DEVELOPMENT OF ACCIDENT-FREE SOLAR POWERED JEEP

S1,2,3,4Students, Department of Mechanical Engineering S.G Balekundri Institute of Technology Engineering school in Belgaum, Karnataka,India

5Professor and Project guide, Department of Mechanical Engineering, S.G. Balekundri Institute of Technology, Belagavi, Karnataka, India

6Professor and HOD, Department of Mechanical Engineering, S.G. Balekundri Institute of Technology, Belagavi, Karnataka, India ***

Abstract - A Problems like air pollution and the consumption of petroleum have gotten worse as there are more and more moving automobiles on the road. The awareness that people have of the energy and environmental issues is promoting research into alternate car technologies including multiple fueling, hybridization, and electrification. The systems are also changed in tandem with the present issues. Road accidents are another problem. India’s Electric vehicle mission is a major initiativebythegovernmentofIndia to bring down pollution. However, the major hurdles faced in the implementation of Electric vehicles on a proper scale are the battery life and the charging range. The unavailability of charging stations is a major hurdle in setting up India’s EV mission as the charging stations need to be set up throughout the country. Since the proposed concept is to develop a fullfledged solar-powered vehicle the cost of operation of the vehicle is zero as it completely runs on solar energy. The vehicle creates zero pollution and is completely eco-friendly and eliminates the need for charging or charging stations to charge the vehicle. Further, the car is made intelligent, which continuously monitors the car’s health and sends it to the cloud so that breakdowns can be avoided. The Car is made 4 WD so that it can be easily driven across non-planar driving conditions. Smart accidental safety systems such as collision avoidance and GPS tracking are also implemented in the project to make the vehicle smart.

Key Words: Electric Car, 4WD, Solar, Smart, Accidental, Tracking, etc.

1.INTRODUCTION

Today,theglobalautomotiveindustryisreadytosubmitEVs to create a greener world. The environmental effect of internalcombustionenginesisrisingbytheday.Tomitigate the consequences of pollution and promote a cleaner environment, the automobile industry is exploring new avenuesforintroducingelectricvehicles.Becauseinthepast, hybridelectricvehicleshaveproventobelesspolluting.But thiswasnotenoughtostopthecontamination'sfullsteam ahead. When compared to internal combustion engines, electric vehicles have greater technology and enormous efficiency. This research article focuses on the overall

structure and components of an electric vehicle. This also includes power generation and battery performance in relation to market circumstances. The key concern, as addressed in this research, is battery performance. The relevance of charging stations and the surrounding area shouldinspirethedesignoffuturestations.Fuelstationsare theprimarysourceofinformationforpricingservicesevery 5 kilometers. This primarily aids in time savings and the creation of a stress-free environment near the charging station.Becauseoftheincreasednumberofautomobileson theroad,issuessuchasairpollutionandoilconsumptionare becomingmorefrequent.Humansensitivitytoenergyand environmental issues drives research into alternative automotive solutions such as fuel multi-fuel, hybrid, and electrification. At the same time, the system has been modifiedtoconsidercurrentissues.Thispaperdiscussesthe conceptofthedesignandfabricationofSolarpowered4WD electric vehicle with an Accidental safety system and GPS Trackingsystem.

1.1 LITERATURE SURVEY

The literature search used vibrant approaches and current research being done in the field of vehicle constructiontofocusmostlyonitslinkedElectriccarsand accidentsafetysystems.

Ashwin Chander et.al (1) create anidea foran electric automobile with a multi-speed gearbox (EV). Due to the added size, complexity, and cost that a multi-speed transmissionsystemwouldimply,electriccarmanufacturers have chosen against putting them in their vehicles in the current environment. While multi-speed transmission systemspromisetoreduceenergyconsumptionandincrease effectiveness for EVs, thus increasing the EV's "range," colourful variations (making the system clutch-less and limitinggearselectiontothreespeeds)canbemadetomake conventional transmission systems suitable for electric vehicles.Therearefurtherbenefitstoloweringthesizeofthe batteryandengine.

