STUDY ON PERFORMANCE OF CONCRETE BY USING ALCCOFINE AS A PARTIAL REPLACEMENT OF CEMENT

Sujana Palamani1,K.Bala Gopi Krishna2M.Tech Student1& Assistant Professor2, Department Civil of Engineering, Vignan's Foundation for Science - Technology & Research, Vadlamudi, Guntur, India. ***

Abstract - This paper presents the study of effect of performance of concrete using supplementary cementious material i.e.Alccofine with M-40 grade of IS cube specimen We partially replaced cement by weight of binder with alccofine replacement with percentages of 3% ,6%,9% and 12%. Also, we've investigated strength in compression ,split lastingness and flexural capability for all various cases. The compressive strength of alccofine concrete is increases at all stages fresh and hardend due to the presence of cementious materialthat is alccofine Comprasion is carried between the properties of the conventional and alccofine concrete.

Key Words: Alccofine, strength, supplementary cementiousmaterial.

1. INTRODUCTION

One of the most often utilised materials in the constructionsectorisconcrete.Concreteispouredintoany desiredshape.Theconcreteisutilisedinnumerouswaysin depends on a structure's ability to support a load. Steel reinforcementisintroducedintoconcretetosupportaxial andflexuralloads.Althoughthesimplecementconcretehas weak tension properties, it exhibits good compressive strength and little crack resistance. Because of incorrect reinforcementalignment,thesteelinreinforcedconcrete structures corrodes, leading to structural failure from insufficientcover.

Inaddition,Thecompressivestrengthcanbeincreased by up to by adding various compounds that may be by products.Comparedtotypicalconcrete,thereisacertain dosage that can help improve compressive strength and resistancetochemicalattackstoacertainamount.Concrete is insufficient due to a lack of materials, particularly cements.Therearemanysubstitutesforcement,including flyash, bottomash,GGBS,and Metaoklin. Via partial and completecementreplacementintraditionalconcrete,these materials are tested in the lab for strength and other qualities. When compared to cement, the replacement exhibitsvariousbeneficialcharacteristics.

A controlled granulation process yields the substance acccofine. It is a slag with a high glass concentration and extremelysmallparticlesize.Althoughthereisadecreasein water consumption, concrete still performs well and

workabilityismaintainedupto70%replacement.Alcofineis anexcellentwaterredundantthatmaybeusedtoenhance the parameters governing strength and other aspects of concrete.Alcofineisusedasacementsubstituteprimarilyfor two conditions: to stabilise the supply of cement and to enhance the characteristics of concrete throughout its life cycle.Alcofinecombinedwithflyashusehenceimprovesthe mechanicalqualitiesofconcrete.

2.REVIEW OF LITERATURE

TheCountoMicrofineProductsLtd.AmbujaCementLtd.and AlconGroupGoa are partnersin theCMPPLgroup. Goa is hometooneofthelargestdedicatedmanufacturingfacilities for microfine materials in the world. In Kolkata, India, Alcofinewasfirstintroduced.Twocutting-edgeproductsin the realm of concrete, Alccofine 1203 and Alccofine 1101, havebeenintroducedbyAmbujaCementCompany(ALC).

3. METHODOLOGY

The following methodology was used to investigate the behavior of Alccofine in workability and mechanical propertiesofconcrete.M50gradeconcretemixdesignwas determined in accordance with IS:10262-2019 for the inquiry at hand. Alccofine was used in place of cement in someplaces.Upto3,6,9,and12%ofthecement'sweight was added as accofine. Concrete's mechanical and fresh characteristicswereexaminedfortheimpactofalccofine.All aspectsofthemixdesignemployedawater/cementratioof 0.45.At the conclusion of thisinvestigation,a comparison between the qualities of conventional and alccofine was made.

4. EXPERIMENTAL PROGRAM

Anexperimentalprogrammehasbeendesignedtodeliver adequate data for determining the Alccofine-based concrete's quality. The behaviour of alccofine in the workabilityandmechanicalqualitiesoftheAlccofine-based concretehasbeenstudied.

