EFFECTS OF FLY ASH ON THE PROPERTIES OF COCONUT FIBRE REINFORCED CONCRETE

1 Senior Lecturer, Department of Building, University of Jos, Nigeria

2 Reader, Department of Civil Engineering, University of Jos, Nigeria

3Lecturer, Department of Quantity Surveying, University of Jos, Nigeria

4 Lecturers, Department of Building, University of Jos, Nigeria

5 Lecturer, Department of Quantity Surveying, University of Jos, Nigeria

6 Student, Department of Building, University of Jos, Nigeria ***

Abstract - This study investigates the effects of partially replacing Ordinary Portland Cement (OPC) with fly ash on properties of coconut fibre reinforced concrete. OPC was partially replaced with fly ash at 0%, 10%, 20% and 30% in coconut fibre reinforced concrete. The coconut fibres were extracted from coconut seeds and shredded into 60mm lengths. All the concrete specimens were reinforced with coconut fibre weighing 0.5% of the weight of fine the aggregates. Mix ratio of 1:2:4 and water/cement ratio 0.58 were adopted in this study. The slump, compaction factor, compressive strength, splitting tensile strength, flexural strength, alkalinity and water absorption of the concrete specimens were tested and analysed after curing periods of 7, 28 and 56 days respectively. Fly ash improved the workability, water absorption and reduced the alkalinity level of the matrix as percentage replacement of OPC with fly ash increases. The results also showed that specimens containing 10% partial replacement of cement with fly ash achieved highest compressive strength, flexural strength and splitting tensile strengths at all ages of curing. It can be concluded that 10% replacement of cement with fly ash replacement gave the best results for compressive strength, flexural strength and split tensile strength and reduced alkalinity and water absorption of coconut fibre reinforced concrete. It is thus recommended that OPC should be partially replaced with fly ash to improve the mechanical and durability properties of coconut fibre reinforced concrete.

Key Words: Coconut fibre, fly ash, workability, alkalinity, water absorption, mechanical properties.

1. INTRODUCTION

Plainconcretepossessesahighcompressivestrengthbutlowtensilestrength.Cracksdevelopinplainconcretesevenbefore loadingduetodryingshrinkageandwhenloadiseventuallyappliedtheinternalcrackspropagateandopenupduetostress and additional cracks are formed [1]. The propagation of these cracks can be arrested by the introduction of randomly distributedsmallpiecesofreinforcingmaterialsknownasfibres.Theintroductionoffibresinconcretehelptotransferloadsat theinternalmicrocracks[2].Thefibrescouldbesyntheticorcellulose(plant)fibres.Thedevelopmentofsteelreinforcement hasovercometheproblemofpoortensilestrengthbutitdoesnotcompletelysolvetheproblemofmicrocracksduetodrying andplasticshrinkageowingtoweatheringconditionsanditisalsoexpensive.Thepresenceofmicrocracksinthemortaraggregateinterfaceisresponsiblefortheinherentweaknessofplainconcrete.Theweaknesscanberemovedbyinclusionof fibresinthemixture.Fibrescannotbeusedasconventionalreinforcementbutitcanlowerdowntherequirementsofsteel reinforcements[3].

Fibresarebroadlyclassifiedintoman-madeandnaturalfibres.Man-madefibresaremadefromsyntheticmaterials(suchas petrochemicals)andmetalswhilenaturalfibresoriginatefromvegetable,animalandmineralsources.Naturalfibresuchas coconut fibre has certain physical and mechanical characteristics that can be utilized effectively in the development of reinforcedconcretematerial[4]..Useofcoconutfibrecanleadtoimprovementinpropertiesofcementconcreteinadditionto providingapropersolutionfordisposalofthisnaturalwaste.Inmostcases,thesecoconutfibresaredumpedasagricultural waste,socanbeeasilyavailableinlargequantityhencemakingthemcheap[5].Coconutfibrehasbeendescribedasthemost ductilefibreamongstallnaturalfibresbeingthattheyarecapableoftakingstrain4-6timesmorethanotherfibres[6].

