Stress Analysis Of Connecting Rod For Diesel Engine With Different Materials

Dipanker Meena1, Kamal Negi2, Karan Pradhan31,2,3 Dept. of Mechanical Engineering, Delhi Technological University, New Delhi-110042 ***

Abstract - The connecting rod is an important component of an engine assembly as it serves the purpose of transferring energy from the piston to the crankshaft. Its primary function is to convert the linear, back-and-forth motion of the piston into the rotary motion of the crankshaft. The connecting rod primarily undergoes tensile and compressive loading under the cyclic engine process. In this project, Static analysis was done on the connecting rod. Different materials are used for the analysis, like structural steel, titanium, and aluminum alloy. The study was done on several research papers, and after that, critical dimension data of the connecting rod was decided upon. A threedimensional model of the connecting rod and its assembly was created on DS SolidWorks 2019. The model was then imported as a geometry parameter in Ansys 2023 R1 for finding von mises stress, Total Deformation, and safety factor. Then they were compared to choose the best materialamongstthemforthe connectingrod.

Key Words: Connecting Rod, Structural Analysis, Finite ElementAnalysis,Titanium,Steel,42CrMo4.

1. INTRODUCTION

Connecting rods are of utmost importance in the functioning of an internal combustion engine. Their primary role is to convertthe reciprocating motion ofthe piston into rotary motion in the crankshaft, enabling the vehicle's wheels to rotate. Comprising a small end connected to the piston and a big end attached to the crankshaft, the connecting rod experiences various forces during each rotation of the crankshaft. These forces include compression when the piston moves downward and tension when the piston moves upward. Any damage to the connecting rod, such as cracking or buckling, can result in engine immobilization. Such failures lead to substantial financial losses due to material damage and pose significant safety risks, as accidents resulting from these failures can have severe and potentially fatal consequences.

Many materials are used to make connecting rods. Every material has its advantages and disadvantages. They are useddependingontheenginerequirement,thepurposeof

the engine (work type), and other factors that matter in theengine'sworking.

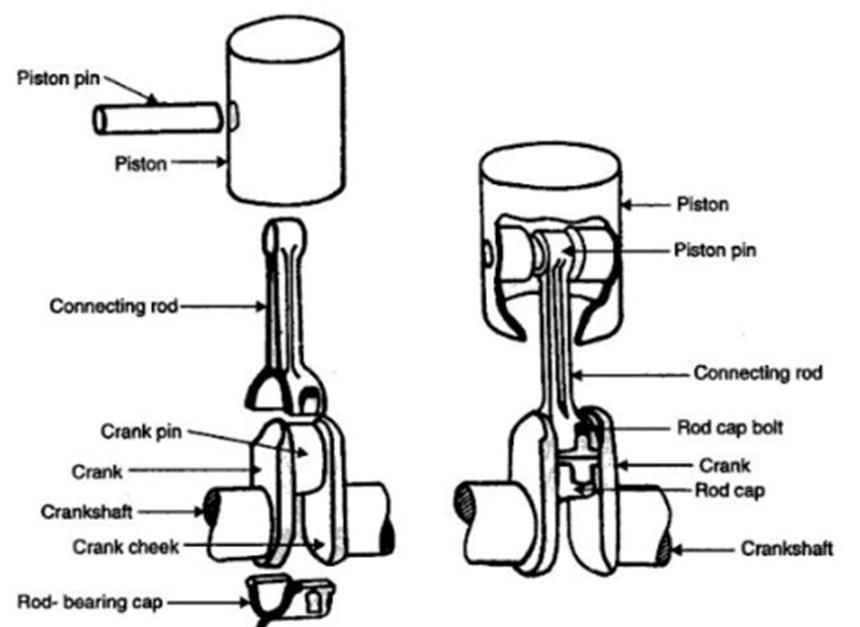

In this research the best material for the connecting rod has been chosen by comparing the von mises stresses, total deformation and factor of safety of different materialsonAnsyssoftware.Theconnectingrodassembly hasbeenshowninFig–1.