4.1 Materials Used

Cement Forthestudy,KCPOrdinaryPortlandCement(OPC) hasbeenused.

4.2 Fine Aggregate

For the experimental purpose, aggregate from a nearby quarrythatpassesthroughanISsievemeasuring4.75mmis gathered.

4.5

4.3 Coarse Aggregate:

The aggregates used are those that passed through a 4.75mmsieve.Thechosenaggregatedimensionis20mm, whichisclearanddevoidofsurfacedustandparticles.Ata nearbyquarry,coarseaggregatewasgathered.

4.4 Alccofine

Alccofineisapozzolanicmaterialthatmaybeusedtocreate concrete structures that are highly resilient.. It is a specificallyprocessedproductmadefromhighglasscontent, high reactivity slag that is obtained by the controlled granulation process. Utilized is alccofine 1203. It's taken fromAmbujaCements.

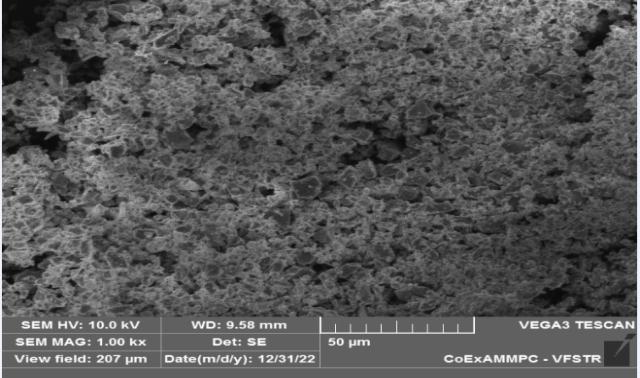

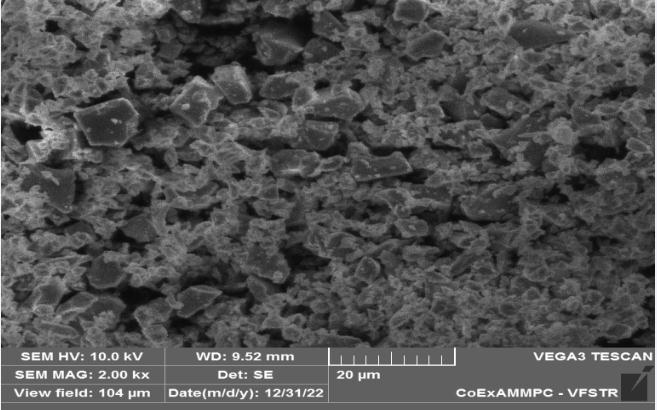

The basic working principle of SEM is Electron beams (primary electrons) striking a surface can either change directionelasticallywithnoenergyloss(elasticscattering) orsomeenergycanbemostinitialelectronsarehaltedasa resultofbeingabsorbed.andsomebackscattered(inelastic scattering). According to the SEM image, the particles of alccofine-1203areextremelyfine,haveaglassysurface,are asymmetricalinshape,andhavesharpedges.

5.MIX DESIGN

The mix design is determined by using IS 10262:2019 recommendations.M40gradeofconcreteisselectedforthe presentwork.

6.EXPERIMENTAL PROCESS

Concretesampleswerecastusingthefollowingmouldsfora varietyofresearch.

6.2 Hardened State Properties of concrete

Strengthincompression,splittensilestrength,andflexural strengthofhardenedconcretewerestudiedinthiswork.

6.2.1 Compressive strength

Threecubesweretestedforstrengthincompressionusinga compression testing machine in accordance with IS 5161959.