Coconutfibreisextractedfromtheoutershellofacoconut.Itsscientificnameandtheplantfamilyofthecoconutfibreis “CocosNucifera”and“Arecaceae(Palm)”respectively,whileitiscommonlyreferredtoas“Coir”[7].Largequantitiesofcoconut fruitareproducedintherainforestzonesofSouth-WestandSouth-SouthregionsofNigeriawithminorproductionsinother geo-politicalzones[8].Coconutfibreisobtainedfromthehuskofthecoconutpalm.Thefruitsaredehuskedwithaspikeand afterretting,thefibresaresubtractedfromthehuskwithbeatingandwashing.

The short comings of natural (plant) fibre reinforced concrete includes poor workability, high water absorption and degradationincementitiousmatrix.Plantfibresdegradeinconcreteduetohighalkalinityofconcrete.Thedurabilityofplant fibresinconcretecanbeimprovedbyreducingthealkalinityofconcretewithpozzolanas.Thedegradationoffibresimmersed inPortlandcementisduetothehighalkalineenvironmentthatdissolvestheligninandhemicellulosephases,thusweakening thefibrestructure[9].

EdeandAgbede[10]investigatedtheeffectofcoconutfibreonthepropertiesofconcreteandfoundthatcompressiveand flexuralstrengthsofcoconutfibrereinforcedconcreteincreasedwithcuringageandwithincreasingpercentageofcoconut fibreupto0.5%oftheweightoffinetheaggregatesandthengraduallybegantodecreasewithincreaseinpercentageofthe fibre.Thestudyalsofoundthatadditionofcoconutfibreinconcreteresultedtopoorworkability.Babafemi,Kolawole&Olalusi [11]investigatedtheeffectofincorporatingcoirfibrecontentontheworkability,density,compressivestrength, splitting tensilestrength,anddurabilityofconcreteandfoundthatcoirfibreinconcretereduceditsworkabilityandimprovedthe compressiveandtensilestrengthoftheconcrete.Kshitija[12]foundthatadditionofcoconutfibresimprovedtheflexural strengthofconcretebyabout12%,andtheyalsoformedgoodbondingintheconcrete.

Additionofpozzolanaslikeflyashinconcretealsoreducesthewaterabsorptionoftheconcretethroughpozzolanicactivity which produces additional cementitious gel which fills the voids in the concrete [13]. It is thus expected that partial replacementofcementwithflyashincoconutfibrereinforcedconcretewillimprovetheworkabilityandthedurabilityofthe concrete.

Flyashconsistingmostlyofsilica,alumina,andiron,formsacompoundsimilartoPortlandcementwhenmixedwithlimeand water.Flyashisanoncombustedby-productofcoal-firedpowerplantsandgenerallyendsupinalandfill.Flyashtendsto reducethealkalinityofconcreteduetocalciumhydroxideconsumption,whichisthemaincontrollingfactorofpHincement paste.Flyashismosteffectiveinreducingthealkalinityoftheporesolution[14].FlyashisavailableinNigeria aswaste productofelectricitygenerationplantinOjiRiver,EnuguState.

Thisstudyisaimedatinvestigatingtheeffectsofpartiallyreplacingcementwithflyashontheworkability,mechanicaland durabilitypropertiesofcoconutfibrereinforcedconcrete.

2. MATERIALS AND METHODS

Thematerialsusedforthisworkarecoconuthuskfibre,cement,fineaggregate,coarseaggregates,waterandflyash. The coconutfibresusedinthisStudywereobtainedfromcoconutsellersinTerminusmarketinJos,Plateaustate.TheCoconut fibrewasextractedfromtheoutershellofacoconutbyhandpicking.Thelengthofthecoconuthuskfibreswerecuttoaverage lengthsof60mm.Theaveragediameterofthecoconutfibresis0.75mmmeaningthelength/diameterratio(i.e.aspectratio) ofthefibreusedinthisstudyis80.Thedensityofthefibrewas0.81g/cm3 .