1.1 Parts of the Connecting Rod

1.SmallEnd 6.Shank

2.BigEnd 7.Crankshaft

3.Bushbearing 8.Piston

4.BearingInsert9.Bearingcap

5.BoltandNut

2. LITERATURE REVIEW

Comparisonsweremadebetweentwodifferentaluminum alloys and forged steel regarding von Mises stress, total deformation,andfactorofsafety[1].

The optimization of IC engine connecting rods involved the selection of forged steel or C-70, with a focus on size optimizationandmaterialchoice[2][3].

ANSYSsoftwarewasutilizedtoassessparameterslikevon Mises stress, strain, deformation, factor of safety, and weight reduction in two-wheeler pistons, indicating that aluminumalloyexhibitedhigherfactorsofsafety,reduced stress, decreased weight, and greater stiffness compared toforgedsteel[4].

An optimization approach to connecting rods was proposed, involving an increase in torque of the bolt assemblytoreducestressamplitude[5].

Load and stress analysis of connecting rods for weight reductionwasconducted[6].

Optimal designs for connecting rods were analyzed using ANSYS Workbench and CATIA V5R19, resulting in improved outcomes within permissible limits and safe stresses[7].

The design of a two-wheeler connecting rod was carried out analytically, followed by FEA for stress calculations and thermal analysis, leading to a significant reduction in weight[8].

Simulation studies involving SolidWorks and ANSYS were performedtoassessvonMisesstressesandfrequenciesof connectingrodmaterials,aidinginmaterialselection[9].

The strength simulation analysis of a low-speed diesel engine'sconnectingrodwasconductedusingprofessional simulation software, followed by a static strength test usingaservouniversaltestingmachine[10].

3. MATERIALS USED

A variety of materials are utilized in the production of connecting rods which includes different grades of structuralsteel,aluminum,andtitanium.Steelrodsarethe mostcommonlyproducedandemployedduetotheirhigh strength and durability, making them suitable for both daily driving and endurance racing. However, one downsidetousingsteel rodsistheirweight,whichplaces addedstressontherotatingassemblyandconsumesmore power. This study examines the use of alternative materials for connecting rods and conducts an analysis of theirproperties. In this work, the below mentioned materialsweretakenforconnectingrodsimulation.

StructuralSteel, 42CrMo4, T6-7075Aluminum, Ti-6Al-4v, C-70(SAE-AISI1070)Carbonsteel

4. METHODOLOGY

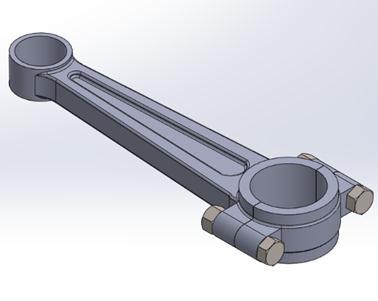

In this research work, a connecting rod was meticulously crafted employing the aid of DS SolidWorks 2019, a sophisticated computer-aided design (CAD) software application renowned for its prowess in generating intricate three-dimensional models of mechanical components, assemblages, and blueprints. Its pervasive adoption by engineers, designers, and manufacturers spanning a spectrum of industries, ranging from automotive and aerospace to consumer goods and industrial machinery, attests to its indispensable nature. This exceptional software offers an extensive array of utilities for the construction of intricate geometries, assemblages,andsimulations,alongwiththegenerationof detailedtechnicaldrawingsandanimatedrepresentations. Capitalizing on a parametric design methodology, this software empowers users to effortlessly manipulate and revise models by effecting modifications to pertinent parametersordimensions.

.The dimensions taken were those, whichare of common useinthe market. Eachof thepartsof theconnectingrod wasmodeledandwasmergedtogetherintheassembly.

