Design and Analysis of Solar-Powered Smart Electric Car with Accidental safety system

,

,

1,2,3,4, Student, S.G. Balekundri Institute of Technology, Department of Mechanical Engineering, Belagavi, Karnataka, India

5, S.G. Balekundri Institute of Technology, Department of Mechanical Engineering, Associate Professor and Project Advisor,

6, Professor and Department Head of Mechanical Engineering, S.G. Balekundri College of Technology, Belagavi, Karnataka, India ***

Abstract - India’s Electric vehicle mission is a major initiative by India’s government to reduce pollution. In this paper, we tend to introduce a new concept in the developing sector of electric vehicles. We develop a completely solarpowered Electric Car, which is light in weight and provides better or extended battery range due to onboard solar panels to charge the vehicle. Since the proposed concept is to develop a fully-fledged solar-powered vehicle, the cost of operation is zero as it completely runs on solar energy. The vehicle creates zero pollution and is completely eco-friendly and to some extent, it eliminates the need for charging or charging stations to charge the vehicle. Further, the car is made with multiple features, which continuously monitor the car’s health and sends it to the cloud so that breakdowns can be avoided. The Car is made 4 WD so that it can be easily driven across nonplanar driving conditions.

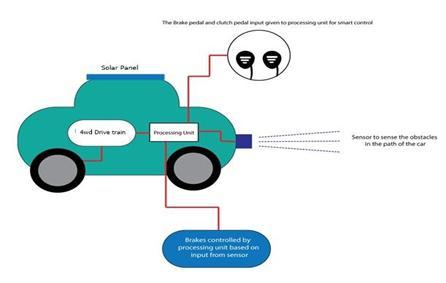

The smart accidental safety system has been added such as collision avoidance and GPS tracking are also implemented in the project to make the vehicle more reliable and add the main difference between other Electric vehicles.

Key Words: Electric Car,4WD, Solar, Smart, Accidental, Tracking, etc..

1. INTRODUCTION

TodayAutomobileindustriesovertheglobeareallsettofile theEVstomakeapollution-freeglobeNowadays,duetothe use of internal combustion engines, the effects on the environmentareincreasingdaybyday.Toavoidthiseffect ofpollutionandtobuildacleanerenvironment,thesociety of automobile industry is trying to find a new way by introducingelectricvehiclesbecauseinthepastaswehave experienced hybrid electric vehicles, were causing less pollutionbutthatwasnotenoughtostopthecompleterate pollution.

An Electric Vehicle has better technology and a more immeasurable efficiency as compared to the Internal Combustion engine. This research article focuses on the

completestructureoftheElectricVehicleandtheelements usedintheElectricVehicles.Thisalsoreferstothepower generatedandtheperformanceofthebatteryaccordingto themarketsituations.

Thechiefissueisthebatteryperformance which wehave highlightedhereinthepaper.

Thesignificanceofthechargingstationsandtheregionto embellishthenewstation.Thefuelstationsaretheforemost sourcewherewecanputonthechargingserviceseveryfive kilometers.Thiswouldprimetosecurethetimeandalsoa rush-freeenvironmentaroundthechargingstation.

Increasing the number of traveling vehicles has increased the problems such as air pollution and to the use of petroleum. The human sensibility for the energetic and environmental problem is encouraging research in alternative solutions for the automotive field, such as multiple-fueling, hybridization, and electrification. At the sametime,thesystemsaremodifiedconsideringthecurrent problems.Thisprojectdealswithdesigningandfabricatinga Solar powered 4WD electric vehicle with an Accidental safetysystemandGPSTrackingsystem.

2. LITERATURE REVIEW

AshwinChanderet.al[1]proposeadesignforamulti-speed transmissionforelectricvehicles(EVs).

Hailemariam N. Hailu et. al[2] conducted a study on the greenvehiclewasintroducedandpromotedtominimizethe problem of air pollution caused by emissions of a conventionalvehicle.

K.W.E CHENG et. al[3] provides an overview of the recent workofelectricvehicleintheregion.Thepaperdescribes the development and the comparison of different part of components.Themajorcomponentsinbatterytechnology, chargerdesign,motor,steeringandbrakingareexamined. Thepaperfinallyshowssomeelectricvehicleprototypeasa conclusionofthepapers.

5yDr.ChokriMahmoudiet.al[5]conductedaresearchwork accordingtowhichPowermanagementinelectricVehicles hasbeenrevolutionizedsincetheoldpowerstructurewas introducedwiththefirstEVs.

