Sustainable and modern prototype of technologies with less carbon emissions for PM Mega Integrated Textile Region and Apparel (MITRA) park at Virudhunagar district in TAMILNADU

A.R.LAKSHMANAN1 , B.A.MOOKAMBIKA2

1M.arch ( construction project management )student, Faculty of architecture, Dr. M.G.R. Educational and research institute, Chennai, INDIA.

2Associate professor, Faculty of architecture, Dr. M.G.R. Educational and research institute, Chennai, INDIA. ***

Abstract - An ideal suggestion for a sustainable and modern prototype of technologies that could add value to the live project of Mega integratedtextileregionandapparelpark inE. Kumaralingapuram(SIPCOT)atVirudhunagardistrict in TAMILNADU. This journal explores all the possible and practical technologies that could mitigate carbon emissions through electricity and vehicular transportation in the logistics of the manufacturing processes involved inthetextile industry and efficient conservation of natural resources such as water and energy management for sustainable maintenance and operations. This journal concludes with the results and advantages of the prototype that is suggested for the live project PM MITRA PARK at VIRUDHUNAGAR.

Key Words: Sustainabletechnology, modern, prototype, textile park , carbon emissions , water usage , water less dyeing,energyefficiency,solar,solarpower,polypond, bio-gas,conveyorsystem

1.INTRODUCTION

Thisresearchjournal isanideal suggestionofsustainable andmodernprototypesoftechnologiesthatcouldbeideally possible for implementation in the commissioned live project of PM MITRA PARK in E. KUMARALINGAPURAM (SIPCOT) at VIRUDHUNAGAR district of Tamil Nadu. This researchhadbeeninitiatedwiththeliteraturestudiesonthe functionality and operations held in the textile industries along with the live case studies held at TIRUPPUR, which made me overgo studies on sustainable technologies that could minimize the carbon emissions from the industry. Post-completionofthestudiesrelatedtothisresearchtopic, all possible sustainable and modern prototypes of technologiesarebeingstudied,alongwiththeirkeybenefits inminimizingthecarbonemissionsfromtheindustry.This research has its outcomes in sustainable and modern prototypesoftechnologiesthatcouldfavorthenation'sgoal of becoming a net zero carbon emitter by 2070. This integrated textile township could be provided with sustainableandmodernprototypetechnologies,including green power utilization, effective water management, and carbon-freetransportationwithineachprocessinvolvedin the manufacturing process, minimizing the utilization of non-renewablesourcesnecessarytomeettheirdailyneeds.

This research provides an innovative solution for the integrationofthemega-integratedtextileregionandapparel parkthatisprovidedtoattractalotofforeignbuyersand investmentsbyprovidingeco-labellingandaddingvalueto theircompletedproducts.

2. METHODOLOGY

LiteraturestudyontheliveprojectproposalofPM MitraPark

Literature study on the environmental damages caused by the industrial development of a textile park

Journalstudiesonthesustainabledevelopmentof the textile industries globally for their finished products

Literature and live case studies on vertical integration of textile parks along with residential andcommercialdevelopment

Comparativeanalysisofthecasestudiesandtheir innovations towards sustainable production and manufacturingoftheirtextileproducts

FinalproposalforPMMitraParkatVirudhunagar with sustainable and modern prototype technologies

Results

Recommendations

Conclusion

3. PM MITRA PARK PROJECT PROPOSAL

The process of integrating all the manufacturing units necessaryfortheproductionoffinishedtextileproductsis inspired by the vision of Shri. Narendra Modi as "farm to fibre tofactoryto fashion to foreignintheseven states of India. This project is pre-planned by the government to providedevelopmentcapitalsupportofINR500croresfor

infrastructuredevelopmentforgreenfieldprojectsandINR 200 crores for brownfield projects in which the parks are ownedbythestateandthecentralgovernmentinPPPmode. This project is set up to lower the logistics cost of the manufacturingprocessinvolvedinthetextileindustryandto increasethestrengthofthetextileindustry,supportingthe economy of the nation and providing a huge amount of employmentopportunitiesdirectlyandindirectlythrough thisproject.

