OLIVE SEED ASH AS PARTIAL REPLACEMENT OF CEMENT IN SANDCRETE BLOCK

1S. I. Anowai, 2T. S. Ketkukah, 3M. Pam, 4M.E. Gukas, 5J.B. Rwang and 6D.C. ANIESODO1 Senior Lecturer, Department of Building, University of Jos, Nigeria

2 Reader, Department of Civil Engineering, University of Jos, Nigeria

3Lecturer, Department of Quantity Surveying, University of Jos, Nigeria

4 Lecturer, Department of Building, University of Jos, Nigeria

5 Lecturer, Department of Quantity Surveying, University of Jos, Nigeria

6 Student, Department of Building, University of Jos, Nigeria ***

Abstract - This research is therefore aimed at assessing the suitability of the use of olive seed ash (OSA) as partial replacement of ordinary Portland cement (OPC) in the production of sandcrete blocks. The olive seeds were completely burnt to ashes at a temperature of 600-7000C in a kiln. Mix ratio of 1:6 (cement: sand) was used in this study. Water cement ratio of 0.45 was adopted in this study. OPC was partially replaced with OSA at 10%, 20% and 30%. The block samples were moulded and cured for 7, 28 and 56 days. The compressive strengths of the blocks were tested by crushing using compressive test machine. The compressive strengths of the blocks were observed to increase with increasing days of curing. Sandcrete block samples made with 10% and 20% replacements of OPC with OSA achieved compressive strengths of 3.53N/mm2 and 3.00N/mm2 respectively at 28 days and increased to 3.83N/mm2 and 3.13N/mm2 at 56 days respectively. These values satisfied the minimum compressive strength requirements of 3.45N/mm2 for load bearing wall at 10% and 2.5N/mm2 for non load bearing walls at 20% replacement levels of OPC with OSA. The densities of the blocks decreased as percentage replacements of OPC with OSA increases. The Blocks also satisfied the maximum water absorption requirement for sandcrete blocks. It is thus recommended that OPC should be partially replaced with 10% and 20% OSA in load bearing and non load bearing sandcrete blocks respectively.

Key Words: Oliveseedash,sandcreteblocks,compressivestrength,densitywaterabsorption.

1. INTRODUCTION

Thehighcostofcementusedasbinderintheproductionofmortar,sandcreteblocksandconcretehasledtoasearchforits alternative.Inadditiontocost,highenergydemandandemissionofCO2,whichisresponsibleforglobalwarming,thedepletion oflimestonedepositsaredisadvantagesassociatedwithcementproduction.Itisimportanttoreplacecementwithother availablematerialsatlowestpossiblecosts[1] Theenvironmentaleffectofcementismostapparentintermsofitsemissions ofcarbondioxide(CO2),andthisisoneofthemainimpactsofcementproductiononanindustrialscale.

Sandcrete block is a composite material made up of cement, sand and water which are moulded into diverse sizes [2]. Sandcreteblocksaremadefromamixtureofsand,cementandwaterandareproducedinamixratioof1:3,1:4,1:6,and1:8as thecasemaybedependingonthemixratioadopted.).However,sandcreteblocksarenotaffordableforlowincomeearners [3.]SometimesotheringredientssuchaspozzolanasareaddedtoreducetheamountofexpensivePortlandcement.

Agricultural waste constitutes a sizeable proportion of the accumulated solid waste in many cities of the world. Attemptshavebeenmadebyvariousresearcherstoconvertsolidwastetobeneficialapplicationswithahighlevelofsuccessas awayofreducingsolidwasteaccumulation[4]

