Wind Turbine Monitoring System Using IoT

Rithika H Poojary1 , Bhoomika M2 , Pooja P Shetty3, Shilpa4, Ganesh V N51Student, Electronics & Communication Engineering, MITE, Karnataka, India

2Student, Electronics & Communication Engineering, MITE, Karnataka, India

3Student, Electronics & Communication Engineering, MITE, Karnataka, India

4Student, Electronics & Communication Engineering, MITE, Karnataka, India

5Associate Professor, Electronics & Communication Engineering, MITE, Moodabidri, India ***

Abstract - Nowadays, wind energy is increasingly utilized as a renewable energy source to meet the high demand for power. To produce environmentally friendlyenergy, it's crucial to implement an effective windturbine trackingsystem. Due to their remote locations, monitoring windmills continuously is time-consuming and energy-intensive using traditional methods. However, using digital equipment that consists of sensors and controllers can produce accurate results. In the study "Wind Turbine Monitoring System Using IoT," researchers used sensors installed on a windmill to measure various factors such as temperature, humidity, pressure, object distance, object detection, and rain detection. The output data from these sensors is essential for tracking the wind turbine's characteristics, enabling prioritization and automation of security measures. For remote tracking, the sensor data is displayed on a dashboard, accessible to authorized personnel and recorded for future reference if necessary. Professionals can utilize this information for designing modifications based on material and geometric parameters.

Key Words: Wind energy, Tracking, Sensors, Controllers, Automate.

1. INTRODUCTION

Tomeettherequirementsofenergynecessity,windenergy isutilizedasthesubstitutewellspringofenergy.Toutilize windenergyadequately,propermaintenanceofwindmillis required.Atsomepointshortcominghappensinwindmill anditturnsintoatroublesomeerrandtoreconfigureit.We needadecentmethodtodoit.TheInternetofThings(IoT) refers to a network of physical objects embedded with technologytocommunicate,sense,andinteract withtheir internalstatesorthesurroundingenvironment.Industries are always looking for ways to reduce energy costs and minimize energy waste, leading them to adopt various energy conservation methods. One of the most widely recognized approaches is performing industrial energy audits. These audits help to identify energy losses in equipmentandheavymachinerythatconsumeasignificant amountofenergy.Thefindingsfromenergyauditsprovide detailedinformationontheindustry'senergyconsumption. By reviewing energy audit reports, industries can take necessarystepstoconserveenergy.Unfortunately,energy audits are not conducted regularly in most industries,

resulting in only a minimal percentage of energy conservation. However, industries can make energy conservationaregularprocessbycontinuouslymonitoring their daily energy consumption. Wind turbine monitoring systemisaremotemonitoringandremotecontrolsystem forwindmills.Ithelpstomonitorsomeinternalandexternal parametersandcontrol the operationof windmillsfroma distance.Itusessensorstodetecttheconditionaroundthe windmill anda wirelessnetwork tosenddata toa central server.Thecentralservercanthengeneratereportsonthe condition of the windmill and send it back to remote locations.Thedatacollectedcanbeanalysedtodetermine the efficiency of the windmill which can also help in predictinganypotentialproblemsthatmightarise,thereby helpinginmaintainingahealthywindmill.Moreover,thelive informationfromthesensorsisshownstraightforwardlyon adashboardfordistantchecking.Thecontrolexpertscanget tothisdashboard,wheneverrequired.Theinformationcan appearonhourly,daybyday,weekafterweek,ormonth-tomonth premise. It is important for windmills to be monitoredbecausetheyareexpensivepiecesofmachinery that produce energy for electricity. If not monitored, they couldbreakdownandwouldneedrepairwhichwouldcost more money. The benefits of using IoT in windmill parametermonitoringsystemincludesremotemonitoring, reduced operating costs, increased efficiency, improved safetyand reduceddowntimeformaintenancework. Also monitoringandcomparingtheactualperformanceoutcome of the machine with the expected outcome can help the managementtounderstandthereasonforthegapusingthe datacollectedfromthemachine.Industriesareusingenergy monitoring devices to track their energy usage. Typically, energymetersandelectricalmeasuringdevicesareinstalled totrackthisconsumption.However,theuseofmeter-based energy tracking systems has become more complex, requiringalargenumberofmeasuringdevices.Byusingan automatedsystemtomonitorenergyconsumptioninsteadof manual data collection, it not only saves time but also enablesinstantanalysisofenergypatterns.

