Ensuring Safety for the Construction Workers involved in Metro Tunnelling Projects

Ar. Govind Raguram Rajan1, Prof. Ar. K. Indrapriya2, Prof. Ar. Fathima Taskeen31Post-Graduate Student , M.Arch Construction Project Management, Faculty of Architecture, Dr. M.G.R Educational and Research Institute, Chennai.

2Deputy HOD, Faculty of Architecture, Dr. M.G.R Educational and Research Institute, Chennai.

3AdditionalHOD, Faculty of Architecture, Dr. M.G.R Educational and Research Institute, Chennai.

Abstract - The growth of Tunnel Construction industry made significant improvement over the past few decades. “Safety First” should be one of the main objectives of any construction projects mainly tunnel and shall be given high priority throughout theconstructionperiod. Thismanyatimes lead to the incompletion of these projects, and ultimately its cost overrun and time overrun. This study aims to bring out the safety measures taken by the management towards the construction workers involved in the tunnelling works. This research involves literature study through reviewing various journal papers and data collections regarding the tunnel workers safety and case studies on various metro tunnel projects and accidents happened during the construction.The outcome of this study is to come up with the proper managing tools for the safety managers towards the safety of the workers and identifying the risk factors in the construction phase and also suggesting some risk mitigation measures and techniques to avoid such accidents in future.

Key Words: Tunnelling, Safety Management, Hazards, Risk Management, Risk Identification, Accidents, Standards.

1. INTRODUCTION

Tunnellingiscommonlyusedintheconstructionofrailways, roads, and irrigation systems. Tunnelling engineering specialisation is a major risk factor during project implementation.Tunnellingandsubterraneanconstruction projectsentailriskstoallpartiesconcerned,includingthose whoarenotdirectlyinvolvedintheoperation.Theimpact has been significant, particularly in residential areas. Influence the local population as well as neighbouring structures. Among the inherent threats are ground and groundwater concerns. There are also conditions, cost overruns,andmajoraccidents.Thereisariskthatthetunnel project could cause public protest, which could have an impactontheproject.Typically,thesedangersaremitigated by employing appropriate risk assessment and mitigation measures.However,alackofappropriateriskmanagement approachesinourcountryhasresultedinmanyprojectcost andtimeoverruns.Implementingriskassessmentandthe needformanagementinthetunnelconstructionsectorhas grownovertimeasthecomplexityoftunnellingprojectshas

increased, as has the rising pressure to reduce costs and shortenconstructiontime.

2. AIM AND OBJECTIVES

The main objective is to assess and manage the risks associated with tunnelling projects in India, as well as to determinetheprobabilityandseverityofrisksinvolvedin variousphasesoftheproject,analyzetherisks,andofferrisk mitigationmethodsfortheprincipalhazardsincludedinthe project.Determine the primary internal and external risks thatthetunnelconstructionindustry'sdevelopmentismost vulnerable to risk assessment in order to rank them for effective risk management. The development of a risk management strategy that incorporates appropriate measurestoreducetunneling-relatedhazards.

3. METHODOLOGY

Thefirststepwillinvolveconductingathoroughreviewof relevant literature on metro tunnel projects, construction safety,andbestpracticesinensuringsafetyforconstruction workers in tunnel projects. This literature review will provideacomprehensiveunderstandingofthecurrentstate ofresearchonthetopic,identifyresearchgaps,andprovidea foundationfortheresearch.

Thesecondstepwillinvolveconductingcasestudiesofmetro tunnelprojectsfromdifferentregionsoftheworldtoidentify andcomparedifferentsafetymeasuresimplementedinthese projects.Thecasestudieswillincludeinterviewswithproject managers,constructionworkers,andsafetyofficerstogain insightsintothevarioussafetymeasuresimplementedand theireffectivenessinensuringworkersafety.

Thethirdstepwillinvolveconductinggatheringdataonthe currentsafetymeasuresbeingimplementedinmetrotunnel projects. This will be designed to gather information from construction workers, supervisors, and project managers involvedinmetrotunnelprojects.Thiswillfocusonthetypes ofsafetyhazardsencounteredinmetrotunnelprojects,the current safety measures being implemented, and the effectivenessofthesemeasuresinensuringworkersafety.

Thefourthstepwillbetoanalysethedatagatheredfromthe data gathered and case studies. The survey data will be evaluatedstatisticallyinordertodetecttrendsandpatterns in the data. Thematic analysis will be used to discover reoccurringthemesandpatternsinthedataobtainedfrom the case studies. The suggestions will be based on best practises discovered in the literature review as well as surveyandcasestudydata.