Hailemariam. Hailu et. al (2) did research on the green vehiclelaunchedandpromotedtominimizetheproblemof

airpollutioncausedbyconventionalvehicleemigrationseen mobilityarecarswithlowenergy/energyconsumptionand low/zero exhaust gas emigration; these vehicles are like a mongrel, battery-powered, and energy cell electric vehicle thatcanbeupgradedtobemoreeffectivethanconventional vehicles via a new design and development of power transmissionsystem.Asvariousexperimentershaveshown, thetypeofgearboxusediscriticalforgreatvehicleefficiency. Avehicleequippedwithabinaryclutchtransmissionandan automatedmanualtransmission(AMT)ismoreefficientin termsofenergylossandsmoothgearshifts.

CHENGet.al(3)Providea summaryofthearea'smost recent efforts to develop electric vehicles. The study discussestheevolutionandevaluationofmanycomponent elements. Examined are the key aspects of battery technology,bowldesign,motor,steering,andretardation.As afinaletothepapers,thearticleultimatelydisplaysvarious electriccarprototypes.

ZHANGet.al(4)Describetheregion'smostrecentefforts to develop electric automobiles. The study discusses the evolution and evaluation of many component elements. Examined are the key aspects of battery technology, bowl design, motor, steering, and retardation. As a finale to the papers, the article ultimately displays various electric car prototypes.

ChokriMahmoudiet.al(5)executedaresearchproject

Since the first EVs were built and the outdated power structure was implemented, power operation in EVs has undergonearevolution.Atthepresent,itmaybefueledbya singlesourceoramixofsources,anditcanbeguidedbya singlealgorithmoracollectionofalgorithms.Theoutcomes aremuchbetterasaresultofthisimprovement.Thisstudy examinesthestate-of-the-artfollowingconception,explains each subcategory, and provides information on power operating tactics and charging methods, as well as urgent issuesandoutcomes.

1.2 METHODOLOGY

Theentiredesigniscarriedoutdifferentlysothatthecrimes canbeminimizedthroughtheapproachofthedesign.The detailedmethodologytocarryoutthedesignisgivenbelow

● Theliteraturecheckandproblemdescription:

Theliteraturereviewiscarriedouttostudythecurrentas well as being system. Different exploration papers from differentexplorationscholarswerestudiedtoarriveatthe problemdescription.

● The designing a of smart adaptive speed control system: To bring about of conception of adaptive speed control with a smart collision discovery and avoidance system, an object detector has connived with the microcontroller. The sensor continuously checks for the

presenceoftheobjectintherangeofthevehicleandkeeps on transferring signals to the microcontroller which is presentinthevehicle.

● Thevehicleframeworkfabrication:

to demonstrate this conception, an electric 4-wheel drive vehicle is fabricated. originally the lattice of the vehicle is fabricated.Thechassisisfabricatedoriginallyasitformsthe structural element of the vehicle and houses all the other corridorsofthevehicle

● TheDrivetrain:

When the chassis is constructed, the system's four-wheel electricdrivetrainisconstructedandfitted.Thedrivetrain transfersthemotor'spowertothebus.Thesuggesteddrive traininthisconceptconsistsofageardriveandasprocket chain drive. In this stage, the electric drive system is reinforcedandputtogethertocreateafullyworkingelectric vehicle.

● TheSolarPowerSystem:

Thedrivetrainispoweredusingbatterieswhicharedriven usingsolarenergy.Inthisphase,thesolarpowersystemis developed which is responsible for making the auto solar powered

● Thesmartaccidentandnotificationsystem:

DiscoveryandannouncementsystemInthisphasetheGPSgroundedaccidentdiscoveryandannouncementsystemis enforced which will decrease the accident of the vehicle using the MEMS detectors present on the vehicle and automaticallysparkanannouncementtothehospitalsand familymembersalongwiththelivetrackingofthejeep.