1.1 Proposed System

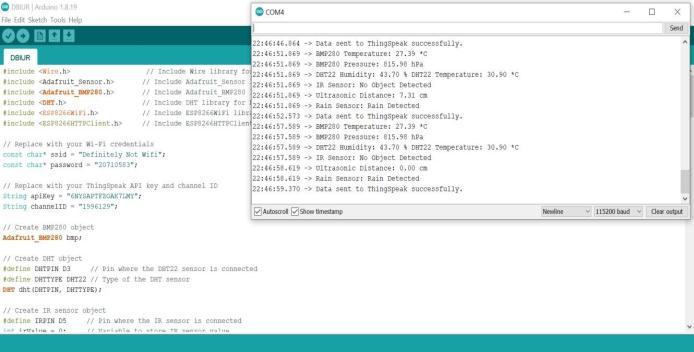

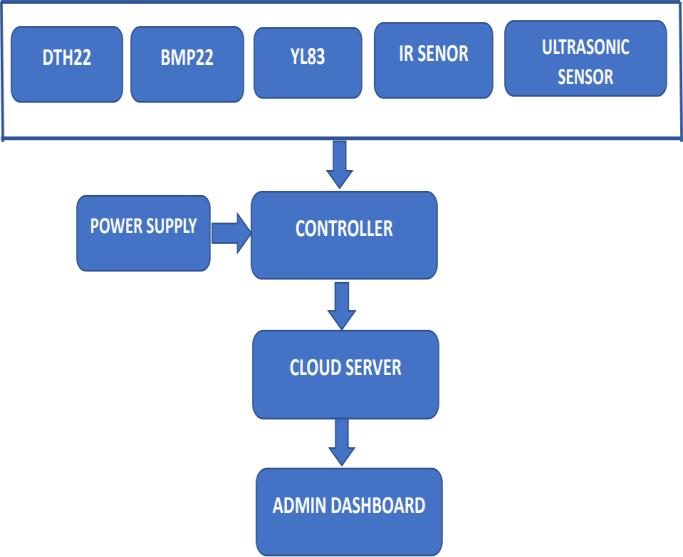

Blockdiagramofthissystemconsistsofamaincontroller, sensors(DHT22,BMP280,YL-83,IRsensorandUltrasonic sensor), a power supply, cloud server and an admin

dashboard.Thesensorscapturethededicateddatafromthe surroundings or the equipment’s surroundings. These sensors are calibrated and able to capture the data in accurate manner. The controller takes the data from the sensorsandthendeterminesthestateofthewindmill.Italso publishes the data on a dashboard for the purpose of monitoring.

DHT22sensorisusedtomeasuretemperatureandhumidity. BMP280 sensor is used to measure temperature and pressure.YL-83sensorisarainsensormodulethatisused todetectrain.YL-83sensorgivestheoutputhighwhenrain is detected and gives output as low when rain is not detected.IRsensorisusedtodetectobject.Ultrasonicsensor is used to measure object distance. The sensors send the collected data to nodeMCU. The output readings are observedinThingSpeakplatform.

TheDHT22sensorisusedtomeasurethetemperatureand humidity levels in the environment. This sensor provides accuratereadingsandiswidelyusedinvariousapplications duetoitshighreliabilityandstability.

TheBMP280sensor,ontheotherhand,isusedtomeasure the atmospheric pressure, which is a crucial factor in determiningtheweatherconditionsofaparticulararea.This sensor is highly accurate and provides precise readings, making it an ideal choice for weather monitoring applications.

Inadditiontothesesensors,theprojectalsointegratesthe YL83sensor,whichisusedtomeasuretheamountofrain falling on the surface. This sensor is highly sensitive and provides accurate readings even in low light conditions, makingitanexcellentchoiceformonitoringtheintensityof lightinindoorenvironments.

IR Sensor is responsible for object detection. The data collected from these sensors can be used to automate the windturbine.

Finally,theprojectalsoincludesanultrasonicsensor,which isusedtomeasurethedistancebetweenobjects.Thissensor emitsultrasonicwavesthatbouncebackwhentheyhitany object,andthetimetakenforthewavestoreturnisusedto calculate the distance between the sensor and the object. Thissensorishighlyaccurateandprovidesprecisereadings, making it ideal for applications that require distance measurement.