4. LITERATURE REVIEW

4.1

Hazards in tunnelling and Underground Works

Thehazardsinvolvedintunnellingandundergroundworks ariseduetothefollowingoperations:

I. Drilling

II. Explosivesandblasting

III. Muckingplantandequipment.

IV. Supportingtheexcavation

4.2 Common Causes of Accidents in Excavation

Workers trapped and buried in an excavation after the sidewalls collapsed; Material falling into the excavation wounded and injured workers; Falling workers into the excavation;Intheeventofflooding,thereareinsufficientand unsafe entry points. Vehicles pushed into or dangerously closetotheedgeofanexcavation,especiallywhenreversing, causing the sides to collapse; Asphyxiation or poisoning inducedbyvaporsheavierthanairenteringtheexcavation, suchasdieselandpetrolengineexhaustfumes..

4.3 Precautions Needed

Precautionsthatshouldbetakenbeforeanyoneisallowedin atrenchorexcavation.

I. Whatconditionscanaffectthestabilityofthesides ofanexcavation?

II. Whyareaconsiderablenumberoftheaccidentsin excavationworkfatal?

III. If the sides of a trench collapse burying a fellow worker,whatactionwouldyoutake?

IV. Whatprecautionsareneededtobetakentoavoid dangerfromundergroundservices?

4.4 Safety Program

SafetyPersonnel-Alloperationsinsidethetunnelorshaft shall be carried out under the immediate charge of a competent foreman. A safety committee shall also be appointedinjobswhere100ormorepersonsareemployed.

Itshallhaveatleastthreemembers-oneeachfromworkers, supervisorsandmanagement.Thiscommitteeshallconduct its meeting at least once in 15 days and discuss safety problemsonthework.

4.5 Medical and Other Facilities

Stretchersandotherequipmentrequiredtotransferinjured peoplemustbeavailableatallshiftsandportals.Wherethere are more than 50 people working in a shift, appropriate artificialrespirationsystemswithtrainedindividualscapable ofgivingartificialrespirationmustbesupplied.

4.6 On-Site Rules

Attheentrancestotheseplaces,1×1.5msignboardswith thefollowinglanguagemustbeinstalled.Unlesstheworksite is within 500 meters of the tunnel's portal, sanitation facilitiesmustbenearby.Unlessitisimpractical,dryclosets, waterclosetsorclosetcarsshallbeprovidedinthetunnelat ascaleofoneunitforeveryfiftymenintheshift.

Up to 100 m of tunnel length, just one of the abovementioned systems shall be provided, however tunnels longerthan100mshallhaveatleasttwosystemsinstalled, with wires running along opposite sides of the tunnel, if practical.Infrontofswitchboards,acorridornolessthan60 cmwidemustbemaintained.Allsubterraneanelectriclines carryingvoltagesof440andabovemustbeinsulated,leadcoveredcablesthatarewellarmoredagainstabrasionand grounded.

Theymusthavea45cmfreeareabetweentheexplosiveand detonatorcompartments,andnothingmaybecarriedinthat gap. Insulated containers used to transport explosives or detonatorsmustbemadeoffinishedwoodthatisatleast5 cmthick,plasticthatisatleast6mmthick,orpressedfibre thatisatleast10mmthick.Theremustbenometalparts, including nails, screws, bolts, and so on, and it must be watertightandhaveatop.Locatedatleast170metersaway fromtheoperatingarea.

Otherthanclaysticks25mmdiaand10cmlong,noother substance shall be used for blinding and sealing the holes aftercharging.Beforeuse,eachelectricdetonatormustbe examinedforapositivetestwithanohm-meter.

5. NET CASE STUDIES

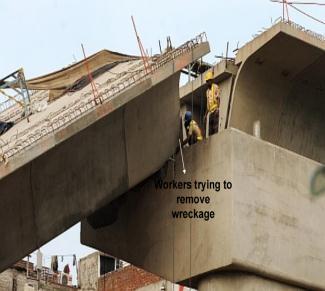

5.1 Delhi Metro Rail Project

On July 12, 2009, an accident occurred in the BadarpurSecretariatsectionclosetoP-67whileliftingsuperstructure segments as part of the construction of Delhi Metro Rail Project'sPhaseII.ThepiercapofpierP-67collapsed,which led to the subsequent collapse of : the erected and prestressedLaunchingGirder,thespanbetweenP-66andP-67,

andsegmentsofthesuperstructureforthespanbetweenP67andP-68.

