EXPERIMENTAL INVESTIGATION ON CEMENT WITH PULVERISED FLYASH AND GROUND GRANULATED BLAST FURNACE SLAG (TRIPLE BLEND) IN DESIGN MIX CONCRETE

1M. Arch (construction project management) student, Faculty of Architecture, Dr.M.G. R Educational and Research Institution, Chennai, India.

2Deputy H.O.D, Faculty of Architecture, Dr .M.G.R Educational and Research Institution, Chennai, India.

3 Additional H.O.D, Faculty of Architecture, Dr .M.G.R Educational and Research Institution, Chennai, India. ***

Abstract - The advancement of concrete technology can minimize the demand on energy and natural resourcesaswell as reduce the impact of pollutants on the environment. The usage of supplemental cementitious materials (SCMs) like fly ash (FA), blast furnace slag, silica fume, metakaolin (MK),and rice has been proven in recent years by a number of researchers. Husk ash (RHA),hypo sludge, and other additives can save building costs by helping to improve the various qualities of concrete in both its fresh and hardened Stages. This research presents laboratory studies on the optimal content of fly ash and Granulated blast furnace slag(GGBS) as partial cement substitutes for studyingthestrengthproperties of concrete. Portland cementwaspartiallyreplacedby30%of GGBS and Fly ash by 20% respectively. The water to cementations ratio was maintained at 0.45 for all mixtures. The strength characteristics of the concrete were evaluated by conducting Workability, Compressive strength test, Splitting Tensile strength test, Flexural strength test, Water penetration test and Rapid chloride penetration test. Compressive strength tests were performedat7and28daysof curing, and split tensile and flexural strength tests were performed at 28 days of curing. The test results proved that the compressive strength, split tensile strength and flexural strength of concrete mixtures containing GGBS and Fly ash remains same. Once an optimal point for GGBS and flyashwas reached, at about 30% of GGBS and 20% of fly ash of the total binder content, further additions did not improve the flexural strength, compressive strength, or split tensile strength.

Key Words: Cement, fly ash, GGBS, CO2 and Global Warming

1. INTRODUCTION

Behind China but ahead of the US and Japan, the Indian cement industry is the world's second-largest cement producer.Itisacknowledgedasacoresector,contributing over1.3%ofGDPandsupportingover0.14millionjobs.350 micro cement plants make up the remaining 210 large cement plants, which together have a combined installed capacity of 410 tons in the country The states of Andhra

Pradesh,Rajasthan,andTamilNaduarehometo77ofthe 210bigcementplantsinIndia.

Directly releasing waste into the environment can have negative effects on the environment. The importance of recycling waste has thus been highlighted. To use natural resources more effectively and preserve the environment fromwastedeposits,wastecanbeusedtocreatenewgoods or used as admixtures. The natural fertility of the soil is ruined when these industrial wastes are dumped on surroundingproperty.

2.NEED AND SCOPE OF THE STUDY

Thecementindustryisexpectedtoreach550-600million tonnesperyear(MTPA)duetoincreasingdemandinvarious sectors ofresidential, commercial and industrial construction.Becauseofhighusageofcement,thenatural resourceisgettingdegradedandco2isemissionisgetting increased.Wasteslagfromindustriesaredumpedandused inthelandfillswhichisanimportantcauseoflandpollution. Slagishighlyavailablematerialwithlowcostandcementis indemandwhichcosthigher.

3. AIM AND OBJECTIVE

To lower the cost, enhance the stability and durability of concrete, a trial cube test of cement which includes pulverisedflyashandgroundgranulatedblastfurnaceslag isbeingconducted.Testingandconcludingtheapplicationof raw materials and developing the designmixare the first activities.Thenextstepistomixatestbatchofconcreteand record its qualities. The cubes are examined for the durabilitytest'shardenedconcretepropertiesafterthedays havebeencounted.Finally,thetestresultsareprovidedfor the comparison of concrete grades M30 and M25. An evaluationof raw materials,including testing, application, andmixdesign.Conductingtrialmixesandmeasuringfresh concrete,withafocusondurability.Providingcomparative studies.