BUA brand ofordinaryPortlandcement(OPC) manufacturedbyBUA CementCompanyPLCin BeninOkeneExpressway, OkpellainEdoStateofNigeriawasusedforallthetests.Thecementconformsto[15].Thefineaggregateusedwascleanriver sandconformingtothespecificationof[16].ThesandwasgottenfromDogonaHauwainJosNorthLocalGovernmentareaof Plateaustate.Thesandwassievedthrough5mmdiametersieveandonlytheportionpassingthroughthesievewasusedinthis study.Thefineaggregate(sand)hasaspecificgravityof2.62andcompactedbulkdensityof1621kg/m3 Thecoarseaggregate usedwas12mmdiametercrushedgravel.ThecoarseaggregatewasgottenfromaprivatequarryinJos,PlateauState.The coarseaggregate(gravel)usedhasaspecificgravityof2.60andcompactedbulkdensityof1484kg/m3respectively.Thewater usedinthisstudywasobtainedfromtapsinconcretelaboratoryofDepartmentofBuilding,UniversityofJos.Thewaterisfit fordrinking.

TheflyashusedwassourcedfromthewastedumpofOjiRiverthermalpowerstationinEnuguStateNigeria.ThePhysical propertiesandchemicalcompositionoftheflyashweredeterminedinaccordancewith [17].Thechemicalanalysisofthe sample was carried out at National Metrological Development Centre (NMDC) Jos, Plateau State, Nigeria using Energy DispersiveX-rayFluorescenceSpectrometer(EDXRF).Theapparentspecificgravityoftheflyashwas2.24,whichwaslessthan thatobtainedforcement.Theloosebulkdensityandcompactedbulkdensityoftheflyashwere1300kg/m3and1418kg/m3 respectively.TheresultshowsthatthesumofSiO2,Al2O3andFe2O3is90.24%whichisgreaterthantheminimumof70.00% specifiedin[15].Theflyashwassievedthrough212µmandonlytheportionpassingthesievesizewasusedforthisstudy.

Aconcretemixofratio1:2:4(Cement:FineAggregate:CoarseAggregate)wasadoptedfortheproductionoftheconcreteata water-cementratioof0.58.Anadditionof0.5%coconutfibrebyweightoffineaggregatewasmadeonallthemixesbeingthe

optimumpercentageestablishedbyEdeetal.[10]forcoconutfibrereinforcedconcrete. Cementwaspartiallyreplacedwithfly ashat0%,10%,20%and30%replacementlevels.Batchingbyabsolutevolumewasadopted.Atotalof48number100mmx 100mm x 100mm cube, 36 number 100mm x 100mm x 500mm beams and 36 number 100mm diameter x 200mm high cylinderswerecastandsubsequentlycuredinwaterfor7days,28daysand56days.Themixproportionsusedforallthemixes arepresentedinTable1.

Batching,mixingandcastingweredoneadoptingastandardprocedureinaccordancewith[18].Thefineaggregatesandcoarse aggregateswerefirstmeasured.Therequiredquantityofthecoconutfibreswerecomputedandmeasuredreadyformixing. Theconcretemixingwasdonebyhandmixingonawatertightplatform.Thecoarseandfineaggregateswerefirstlythoroughly mixedbeforetherequiredquantityofcementandfibreswereadded.Allthematerialswerethenmixedtoauniformcolour.For mixtureinwhichPortlandcementwaspartiallyreplacedwithflyash,theflyashandcementweremixeddrytouniformcolour separately.Therequiredamountofwaterwereweighedandaddedcarefullysothatnowaterwaslostduringmixing.

Theslumptestforeachoftheconcretemixwasdeterminedinaccordancewiththeprovisionsof[19]onthewetconcrete.The compactionfactortestswerealsoconductedoneachconcretemixinaccordancewiththeprovisionsof[20].Thewetconcrete wasthencastintocubes,cylindersandbeamsforcompressive,splittingtensileandflexuralstrengthtestsrespectivelyand vibratedusingtablevibrator.Aftersettingfor24hours,thespecimensweredemouldedandcuredinwaterfor7,28and56 days.Thecompressivestrength,splittingtensilestrengthandflexuralstrengthoftheconcretespecimensweredeterminedin accordancewithwiththeprovisionsof[21],[22]and[23]respectively.

