Influence Of Oregano Essential Oil in Bio Electrochemical System for Electricity Generation

Vismaya U K1 , Ihjas K2 , S. Shika3

1PG student, Environmental engineering in Department of Civil Engineering, M-Dasan Institute of Technology Ulliyeri, Kerala, India

2 Scientist, Ecology and Environment Research Group, CWRDM, Kozhikode, Kerala, India

3 Associate Professor, Department of Civil Engineering, M-Dasan Institute of Technology Ulliyeri, Kerala, India ***

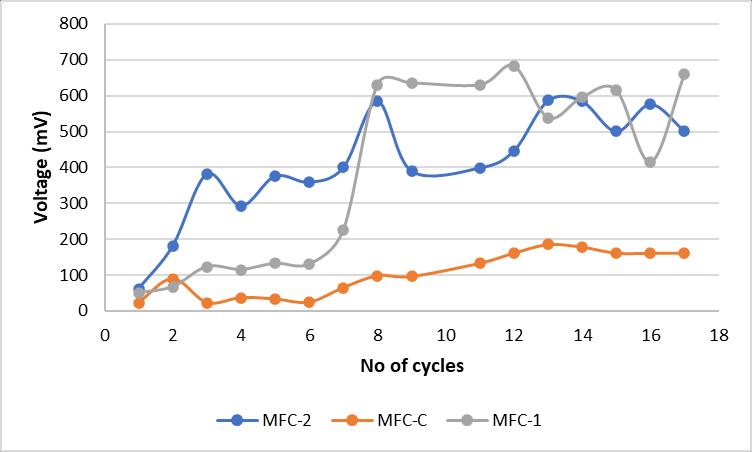

Abstract - Bio electrochemical systems are revolutionary new bioengineering technologies which integrate microorganisms or enzymes with the electrochemical method to improve the reducing or oxidizing metabolism. Hence in present study MFC was applied to generate electricity using anaerobic sludge from Milma diary Kozhikode using carbon felt as anode and cathode. MFCs in terms of electricity generation were observed by measuring closed circuit voltage (CCV) and open circuit voltage (OCV) values on a daily basis. Average operating voltage (OV) of MFC-1, MFC-2 and MFC-C of 584 mV, 533 mV and 167 mV and average OCV of 881 ± 23 mV, 880 ± 14 mV, and 571 ± 41 mV were observed in MFCO, MFCH and MFCC respectively after seventeen cycles each of 48 h. A gradual increase in OV is observed after each cycle. All the pretreatment techniques used in this investigation exhibited a better operating voltage compared to that of MFC without any inoculum pretreatment. Even though pretreatment with heat and oregano extract had a comparable OV, a slightly higher OV was observed in case of oregano extract-based treatment.

Key Words: Anaerobic sludge, Microbial fuel cell, bio electrochemical cell, Oregano essential oil, methane suppression.

1.INTRODUCTION

Rapidpopulationgrowthandurbanizationhasled toan increase in waterusageand apparentlygave way to increased wastewater generation. As it is always recommended to use water wisely, same is applicable for wastewater.Hence,wastewatergeneratedfromhouseholds, industriesandagricultureshouldnotbeseenasathreatto environment rather should be looked into as valuable resource,whichcouldmeetthedemandsforwater,energy and nutrients. Microbial fuel cells (MFCs) are one of the promising technologies capable of converting chemical energycontainedinthewastewaterintoelectricalenergyby achieving simultaneous wastewater bioremediation [2]. Different micro-organisms, which can compete with the electrogensforthesubstrate,arecapableofsurvivinginthe anodicchamberofMFC’s[2].Sincemixedanaerobicsludge is used as anoculum by many researchers, a significant amount of methane production has been reported in the biochemicalcells[1].isreportedthatmethaneproductionin

MFCs increases with increasing substrate concentration, suggesting that organic rate is an important factor in methaneproduction.thepresenceofmethanogensleadstoa decreaseinthepoweroutputofMFCsastheycompetewith theelectrogensforfoodandspaceontheanode.Thesludge added as inoculum is the primary microbial reserve. If methanogens can be selectively eliminated from the inoculumitself,itismorelikelythatagreaterproportionof substrateutilizingmicroorganismswillbeelectrochemically active. Therefore, pretreatment methods for anaerobic sludgemustbeusedthatareabletosuppresstheactivityof methanogens without affecting the suppression of the activity of electrogenic microorganisms and other fermentativemicroorganisms[4].Henceinordertoreduce loss of electrons from the anodic chamber of MFC, it is necessarytosuppressactivityofmethanogens.Essentialoils such as oregano essential oil (OEO) which consist of bioactive compounds have been confirmed to modify the ruminalfermentationbyenhancingtheefficiencyofenergy utilizationwhiledecreasingmethaneemissions[6].