Figure1:MonitoringSystemforWindTurbine

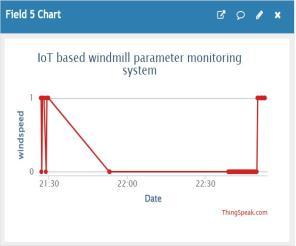

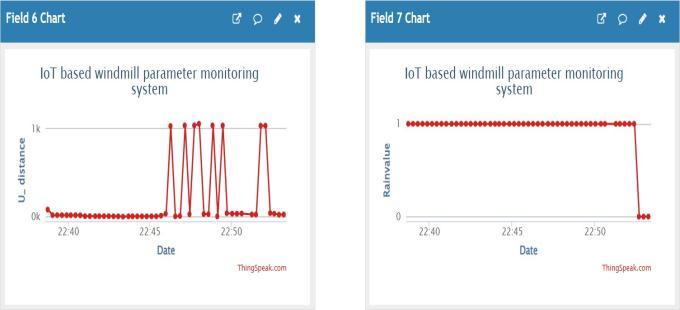

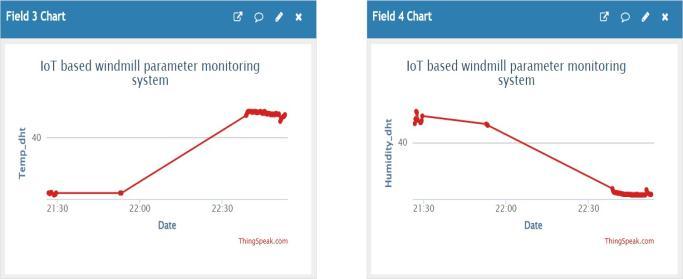

In ThingSpeak, data is observed in the form of graph. The visual representation of data helps in observing and analyzingitfromtimetotime.

Allthedatacollectedfromthesesensorsaretransmittedto ThingSpeakviatheinternet.ThingSpeakisanopen-source IoT platform that enables the collection, analysis, and visualizationofdatafromvariousIoTdevices.

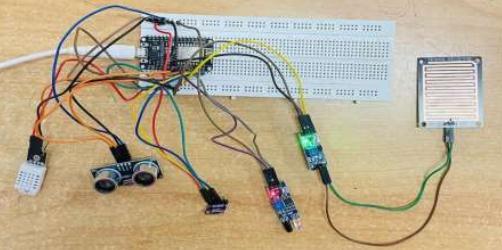

Figure2:Hardwareimplementation

Thefigure2demonstratesthephysicalimplementationof theproject,whichincludestheintegrationofvarioussensors suchasDHT22,BMP280,YL83,IRsensorandanultrasonic sensor.Eachofthesesensorsservesauniquepurposeinthe monitoringandtrackingofenvironmentalconditions.

2. RESULTS AND DISCUSSION

TheIoT-basedwindmillparametermonitoringsystemwas successfully implemented and tested in a real-world scenario. The system was able to collect data on various parameters such as temperature, humidity, pressure, rain detection,andobjectdetectionwithdistance.Thecollected data was then analyzed to identify any potential faults or issues with the windmill. The results obtained from the monitoring system were compared to the expected

outcomes,andthesystemwasfoundtobehighlyaccuratein detectingfaultsandpotentialissues.Thesystemwasableto monitor the windmill parameters in real-time and send alerts to the maintenance team when necessary. The maintenanceteamwasabletoaccessthedataremotely,and schedulemaintenanceactivitiesaccordingly.Thishelpedin reducing the downtime of the windmill, and thereby increasingitsproductivity.TheIoT-basedsystemwasalso foundtobehighlyefficientintermsofreducingoperating costs,asiteliminatedtheneedforphysicalinspections.The use of IoT-based monitoring systems for windmills has become increasingly popular in recent years, owing to its numerousbenefits.Thesystemnotonlyhelpsinreducing operatingcostsandincreasingefficiencybutalsoimproves safety by detecting potential faults and disasters. The collected data can also be used by the management to compare the actual performance outcome of the machine withtheexpectedoutcome,andidentifythereasonforthe gap. The implementation of the IoT-based windmill parameter monitoring system has numerous advantages overconventionalmethods.Oneofthekeyadvantagesisthe ability to remotely monitor the windmill parameters, therebyeliminatingtheneedforphysicalinspections.This notonlysavestimebutalsoreducestheriskassociatedwith physical inspections. The system is also highly efficient in termsofreducingoperatingcosts.Byeliminatingtheneed for physical inspections, the system reduces the need for manpower, and thereby reduces the associated costs. The collected data can also be used to identify potential faults and disasters, and thereby reduce the downtime of the windmill. This not only increases productivity but also reduces the associated costs. In conclusion, the implementation of the IoT-based windmill parameter monitoringsystemhasnumerousbenefits,includingremote monitoring, reduced operating costs, increased efficiency, improved safety, and reduced downtime for maintenance work. The system is able to detect potential faults and disasters,andthecollecteddatacanbeusedtoidentifythe reasonforthegapbetweentheactualperformanceoutcome ofthemachineandtheexpectedoutcome.