4. ENVIRONMENTAL DAMAGES BY THE TEXTILE INDUSTRY

4.1. SOIL and WATER POLLUTION

Thedyeingprocessinthetextileindustries,duetotheirlack of environmental concerns, is majorly responsible for the soil and water pollution of two major rivers, namely the Noyyal and Bandhi rivers, in India, making the water unsuitable for drinking or irrigation purposes. This led to hugeenvironmentalcostsforthereclamationofthenatural sourcesoffreshwater.

4.2. AIR POLLUTION

Lackofintegrationofthetextileindustrypavedthewayfor nucleatedunitsservingthemanufacturingprocess,making logisticsanecessaryoptiontotransportthegoodsfromeach process involved in the textile industry, causing carbon emissions through transportation along with larger electricity needs for the operation, which are also met through the combustion of fossil fuels and coal instead of utilizing natural resources, causing carbon emissions throughcombustionandallpollution.

5. RESEARCH PURPOSE

Carbon-free, structured framework to mitigate furtherpollutionfromthetextileindustry.

Attracting foreign buyers through a structured, sustainable framework with an environmentally friendly production process for their finished products

Improving the strength among the foreign competitors,namelyBangladeshandChina.

Ensuringprofitabilityfortheenvironmentandthe economy through the innovative development of the textile industry with sustainable and modern technologies.

Theprototypesuggestedalsopavesthewayforthe nationtomeetitssustainabilitygoalofbecominga zero-carbon emitter by 2070 through its developmentvisionforthetextileindustry.

6. ADVANTAGES

Theprocessofintegratingallthetextileunitsinvolvedinthe manufacturingofthefinishedtextileproductsoffersseveral advantages,including:

1. Improved collaboration:Integratingall thetextile units could provide better collaboration and a betteroutcomeforthefinishedproducts.

2. Lowering logistics costs and carbon emissions: Integratingallunitscouldalsoprovideasustainable sourceoftransportationofmaterialsfromeachunit withinthemanufacturing process.Materialsfrom each unit can be transported through conveyor systems,replacingvehiculartransportation,which could mitigate the costs involved in the logistical transportationofgoodsandcarbonemissionsfrom theburningoffossilfuels.

3. Energy efficiency and water conservation: Integrating these units together could require a larger area for operation, which in turn could be utilisedtogenerateelectricitythroughsolarpower to meet their electricity needs. With larger roof areas, these roofs could also collect runoff water throughrainwaterharvestingsystemsandutiliseit forfuturepurposesasasaferwaytofacescarcity.

7.DISADVANTAGES

Whileintegratingtextileunitsoffersmanybenefits,thereare alsosomepotentialdisadvantagestoconsider:

1. HIGHERINVESTMENTCOST:Integratingalltextile units requires a higher investment cost for the construction of the built-up structures, which, togetherwiththeautomatedmachinerynecessary fortheprocesses,makeforhigherinvestmentcosts fortheproject.

2. LONGER TIME PERIOD FOR COMPLETE DEVELOPMENT:Astheprojecttendstobealargescaledevelopmenton1054acreswithaschemeof long-terminvestmentsoncommercial,hospital,and housingfacilitiesintegrated,theprojectcouldtakea longertimethanusual.

3. Lack of uniformity: As this will be the first PPP modelforlarge-scaleindustrialdevelopmentinthe textileindustry,investorslacktheabilitytofollow thedesignprototype.