OEOinclusionratewithcertainamountinanaerobic sludgecansuppresstheeffectivemethanogenesisbacteria present in anaerobic inoculum. Oregano essential oil has been reported to have second-largest oxygen radical absorbance capacity compared with clove, followed by cinnamon, ginger and rosemary essential oil [1]. Oregano leafmaterialasananti-methanogenicplantproduct,withno adverseeffectsonruminalfermentationorneutraldetergent fiberdegradabilityhasbeenreportedinvitro[6]

2 METHODS AND MATERIALS

2.1 MFC setup

Experimentswereperformedindualchamberedaqueous cathodeMFCswithananodicliquidvolumeof50mL.Baked clayware cylinders served as the anodic chamber of these MFCs and the wall material of the cylinder acted as a separatorbetweenanodicandcathodicchambers.

TheanodeandcathodeelectrodesofbothMFCsweremade upofcarbonfelt.Copperwirewasusedtoconnectboththe electrodesthroughanexternalresistanceof100Ω

2.2 Operating conditions

Mixed anaerobic sludge collected from anaerobic digester wasusedastheinoculumintheanodicchamber.Thecontrol MFC(MFC-C)wasinoculated20mLofsludgewithoutany pre-treatment.Theanaerobicsludgewaspre-treatedwith 0.2mL/Loforeganoextract,whichwasprovidedinMFC-1 afterincubatingatroomtemperatureforovernightinorder to suppress the growth of methanogens. MFC-2 was inoculatedwithsludgeheattreatedatatemperatureof100 ℃ for 10 min. Synthetic wastewater containing sodium acetate as the carbon source having chemical oxygen demand(COD)ofabout3000mg/Lwasusedasthefeedin both MFCs. These MFCs were operated under room temperaturewithafreshfeedingintervalof48h.

3 Methane suppression using OEO

Aknownvolumeofanaerobicsludgewastakeninconical flask. Rubber septum cap is used for covering the conical flaskwhichisfilledwithanaerobicsludge. Thesetupwas keptlikethatfor8hoursformethanegasproductioninit

Agasdisplacementset-upwasusedtocalculatethemethane gasproductionrate.PVCtransparentpipewithoneendfixed withasyringe-needleandotherendisinsertedtotheconical flaskhavingwaterwereusedtoconnectsludgecontaining conicalflaskto1/3rdofwaterfilledconicalflaskandbeaker. After 8 hours, the needle is inserted through the rubber septumfortheflowofgasproducedinsidetheconicalflask containing anaerobic sludge to water containing conical flask.

Gasproducedfromtheanaerobicsludgewillpassthrough the needle and change in volume of water occurs due the pressureexertedbythegasproduced.Somevolumeofwater gets displaced into the beaker giving the amount of gas produced by the anaerobic sludge in the conical flask containing controlled cell. In the conical flask containing water, one PVC pipe is touched on the water surface and anotheriskeptabovewaterlevel.Thisdisplacementmethod isusedtomeasurethevolumeofirregularlyshapedobject. Here the objective of set-up is to gas produced after the suppressionofmethanogenesis(ie,Methanegas).

The amount of water displaced can be concluded as the amount of gas generated by the action of electrogenesis bacteria,fermentativemicro-organism,sulfatereducers.The more the water gets displaced from the different OEO concentration,inclusionratecanbetakenastheoptimum OEOdosagevalue

2.4 Measurements and analysis

MCCs were continuously monitored for voltage produced using a data acquisition unit across a fixed external resistance(Rext)of100Ω[8]andcurrent(I)inamperes(A) was calculated from Ohm’s law (I= V/Rext), where V is the potentialdropinvolts(V)acrossexternalloadresistance(R, Ohms).TheoverallperformanceoftheMCCswasevaluated through power output (P, Watts) as per equation given below[9], P=IV (1)

The maximum power density was obtained from polarization curve plotted by varying the external resistancesfrom10000to10Ωusingtheresistanceboxover afixedtimeintervaltillastablevoltagewasachieved.