Sixpeoplediedandmanyotherswerehurtintheincident. Initially the support system for viaduct was designed as portal pier till the casting of the pier was over. The shop ownersinthenearbyareaputupresistanceagainstcastingof theotherlegoftheportalanditwassubsequentlydecidedby DMRCthatthiswouldbechangedtoacantileverpier,similar toP-68.Thetopreinforcementofthecantileverbeamdidnot haveanydevelopmentlengthintopierconcrete.Aslearned from the sources, the top reinforcement of the cantilever beamhadan“L”bendof500mmonly.

The project was about two months behind schedule. According to nearby residents, cracks were obvious in the collapsedpillar,andworkhadbeenhaltedforapproximately twomonthsto‘repair'it.Thephase2project,whichincludes a121-kilometerlineand81metrostations,wasapprovedin 2005,withacompletiondateofOctober2010.PhaseIbegan on October 1, 1998, and ended in November of 2006. The project'stotallengthwas65kilometers.Thetotaltimelimit forphase1was8years,whereasthetimelimitforphase2is 5 years, despite the fact that the project's length is nearly double.Workwasmovingatarapidrateduetotherestricted timeframe.

According to experts because to the limited time frame, severalconcessionsweremadewiththeconstructionwork andsafetystandards.Thecontractor'sperformanceisalso beingscrutinized.Iftheprojectisdelayed,thecontractorwill be fined heavily, according to the contract terms and conditions.

Asaresult,inordertocompletetheprojectontime,which had already been delayed, the contractor disobeyed the safetyregulations,resultingintheaccident.

5.2 Pune Metro Rail Project

Fig -1:DelhiMetroProjectAccidentonJuly122009

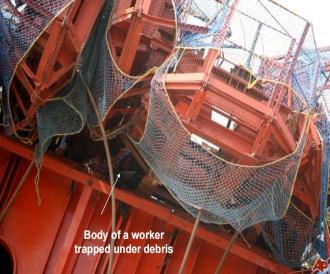

On 13th July, 2009, while clearing the site of all debris, 4 cranesweredeployedbyDMRCfortakingouttheentrapped launchinggirder.Threeoutoffourcranesfailedduringthis operation. The boom of the crane, used for lifting the launchinggirder hadfailed in bending andshowed a clear signofoverloading.

A 19-year-old worker, Mulchandrakumar Sitaram from Fatehpur.Sitaramfellfromaheightof50FeetattheMetro Crashed construction site near Vanaz. He was taken immediatelytoanearbyhospitalashewasseriouslyinjured, but he succumbed to his injuries on arrival at the hospital beforehecouldbetreated.

“Sitaramhadwornsafetygear,buthedidnotattachhishook to the rope while working at such a height. He suffered a grave and painful injury and subsequent death because of falling from such a height”, said Senior police inspector MahendraJagtapofKothrudPolicestation.

Theprioritymodelcanbeusedtoevaluaterisks.Thiswillbe usefulforreducingriskandmonitoringit.Furtherresearchis needed to assess risk. According to this study, design and technologyselection delaysarea significantrisk factor for projectdelaysinthemajorityofinfrastructureprojects.Itis advised to research these dangers using risk assessment methods.

Risk control is the process used to identify, develop, implementandcontinuallyreviewallpracticablemeasures foreliminatingorreducingthelikelihoodofaninjury,illness ordiseasesintheworkplace.

The phase of risk identification is essential, because it establishesthebasesoftheriskanalysis.Indeed,thedataof riskidentificationwillbetheinputoftheevaluationand/or hierarchizationphases.Therefore,itisnecessarytomakean identification phase in an exhaustive way to get the best results.

5.3 Shanghai Metro Rail Project

Beijing, June 2 2019 (IANS) Five workers, trapped in a collapse at an under-construction Metro tunnel site in Qingdao,China’sShandongProvince,havebeenconfirmed dead,accordingtotheprojectmanagementcompany.With the problems of existing safety standards,safety accidents often occur in construction projects. According to the statisticsoftheMinistryofHousingandUrban(Ministryof HousingandUrbanRuralDevelopmentofPeople’sRepublic ofChina,2017),nearly80accidentstookplacefrom2011to 2016duringmetroconstruction,includinghighfallingand other types of accidents. Among them, the high falling, collapseand objectstrike were the most frequenttypesof accidents,accounting for upto 66% of the total accidents; vehicleinjury,electricshockandliftinginjuryrespectively tookanidenticalproportionofabout6%whichwasslightly lowerthanthatofmechanicalinjury,7%.Wuhan,Beijingand Shenzhenrankedthetopthree.