6.1 Fresh Properties of Concrete

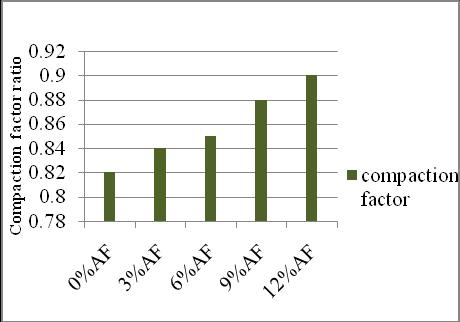

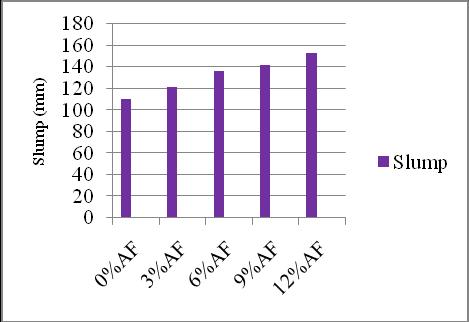

SlumpandCompactionfactortestswasconductedbyusing slumpconeandcompactionratioapparatus.

Table 7 Freshpropertiesofconcretebyusingslumpcone andcompactionfactorratiotests.

Table

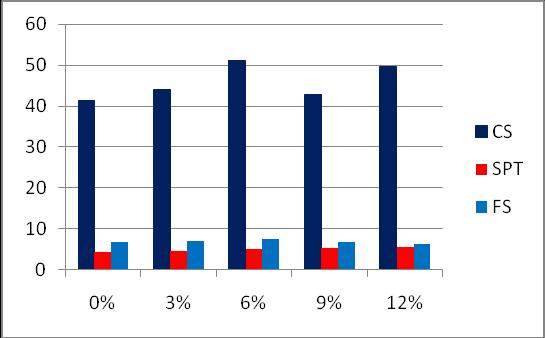

CompressiveStrengthofConcrete

Split tensile strength

The test procedure focuses on figuring out the splitting tensilestrengthofcylindricalconcretesample.Byusingthis technique, a cylindrical specimen is compressed over its wholelength.

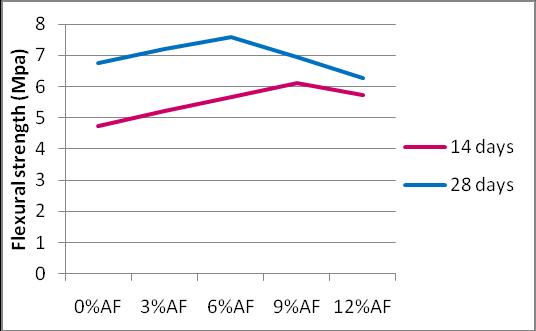

6.2.3 Flexural strength

Thistestprocedureusesasimplebeamunderatwo-point forcetoassesstheflexuralstrengthofconcrete.Forthetest, thetwopointbendingtestapparatuswasutilised.

7.Comparison of test results

Severalconcretecompositions'maximumvaluesforstrength incompression,splittensilestrength,andflexuralstrength arecomparedinthe28-daystrengthtest.

8. CONCLUSIONS

TheresultsindicatethataddingAlccofinewillenhancethe mechanical and workability characteristics of Alccofine concrete.WorkabilityincreasesonintroductionofAlccofine tonormalconcrete.

Addition of Alccofine shows immense improvement in workabilityofAlccofineconcrete.Strengthincompression, splittensilestrengthandflexuralstrengthshowsmaximum at 6% Partial replacement of Alccofine.It may be deduced thattheidealrangeforreplacingcementwithAlccofineis between3%-6%.

Alccofine has outstanding mixing behaviour in terms of workabilityandstrengthimprovement.Alcofine'sultra-fine particlesizeproducesabetterandsmoothersurfacefinish, and it is easy to use and may be applied right to cement.

Employing this substance improves the properties of hardenedconcretewhileloweringthecostoftheconcrete mixforhighstrengthconcretecomparedtoconcretewithout alccofine.

REFERENCES

[1]Pawar,M.S.,andA.C.Saoji."EffectofAlccofineonself compactingconcrete."InternationalJournalofEngineering andScience2,no.6(2013):05-09.