Another software that was used for conducting Finite Element Analysis was Ansys Workbench 2023 R1. It is a software commonly used for stress/strain analysis and to determinethefactorofsafetyofaproposedprototype.

The assembly of Solidworks is imported into Ansys as a geometry to perform FEA. Forces were applied on the connectingrodbasedonanumberofresearchtextsand

5. MODELING AND ANALYSIS OF CONNECTING ROD

Solidworks is a comprehensive 3D solid modeling softwarethatprovidesuserswiththeabilitytodesignand analyze models in a virtual environment. It empowers designers, engineers, and professionals to conceptualize ideasandexploredifferentdesignpossibilitiesbycreating accurate and detailed 3D models, assemblies, and drawings. By leveraging the capabilities of Solidworks, users can significantly reduce the time, effort, and expenses associated with physical prototyping. The software offers a streamlined and efficient approach to design, enabling users to visualize and evaluate their designsbeforemovingforwardwithproduction.

simulation technologies in the industry. Its distinctive project schematic view seamlessly connects the entire simulation process, providing guidance to users at each step.WithANSYSWorkbench,evenintricatemulti-physics analyses can be conducted effortlessly using a drag-anddrop approach. The platform facilitates automatic geometry sharing between fluid and structural analyses, streamliningdatastorageandenablingeasyexplorationof the effects of geometry modifications in both analyses. In the research, the Static Structural module of ANSYS was utilized.

5.1 Static Structural Analysis

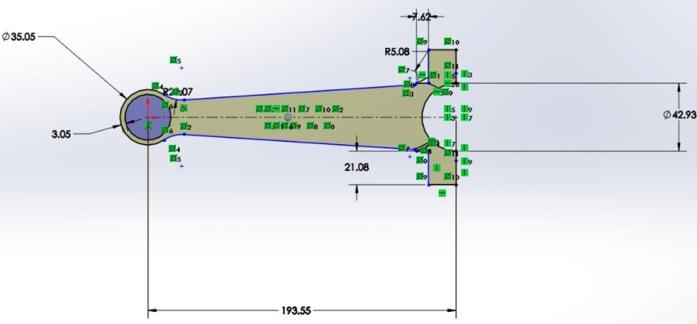

In this research, a connecting rod model was designed in SolidWorks 2019 software. The connecting rod was fabricated with a length of 193.55 mm, diameter of the smallerend,35.05mm,andthediameterofthebiggerend, 42.93mm,showninFig-2.

Connectingrodassemblyincludespistonrod,capend,nut, and bolt. The 3-Dimensional model of the assembly is showninFig-3.

FEA,orFiniteElementAnalysis,isfoundedontheconcept ofdividingagivendomainintoafinitenumberofsmaller regions called elements. By employing the variational or weighted residual method, FEA constructs a systematic approximate solution for these elements. This approach enables the reduction of the original problem, which involves an infinite number of unknowns, into a finite number of unknowns. The division of the domain into elements allows the representation of the unknown field variablethroughassumedapproximatingfunctionswithin eachelement.

ANSYS Workbench serves as the foundation for a comprehensive range of cutting-edge engineering