Manystudieshaveshowntheashesfromagriculturalwastescanbeeconomicallyusedaspartialreplacementof cementinsandcreteblocks.AnowaiandAfunanya[5]investigatedthesuitabilityofMilletHuskAsh(MHA)inhollowblocks production.CementwaspartiallyreplacedwithMHAinvaryingpercentagesof0,10,20and30%byweight.Itwasfoundthat cementcouldbepartiallyreplacedwithupto20%MHAinsandcreteblockproduction.AnotherresearchbyAnowaiet.al,[6] alsofoundMaizeCobAshcanbeusedaspartialreplacementofordinaryPortlandcement(OPC)intheproductionofSandcrete Blocks.Afolayan,Oriola,MosesandSani[4],investigatedtheeffectofeggshellash(ESA)onthepropertiesofsandcreteblocks andfoundthatcementcouldbepartiallyreplacedwithESAinsandcreteblockproduction.Aginam,OnodaguandNwakaire, Chidozie[7]investigatedtheuseofbreadfruitstemashasapartialreplacementofcementinsandcreteandrecommendedthat notmore10%ofcementshouldbereplacedwithbreadfruitstemash.Similarly,Sangeetha[8]foundtheoptimumreplacement levelofOPCwithricehuskash15-20%.

Oliveseedsarepartofagriculturalwastethatlitterstheenvironment.Intheeverincreasingendeavorstoconvert wastetowealth,thevalueofconvertingoliveseedtobeneficialusebecomesanideaworthinvestigating.OliveSeedsarefound abundantlyatvariousfarmsacrossNigeriaaretreatedaswastematerials.Theoliveseedashisobtainedbythecombustionof OliveSeed.

ThisStudyisaimedatassessingthesuitabilityofOliveseedashaspartialreplacementofcementinsandcrete blockbycomparingthecompressivestrengthsandwaterabsorptionsatdifferentpercentagesofreplacement.

2. MATERIALS AND METHODS

Themainconstituentmaterialsusedinthisresearchworkarecement,Oliveseedash,sandandwater. OrdinaryPortland Cement(OPC)usedinthisstudywas“BUA”brandofgrade43cement,conformingto[9] Thespecificgravityofthecementwas foundtobe3.15

TheoliveseedsusedinthisstudywassourcedfromBwonpevillageofAmpangwest,Plateaustate,Nigeria..Theseeds weresundriedandburntunderacontrolledtemperatureinakilnattemperatureofapproximately600˚Cto700˚Ctoobtain theash.Theashobtained wassievedthrougha 150um sieve beforeuse. Chemical analysisandspecific gravitytestwere performed on the ash. The chemical analysis of the sample was carried out using Energy Dispersive X-ray Fluorescence Spectrometer(EDXRF).TheapparentspecificgravityoftheOSAwas2.75,whichwaslessthanthatofcement.

Thefineaggregateusedwasriversandpassing4.75mm sieve.Sieveanalysisresultofthesandshowthatthesandfalls underzone2inaccordancewith[10].Thespecificgravityofthefineaggregatewasfoundtobe2.72.Thewaterusedforthis researchwasboreholewaterwhichisfitfordrinkingandconformingto[11]

Inthisstudy,225mmx450mmhollowblockswereproducedattheconcretelaboratoryoftheDepartmentofbuilding UniversityofJos.Mixratio1:6(cement:sand)wasusedinthisstudyforthesandcreteblocksproduction.Cementwaspartially replacedwithOliveseedashatvaryingpercentagesof0,10,20and30%byweight.Watercementratioof0.5wasadopted. Theblocksweremoldedandcuredfor7,14and28days.Themixingprocedurewasdoneinthreestages.Inthefirststage,all binders(cement,Oliveseedash)wereweighedandmixedmanuallyuntilalltheconstituentsmixeduniformly.Thesecond stageinvolvesmixingthebinderwiththeaggregateforabout5minutesuntilahomogenousmixisachieved.Atthefinalstage, measuredwaterisaddedontothesandcretemix.Aftermixing,thesandcretewaspouredintoanelectricmouldingmachine andwellvibrated.Aftervibration,theblockswereremovedfromthemouldandcuredafter24hoursbymethodofsprinkling in accordance with [12] This involves wetting of blocks regularly with water so as to permit proper hydration. The compressivestrengthsoftheblocksweredeterminedat7,14and28daysbycrushingusingcompressivestrengthtesting machineinaccordancewiththestandardproceduregivenby[12].Waterabsorptiontestwasalsocarriedoutontheblock samplesafter28daycuringinaccordancewith[12].