3. CONCLUSIONS

IoT-based windmill parameter monitoring system has shown to be a very effective and efficient option for monitoringwindmillparameters.Thedevicewascapableof collecting data on a variety of characteristics, including temperature,humidity,pressure,raindetection,andobject detection with distance. The collected data was then analysed to identify any possible windmill defects or concerns, and the method was shown to be extremely accurate in detecting faults and potential issues. The adoption of an IoT-based windmill monitoring system provides various advantages over traditional techniques. Thetechnologynotonlyreducesrunningcostsandincreases efficiency,butitalsoenhancessafetybydetectingpossible flawsanddisastersinrealtime.Theobtaineddatamayalso

be used to compare the machine's actual performance outputtotheprojected outcomeandfindthecause ofthe difference. Furthermore, the capacity of the system to remotelymonitorwindmillparametersreducestheneedfor physical inspections, saving time and lowering related hazards.Theacquireddatamaybeaccessedremotelybythe maintenance crew, and maintenance procedures can be scheduledaccordingly,decreasingwindmilldowntimeand boosting production. The deployment of an IoT-based windmillparametermonitoringsystemisanimportantstep towards offering dependable and cost-effective energy generation.Thesystem'smanybenefitsmakeitanappealing alternative for windmill monitoring and maintenance. As more wind energy producing projects are created throughout the world, the usage of IoT-based monitoring systems for windmills is projected to grow in the future years.Overall,theIoT-basedwindmillparametermonitoring system has shown to be a very effective and dependable methodofmonitoringwindmillparameters.Ithastheability tosaveoperatingcosts,boostefficiency,andimprovesafety, ultimatelycontributingtothecreationofsustainableenergy.

REFERENCES

[1] K.G.Chaudhari,“Windmill MonitoringSystemUsing InternetofThingswithRaspberryPi,” SSRN Electronic Journal,Nov.2020,doi:10.2139/ssrn.3729041.

[2] M.D.MudaliarandN.Sivakumar,“IoTbasedrealtime energymonitoringsystemusingRaspberryPi,” Internet of Things (Netherlands), vol. 12, Dec. 2020, doi: 10.1016/j.iot.2020.100292.

[3] Raj Kamal, “INTERNETOFTHINGSArchitecture and DesignPrinciples,”2017.

[4] M. S,D.G,C. B, andD. D,“IoT BasedMonitoring and ControlSystemusingSensors,”Journal of ISMAC,vol.2, no. 2, pp. 111–120, Jun. 2021, doi: 10.36548/jismac.2021.2.004.

[5] F.lizzaM,Rr.Mohan,U.scholar,andA.Professor,“IoT BASED WIND TURBINE MONITORING, FAULT DIAGNOSISANDCONTROLUSINGUART,”International Journal of Advanced Research in Management, vol. 3, no.6,2017,[Online].Available:www.ijarmate.com

[6] G.BalakrishnaandM.NageshwaraRao,“StudyReport onUsingIoTAgricultureFarmMonitoring,”in Lecture Notes in Networks and Systems,vol.74,Springer,2019, pp 483–491.doi:10.1007/978-981-13-7082-3_55.

[7] K. Ioannou, D. Karampatzakis, P. Amanatidis, V. Aggelopoulos, and I. Karmiris, “Low-cost automatic weatherstationsintheinternetofthings,” Information (Switzerland),vol.12,no.4. MDPIAG,Apr.01,2021 doi:10.3390/info12040146.

[8] A.Sunardi,D.Agus,H.Aditya,andW.Susila,“Onlineair velocitycontrol,temperatureandhumiditymonitoring system for clean room using Raspberry Pi,” in IOP ConferenceSeries: Materials Science and Engineering, Aug. 2019, vol. 550, no. 1. doi: 10.1088/1757899X/550/1/012011.

[9] I. G. M. N. Desnanjaya, A. A. G. B. Ariana, I. M. A. Nugraha, I. K. A. G. Wiguna, and M. U. Sumaharja, “Room Monitoring Uses ESP-12E Based DHT22 and BH1750Sensors,”Journalof RoboticsandControl(JRC), vol. 3, no. 2, pp. 205–211, Mar. 2022, doi: 10.18196/jrc.v3i2.11023.

[10] M. Bogdan, “How to Use the DHT22 Sensor for Measuring Temperature and Humidity with the ArduinoBoard,” ACTA Universitatis Cibiniensis,vol.68, no.1,pp.22–25,Dec.2016,doi:10.1515/aucts-20160005.

[11] E.Avallone et al.,“Aninexpensiveanemometerusing Arduinoboard,” Facta universitatis -series:Electronics and Energetics,vol.32,no.3,pp.359–368,2019,doi: 10.2298/fuee1903359a.

[12] A.A.Mungekar,Y.K.Solanki,andR.Swarnalatha,“Real time weather surveillance via lab view interfaced arduino,” International Journal of Engineering and Technology(UAE),vol.7,no.4,pp.2715–2717,2018, doi:10.14419/ijet.v7i4.15661.

[13] L.Louis,“WorkingPrincipleofArduinoandUsingitasa ToolforStudyandResearch,”International Journal of Control, Automation, Communication and Systems,vol. 1, no. 2, pp. 21–29, Apr. 2016, doi: 10.5121/ijcacs.2016.1203.