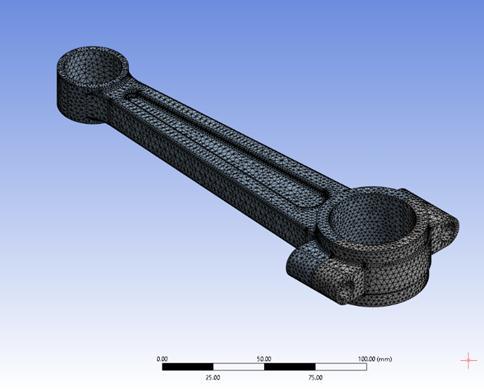

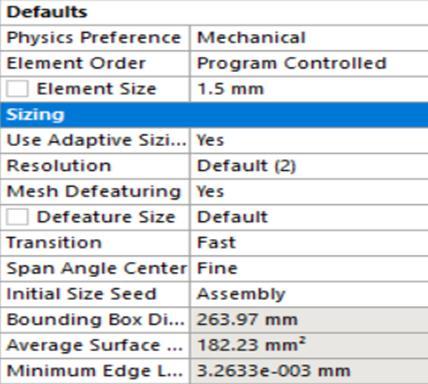

Static analysis involves the meticulous examination of equilibrium conditions exhibited by objects when subjected to external forces. It encompasses both linear andnonlinear approaches, withthelatteraccommodating an extensive array of nonlinear phenomena such as significantdeformations,plasticity,creep,stressstiffening, and contact elements. The current focus pertains specificallytostaticanalysis,acomprehensiveexploration of the effects resulting from sustained loading conditions on a given structure. Notably, this analysis disregards the intricate dynamics introduced by inertia and damping effects inherent in time-varying loads. The primary objective of static analysis lies in the precise determination of essential parameters including displacements, stresses, strains, and forces within structures or components, all of which arise from loads that lack substantial influence from inertia and damping mechanisms. Additionally, the process of meshing, an indispensable aspect of numerical analysis, assumes a significant role. Meshing involves the intricate segmentation of complex geometries or domains into simpler, more manageable elements. This segmentation facilitates enhanced analytical techniques and contributes substantially to the accuracy and efficiency of the overall analysis. To illustrate this concept further, Figure 4 provides a visual representation of intricate mesh details, while Figure 5 demonstrates the process of meshing specifically applied to the connecting rod under investigation.

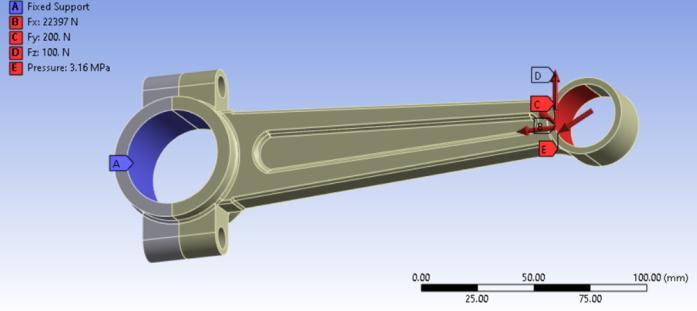

Establishing boundary conditions is an essential and crucialstepinFiniteElementAnalysis(FEA).This process involves defining constraints for the meshed model to simulate real-life scenarios accurately. The boundary conditions encompass fixed support, forces, and pressure that are applied to the model. By specifying these constraints, the analysis can determine the deformation, fatigue, stress, and strain values of the connecting rod whileadhering toacceptabledesignlimits. In the analysis of the connecting rod, a fixed support was applied at the bigger end, which is connected to the crankshaft. Additionally, pressure and forces were exerted at the smaller end, connected to the piston, as illustrated in Figure5.

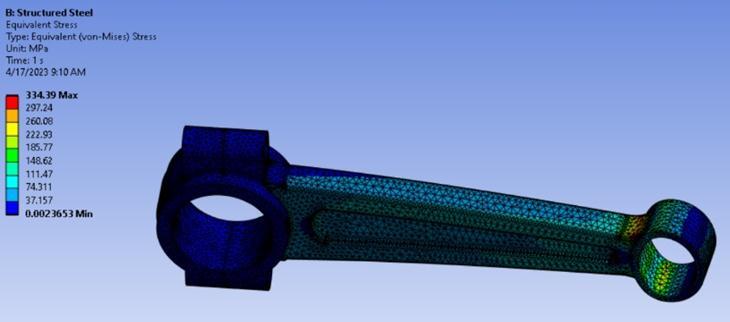

The Static Structural module of ANSYS has been used to perform the simulation on steel, aluminum and titanium alloys which are used nowadays for the production of connecting rods for vehicles. Following are the materials whichwereusedintheresearchforsimulation:structural steel,42CrMo4,T6-7075aluminum,Ti-6Al-4vandC-70.