3. RESULTS AND DISCUSSION

3.1 Chemical Composition of Olive Seed Ash

The result of chemical analysis result of Olive seed ash is presented in Table 1. The result showed that the sum of the percentagesofSiliconOxide,AluminiumOxideandIronOxide(SiO2+Al2O3+Fe2O3)is72.54%.Thisisgreaterthantheminimum sumof70%specifiedby[13]forpozzolanas.Thisindicatesthatoliveseedashisagoodpozzolanicmaterialandcanbeusedas partialreplacementofcementinsandcreteblockproduction.

Table 1: Olive Seed Ash Chemical Composition and Percentage content.

3.2 Compressive Strength of the Blocks

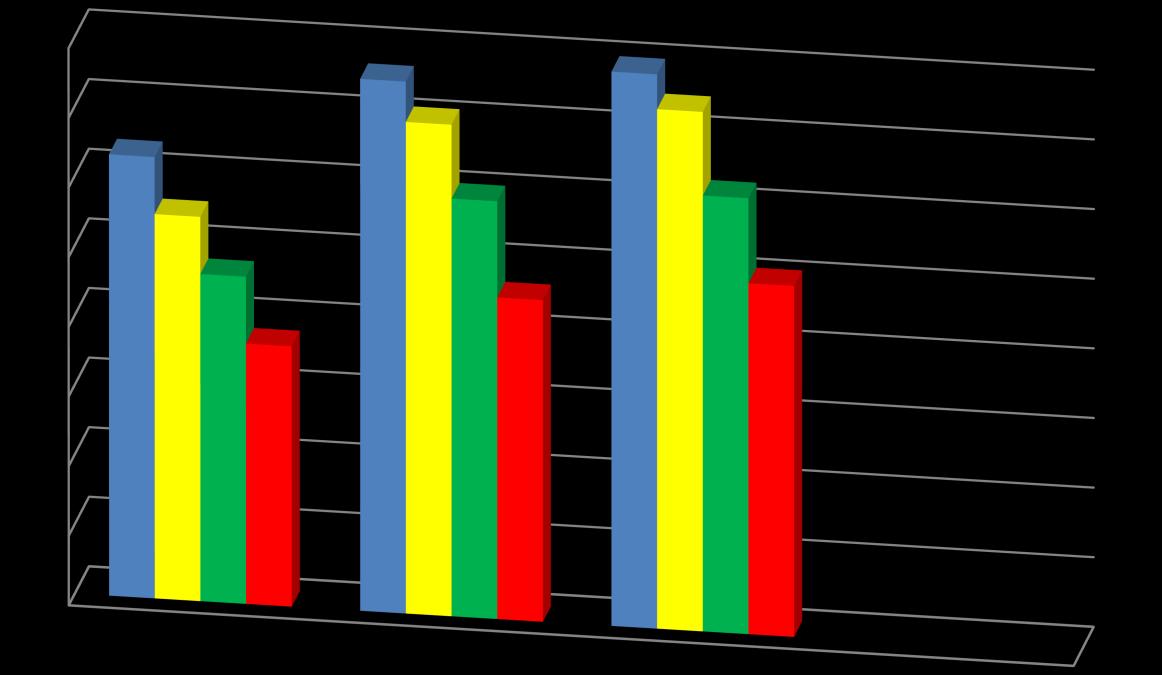

Figure1showstheresultofthecompressivestrengthdevelopmentofsandcreteblocksproducedwithOliveSeedAsh. Theresultshowsthecompressivestrengthsofthebblocksatcuringdurationsof7,28and56days.BasedonFigure2,the compressivestrengthoftheblocksincreasedwithincreaseincuringdurationanddecreasedwithincreaseinpercentage replacementofOSA.