Theresultsofthisinstrumentationprogramshowthatthe EPB shield at the Shanghai Metro Tunnel-line 2 project performedsuccessfully.Groundmovementswereheldwithin limitswhichweretypicallymuchsmallerthanwhatwouldbe expectedwithaconventionalshield.TheadvanceoftheEPB shield at the instrumentation site led to initial outward movements from the shield, movements that were largely lateralandconfinedtothesoilimmediatelytothesideandin frontoftheshield.

Thisresultindicatesthatthespecialprovisionsofbalancing theearthpressureatthecuttingfaceandthecompensation tailgroutingtechniqueadoptedbytheEPBshieldareableto effectively reduce the potential shear stress development inducedbythetunnelexcavationprocess.

However,theoverburdenpressuredevelopedatthetunnel crownandtheweightofthetunnelliningwillbeeventually transferredtothebottomofthetunnellining.

5.4 Comparative Analysis

Duetotheshorttimeframe,someconcessionsweremade with the building work and safety standards. In order to complete the job on schedule, which had already been delayed,thecontractorviolatedsafetyregulations,resulting in the accident. The Delhi metro has been praised for its superior safety standards and more efficient building procedure. Construction businesses' safety departments should compile basic safety regulations, technological requirements, and other safety knowledge into safety behaviorstandards.Employeescanlearnsafetyknowledge and eliminate unsafe behaviors by using the standards to trainthem.

When hazards are identified and their likelihood of occurrence is quantified, it is anticipated that they will operate as intended in the absence of unforeseen events (componentandmaterialfailure,humanmistake,external event, process unknown) that may change process behaviour.Eachmeasuremusthaveadesignatedpersonand adeadlineforcontrolimplementation.Thisguaranteesthat allnecessarysafetyprecautionsaretaken.

6. LIVE CASE STUDY

6.1 Chennai Metro Rail Project: Phase II

PhaseIIextensionisproposedfora 118.9kmnetwork with 128 stations. Corridor -3 connects Madhavaram to SIPCOT(45.8kilometers),Corridor-4connectsLighthouseto Poonamalle Bypass (26.1 kilometers), and Corridor-5 connectsMadhavaramtoSholinganallur(47km).

L&T | TATA provides structural consulting services. The project'sprojectedcostisRs.63246/-Cr(RupeesSixty-three thousandtwohundredandforty-sixonly) (includingIDC). Thisplanisintheworksandisexpectedtobefinishedbythe endof2026.

6.1.1 Stretch I – Kellys to Ayanavaram

StretchName:AyanavaramtoKellys

MainStation:Purasaiwakkam

Sub-stations: Otteri, Pattalam, Perambur Barracks Road, Dovetown

Lengthofthetunnel:2.8kmsApprox.

StartDate:June212021

CompletionDate:Expected48monthsfromthestartdate

ProjectCost:200-225crores

CurrentStatus:Excavation,drilling,De-walling

TotalNumberofWorkers:150-180workersperShift

Number of Shifts: 02 [ 8am to 8pm & 8pm to 8am] (with 2hoursbreak)

TypeoftheTunnel:Twin-BoredTunnel

StructuralConsultants:TATAPROJECTS

TunnelDetails:Innerdia.5.8m,Outerdia.7.05m

InsuranceConsultants:TATAZeToGroupInsurance

MainContractor:TATAPROJECTSLIMITED

Sub-Contractor:NKAB

-5:ChennaiMetroRailWorks(Purasaiwakkam)

First aid room is provided for the workers in case of any emergencies. PPE equipment were not followed by some workersonthesite.Therearenosafetypersonspresenton thesiteandthereisnopropermonitoringoftheworksand workers.Manyplacesdidnothaveanypropersecurityand theworkerswerenotpresenttheresothatanyonecanaccess the place and also to some equipment. Workers does not seemtobeproductiveasthereisnopropersupervisionin thesite.Fireevacuationplaceforthesitewasnotprovidedby the safety management. No proper space for workers training.

6.1.2 Stretch II – Kellys to Greenways Road

StretchName:KellystoGreenwaysRoad

MainStation:Chetpet

Sub-stations:Thousandlights,Royapettah

Lengthofthetunnel:6kmsApprox.