● Assemblingandoperating:

Thecompletionofthedesignprocessentailsputtingallthe components together. The integrated components both designedandmanufactured areputthroughperformance testing.Thisstageinvolvesdoinganyoptimizationsthatare required.

● Conclusion

1.3 WORKING PRINCILE

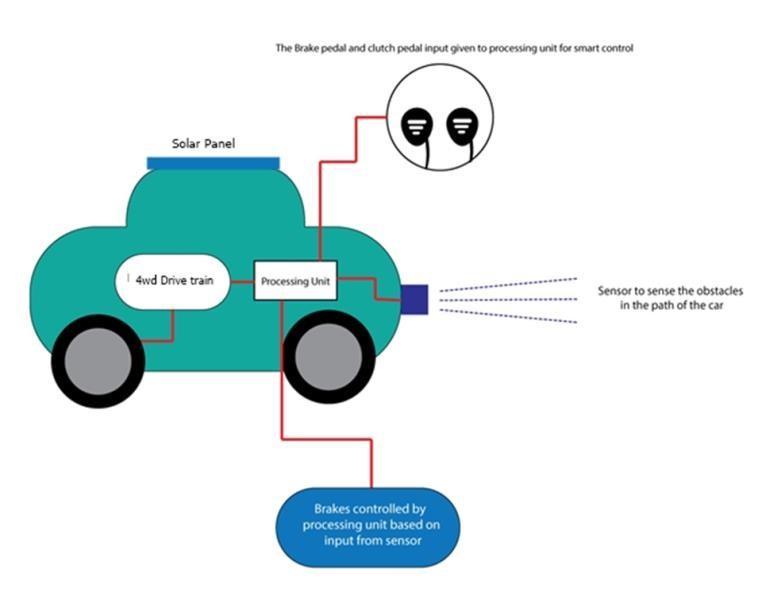

Fig1WorkingPrincipalModel

3. DESIGN CALCULATIONS

GVW(grossvehicleweight)=250kg=250*9.81= 2452.5N

2452.5/4=613.125Nweightoneachdrivingwheel(WW)

Theradiusofthewheel/tire(RW)isequalto0.22m. Vmax(desiredhighestspeed)=25Kmph=6.94m/s

Thedesiredaccelerationtime(ta)is40seconds.

2 degrees is the maximum inclination angle. Concrete providesagoodworkingsurface

Vehicletotaltractiveeffort(TTE)requirement:

RR+GR+FA=TTETTE=TotalTractiveEffort[N].

TTEstandsforTotalTractiveEffort[N].

GR=ForceRequiredtoClimbaGrade[N]

FA=Accelerationforcenecessarytoreachultimatevelocity [N]

The following procedures will reveal the variables of this equation.

Fig 1. Working Principle

As shown in the illustrative diagram the system consists of the development of solar powered4wdelectriccarwithanaccidentalsafetysystem.

Thesensorsmountedonthevehicleareinterfacedwitha microcontroller.Themicrocontrollerprocessesthedatafed by the sensors. If there is an obstacle in the range of the vehicleatacertaindistancefromthevehicle,thevehiclefirst drops its speed adjusting to the proximity of the obstacle. Whenthedistancebetweentheobjectandthecargetsmore, the speed gets slower. This is done with the help of ultrasonic range finders which continuously feed the distance between obstacles to the microcontroller which automaticallyadjuststhespeed.

The4-wheeldriveelectricvehicleisfabricatedwhichis drivencompletelyusingsolarenergyandcanbeeasilyused fordailycommutes.

2. STANDARD COMPONENTS USED

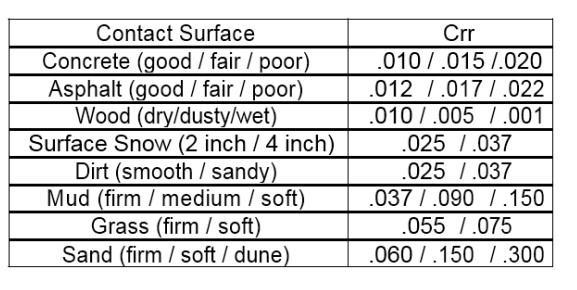

RollingResistanceCalculation:

The type of surface the vehicle will drive on should be considered. Rolling resistance is the amount of force requiredtomoveavehicleoveracertainsurface(RR).