At0%replacementofOPCwithOSA,thecompressivestrengthswere3.17N/mm2,3.82N/mm2 and3.98N/mm2 at7 days,28daysand56dayscuringdurationsrespectively.At10%percentagereplacement,thecompressivestrengthswere 2.76N/mm2,3.53N/mm2 and3.73N/mm2at7days,28daysand56dayscuringdurationsrespectively. At20%percentage replacement,thecompressivestrengthswere2.35N/mm2,3.00N/mm2and3.13N/mm2at7days,28daysand56dayscuring durations respectively. At 30% percentage replacement, the compressive strengths were 1.87N/mm2, 2.31N/mm2 and 2.52N/mm2 at7days,28daysand56dayscuringdurationsrespectively.

Theresultsshowedthattheblocksproducedwith0%OSAachievedtherequiredstrengthsof3.45N/mm2forload bearingwallsand2.5N/mm2fornon-loadbearingwallsasspecifiedby[13]forsandcreteblockproductionat28daysofcuring. Sandcrete block samples made with 10% and 20% replacements of OPC with OSA achieved compressive strengths of 3.53N/mm2 and3.00N/mm2 respectivelyat28daysandincreasedto3.73N/mm2 and3.13N/mm2at56daysrespectively. Thesevaluessatisfied the minimumcompressivestrengthrequirementsof3.45N/mm2 forloadbearingwall at 10%and 2.5N/mm2 fornonloadbearingwallsat20%replacementlevelsofOPCwithOSA.

3.3 Density of Sandcrete Blocks

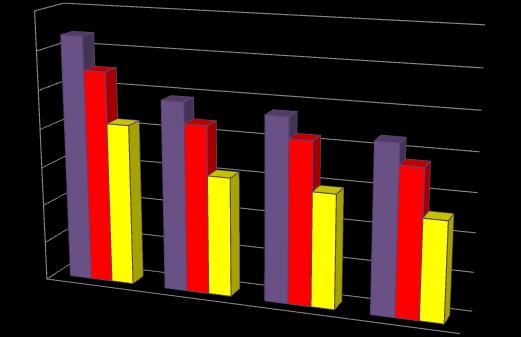

ThedensitiesoftheblocksamplestestedarepresentedinFigure3.Theresultshowsthatthemorequantityofcementpresent in the blocks the more their densities. This implies that increase in the percentage replacement of OSA results in the correspondingdecreaseinitsdensity.Basedontheresults,with0%replacementofOPCwithOSAgavethehighestdensityof 2317.8kg/m3andthedensitydecreasedprogressivelyasthepercentagereplacementofOPC|withOSAintheblocksincreased.

7 days 28 days 56 days

Percentage Replacements of OPC with OSA

Figure 2: Density Test Representation in kg/m3

3.4 Water Absorption of Sandcrete Blocks

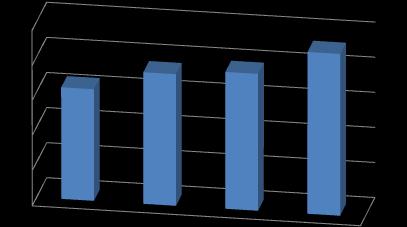

WaterabsorptiontestresultsoftheblocksatdifferentpercentagereplacementsofOPCwithOSAarepresentedin Figure4.NigerianIndustrialStandard[13]thatwaterabsorptioninsandcreteblocksshallnotbegreaterthan12%.Theresult showedthatthewaterabsorptionoftheblockswith0%,10%,20%and30%replacementsofOPCwithOSAare6.37%,7.59%, 8.5% and 9.25% respectively. The results showed that the water absorption of the blocks increased with increase in the percentagereplacementofOPCwithOSA.Although,alltheblockshavetheirwaterabsorptionsbelowthemaximumvalue specifiedby[13]thespecimenwith0%OSAgavethelowestwaterabsorptionof6.37%.