8. CASE STUDIES

The case studies that are executed for the research on sustainabledevelopmentofthetextileindustryare:

1. ANUGRAHAFASHIONMILLSPRIVATELIMITED

2. KPRMILLSPRIVATELIMITED

3. VIJIKNITTINGPRIVATELIMITED

4. MITHRAANDCODYEINGPROCESSING

5. NAADHANANDCO

6. MAHINDRAGLOBALCITY

8.1. ANUGRAHA FASHION MILLS PRIVATE LIMITED

AnugrahaFashionMillsatKangeyaminTirupurdistrictisa vertically integrated textile manufacturing mill except for theirdyeingunit,whichisbeingprovidedoutsidethetextile complex,whichis35kmfromthiscomplex.Thismilloffers finishedtextileproductexportservicesto07international buyers,withaproductioncapacityof350MT/month,knitting capacityof250MT/month,dyeingcapacityof350MT/month, printingcapacityof50,000Pcs/day,embroiderycapacityof 20,000Pcs/day,andfinallygarmentingcapacityof1,00,000 Pcs/dayin350acres,aswellashostelfacilitiesforworkers andhousingfacilitiesfortheiremployers.Thisfashionmillis providedwithsustainablesourcestocatertoalmost90%of their electricity needs through roof-top solar panel installationanda2MWsolarfarmtogenerateelectricityfor theiroperationalneeds.Theyarealsoprovidedwithaninhouse water treatment plant for reusing treated effluent water for dyeing processes,mitigatingthe consumptionof freshwater.InordertomitigatetheusageofLPGgasesfor cookingpurposesforthepeopleinsidethecomplex,aninhouse biogas plant recycles food waste to cater to the gas needs for cooking purposes. This integration of all units insideasinglecomplex,excludingthedyeingunit,provides better results on the quality of the finished garments that undergo quality checks for exporting. This integration providescompletein-houseproduction,mitigatingtherisks involved in quality and delays due to transportation, an inadequateworkforce,orinefficientcapacitytodeliverthe jobordersontimebyothernucleatedunitsinandaroundthe city.

Constructiontechnology

Sustainable technologies implemented

Conventional

Solar power generation . ZLD plant for water recycling and Bio-gas plant for recycling of foodwastetogenerateCBGfor cookingpurposes

8.2. KPR MILLS PRIVATE LIMITED

TheKPRmillsatKarumathampattiinCoimbatoredistrictare also similar vertically integrated textile production units, twiceasbigastheAnugrahafashionmillsinKangeyam.This millisalsoprovidedwithseparatedyeingunitsoutsidethe textilecomplexduetotheheavywaterrequirementforthe dyeingprocesstocatertotheirproductionneeds.ThisKPR millhasitsownopeninternationalbrandsoftextilesalong withexportoperationsoffinishedtextilegarmentstomore than15international buyersglobally.Thisintegrationofa verticalcomplexmitigatedthelogisticscostsinvolvedinthe transportationofgoodsforthemanufacturingprocessand also ensured quality production of garments along with followingdeadlinesfordelivery.ThisKPRmillhasaspinning capacity of 100,000MT/year, knitting capacity of 40,000MT/year, dyeing capacity of 18,000MT/year, and garmenting capacity of 115 million readymade garments/year.Theircarefulintegrationstrategypavedthe way for a seamless flow of their operations for a healthy business.ThisKPRmillisprovidedwith66windmills,each withapowergenerationcapacityof45–55MW,tocaterto theirelectricityneeds.

Constructiontechnology Conventional

Sustainable technologies implemented

Wind power generation . ZLD plant for water recycling and Bio-gas plant for recycling of foodwastetogenerateCBGfor cookingpurposes

Constructiontypology Industrial shed roofing for factorybuildings,RCCslabroof structures for office and hostel facilities

8.3. VIJI KNITTING PRIVATE LIMITED

Constructiontypology

Industrial shed roofing for factorybuildings,RCCslabroof structures for office and hostel facilities

VijiKnittingPrivateLimited,locatedatGanapathipalayamin Tirupur,isanucleatedknittingunitwithabuilt-upareaof around45,000sq.ft.andequippedwithsolarroofpanelsto generateelectricitytocaterfor1/3rdoftheirdailyelectricity needswithaseamlessflowofknittingoperations.Thisunit provides job assistance to knitters involved in the process afterspinningandbeforedyeinginthetextileindustry.This unitprocuresyarnsfortheprocessofknittinganddelivers the knitted fabric to the dyeing process, which is also a nucleatedunitcateringtothedyeingpurposesofthefinished yarn and fabric for the process of garmenting. These nucleatedunitsareverypopularintextileindustrialcities, causingamajorneedforlogisticsforproductionpurposes.