AdigitalpHmeterwasusedtodeterminethepHoftheconcretespecimens.ThepHmeterwasfirstcalibratedbyimmersingthe testerinpH7buffer.Afterallowingthereadingtostabilisethecalibrationtrimmerwasturnedtoread7.0.Concretepowders werescrappedfromtheconcretecubesafterspecifieddaysofcuringandgroundtofinepowders.Onepartofthepowderwas mixedwithtwopartsofdistilledwater.Aftermixing,thewaterwassievedthroughfilterpaperintoabeaker.ThedigitalpH meterwasthenimmersedintothewaterandthepHreadingtaken.Waterabsorptiontestswereconductedoneachmixin accordancewith[24]

3. RESULTS AND DISCUSSION

3.1 Workability Tests Results

TheslumpandcompactingfactorvaluesforthewetcoconutfibrereinforcedflyashconcretearepresentedinTable2.The slumprangesfrom15mmto20mmAt0%replacementofcementwithflyashtheslumpis15mm.10%replacementofcement with fly ash resulted to the slump of 17mm. 20% replacement of cement with fly ash gave slump of 19mm while 30% replacementofcementwithflyashgavetheslumpof20mm.Thisimpliesthatasthepercentageofflyashincreasesforallthe various mixes the workability slightly increases. The compacting factor was also found decrease progressively as the percentagereplacementofcementwithflyashincreaseswiththesamplewith0%flyashhavingthehighestcompactingfactor

of0.90.Itcanthereforebededucedthatflyashincreasestheworkabilityofcoconutfibrereinforcedflyashconcretebecauseas thepercentagereplacementofthecementwithflyashincreases,theslumpalsoincreasesataconstantfreewater/cementratio of0.58.

3.2 Density Tests Results

ThedensitiesoftheconcretecubesofvariousmixestestedarepresentedinTable3.Theresultsindicateastrongrelationship existingbetweenthedensityandtheadditionofflyashinthemix.Thehighertheamountofflyashinthemix,thelesserthe densityoftheconcreteproduced.Thiscouldbeasaresultofthelowspecificgravityoftheflyashat2.49whichoccupied a proportionofthevolumewithsignificant weightdecrease.Itwasalsoobservedthatthedensitywasalsoaffectedbythe hydrationperiodforallthemixes.Thedensityincreasesprogressivelywithincreaseinhydrationperiod.