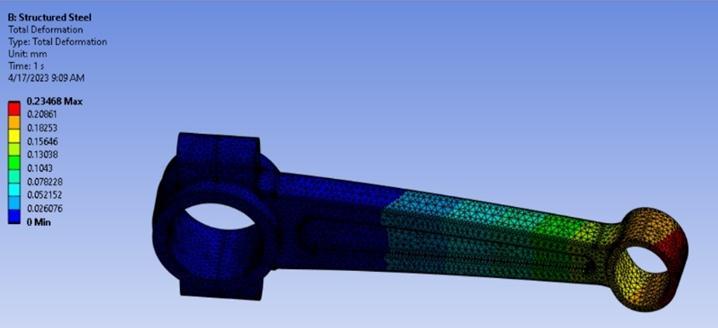

Total Deformation and Equivalent stress of Structural SteelhasbeenshowninFig-7andFig-8respectively.

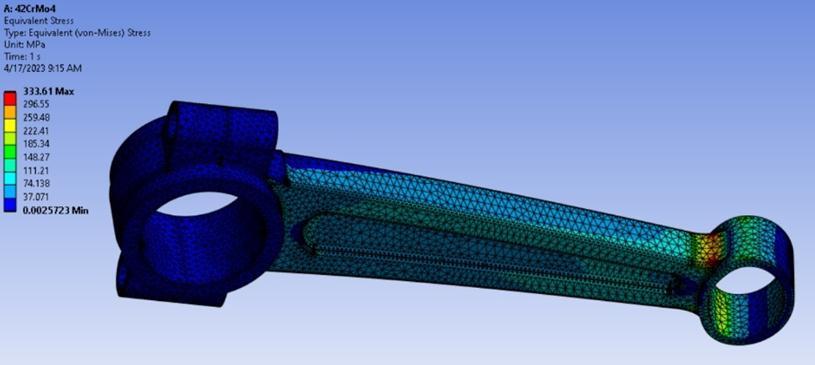

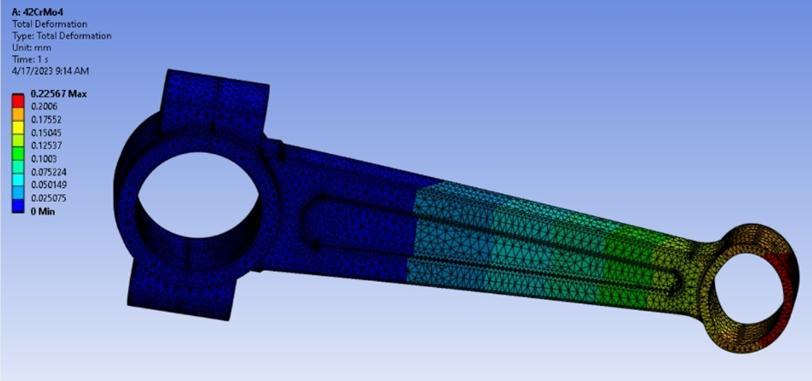

Total Deformation and Equivalent stress of 42CrMo4( an engineering alloy steel containing chromium and molybdenum) has been shown in Fig -9 and Fig -10 respectively.