Constructiontechnology Conventional Buildingtypology

Sustainable technologies implemented

Industrialidentification

Industrialshedroofingstructure

250KWpsolarpoweredrooftop withapowergenerationof875975units/day

Nucleated knitting unit serving joborders.

8.4. MITHRA AND CO DYEING PROCESSING UNIT

Mithra and Co. Dyeing Processing Unit is also another nucleateddyeingprocessingunitfordyeingfinishedyarns andfabricsfortheprocessofgarmentingthefinalproducts. This dyeing unit is provided with an in-build effluent treatmentplantwithacapacityof1lakhlitresin1.5daysto minimize the consumption of fresh water for the dyeing process. This in-built effluent plant is provided by perfect drains that connect to the tank through separate built-up drains without contaminating the soil. This unit is also provided with a 200 KW solar-powered rooftop with an electricity generating capacity of 150–200 units per day. Theirenergyrequirementperdayisaround850–950units, whichis1/4thoftheneedwithawaiveronelectricitybillsof aroundINR50,000permonth.

Constructiontechnology Conventional

Sustainable technologies implemented

Roof-top solar powered, Inhouse ZLD plant for water recycling.

Constructiontypology Industrial shed roofing for factorybuildingwithmaximum daylightutilizationfromtheG.I roofingmaterials

Industrialidentification NucleatedDyeingunit

Constructiontechnology Conventional Sustainable technologies implemented Nil

Constructiontypology RCC built-up structureonlyfor the admin activities of the business

Industrialidentification Nucleated domestic manufacturer and retailer of openendyarnfabric.

Mahindra Global City at Chengalpattu in Chennai is an industrial township organized on 15,000 acres, which includes1,000acresofreservedforestsconsistingof7lakes withinthecomplex.Thisstudywascarriedouttoanalyzethe areaallocationprovidedforhousingunitssuchasvillasand apartments.Fromthestudy,itiscleartostatethat62%are forindividualvillasand38%areforhigh-risedevelopments for housing communities. This Mahindra global city is provided with efficient water and energy conservation technologiestocatertotheirneedsforelectricityandwater. Thiscityisalsoprovidedwithabio-gasplanttogenerateCNG (compressednaturalgas)fuelfortransportation.Thisproject wasalsoawarded gold certification from the IGBC(Indian GreenBuildingCouncil).

8.7.COMPARITIVE

OF THE CASE STUDIES

Naadhan and Co. is a domestic retailer of recycled cotton garments at 15 Velampalayam in Tirupur. This company provides job orders for all nucleated units involved in the OYE knitting garment manufacturing process, such as spinning, knitting, dyeing, printing, embroidery, stitching, checking,ironing,andpacking,indifferentunitsandstocks thefinalfinishedgarmentswithintheofficetocatertotheir deliveryofbusinessthroughplatformslikeAJIO,MYNTRA, etc. This kind of nucleated business unit is also popularly found in the cities of textile industry developing regions possessing a need for vehicular transportation, causing carbonemissionsonalargescale.

Keyspecifications Anugraha fashion millspvt.ltd., KPRmillspvtltd., Verticalintegration in textile manufacturing process

Excluding dyeing unit

Excluding dyeing unit

Sitearea 35acres 65acres

Buildingtypology G+3 industrial shed roofing for factory developedsites

Sustainability in practice Solar power generation, bio-gas plantforcookinggas, in-house ZLD plant for water recycling, vertical integration minimizing carbon emission through transportation.