Thevolumetricpowerdensity(P,mW/m3)wasnormalized toanodicchambervolume(Van)asbyusinggivenequation (2)

3 Results and discussion

3.1 Specific methanogenic activity

Gasdisplacementmethodismonitoredfor3setsof inclusion rate of OEO and for control. For each set fresh anaerobic sludge is used. More water displaced at 0.2ml concentration of OEO (25ml) which is more than control, which means that gas produced after suppressing methanogenesis.Forincontrolledanaerobicsludgethegas producedismixtureofgasesincludingmethane.Optimum dosage is taken as 0.2ml/L OEO. Cell is fabricated for the optimumdosageofOEOas0.2mlandvoltagegeneratedhas beenrecorded.

3.2 Electricity generation

The performances of MFCs in terms of electricity generationwereobservedbymeasuringOVandOCVvalues onadailybasis.MaximumOVof584mV,533mVand167 mVandaverageOCVof881±23mV,880±14mV,and571 ± 41 mV were observed in MFC-1, MFC-2, and MFC-C, respectivelyafterseventeencycleseachof48h.

A gradual increase in OV is observed after each cycle. All the pre-treatment techniques used in this investigationexhibitedabetteroperatingvoltagecompared to that of MFC without any inoculum pretreatment. Even though pretreatment withheatand oregano extracthad a comparableOV,aslightlyhigherOVwasobservedincaseof oreganoextract-basedtreatment.

4 CONCLUSIONS

Thepresentstudyfocusedonthedevelopmentofa bioelectricchemicalcellanditsperformanceevaluationon electricity generation, also progressive inhibition of methanogenesis from OC/CC operations within the developedsystemusingOreganoessentialoil(OEO).Byusing cost effective materials, a two-chambered bioelectric chemical cell was developed and evaluated electricity generationinthedevelopedcell.MFCoftreatingcapacityof 50 ml with a surface area of 324.99 cm2 was constructed. The performance of MFC under three different inoculum conditionwasobserved.Theyareasfollows(i)heattreated (ii)OEOadded(iii)control.Thisstudyaimstodeterminethe electricity generation By using different inoculum pretreatment techniques, a better performance was observedinMFCsthathasundergonesludgepretreatment on addition of oregano extract as well as heat pretreated inoculumfedMFC.

REFERENCES

[1] Clauwaert,P.,Mulenga,S.,Aeltermam,P.(2009)Litrescalemicrobial fuel cellsoperated in a complete loop, Appl Microbiol Biotechnology, 83,241-247

[2] Rajesh, P.P., Jhadhav, D.A., Ghangrekar, M.M. (2014) Improving performance of microbial fuel cell while controlling methanogenesis by chaetoceros pretreatment of anodic inoculum, Bioresource Technology,98,994-998

[3] Rui,Z.,Wu,J.,Lang,X.,Liu,L.,Casper.P.D.,Wang,Cailian, W.,andZhang,L.(2020)EffectsofOreganoEssentialOil oninvitroruminalfermentation,methaneproduction andruminalmicrobialcommunity, Animal Feed Science and Technology, 148,321-327.

[4] Santoro, C., Kodali, M., Sergio, H., Serov, A., Ioannis, I., Atanassov,P.(2018)Powergenerationinmicrobialfuel cellsusingplatinumgroupmetal-freecathodecatalyst: Effectofthecatalystloadingonperformanceandcosts, Journal of Power Sources,378,169-175

[5] Tiwari, B.R., and Ghangrekar, M.M. (2015) Enhancing Electrogenesis by pretreatment of Mixed Anaerobic Sludge to be used as inoculum in microbial fuel cell, Energy Fuels, volume29,Issue5

[6] Tekippe, J.A., Tacoma, R., Hristov, A.N., Lee, C., Oh, J., Heyler,K.S.,Cassidy,T.W.,Varga,G.A.,Bravo,D.(2013), Journal Of Diary Science, volume96,Issue12

[7] Walter,A.X.,Madrid,A.,Iwona,G.,Greenman,J.,Ioannis, I. (2022) Microbial fuel cell scale-up options: Performance evaluation of membrane (c-MFC) and membrane-less(s-MFC)systemsunderdifferentfeeding regimes, Journal of Power Sources,520,230-275

[8] Winfield,J.,Iwona,G.,Greenman,J,and Ieropoulos,I. (2016) Areview intotheuseof ceramicsin microbial fuelcells, Bioresource Technology, volume215,296-303

[9] Xie,R.,Wang,S.,Wang,K.,Chen,B.,Wang,Z.,andTan,T. (2022)Improvedenergyefficiencyinmicrobialfuelcell by bioethanol and electricity co-generation, Biotechnology For Biofuels and Bioproduct, volume15, Issue9