3.3 Compressive Strength Test Results

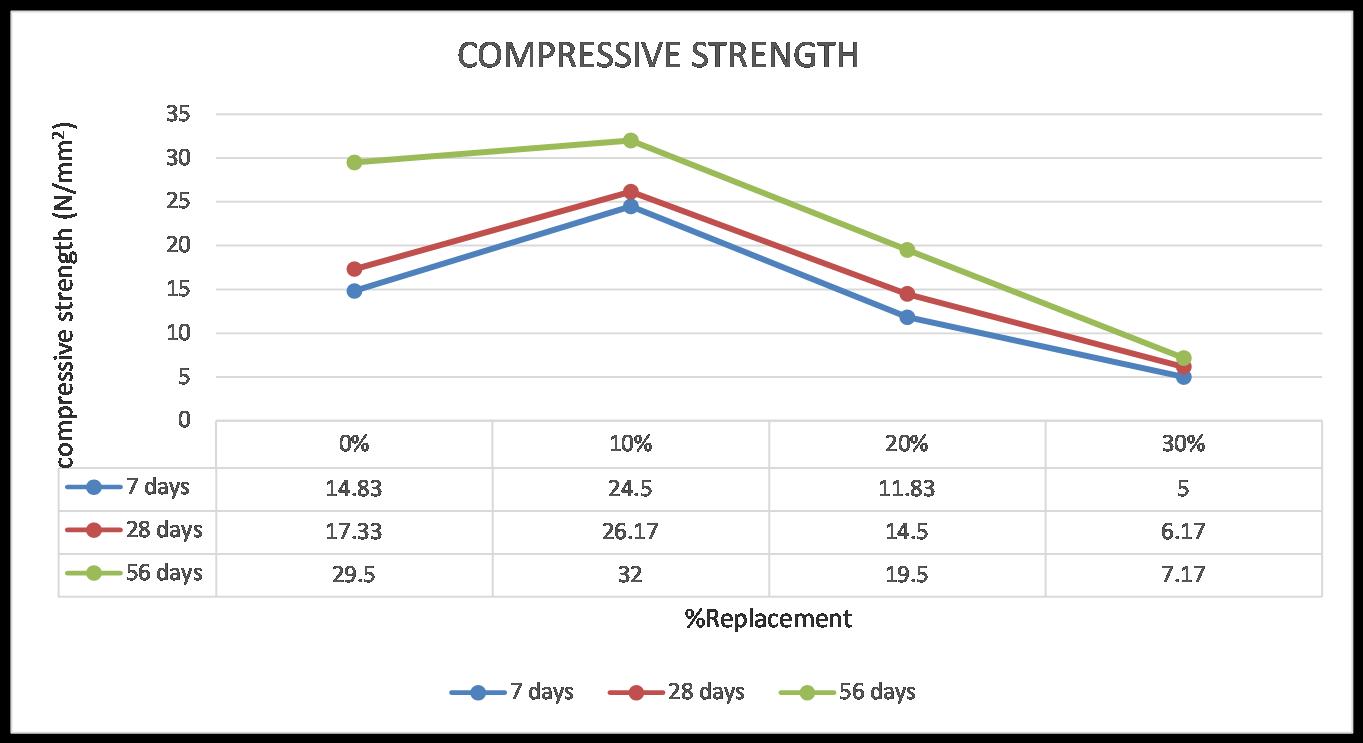

Figure1showsthecompressivestrengthofcoconutfibrereinforcedconcreteproducedwithdifferentpercentagereplacement ofcementwithflyash.Theresultsindicatethatthecompressivestrengthofcoconutfibrereinforcedconcreteincreaseswith increaseincuringage.Themaximumstrengthattainedat56daysis29.5N/mm2.Thecompressivestrengthofcoconutfibre reinforcedconcretewith10%replacementofcementwithflyashat56daysis32.00N/mm2 .Thisisslightlyhigherthanthe compressivestrengthofthecontrolmix(with0%flyash).Theresultofcompressivestrengthat20%replacementof(OPC) withflyashare11.83N/mm2,14.50N/mm2 and19.50N/mm2 at7,28and56daysrespectivelyshowingdecreaseinvalues whencomparedtothecontrolspecimen.

Thecompressivestrengthofcoconutfibrereinforcedflyashconcretewith30%replacementshowedfurtherreductionin compressive strength. This indicated that partial replacement of cement with fly ash beyond 10% adversely affects the compressivestrengthofcoconutfibrereinforcedconcrete.SimilartrendwasobservedbyAnowaiandJob[13]forbananafibre reinforcedflyashconcrete

3.4 Flexural Strength Test Results

Figure2showstheresultsofflexuralstrengthtestsoncoconutfibrereinforcedflyashconcreteproducedwith0%,10%,20% and30%replacementsofcementwithflyashcuredinwaterforhydrationperiodof7,28and56days.At7daystheflexural strengthsofspecimenswith0%,10%,20%and30%replacementsofcementwithflyashwere6.38N/mm2,6.62N/mm2,1.23 N/mm2 and1.13N/mm2 respectively.

At28dayscuringagetheflexuralstrengthswere7.58N/mm2,8.00N/mm2,3.00N/mm2and1.63N/mm2forspecimenswith 0%,10%,20%and30%replacementsofcementwithflyashrespectively.At56dayscuringage,theflexuralstrengthswere8.5 N/mm2,8.63N/mm2,3.75N/mm2and1.75N/mm2forspecimenswith0%,10%,20%and30% replacementsofcementwith flyashrespectively.

Figure 2: Flexural Strengths of Coconut Fibre Reinforced Fly Ash Concrete at Various Hydration Periods

3.5 Flexural Strength Test Results

Theresultsofthesplittingtensilestrengthtestobtainedforthevariouscylindricalsamplesofcoconutfibrereinforcedflyash concreteatdifferentpercentagesofflyashandhydrationperiodsof7,28,and56daysarepresentedinFigure3.Theresults showthatthesplittingtensilestrengthofcoconutfibrereinforcedflyashconcretedecreaseswithpercentageincreaseinfly ash.Thespecimenwith10%replacementofcementwithflyashachievedthehighestsplittingtensilestrengthsof2.49and 2.97N/mm2 at28and56dayscuringperiodsrespectively.

Periods

3.6 Water Absorption Test Results at 28 Days

The resultsof waterabsorptionobtainedareshown in Table4. The resultsshowed thatcoconutfibrereinforcednormal concreteabsorbedmorewaterthanthecoconutfibrereinforcedflyashconcrete.At0%replacementofcementwithflyash,the waterabsorptionwas6.30%forcoconutfibrereinforcedconcretewhile10%,20%and30%replacementofcementwithfly ashthewaterabsorptionswere5.40%,3.30%and3.3%respectively.