4. METHODOLOGY

Using my literature review as a starting point, I drew inferencesabouttheexamscoresandthenumberofmixedup items. The data in my literature analysis is based on a careful examination of the necessary test methods and standardsetupforaggregates,flyash,cementandGGBS.My journal research of the experiments I conducted using cementwithflyashandcementwithgroundgranulatedblast furnace slag helped me to identify the optimal mix proportionformytrialmixexperiment.Thejournalarticle demonstrates the strength, workability, and durability of flyashandGGBSwithcement.GGBS,flyash,andcementhave all been used in experimental studies with concrete. The studyoftheflyashandGGBSmixpercentinmyexperiment testprocess

5.LITERATURE STUDY

Sincecementisacrucialcomponentofconstructionallover theworld,itisasignificantsourceofcarbondioxide(CO2) emissions, accounting for about 2.4 percent of all CO2 emissionsfromenergyandindustrialsources.Bothdirectly and indirectly, the heating of limestone releases carbon dioxide(CO2)intotheatmosphere,whileutilisingfossilfuels toheatthekilnresultsinindirectemissionsofCO2.Cement emits direct emissions as a result of a chemical reaction known as calcination. Due to its high concentration of calciumcarbonate,asubstancerequiredtoproducecement, limestone crushing and heating is a significant source of greenhousegasesatcementmanufacturingfacilities.About 0.8 tonnes of carbon dioxide are released during the manufactureofonetonneofcement.Thefirstarticleinmy investigationfocusedontheimpactofflyashonthestrength propertiesofaroller-compactedconcretepavement,andit was crucial to moving forward with my experiment. In accordancewiththeresearchmethodsutilisedinthisarticle, cement was substituted at various percentages, including 20%,30%,40%,and60%.anditwasevaluatedbytheuseof experimentsusingconcretecubesthatcontained318kgof cement per cubic metre. The mixture when 60% of the cementissubstitutedwithflyashyieldstheloweststrength values across all ages. Flyash's contribution to concrete's strengthissmallerthanthatofcement,evenuptoacertain point,whichcausesthemixture'sstrengthtodecrease.The followingarticlewasatestresearchusingGGBStopartially substitutecementinconcrete.Theprocessincludestesting of raw materials, identifying mix with the replacement of GGBS,andcompressivestrengthtesting.Analysiswasdone onthe7and28-daystrengthtestsusing20,30,40,and60% ofGGBSinplaceofcement.Concretereachesitsmaximum compressive, flexural, and tensile strength at a 30% replacementofcementwithGGBS. Mycasestudyinvolved thecommercialprojectofbuildingTidelParkinPattabiram, whereGGBSwasusedtoreplacemineraladditives.35%of the mineral combination was replaced; the project had a

valueof279croresandcovered11.4acres.ConcreteisM35 grade.Concretehasa180-minuteretentiontime,and51.97 Mpa of strength can be attained in 28 days. The 0.5 lakh cubic metres of concrete employed in this project has potentialstrength.Cementsavingsasapercentageofproject valueare0.80%.

6. MATERIALS AND ITS PROPERTIES

6.1 CEMENT

In general, cement can be defined as a material with very goodadhesiveandcohesivepropertiesthatallowsittobond withothermaterialsintoacompactmass. Locallyavailable Ordinary Portland cement of 53 grade of the ACC cement BranchcomplieswithISIstandardswasprocuredandthe followingtestswereperformedinaccordancewithIS:81121989.InthechemicalcompositionAI2O3is1.23,CIis0.02, MgOis1.03,LSFis0.92,C3Ais7.09,SO3IS1.42andlossof Ignitionis2.5andphysicalpropertiesofOPCisfinenessis 309m2/Kg,specificgravityis3.1,soundnessis1mm,comp. strengthfor7daysis45.6Mpa,comp.strengthfor28daysis 62.4 Mpa, the initial setting time is 121min and the final settingtimeis203min.

6.2 FINE AGGREGATES

Localriversandthatisfreeoforganicmatter.Thesandsize passingthroughthesieveis4.75mm,anda150µmISsieve was used in the study. It is important to make sure the screen is clean before use. (IS: 2386 (Part I) - 1963). The physicalpropertiesofthefineaggregatefinenessmodulus are 3.1, specific gravity is 2.80.the bulk density of loose aggregateis1320kg/m3 andcompactedaggregateis1760 kg/m3intheZone–IIgrading.

6.3 COARSE AGGREGATES

Themaximumsizecoarseaggregateusedhereis20mm.We used the IS 383:1970 to find out the proportion of mix of coarse aggregate, with 60% 10mm size and 40% 20mm. PhysicalPropertiesofCoarseAggregateisspecificgravityis 2.73.finenessmodulusis3.93andthebulkdensityofloose aggregate is 1440 kg/M3 and compacted aggregate is 1590kg/M3,thewaterabsorptionis0.5%.