4. SUMMARY OF FINDINGS

Basedontheresultsofvarioustestscarriedoutonthesandcreteblocksamples,thefollowingconclusionsweremade:

1. Oliveseedashispozzolanicandsuitableforuseaspartialreplacementofcementinsandcreteblockproduction.

2. ThedensityofsandcreteblocksdecreasewithincreaseinthepercentagereplacementofOPCwithOSA.

3. Sancreteblockswith10%replacementofOPCwithOSAsatisfiedtheminimumcompressivestrengthrequirementsof 3.45N/mm2 forloadbearingat28dayswhileSancreteblockswith10%replacementofOPCwithOSAsatisfiedthe minimumcompressivestrengthrequirementsof2.50N/mm2 forloadbearingat28days

4. ThewaterabsorptionoftheblocksincreasedwithincreaseinthepercentagereplacementofOPCwithOSA.However, allthesamplesatisfiedthemaximumwaterabsorptionrequirement

5. CONCLUSION

Oliveseedashisfoundtobepozzolanicandcanbeusedaspartialreplacementinsandcreteblockproduction.Cementcanbe partiallyreplacedwithOliveseedashat10%and29%insandcreteblockstobeusedforloadbearingandnonloadbearing wallsrespectively.

REFERENCES

[1] Tayeh,B.A.,Nyarko,M.H.,Zeyad,A.M&Al-Harazin,S.Z.(2021).PropertiesandDurabilityofConcretewithOliveWaste AshasaPartialCementReplacement.Advances in Concrete Construction.11(1),59-71

[2] Odeyemi,S.O.,Akinpelu,M.A.,Atoyebi,O.D.&Orire,K.J.(2018).Qualityassessmentofsandcreteblocks producedinAdeta,kwarastate,Nigeria, Nigerian Journal of Technology.37(1),53-59.

[3] Sholanke,A.B.,Fagbenle,O.I, Aderonmu,A.P&Ajagbe,M.A. (2015).SandcreteBlockandBrickProductioninNigeriaProspectsandChallenges.International Journal of Environmental Research.1(4),1-17.

[4] Afolayan, J. O., Oriola F.O.P., Moses, G & Sani J.E. (2017). Investigating the Effect of Eggshell Ash on the Properties ofSandcreteBlock.International Journal of Engineering and Applied Sciences (IJEAS).4(12),43-54.

[5] Anowai,S.I&Afunanya,J.E.(2017).MilletHuskAshasPartialReplacementofCementinSandcreteBlocks.International Research Journal of Engineering and Technology (IRJET).4(7),677-680

[6] Anowai,S.I.,Ishaya,A.A.,Zakka,P.W.,Yahaya,A.M.,&Oyelade,O.M. (2019).SuitabilityofMaizeCobAshasaPartial ReplacementofCementinSandcrete Blocks. International Journal of Environmental Studies and Safety Research, 4(3), 25-30.

[7] Aginam,C.H.,Onodagu,P.D.andNwakaire,Chidozie(2013).Breadfruitstemashasapartialreplacementofcementin sancreteblockmaking. International Journal of Engineering Research and Applications,3(4),60-65.

[8] Sangeetha,S.P.(2016).RiceHuskAshSandcreteBlockasLowCostBuildingMaterial, International. Journal of Engineering Research and Application,6(6),46-49.

[9] BritishStandardsInstitution(1991). BS 12. Specification for Portland Cements: London,England:BSI

[10] BritishStandardsInstitution(1992). BS 882. Specification for Aggregates from Natural Sources for Concrete. London, England:BSI

[11] BritishStandardsInstitution1980). BS 3148. Methods of Tests for Water for Making Concrete.London,England: BSI.

[12] NigerianIndustrialStandard(2004).NigerianIndustrialStandardStandardforsandcreteblocks.NigerianIndustrial StandardapprovedbyTheStandardOrganisationofNigeria(SON),NIS:87.

[13] AmericanSocietyforTestingandMaterials(2000).SpecificationsforPozzolanas.ASTMInternational,USA,ASTMC618.