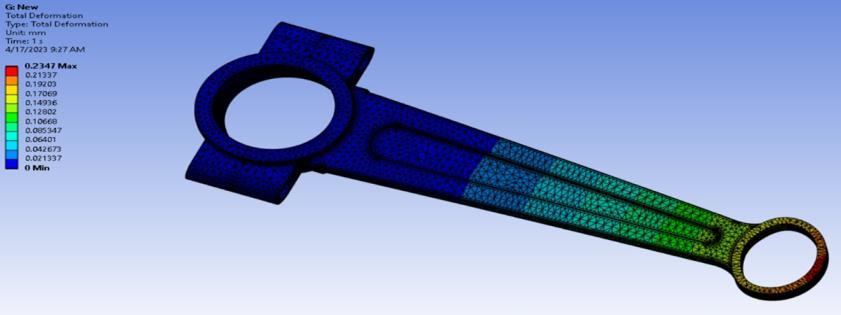

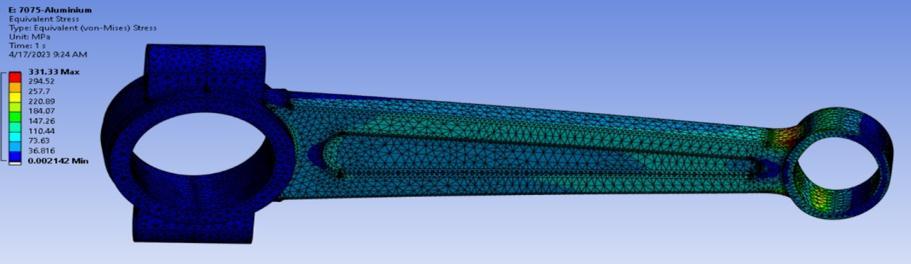

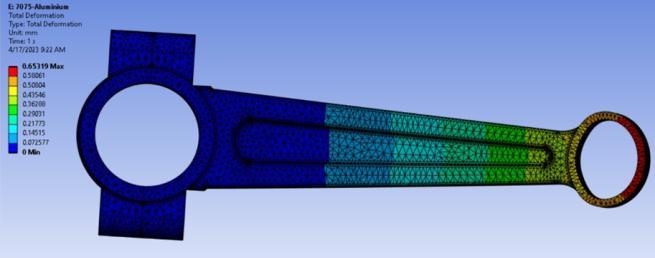

Total Deformation and Equivalent stress of T6-7075 Aluminium( an Aluminium alloy) has been shown in Fig11andFig-12respectively.

Total Deformation and Equivalent stress of Ti-6Al-4v(a titanium alloy composed of 90% titanium, 6% aluminum and4%vanadium)hasbeenshowninFig -13andFig-14 respectively.