6.4 FLY ASH

Fly ash is a finely divided mineral residue produced by burninggroundorpulverizedcoalinthermalpowerplants togenerateelectricity.Flyashisabeneficialmineraladditive forconcrete.Itaffectsmanypropertiesofconcreteinboth fresh and hardened states. Moreover, utilization of waste materials in cement and concrete industry reduces the environmental problems of power plants and decreases electricitygenerationcosts.

6.4.1 FLY ASH IN OPC

FlyashcanbeusedinPortlandcementconcretetoimprove concreteperformance.Portlandcementismadeofcalcium oxide (CaO), some of which is released in the Free State during hydration.As much as 20 pounds of free lime is released during hydration of 100 pounds of cement. The PhysicalPropertiesofFLYASHasshowninTable1

6.6 Water (IS:

BulkDensity(Loose) 1000-1100Kg/m3

BulkDensity(vibrate) 1200-1300Kg/m4

Table

1: PhysicalPropertiesofFLYASH

6.5 GROUND GRANULATED BLAST FURNACE SLAG (GGBS)

Crushedblastfurnaceisaby-productofblastfurnaceslag,a solidwaste massdisposed ofby theIndiansteel industry. Theseoperateattemperaturesaround1500degreesCelsius andarefedacarefullycontrolledmixtureofironore,coke andlimestone.Ironoreisreducedtoaresidueofironand slag floating on top of theiron. Thisslag is periodically tapped offasa moltenliquidandifitistobeusedforthe manufactureofGGBSithasbeenrapidlyquenchedinlarge volumesofwater.Quenchingoptimizescementproperties and produces granules resembling coarse sand. Thisgranulated slag is dried and pulverized into fine powder.The Chemical Composition (%) of Ground Granulated Blast Furnace Slag (GGBS) and Physical PropertiesofGroundGranulatedBlastFurnaceSlag(GGBS) asshowninTable2&3

The water used for mixing and curing is clean, free of harmfullevelsofoils,acids,alkalis,salts,sugars,organics,or othersubstancesthatcanharmconcrete.Drinkingwateris usedformixingconcrete

6.7Casting and Curing of Control Specimen

Foreachblend,3cubesofsize150mmx150mmx150mm,3 cylinders of 150mm diameter and 300mm height, and 3 prismsof100mmx100mmx500mmwerecastusingsteel molds.Castsampleswerekeptatambienttemperaturefor 24hours.After24hourstheyweredemoldedandplacedin water for curing. Cubes are used to determine the compressive strength of concrete for 7 days and 28 days. Three cylinders were used to determine the split tensile strengthofconcretefor28days.Threeprismswereusedto determinetheFlexuralstrengthofconcretefor28daysby two-point bending test with a supporting span, using universaltestingmachineofcapacity1000kN

AsperIS10262:2009M30 andM25grades were blended and used to create the test samples. For compressive and splitstrength,standardmetalliccubemoulds(150*150*150 mm) were cast. The hand-filled concrete cubes were compacted using a table vibrator. After 24 hours, the specimens were demoulded and submerged in water for varioustestingages.Threesamplesweretestedateachage todeterminetheaveragecompressiveandsplitstrengths.A 200MTcapacitycompressiontestingequipmentwasused forthetest.

8. RESULTS AND DISCUSSION

8.1Tests on Fresh Concrete

8.1.1Workability Characteristics

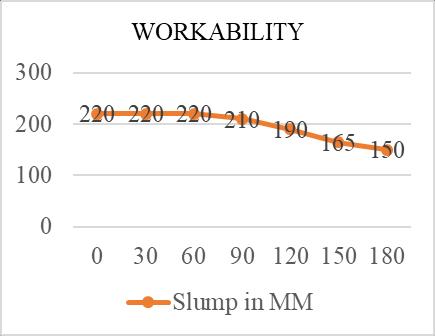

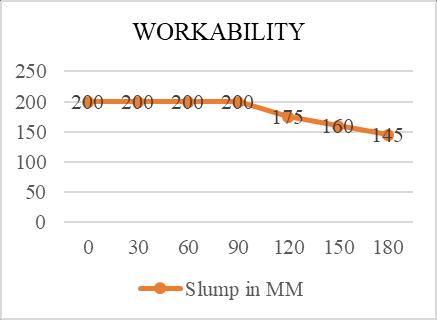

SlumpConeTest:Theslumpconeisproperlycleanedand oiledontheinteriorsurface.Theconsistometeristhenset down on a flat surface withthe droop cone put inside the consistometer'scylindricalsheetmetalpot.Theconeisthen fourlevelsdeepwithconcrete.Usinga16mmtampingrod, each layer is tamped 25 times. The cone is fully filled, its initialheightisdetermined,anditisthencarefullyliftedoff the ground. The final reading is recorded together with a dropinheightatthecentreoftheslumpedconcrete.