G+3 industrial shed roofing for factory developedsites

Wind power generation,in-house ZLD plant for water recycling, vertical integration minimizing carbon emission through transportation

9.

9.1. PROPOSED SITE

ThestategovernmentofTamilNadu,onbehalfofproviding industrial development in the southern regions, had its proposal with the SIPCOT land area of 1054 acres at E.KumaralingapuraminVirudhunagardistrict.Thereareno furtherdelaysinthelandacquisitionprocessasthelandis alreadypre-ownedbythestategovernmentofTamilNadu forindustrialdevelopmentpurposes.ThisPMMitraParkat Virudhunagar will be fundedwith approximatelyINR 500 crore from the Central Government of India for the developmentofthetextileindustry.

9.2. PROPOSAL

9.2.1. EFFICIENT LAND ALLOCATION

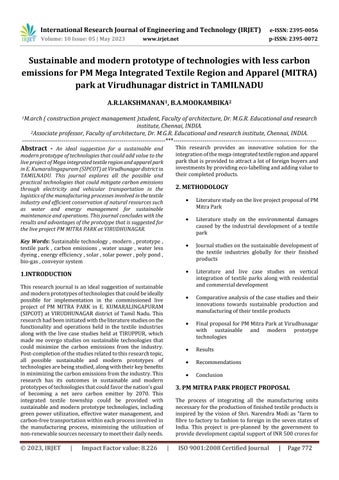

TheareaallocationisasperthenormsofDTCP(directorate oftownshipandcityplanning)andCBR(combinedbuilding rules) for efficient utilization of the available land of 1054 acres.This1054-acreareaisprovidedwitha greenbeltof 116.51 acres of xeriscaping, which requires less water for irrigation purposes, industrially developed sites at 508.17 acres, individual housing units at 40 acres, and high-rise housing units at 25 acres, along with 15 acres for hostel facilitiesfortheworkmen,abio-gasplantat25acres,roads at94.32acres,100acresforlogisticsparks,40acresforother sewageandwastewatertreatmentplants,20acresformultispecialty hospital, 40 acres for commercial spaces, and 50 acresforZLDtreatmentplant,includingman-madepondsto collect surface run-off water with rain and storm water managementfacilities.