3.7 Effects of Fly Ash on the pH of Coconut Fibre Reinforced Concrete

TheresultsofpHofCoconutfibrereinforcedflyashconcretespecimensarepresentedinTable5.Theresultsshowedthatthe partial replacement of cement with fly ash resulted to a reduction in the concentration of OH- ions and led to significant reductionofthepHoftheconcretespecimenstested.At0%,10%,20%and30%partialreplacementsofcementwithflyash thepHoftheconcreteproducedare10.2,9.8,9.8and8.8respectivelyaftercuringfor56days.Theseresultsfollowthesame trendasthatobtainedbyRewiandKhafagy[25]whichshowedthatpartialreplacementofcementwithbauxite(pozzolana)at variouspercentagesofreplacementof10%,20%and30%resultedtosignificantreductionofpHofconcrete.Gram(1988)also foundthatthealkalinityofcementmatriceswerereducedbypartiallyreplacingordinaryPortlandcement(OPC)withsilica fume,flyashorcompletelyreplacingordinaryPortlandcementwithhighaluminacement.

Table 5. The pH-Level of Coconut Fibre Reinforced Fly Ash Concrete at 56 Days

4. SUMMARY OF FINDINGS

Thefindingsofthisresearchcanbesummarizesasfollows;

1. Theworkabilityofcoconutfibrereinforcedconcreteincreaseswithincreaseinpercentagereplacementofcement withflyash.

2. ThepHofcoconutfibrereinforcedflyashconcretedecreaseswithincreasesinflyashdosage.

3. TheCompressiveStrengthresultsrevealedthattheconcretewith10%replacementofcementwithflyashachieved highestcompressivestrengthatallhydrationperiods.

4. The results revealed that flexural strength of coconut fibre reinforced fly ash concrete with 10% replacement of cementwithflyashachievedthehighestflexuralstrengthatallagesofhydration.Theflexuralstrengthsreduced drasticallyat20%and30%replacementsofcementwithflyash.

5. The splitting tensile strength results showed progressive increase in splitting tensile strengths with increase in hydrationperiod.Thecontrolsamplegavesplittingtensilestrengthsof2.02N/m2,2.33N/m2,2.44N/m2at7,28and 56daysrespectively.Specimenswith10%replacementofcementwithflyashwhichgavethehighestsplittingtensile strengthsof1.8N/m2,2.49N/m2 and2.97N/m2at7,28and56daysrespectively.

6. Thewaterabsorptiontestresultsat56daysrevealedthattherewasaprogressivedecreaseinthewaterabsorption coconutfibrereinforcedconcretewithincreaseinpercentagereplacementofcementwithflyash.

7. Theresultsshowedthatthepartialreplacementofcementwithflyashresultedtoareductionintheconcentrationof OH- ionsandledtosignificantreductionofthepHoftheconcretespecimenstested.Thisshowsthatthealkalinityof coconutfibrereinforcedconcretereduceswithincreaseinpercentagereplacementofcementwithflyash.

5. CONCLUSION

Based on the findings of this study, it can be concluded that partial replacement of cement with fly ash improves the workabilityanddurabilityofcoconutfibrereinforcedconcrete.Theoptimumpercentagereplacementofcementwithflyashin coconutfibrereinforcedconcretewasfoundtobe10%.

6. RECOMMENDATION

Partialreplacementofcementwithtenpercentflyashisrecommendedtoimprovetheworkability,mechanicalpropertiesand durabilityofcoconutfibrereinforcedconcrete.

REFERENCES

[1] Vejje,S.,&Krishna-murthyN.R.(2013).StudyonAdditionoftheNaturalFibresintoConcrete. International Journal of Scientific and Technology Research. 2(11),213-218.

[2] Kene,K.S.,Vairagade,V.S.,&Sathawane,S.(2012).Experimentalstudyonthebehaviourofsteelandglassfibrereinforced concretecomposites. Bonfring International Journal of Industrial Engineering and Management Science, 2(4),125-130.