8.1.2

result

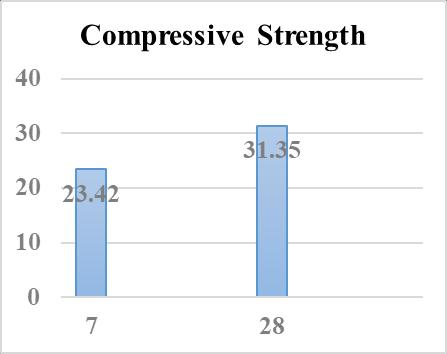

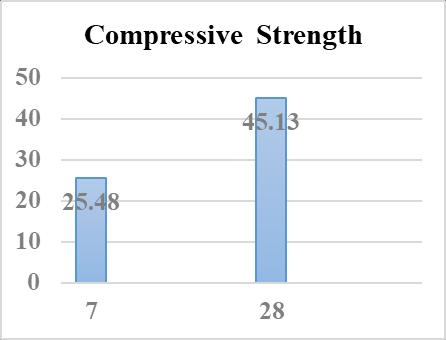

Fig–1and2showsthecompressivestrengthofconcretefor cubesofallmixturesat7and28daysofcuring.Fordifferent % substitutions of cement by FA and GGBS, only 6 cubes werecast.Theoutcomedemonstratesthatthecompressive strength rose with the addition of fly ash up to 20% and GGBSupto30%replacebyweightofcement,andthatany additionaladditionofFAandGGBScausesthecompressive strengthtodecrease.Initialcompressivestrengthincreases by84.93%forthefirst7daysandby150.43%forthefirst 28 days for M30 Grade. Initial compressive strength increasesby93.68%forthefirst7daysandby125.4%for thefirst28daysforM25Grade.

Compressivestrengthin7days93.68%,Compressive strengthin28days125.4%

8.1.3 Tensile Strength Tests result

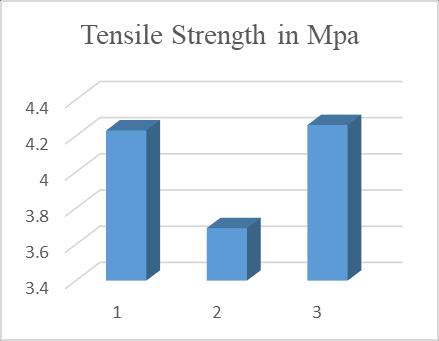

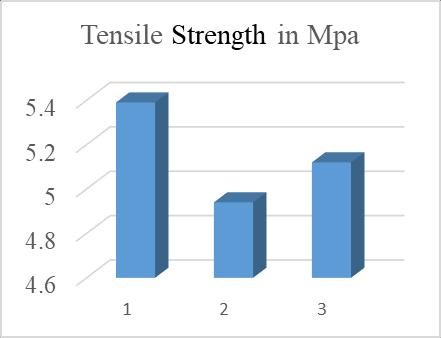

Fig-3and4showsthesplittensilestrengthofconcretefor cylindersmadeofallmixturesafter28daysofcuring.For different%substitutionsofcementbyFAandGGBS,only3 cylinderswerecast.Theadditionofflyashupto20%and GGBSupto30%replacebyweightofcementincreasesthe splittensilestrengthofcylinders;however,anyfurtherFA andGGBSreducessplittensilestrength.Figure3&4depicts it,demonstratinghowcuringaffectsthesplittensilestrength ofM30andM25Grade.