[2] P. Narasimha Reddy*, J. Ahmed Naqash “Effect of AlccofineonMechanicalandDurabilityIndexPropertiesof GreenConcrete”NationalInstituteofTechnology,Srinagar, Jammu&Kashmir,India

[3]BhanavathSagar&MVNSivakumar“Useofalccofine1203 in concrete: review on mechanical and durability properties”InternationalJournalofSustainableEngineering.

[4] Upadhyay, Siddharth P., and M. A. Jamnu. "Effect on compressive strength of high performance concrete incorporatingAlccofineandflyash."InternationalJournalof Innovative Research & Development3, no. 2 (2014): 124128

[5]P.R.KalyanaChakravarthyandR.RathanRaj“Analysis on compressive strength of concrete with partial replacement of cement with alccofine “ARPN Journal of Engineering and Applied Sciences ©2006-2017 Asian ResearchPublishingNetwork(ARPN).

[6] Gayathri, K., K. Ravichandran, and J. Saravanan. "Durability and cementing efficiency of Alccofine in concretes."InternationalJournalofEngineeringResearch& Technology5,no.5(2016):460-467.

[7] Ankitha , R., Prakruthi S, S Sneha, Seema Tharannum. “ArecanutasaPotentialBio-adsorbentforRemediationof Chromium.”InternationalJournalofScienceEngineeringand Management(IJSEM)(2017):7-14.

[8]JeykarK.,SrinivasanV.,Performancecharacteristicsof twincylinderDidieselengineoperatedwiththreedifferent nonediblevegetableoilblendswithdiesel,International JournalofAppliedEngineeringResearch,v-9,i-22,pp7601-7607,2014.

[9]AmbicaA.,TamizharasanV.,VenkatramanK.,Treatment of domestic waste water by electrochemical method, InternationalJournalofAppliedEngineeringResearch,v-9,i22,pp-5537-5542,2014.

[10] Gokul V., Ambica A., An experimental study on high strengthconcretewithreplacementof fineaggregateusing weldingslag,InternationalJournalofAppliedEngineering Research,v-9,i-22,pp-5570-5575,2014.

[11]DivyaaK.,VenkatramanK.,Designofflexiblepavement foranengineeringcollege,InternationalJournalofApplied EngineeringResearch,v-9,i-22,pp-5576-5581,2014.

[12] Venkatraman S., Sathish Kumar K., Effect of glass powderonperformanceof concretesubjectedtosulphate attack, International Journal of Applied Engineering Research,v-9,i-22,pp-5636-5659,2014.

[13] Iyappan L., Maria Subashini L., Landuse change detection in namakkal taluk using remote sensing, InternationalJournalofAppliedEngineeringResearch,v-9,i22,pp-5699-5707,2014.

[14]AnsariU.S.,ChaudhriI.M.,GhugeN.P.,PhatangreR.R., Concrete With ALCCOFINE & Fly Ash An Economical & Environment Friendly Approach ,International Journal of ModernTrendsinEngineeringandResearch,(2015).

[15] Siddharth P Upadhyay, Prof. M.A.Jamnu, Effect On Compressive Strength Of High Performance Concrete IncorporatingAlccofineAndFlyAsh,JournalOfInternational AcademicResearchForMultidisciplinary,Volume2,(2014).

[16] Dr. Mohid Hamraj, Experimental Study On Binary BlendedHighStrengthSteelFibrereinforcedConcreteUsing Alccofine As Mineral Admixture, International Journal Of Science,EngineeringAndTechnology,Volume2,(2014).

[17] Abhijitsinh Parmar, Dhaval M Patel, Dron Chaudhari, HarpalsinhRaol,EffectofAlccofineandFlyAshAdditionon theDurabilityofHighPerformanceConcrete,International Journal of Engineering Research & Technology, Volume 3, (2014)

[18] Praveen Nayak S, H. S. Narashimhan, Raghunandan V.Kadaba Hardened Properties of Concretes made with Micro Silica and Alccofine-A Performance Optimization based Comparative Study, International Journal of EngineeringResearchandDevelopment,Volume10,(2014).