StartDate:July152021

CompletionDate:Expected:43monthsfromthestartdate

ProjectCost:370-400crores

CurrentStatus:Excavation,drilling,De-walling

TotalNumberofWorkers:200-220workersperShift

NumberofShifts:028amto8pm&8pmto8am(with2hours break)

TypeoftheTunnel:Twin-BoredTunnel

StructuralConsultants:LarsenTaubro

TunnelDetails:Innerdia.5.8m&Outerdia.7.05m

InsuranceConsultants:BAUERGroupInsurance

MainContractor:LarsenTaubro

Sub-Contractor:NKAB|BAUER

First aid room is provided for the workers in case of any emergencies. All the workers in the site were strictly following their rules by wearing PPE equipment (helmets, jackets,boots,gloves,etc.).Alltheworkersinthesitewere found productive in their work. The safety monitoring persons were present at thesiteFire Evacuation Plan was clearlymarkedandprovidedatthesite.

A45-year-oldcontractworkerdiedfollowingacave-inwhile working underground for laying sewage pipeline for the ChennaiMetroRailprojectnearMedavakkam.

Thepipelinesweremovedandre-laidafewmetersawayat adepthof10feetinordertoallowsoiltestinginthecentre oftheroad,”saidaseniorpoliceofficer.Around1am,Ravi entered the 10-feet pit without any protection and was involvedinlayingthepipe,whenthesoilcaved-in.

7. FINDINGS FROM THE STUDY

Safety supervisors should be present on the job site to increaseworkplaceefficiencywhilealsomonitoringworker andworkplacesafety.Allworkersmustrigorouslyadhereto the safety regulations. These should be monitored by a supervisor, and any infractions should result in a punishment.Eachzoneshouldhaveasecurityguardandbe monitoredbythemanagement.Accesstocertainareasand equipmentshouldbecontrolled.

Theadministrationshouldofferenoughmedicalandother amenities for the personnel. According to IS regulations, safety sign boards should be placed on the job site. Emergencycontactinformationshouldbepostedonthesite so thatanybody there may transfer the information to the safetyteamintheeventofanemergency.

According to the IS and BOCW Act, all workers must be equippedwithappropriatesafetyandPPEequipment.Afire

evacuation plan must be given at thesite tosavestaffand guestsintheeventofanemergency.Workersandemployees musthaveanEmergencyAssembleAreathatmaybeutilized toprotectthemintheeventofanemergency.

Communication between employees and management is required and must be considered. To promote communication, many communication techniques can be given.

According to IS regulations, emergency exits must be providedevery30metres.Thisisabsentinbothsegments. Thiselementmustbeconsideredinalltunnellingprojectsin order to promote worker wellbeing. Workers must be educated about the dangers linked with their jobs. Managementshouldprovideregulartraininginallelements ofthejob.

8. RESULTS AND DISCUSSIONS

Different techniques are used to stabilize the tunnel face dependingonthesoilandgroundwaterconditions.Oneof them and the most efficient one is compressed air face support, but it is pricey. Under the beginning, a crew of workerswouldbesentundergroundincompressedairtodig andconstructatunnel,theTBMhandlesthiscurrently.

Usuallytunnellinghappens26mbelowthesafegroundlevel. [ 4m below the ground - safe ground level] TBM Air lock accidents,whilechangingthegutterworkersfacesbreathing suffocation and this is said as the serious issues by the workers.

BreathingAir:Airwassuppliedbyelectriccompressors,and a sample was taken from each compressor and tested for purity.Asabenchmarkforairquality,IS15879(2002),an Indianstandardfor"Breathingairquality," wasemployed. Consequently, safety workers used handheld multigap monitors to check the air quality once every shift. Filters wereincorporatedontheairlineasanadditionalsafety.

Hazards of compressed air working: Barotrauma | Decompressionsickness(DCS)|Dysbaricosteonecrosis.

Noise:TBMoperatoriswellprotectedinasound-proofcabin andallotherpersonsaremorethan100maway.Theyshould beprovidedwithearplugs.

Floodproblems:Thiscannotbeavoidedinanunderground tunnelling, as the electric wires Unpredictable accidents whichcannotbeavoidedalsoamajorreason.Workersgets injuredbysharppiecesduringtheexcavations.Landslides alsoareason.

Post-WorkSolutions:AstheTBMhitsanunevensurface, hardrocksbecomesclay,thisleadstothecreationofsink holes in the upper layer. It is due to the loosening of soil. This can be prevented by back filling with concrete to

stabilizethegroundhardtoavoidcollapse.Workersrequires a regularmonitoringand inspectionofthe workplaceand workershealth.