Compressive strength in 7 days 84.93 %, Compressive strengthin28days150.43%

TheaverageTensilestrengthofconcreteis5.15Mpaat28 daysofcuring

TheaverageTensilestrengthofconcreteis4.06Mpaat28 daysofcuring

8.1.4 Flexural Strength Tests result

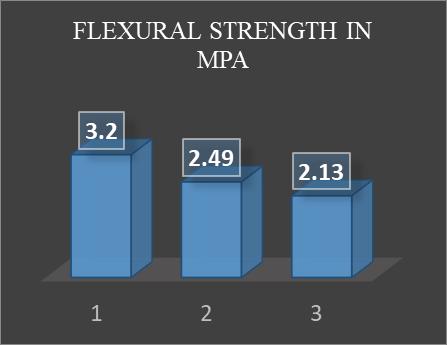

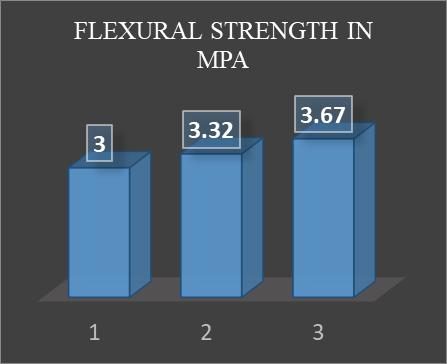

Fig -5 and 6 shows the flexural strength of concrete for prisms, for all mixtures, after 28 days of curing. Only 3 prismswerecastinorderforFAandGGBStoreplacevarious percentagesofcement.Theadditionofflyashupto20%and GGBSupto30%replacebyweightofcementincreasesthe flexuralstrengthofprisms,howeveranyadditionalFAand GGBS reduces flexural strength. The average flexural strength of M30 was 3.36 Mpa at 28 days of curing The averageflexuralstrengthofM25was2.61Mpaat28daysof curing.Figure5and6illustratestheimpactofcuringonthe flexuralstrengthofM30andM25Grade.

compressivestrengthforM25gradeusing35%GGBSand 20% fly ash as a cement substitute was determined to be 93.68N/mm2 after7daysofcuring.At28daysofcuring,it wasdiscoveredthatthecompressivestrengthforM25grade at 35% GGBS and 20% fly ash as a partial replacement of cementwasoptimalat125.4N/mm2.At28daysofcuring, 5.15 Mpa was determined to be the optimal value of split tensilestrengthforM30gradeat30%ofGGBSand20%of fly ash as a partial replacement of cement. At 28 days of curing,4.06Mpawasdeterminedtobetheoptimalvalueof splittensilestrengthforM25gradeat35%ofGGBSand20% offlyashasapartialreplacementofcement. At28daysof curing, it was discovered that the M30 grade's optimal flexuralstrengthat30%GGBSand20%flyashasapartial replacementforcementwas3.36Mpa.At28daysofcuring, it was discovered that the M25 grade's optimal flexural strength at 35% GGBS and 20% fly ash as a partial replacementforcementwas2.61MpaTheconsumptionof cementisreducedby50%byreplacingPulverizedFlyash andGroundGranulatedBlastFurnaceSlagTheconsumption of cement is reduced by 50% which leads to savings in ConsumptionofnaturalresourceslikeLimestone,Laterite, Hematite, Gypsum etc. The Emission of carbon dioxide is reducedby50%

REFERENCES

[1] NikolsTosic,SnezanaMarinkovic,NenadPecic,Ivan ignjatovic,JelenaDragas,“long-termbehaviourof reinforced beams made with natural recycled aggregate concrete and high volume fly ash concrete” construction and building materials, volume-176,10July2018pages344-358

[2] K.S. Tan, M.F.M. Zain, K.M. Ysof, M. Saffiudin, T.Y. ChangandK.S.Lee,“influenceofquarrydustand silica fume on properties of high performance concrete” proceedings of second international conferenceonadvancesinstrategictechnologies

[3] M.L. Gambhir, Concrete Technology – Second Edition, Tata McGraw-Hill Publishing Company Limited,NewDelhi,1995

9. CONCLUSION

results

The most effective amounts of fly ash and GGBS were discoveredtobe20%and30%,respectively.Themaximum compressivestrengthforM30gradeusing30%GGBSand 20% fly ash as a cement substitute was determined to be 84.93N/mm2 after7daysofcuring.At28daysofcuring,it wasdiscoveredthatthecompressivestrengthforM30grade at 30% GGBS and 20% fly ash as a partial replacement of cement was optimal at 150.43 N/mm2.The maximum

[4] RafatSiddique"Effectoffineaggregatereplacement withClassFflyashonthemechanicalpropertiesof concrete".CementandConcreteResearch33,2003

[5] SubramaniandK.S.Ramesh"ExperimentalStudyon Partial Replacement of Cement with Fly Ash and Complete Replacement of Sand with M sand". InternationalJournalofApplicationorInnovationin Engineering&Management,Volume4,Issue5,May 2015

[6] A.M. Neville, Properties of Concrete – Fourth and Final Edition, Pearson Education Limited, Essex, 2002.

[7] AmanJatale, KartikeyTiwari, SahilKhandelwal (EffectsonCompressiveStrengthWhenCementIs PartiallyReplacedbyFly-Ash).e-ISSN:2278-1684 Volume5,Issue4(Jan.-Feb.2013),PP34-43.

[8] BS 1881: Part 116: 1983, “Method for determinationofcompressivestrengthofoncrete cubes”, Testing Concrete, British Standards Institution,London,1983.

[9] IS–10262-2009Guidelinesforconcrete