M. Prabha , M. Seema, P. Saraswathi et. al [1] developed a distance-based accident avoidance system using Arduino. The proposed system comprises an idea of having safety while reversing a vehicle, detects any object within the followingdistance,anddisplaysthedistancebetweenone vehicleandanothervehicletothedriverusingLCD.

Divya Thakur, A. P. Thakare developed an FPGA for an automatic Reverse braking system. which the devices and sensors are interfaced. This system is suitable for commercial vehicles such as cars, emergency services vehicles,trucks,andbuses.

VishalKumar[3]developedanautomaticemergencybraking system. An Automatic Emergency Braking System (AEBS) combines Advanced Driver Assist systems and Electronic Stability Control to slow down the vehicle and potentially mitigate the severity of an impact when a collision is inevitable.

ShivamS. Shinde,AditiV. Lawate[4] Developedautomatic intelligentaccidentavoidancesystem.

3. COMPONENTS

The motor:Themotordriverusedis24V20AmpDCmotor H-bridge.TheH-bridgeICisusedtoprovidethedirectional controltotheDCmotorsaswellastocontrolthespeedof theDCmotors.Howeverinourprojectwewillbekeeping thespeedofthescissorliftsameandconcentratingonlyon thedirectioncontroloftheDCmotor.

The microcontroller:AESP32SOCmicrocontrollerisused in this project. A compact microcomputer designed to governtheoperationofembeddedsystemsinmotorvehicles whichincludesaprocessor,memory,andperipherals.They are used as Input and output devices including solenoids, LCD displays, relays, switches, and sensors for data like humidity, temperature, or light level, amongst others. a single integrated circuit containing a processor core, memory,andprogrammableinput/outputperipherals.The ESP32 SOC microcontroller has several specifications includingWIFImodule:ESP-WROOM-32;Processor:ESP32D0WDQ6; Built-in Flash: 32Mbit; Antenna: Onboard PCB antenna; Peripheral interface: UART/GPIO/ADC/DAC/SDIO/PWM/I2C/I2S;WiFiprotocol: IEEE 802.11 b/g/n; Bluetooth: Bluetooth 4.2; Frequency range:2.4G~2.5G(2400M~2483.5M);WIFImode:Station / SoftAP / SoftAP+Station; Power supply: 5V; Logic level: 3.3V;Dimensions:48.26mmx25.4mm.

Battery: Thebatteryusedinthisprojectis12V30AHsealed leadacidbatteryandTwobatteriesareusedinthisproject tomakethevoltage24V.Batteriesareacrucialcomponent of electric cars, as they provide the energy necessary to power the vehicle. One of the key advantages of using batteriesinelectriccarsisthattheyaremuchmoreefficient thaninternalcombustionengines.Batteriescanconvertup to 90% of the energy stored in them into usable power, comparedtoonlyaround20%forgasolineengines.

ThecomponentslikeGPSmodem,solarpanels,LCDdisplay, Chassismaterialsisalsoincludedtobuildthefinalassembly.

4. RESEARCH METHODOLOGY

Theimplementationofthisprojectinvolvesdesigning and fabricationofsmartsystemandalso4wheeldriveelectric vehicle on which the concept can be demonstrated. The methodologyimplementedintheprojectisasfollows.

1) The designing of smart adaptive speed control system: Tobringaboutofconceptofadaptivespeedcontrol with smart collision detection and avoidance system, an obstaclesensorisinterfacedwiththemicrocontroller.

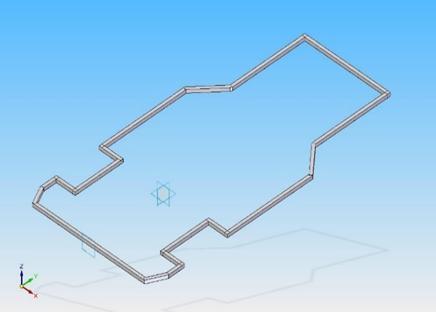

2) Thevehiclechassisfabrication:

Todemonstratethisconcept,electric4wheel drivenvehicle isfabricated.Initiallythechassisofthevehicleisfabricated. Thechassisisfabricatedinitiallyasitformsthestructural componentofthevehicleandhousesalltheotherpartsof thevehicle.Thechassisshouldbestrongenoughtotransfer alltheloadtogroundaswellhaveadequateamountofspace formountingalltheothercomponents.