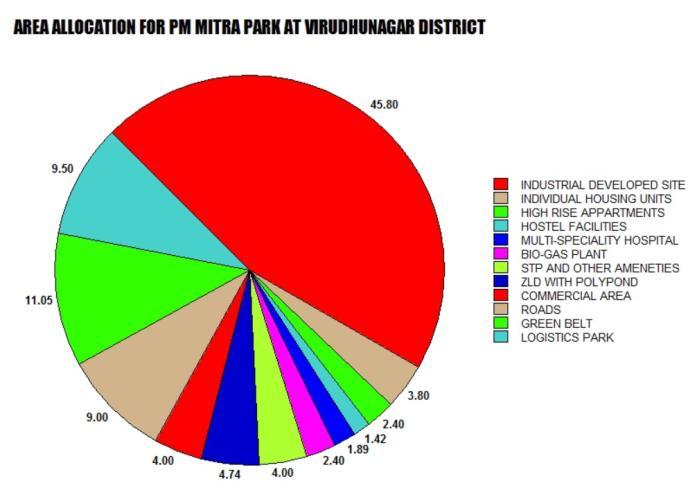

9.2.2. PROTOTYPE FOR BUILT-UP STRUCTURES

Aprototypeforthebuilt-upstructuresissuggestedwithprecasttechnologyforindustriallydevelopedsitesandhigh-rise and mid-rise housing and hostel facilities, along with commercialandhospitalspaces,andotheramenitiesinthe area of conventional construction for areas allocated for individualvillahousingplots.This40-acreareaallocatedas individualplotsforvillaswillinitiallycatertoatemporary pre-cast batching plant to fabricate the pre-cast elements necessaryfortheconstructionofthepre-caststructures.The industrialdevelopmentsitesareprovidedin508.17acresto provide a uniform specification for built-up structures, of which496.25acresaretobespecifiedwithprecastindustrial shedroofbuildingsintheallocatedplotsforeachunit,while 11.92 acres of site are provided for mid-rise vertical developmentstructurestocatertotheindustrialneedsfor the production of textile garments. On considering the previous studies on textile integrated private units, the constructiontimehasanoverrunoflongerthanexpecteddue toinadequatemanpowerandmachineryresources,leading to delays in the completion of the project through conventional methods, so this suggested prototype could enhance uniformity in the projectalong withthe value for moneyinitsquality.

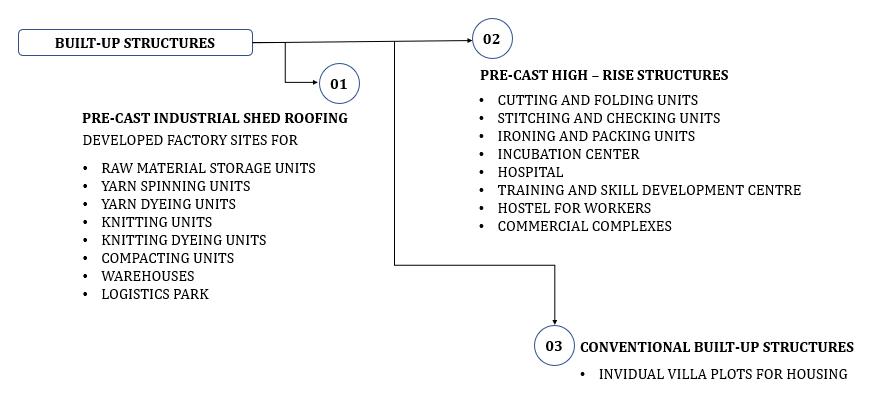

9.2.3. WATER LESS DYEING AND ZLD TREATMENT PLANTS

ZLD (zero liquid discharge) plants have now become a mandatoryprocesstobelicensedtoprovidedyeingservices in the textile industry in India. On average, 1kg of fabric requires250litresofwaterfortheprocessofdyeinginthe textileindustry.Thesedyeingunitsaretermedtorequirea hugeamountofwateramongstotherprocessesindyeing. ThisdyeingeffluentwaterisbeingtreatedintheZLDplants andisbeingrecycledandreusedfordyeingandlandscape purposes.Apartfromtheinnovationofotherresearchand developments in the textile industry, an important masterpiece could be the invention of waterless dyeing machines.Thewater-lessdyeingprocessisanewtechnology

in the process of dyeing fabric or yarn without the use of water. This water-less dyeing machine uses liquid carbon dioxide heated in a controlled environment to probably minimizethelargerneedsofwaterfortheprocessofdyeing inthetextileindustry.

Thisproposalfordyeingunitsisprovidedtomeetafabric productioncapacityofapproximately6250MT/month.

As1MT=1000kg,and6250MT=62,50,000kg,

Onanaverageof24workingdays,260MT(i.e.,2,60,000kg)

Water required for dyeing 1kg of fabric is 150–350 litres, taking250litresasanaverage.Thesedyeingunitsrequire 6,500,000litresof waterperday.Thiswaterrequirement couldbemitigatedbyprovidingdyeingunitswithwater-less dyeing technologies and utilizing fresh water for drinking andotherirrigationfacilities.