9. CONCLUSION

The need of suitable risk transfer procedures must be increasedbecauseexternalrisksarethemostimportantones andcannotbecontrolledbytheproject.Theimplementation of a risk management plan should begin at the project's inception and continue throughout the duration of the project.Additionally, it's important to periodicallyidentify secondaryandresidualconcernsandupdatetheriskregister withthem.Theideathatthecostofreducingoravoidinga riskshouldn'tbehigherthanthecostoftheriskitselfshould bekeptinmindwhenmanagingrisksisanothercrucialidea.

Ahighleveloftransparencyisnecessarytobeabletomanage the risks involved in tunnelling. For the purpose of developingappropriateoperationalplansassoonasfeasible, itiscrucialfortunneloperatorstoquicklygathersituational knowledgethatcanbeacquiredfrompreviouslyoccurring occurrences.

Thetypeofincident,thenumberandlocationofindividuals trapped, the infrastructure status, and the tunnel asset management condition are all part of the situation information. To management the risk effectively and efficiently, the contractor must understand risk responsibilities,risk eventconditions,risk preference,and riskmanagementcapabilities.

Inordertobuildamoreeffectiveriskmanagementstrategy basedontheirpriorexperience,theoperatorsorauthorities in charge should constantly refresh the operation and maintenanceplanbyaddingallthatinformation.Andoneof the most valuable pieces of knowledge that all tunnel operators need is all the general dangers that have been recognizedandexamined.

10. RECOMMENDATION

In order to prevent the risks, the usage of AI can be implementedwiththesafetymanagement.Astherearemany technologies have been used in many countries, some of thosemaybeadoptedbyknowingthelevelofusageinIndia.

A thermographic camera is a device that creates an image usinginfrared(IR)radiation,similartoanormalcamerathat forms an image using visible light. An Online safety management system helps prevent accidents and their human and financial consequences. Effective safety managementreducesthecostsassociatedwithaccidentsand manyhiddencosts.Wearingahearingprotectorisimportant ifthenoiseorsoundlevelataworkplaceexceeds85decibels. Byusingahearingprotector,theriskofhearinglosscanbe reduced.

The inspection of the tunnel can be carried out by a fully autonomoussystemwithoutendangeringthesecurityofthe operators. Future systems must be able to perform maintenanceandinspectionwithlittletonooversightfrom humans,ifnotatall.

REFERENCES

[1] Pamukcu,Cagatay.(2015)"Analysisandmanagementof risks experienced in tunnel construction." Acta MontanisticaSlovaca20.4.

[2] Mishra,Surabhi,andBrajeshMishra.(2016)"Astudyon risk factors involved in the construction projects."

InternationalJournalofInnovativeResearchinScience, EngineeringandTechnology5.2:1190-1196.

[3] Pamukcu,Cagatay.(2015)"Analysisandmanagementof risks experienced in tunnel construction." Acta MontanisticaSlovaca20.4.

[4] Mishra,Surabhi,andBrajeshMishra.(2016)"Astudyon risk factors involved in the construction projects."

InternationalJournalofInnovativeResearchinScience, EngineeringandTechnology5.2:1190-1196.

[5] Gupta, Vishal Kumar, and Jitesh J. Thakkar. (2018) "A quantitative risk assessment methodology for constructionproject."Sādhanā43.7:116.

[6] Pamukcu,Cagatay.(2015)"Analysisandmanagementof risks experienced in tunnel construction." Acta MontanisticaSlovaca20.4.

[7] Mishra,Surabhi,andBrajeshMishra.(2016)"Astudyon risk factors involved in the construction projects."

InternationalJournalofInnovativeResearchinScience, EngineeringandTechnology5.2:1190-1196.

[8] Pamukcu,Cagatay.(2015)"Analysisandmanagementof risks experienced in tunnel construction." Acta MontanisticaSlovaca20.4.

[9] Mishra,Surabhi,andBrajeshMishra.(2016)"Astudyon risk factors involved in the construction projects."

InternationalJournalofInnovativeResearchinScience, EngineeringandTechnology5.2:1190-1196.

[10] Gupta, Vishal Kumar, and Jitesh J. Thakkar. (2018) "A quantitative risk assessment methodology for constructionproject."Sādhanā43.7:116.

[11] Pamukcu,Cagatay.(2015)"Analysisandmanagementof risks experienced in tunnel construction." Acta MontanisticaSlovaca20.4.