RR=GVWxCrr=24.52N=2452.8x0.37(mud)=907.24N =2452x0.60(sand)=1471.2N

Where:

RollingResistance[N]=GVWisanabbreviationforGross VehicleWeight[N].

SurfaceFriction=Crr(valuefromTablebelow)

GradeResistanceCalculation:

Graderesistanceistheforcerequiredtopushavehicleupa grade or slope. In this calculation, the maximum angle or gradientthatthevehicleisexpectedtoclimbduringnormal operationmustbeemployed.

Convertinganinclinationangletograderesistance.

GR=GVWxsin20=838.6N

Where GR denotes Grade Resistance [N]. GVW is an abbreviationforGrossVehicleWeight[N].

α=MaximumInclineAngle(indegrees)

CalculatingAccelerationForce: AccelerationForce(FA)istheforcerequiredtoaccelerate from a standstill to maximum speed in a given amount of time.

FA=GVWxVmax/(9.81xta)/(9.81x40)=43.366N

Where:

FA=ForceofAcceleration[N]

GVWisanabbreviationforGrossVehicleWeight[N]. ta=timenecessarytoobtainmaximumspeed[s]

Vmax=maximumspeed[m/s]

Totaltractiveeffortcalculation:

Theforcesassessedinphases1,2,and3areputtogetherto generate the Total Tractive Effort (TTE). (With faster automobiles, friction in the drive components may necessitateanincreaseintotaltractiveeffortof10to15%to provideadequatevehicleperformance.)

TTE=24.52N+838.6N+43.36N=906.48N

DeterminationofWheelMotorTorque: Calculatingthenecessarywheeltorque(TW)basedonthe tractiveeffortiscriticaltoensurethevehiclewilloperateas intendedintermsoftractiveeffortandacceleration.

TW=TTExRWxRF=906.48x0.22x1.1=219N-mWhere:

TW=wheeltorque[N-m]

TTE=TotalTractiveEffort[N]

RW=radiusofthewheel/tire[m]

RF=ResistanceFactor[-]

The resistancefactor takesintoconsiderationthe drag on themotorbearingsaswellasthefrictionallossesbetween the caster wheels and their axles. Values typically fall between1.1and1.15.

4. RESULTS

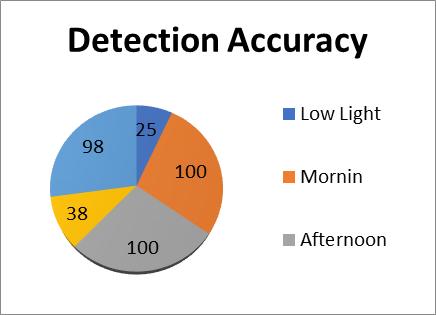

Detection results for type of obstacle at different times of the day: The detection of the kind of barrier was performed at several times of the day to ensure accuracy. Thiswasdonetobetterunderstandhowlightingconditions impactimageprocessingoperations.

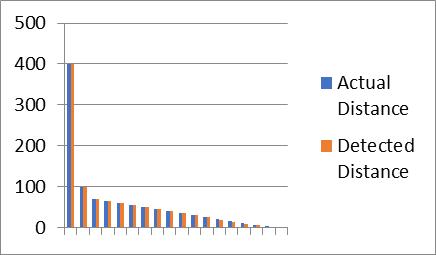

Testing of obstacle detection distance: Varioustestswere conducted to identify the obstacle detection for the smart system created in the hybrid vehicle with the distance specifiedintheprogram,aswellastoassesstheaccuracy. The detection distance is chosen, and the table below illustratestherealvs.detecteddistancewhentheultrasonic sonarsensorisusedtodothetest.