[3] Patel,P., & Patel,I. (2013). Aliterature ReviewonUse ofCelluloseFibreandSupplementaryMaterial,Silica Fumein Concrete. Global Research Analysis International, 2(5),63-64.

[4] Uday,V.S.&Ajitha,B.(2017).ConcreteReinforcedwithCoconutFibres. International Journal of Engineering Science and Computing,7(4),10436-10439.

[5] Kshitija,N.(2015).CoconutFibreReinforcedConcrete. International Journal of Mechanical and Production Engineering. 1(3),2320-2092.

[6] Munawar, S. S., Umemura .K., & Kawai, S. (2007). Characterization of The Morphorlogical, Physical, and Mechanical PropertiesofSevenNon-WoodPlantFibreBundles.J.WoodScience.53(2),108-113.

[7] Patil, D., Vanmali, M, Sonar, J., Tandel, T. & Dhurve5, S. (2021). Effects of coconut fibers on mechanical properties of concrete. International Journal of Innovations in Engineering and Science, 6(3),1-5.

[8] Olanade, K.A., Aleke, A.D., & Morakinyo (2013). Strength development and crack pattern of coconut fibre reinforced concrete. Civil and Engineering research. 4,46-53.

[9] Gram,H.E.(1988).DurabilityofNaturalFibreinConcrete,ConcreteTechnologyandDesign.London:BlackieandSonsLtd.

[10] Ede,A.N.andAgbede,J.O.(2015).Useofcoconuthuskfiberforimprovedcompressive andflexuralstrengthofconcrete. International Journal of Scientific & Engineering Research,6(2),968-974.

[11] Babafemi, A J., Kolawole, J. T., & Olalusi, O. B. (2019). Mechanical and Durability Properties of Coir Fibre Reinforced Concrete. Journal of Engineering Science and Technology. 14(3),1482–1496.

[12] Kshitija,N.(2015).CoconutFibreReinforcedConcrete. International Journal of Mechanical and Production Engineering. 1(3),2320-2092

[13] Anowai,S.I.&Job,O.F.(2017).PropertiesofBananaFibreReinforcedFlyAshConcrete. International Journal of Modern Trends in Engineering and Research 4(7),227-236.

[14] Marcelo, H. M., Janderson, W. R., Juarez, H. F. & Ronaldo, A. M. (2017). Partial replacement and addition of fly ash in Portlandcement:influencesoncarbonationandalkalinereserveSpringer. International Publishing Switzerland.

[15] AmericanSocietyforTestingandMaterials,ASTMC595/C595M. “SpecificationforBlendedHydraulicCements”,USA: ASTMInternational,2016.

[16] BritishStandardInstitution.BSEN12620.“Aggregatesforconcrete”,2002.

[17] AmericanSocietyofTestingandMaterials.ASTMC618-19.“StandardSpecificationfor CoalFlyAshandRaworCalcined NaturalPozzolanforUseinConcrete”,2019:1-5.

[18] AmericanSocietyforTestingandMaterials,ASTMC172.“StandardPracticefor SamplingFreshlyMixedConcrete”.USA: ASTMInternational,2017.

[19] BritishStandardsInstitution,BSEN12350-2.“TestingFreshConcrete.SlumpTest”.2019;1-26.

[20] BritishStandardsInstitution,BS1881Part103:1993.“MethodforDeterminationofCompactingFactor,”1993.

[21] BritishStandardsInstitution,BSEN12390-3.“TestingHardenedConcrete.Compressive strengthoftestspecimens”.2019; 1-24.

[22] BritishStandardsInstitution,BSEN12390-5.TestingHardenedConcrete.FlexuralStrengthofTestSpecimens”.2019;114.

[23] BritishStandardsInstitution,BSEN12350-6.“TestingHardenedConcrete.TensileSplittingStrengthofTestSpecimens”. 2019;1-12.

[24] AmericanSocietyforTestingandMaterials,C1585.“StandardTestMethodforMeasurementofRateofWaterAbsorption inHydraulicCementConcrete”.ASTMInternational,2016.

[25] Rewi,K.H.A,&Khafagy,M.A.S.A.(2011).EffectsofaddingSisalFibreandIraqiBauxiteonSomePropertiesofConcrete. ALTAQANI, 24(2),58-73.