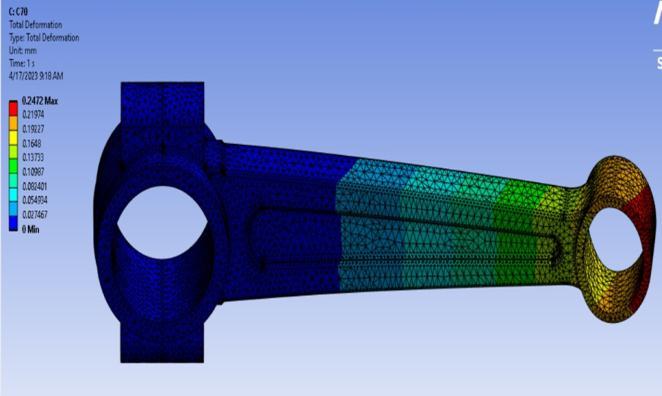

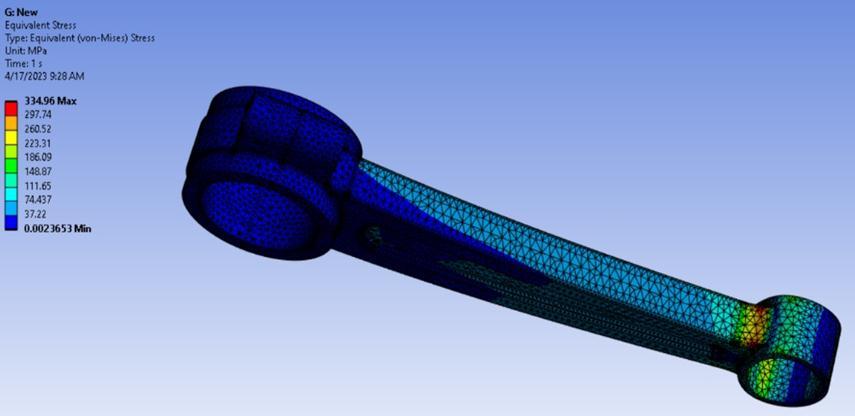

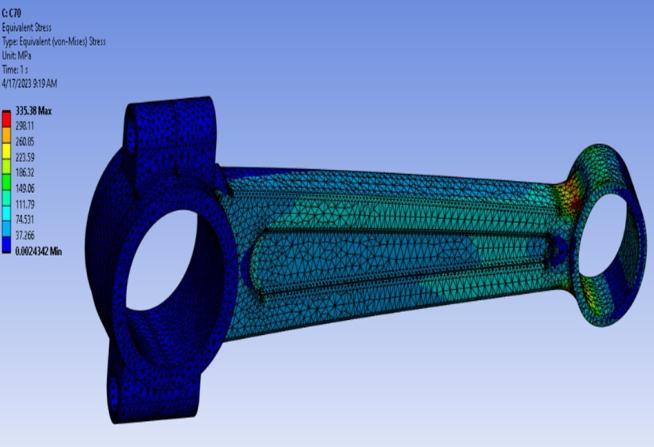

Total Deformation and Equivalent stress of C-70(Carbon Steel)hasbeenshowninFig-15andFig-16respectively.

6. RESULTS AND DISCUSSIONS

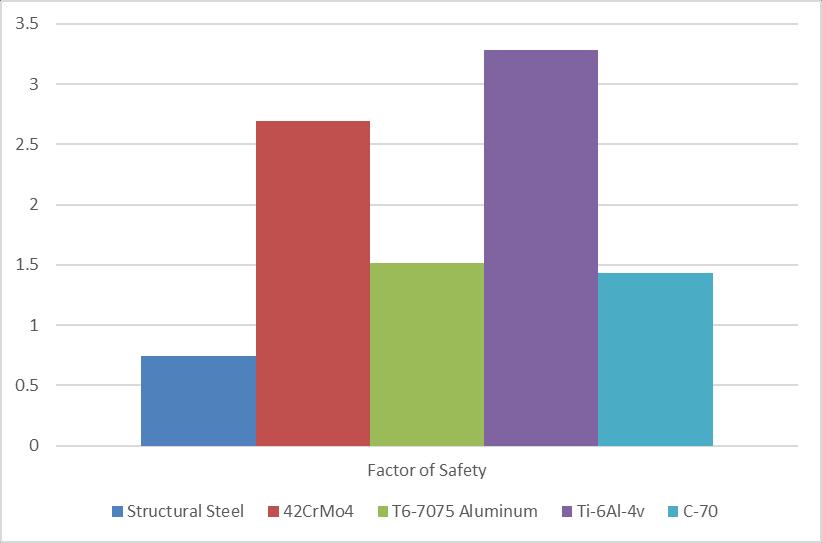

Table -1: Comparison of Values

7. CONCLUSIONS

From the static analysis the stress is found maximum at thesmallendoftheconnectingrodwhichisconnectedto thepiston.

It has been found that titanium alloy is the best material formanufacturingconnectingrodsasithasahighfactorof safety although it has more weight than aluminum alloy. The only thing that is a barrier to implement Titanium alloyiscost,availability,anditsrepair.

42CrMo4is the secondchoiceforproductionasit hasthe lowest value of total deformation and has a high factor of safetyafterTitaniumalloy.

Structural steel is not effective regarding mass, and it increasesthe weight of the connecting rod. Italsohasthe lowestfactorofsafetyamongthechosenmaterials.

A comparison of values of total deformation, equivalent stress, and factor of safety for five different materials has beenshowninTable1.Fromthetableitcanbeconcluded that the minimum total deformation has been shown by 42CrMo4(Steel alloy) while the maximum total deformationhasbeenshownbyT6-7075Aluminum.