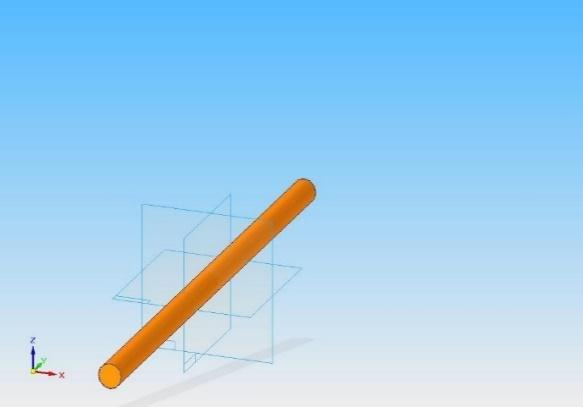

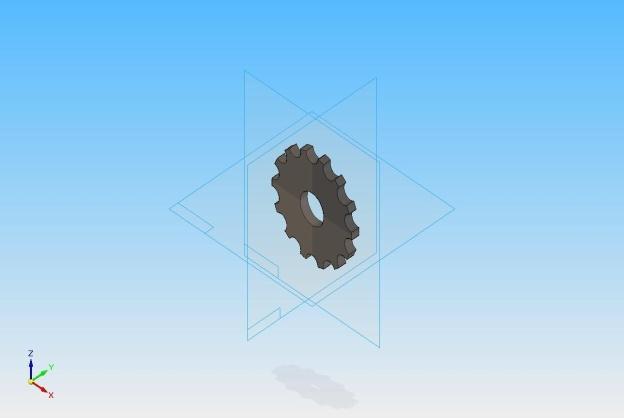

3) TheDrivetrain:

Afterthechassisisfabricated,4wheelelectricdrivetrainis fabricated and installed on the system. The power of the motor isgiven tothewheelsusingthedrivetrain.Inthis projecttheproposeddrivetrainisSprocketChainDriveand Gear drive. The electric drive train is implemented and assembled in this phase to make completely functional electriccar.Thedrivetrainshouldbesuitablychosensothat itshouldbeaproperbalancebetweenthespeedandpower

4) TheSolarPowerSystem:Thedrivetrainispowered usingbatterieswhicharedrivenusingsolarenergy.Inthis phase the solar power system is developed which is responsibleformakingthecarsolarpowered

5) The smart accident detection and notification system:InthisphasetheGPSbasedaccidentdetectionand notification system is implemented which will detect the vehicleusingtheMEMSsensorspresentonthevehicleand automatically trigger an notification to the hospitals and familymembersalongwiththelivetrackingofthecar.

6) Assemblyandoptimization:Thisisthefinalphaseof theprojectandinvolvesassemblingofallthecomponents. The fabricated as well as designed components are assembled and tested for performance. The optimizations requiredifanyaredoneinthisphase.

5. WORKING PRINCIPLE

The sensors mounted on the vehicle are interfaced with microcontroller.Themicrocontrollerprocessesthedatafed

by the sensors. If there is an obstacle in the range of the vehicleatcertaindistancefromthevehicle,thevehiclefirst dropsitsspeedadjustingtotheproximityoftheobstacle.As thedistancebetweentheobstacleandthevehiclegoeson increasingthespeedgoesondropping.Thisisdonewiththe helpofultrasonicrangefinderswhichcontinuouslyfeedthe distance between obstacle to the microcontroller which automaticallyadjuststhespeed.

When a particular point approaches where the car is too close to the obstacle and is about to collide the braking systemisautomaticallyactivatedwhichbrakesthevehicle thuspreventingheadoncollision.

Threecasescanbeconsideredtounderstandtheconceptof theproject.

1) There roadisempty: When theroad isemptythe vehiclewillbemovingwithfullspeedasyoucanseeinthe figureabove.Theadaptivecruisecontrol systemwon’t be workingthistime.

2) Whenthecarapproachesanothercaroranobstacle: When the car approaches another car or obstacle and the obstacleisstillatasufficientdistancefromthecar,thespeed of the car goes on dropping as it approaches another car. Thisisnothingbutadaptingthespeedofthecarwithrespect toanothercar,thecoreconceptofadaptivecruisecontrol.

3) Whenthecarisabouttocollide:

When the car is about to collide, the car automatically appliesthebrakeevenifthethrottleispressedbythedrives. Thispreventsthehead-oncollisionbetweenthecars.