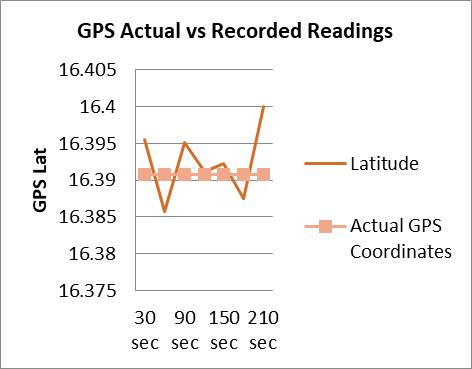

GPS readings: The GPS data was recorded at known coordinatesoveraperiod

5. CONCLUSION

Thepaperdiscussedtheconceptoftheprojectisexpectedto provideaSolarpoweredsmartelectriccarthatrunsonsolar energymakingitcleangreenandecofriendly.Bymakingthe automobilesolar-powered,theplannedideaisanticipatedto address the issues with charging facilities that now affect electricalvehicles.Theprojectimplementedisexpectedto reducethedependencyonfuel-poweredcarstherebysaving fuel as well as reducing pollution. The project is also expected to provide a cost-efficient solution for daily commutes since the cost per km is almost negligible with this solarpowered car. The project is also expected to provideaccidentalsafetyandalertsystemby implantinga smartsystemthatcanpreventacollision,andover-speeding andnotifyimmediatelyifanaccidenthappens.

REFERENCES

[1]AshwinChander,MadanKumar,ShobithNambiar, Harsh Zaveri; “Design and Study of Transmission System for Electric Vehicles” International Journal of Engineering Science and Computing, March 2018, Volume 8 Issue No.3.16512http://ijesc.org/[pp16512]

[2]HailemariamN.Hailu*andDanielT.Redda;“Designand DevelopmentofPowerTransmissionSystemforGreen and Light Weight Vehicles: A Review”, The Open Mechanical Engineering Journal, 2018, Volume12DOI:10.2174/1874155X01812010081

[3]K.W.ECHENG;“RecentDevelopmentonElectricVehicles” 20093rdInternationalConferenceonPowerElectronics Systemsand Applications.

https://www.researchgate.net/publication/224585929

[4]ZHANG*, C. ZUO, W. HAO, Y. ZUO, X. L. ZHAO and M. ZHANG;“Three-SpeedTransmissionSystemForPurely Electric Vehicles” International Journal of Automotive Technology,Vol.14,No.5,(2013),[pp.773].0

[5]Dr.ChokriMAHMOUDI;“AnOverviewofElectricVehicle Concept And Power Management Strategies” 978-14799-7300-2/14/$31.00 ©2014 IEEE

https://www.researchgate.net/publication/265709143

[6]Jae-Oh Han, Jae-Won Shin, Jae-Chang Kim and SeHoon Oh;“Design2-SpeedTransmissionforCompactElectric Vehicle Using Dual Brake System” Appl. Sci. 2019, 9, 1793; doi:10.3390/app9091793

www.mdpi.com/journal/applsci.[pp1]

[7]M. Prabha, M. Seema, P. Saraswathi, “Distance-based Accident-AvoidanceSystemusingArduino”,International ResearchJournalofEngineeringandTechnology(IRJET)

e-ISSN:2395-0056

[8]Divya Thakur, A. P. Thakare, “A Review on ImplementationofFPGAforAutomaticReverseBraking System”,International Journal ofScienceandResearch (IJSR)ISSN(Online):2319-7064

[9]SushilKumar,VishalKumar,“AUTOMATICEMERGENCY BRAKINGSYSTEM”,InternationalJournalofResearchIn Science & Engineering e-ISSN: 2394-8299 Volume: 1 Issue:3

[10] Shivam S. Shinde, Aditi V. Lawate, “Intelligent Automobile Accident Avoidance System”, International JournalofScientific&EngineeringResearch,Volume4, Issue10,October-2013 ISSN2229-5518