The minimum equivalent stress has been shown by T67075Aluminumandmaximumequivalentstresshasbeen shownbyC-70(Carbonsteel).

The highest factor of safety has been shown by Ti-6Al-4v (a Titanium alloy) while Structural steel has the lowest factorofsafety.

ACKNOWLEDGEMENT

This Bachelor of Technology dissertation titled "Static Analysis of Connecting Rod" has been carried out under the guidance and supervision of Prof. R.C Singh and the aegis of the Mechanical Engineering Department, Delhi TechnologicalUniversity.

In this research journey, we came across several people who helped and traveled with us to achieve this ambition of our life. Therefore, for this achievement of ours, we should express our sense of gratitude towards those persons who unconditionally supported, helped, and encouraged us in all situations. We are highly thankful to the Almighty for blessing us and giving us the strength, energy, and patience to overcome all the difficulties and reachthisambition.

Firstly, we would like to thank Prof. S. K. Garg (Head of theDepartment)forgiving us theopportunity towork on thisproject.Withourprofoundgratitudeanddeepregards, we would also like to thank Prof. R.C. Singh for their personal input, enthusiasm, meticulous manuscript checking,constructivecomments,andremarks.Exceptfor thevisiontheysetforus,theyhelpedusconceptualizethe projectandhelpedintheactualbuildingandprocedureto completeit.

We thank Ms. Yamika Patel for their continuous support andguidancethroughouttheproject.

We want to thank our professors for their guidance and patience and for imparting in-depth knowledge about the subjects,whichhelpedcompleteourproject.

REFERENCES

[1] R A Savanoor, Abhishek Patil, Rakesh Patil and Amit Rodagi, Int. J. Mech. Eng. & Rob. Res. 2014, ISSN 2278 –0149Vol.3,No.3.

[2] Kumbha Sambaiah, DR. Rama Rao and DR. M Mahesh “Optimization for thermal analysis connecting rod of internal combustion engine by using two different materials”, International Journal of Applied Research 2017;3(12):278-282

[3] Ashish Kumar and Er. Shubham Parmar “Analytical StudyandDesignAnalysisofConnectingRodofMahindra Pijo by Finite Element Analysis”, International Journal of Scientific Development and Research (IJSDR) www.ijsdr.org

[4] Mr. H D. Nitturkar, Mr. S M. Kalshetti and Mr. A R. Nadaf “Design and Analysis of Connecting Rod using Different Materials”, International Research Journal of EngineeringandTechnology(IRJET).

[5]Griza,S.;Bertoni,F.;Zanon,G.;Reguly,A.;Strohaecker, T. Fatigue in engine connecting rod bolts due to forming laps.Eng.Fail.Anal.2009,16,1542–1548.

[6] Ramani et al Int. Journal of Engineering Research and Applications, Vol. 4, Issue 3(Version 1), March 2014, pp.216-220

[7] DR. B.K.Roy “Design Analysis and Optimization of Various Parameters of Connecting Rod using CAE Softwares” International Journal of New Innovations in EngineeringandTechnology(IJNIET)

[8] Vivek C. Pathade, Bhumeshwar Patle and Ajay N. Ingale, “Stress analysis of I.C engine connecting rod by

FEM”,InternationalJournalofEngineeringandInnovative Technology,Vol-1,Issue-3,pp.12-15,March2014

[9] Chinnari Natraj, Bantu Sandhya, Agatha Naveen, Seera vivek and Seera N. Kumar,“Design, Static and Modal analysis of connecting rod of four stroke Spark Ignition engine”, Anil Neerukonda Institute of Technology and Science,India,2022.

[10] W. Gao, G. Wang, J. Zhu, Z. Fan, Xiaobo “Structural Optimization Design and Strength Test Research of Connecting Rod Assembly of High-Power Low-Speed Diesel Engine” College of Power and Energy Engineering, Harbin Engineering University, Harbin 150001, China,2022.