6. 3D MODELLING AND DESIGN CALCULATION

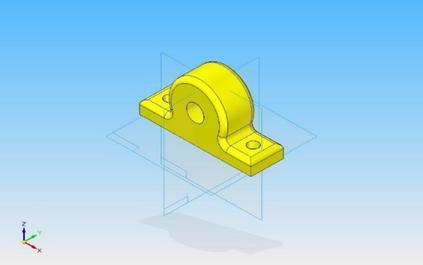

3DModelsofthecomponents:

Designcalculation:

Weightoneachdrivewheel(WW)2452.5/4 =613.125N

Radiusofwheel/tire(RW)=0.22m

Desiredtopspeed(Vmax)=25Kmph=6.94m/s

Desiredaccelerationtime(ta)=40sec

Maximum incline angle = 2 degrees Working surface= concrete(good)Totaltractiveeffort(TTE)requirementfor thevehicle:TTE=RR+GR+FAWhere:

TTE=TotalTractiveEffort[N]

TTE=TotalTractiveEffort[N]

GR=ForcerequiredtoClimbaGrade[N]

FA=Forcerequiredtoacceleratetofinalvelocity[N]

CalculationofRollingResistance:

Surface type to be encountered by the vehicle should be factored into the equation. Rolling Resistance (RR) is the forcenecessarytopropelavehicleoveraparticularsurface.

RR=GVWxCrr

=2452x0:01(goodconcrete)=24.52N

=2452.8x0.37(mud)=907.24N

=2452x0.60(sand)=1471.2N

Where:

RR=RollingResistance[N]GVW=GrossVehicleWeight[N]

Crr=SurfaceFriction

6. CONCLUSION

The proposed project is expected to provide an Solar powered smart electric car which runs on solar energy makingitcleangreenandecofriendly.Theproposedproject isexpectedtosolvetheproblemsofchargingstationswhich exist in the current electrical vehicles by making the car solar powered. The project implemented is expected to reducethedependencyonthefuel poweredcarsthere by savingthefuelsaswellasreducingthepollution.Theproject is also expected provide a cost efficient solution for daily

commutesincethecostofperkmisalmostnegligiblewith this solar powered car. The project is also expected to provide accidental safety and alert system by implanting smartsystemwhichcanpreventcollision,over-speedingand alsonotifyimmediatelyifaccidenthappens.

REFERENCES

[1]AshwinChander,MadanKumar,ShobithNambiar,Harsh Zaveri;“DesignandStudyofTransmissionSystemfor ElectricVehicles”InternationalJournalofEngineering Science and Computing, March 2018, Volume 8 Issue No.3.16512http://ijesc.org/[pp16512]

[2]HailemariamN.Hailu*andDanielT.Redda;“Designand DevelopmentofPowerTransmissionSystemforGreen and Light Weight Vehicles: A Review”, The Open Mechanical Engineering Journal, 2018, Volume12DOI:10.2174/1874155X01812010081

[3]K.W.ECHENG;“RecentDevelopmentonElectric Vehicles”20093rdInternationalConferenceonPower ElectronicsSystemsandApplications.

https://www.researchgate.net/publication/22458592 9

[4]ZHANG*, C. ZUO, W. HAO, Y. ZUO, X. L. ZHAO and M. ZHANG;“Three-SpeedTransmissionSystemForPurely ElectricVehicles”InternationalJournalofAutomotive Technology,Vol.14,No.5,(2013),[pp.773].0

[5]Dr.ChokriMAHMOUDI;“AnOverviewofElectricVehicle Concept And Power Management Strategies” 978-14799-7300-2/14/$31.00 ©2014 IEEE

https://www.researchgate.net/publication/265709143

[6]Jae-OhHan,Jae-WonShin,Jae-ChangKimandSeHoon Oh;“Design2-SpeedTransmissionforCompactElectric Vehicle Using Dual Brake System” Appl. Sci. 2019, 9, 1793; doi:10.3390/app9091793 www.mdpi.com/journal/applsci.[pp1]

[7]M. Prabha, M. Seema, P. Saraswathi, “Distance-based Accident-AvoidanceSystemusingArduino”,International ResearchJournalofEngineeringandTechnology(IRJET)

e-ISSN:2395-0056

[8]Divya Thakur, A. P. Thakare, “A Review on ImplementationofFPGAforAutomaticReverseBraking System”,InternationalJournalofScienceandResearch (IJSR)ISSN(Online):2319-7064

[9]Sushil Kumar, Vishal Kumar, “AUTOMATIC EMERGENCY BRAKINGSYSTEM”,InternationalJournalofResearchIn Science & Engineering e-ISSN: 2394-8299 Volume: 1 Issue:3

[10] Shivam S. Shinde, Aditi V. Lawate, “Intelligent AutomobileAccidentAvoidanceSystem”,International JournalofScientific&EngineeringResearch,Volume4, Issue10,October-2013 ISSN2229-5518