the issue is that they are only employed to produce one or two plates at once, which indicates a lower manufacturing rate. By concurrently punching a lot of sheets in a single pass, there may be a chance of increasingoutputpace.

REFERENCES

1] C.T. McCarthy , M. Hussey, M.D. Gilchrist, “On the sharpness of straight edge blades in cutting soft solids: Part I – indentation experiments”, International Journal of Engineering Fracture Mechanics74 (2007) 2205

2224.

2] C.T. McCarthy , A. Ní Annaidh, M.D. Gilchrist, “On the sharpness of straight edge blades in cutting soft solids: Part II – Analysis of blade geometry”, International Journal of Engineering Fracture Mechanics 77 (2010) 437–451

3] Shirong Zhang, Xiaohua Xia, “Optimal control of operation efficiency of belt conveyor systems”, Journal Applied Energy, Volume 87, Issue 6, June 2010, Pages 1929-1937.

4]V.P.Astakhov,S.V.Shvets,“Asystemconceptinmetal cutting”, Journal of Materials Processing Technology, Volume79,Issues1–3,1July1998,Pages189-199.

5] G.J.A. Bing, J. Wallbank, “The effect of using a sprung stripper in sheet metal cutting”, Journal of Materials Processing Technology, Volume 200, Issues 1–3, 8 May 2008,Pages176-184.