9.2.4.WATERCONSERVATIONTHROUGHEFFICIENT STORM AND RAIN WATER MANAGEMENT SYSTEM

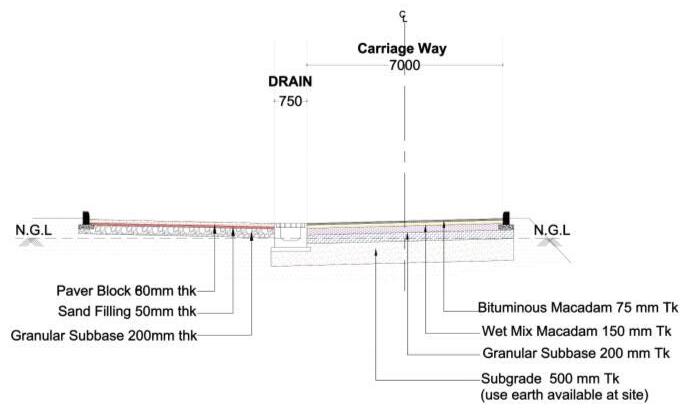

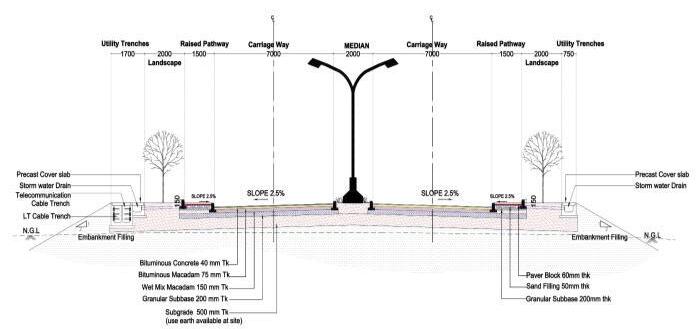

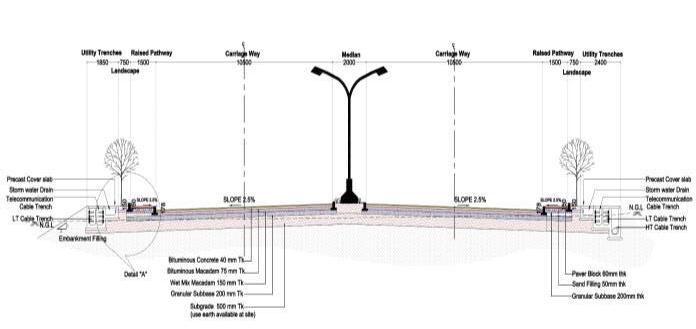

Surfacerun-offwaterisbeingcollectedfromtheroofsand terraces of the built-up structures and roads through the drainstothewaterstoragetanksthatareprovidedasmanmadepondswithinthesitetocatertothestoragenecessities of the water for later utilization. Providing prototype accessoryroadswithinthecomplexwithdrainscouldbea suggestiontocollectsurfacerunoffwaterfromtheroads.

Onconsideringtheannualrainfallrecordedintheprevious year in the Virudhunagar district of 724mm from the rooftops and terrace areas of the built-up structures, the surface runoff water could also be collected in the storm drainsanddepositedintheman-madepolypondswithinthe industrialcomplexforfurtherutilization.

ANNUAL RAINFALL 724 MM

WATER CATCHMENT AREA 30,00,000SQ.M(APPROX.,)

WATER HARVESTMENT 2,17,20,00,000Litres/annum

Thislargerindustrialdevelopmentcouldalsobeprovided with 75% rooftop solar panels for power generation for industrialroofedstructuresand50%rooftopsolarpanelson theterracesfor powergeneration to minimizethecarbon emissions from the combustion of fossil fuels, coal, etc. Providingroof-topsolarpanelpanelscouldprobablymeet

half of the energy consumption necessary for the overall operationsofthistextileindustrialdevelopment.

Thearearequiredfortheinstallationofa1MWpsolarplant is75,000sq.ft.withapowergenerationcapacityof3,500–4,500 units per day. The projected approximate roof and terrace area of the industrial complex is around 1,456,673,300 sq. ft., which excludes the other services provided in the roof and terrace areas of the built-up structuresthatcanbeprovidedwithsolarpanelstogenerate electricity.

Hence,

Availableroofarea/arearequiredfor1MWpsolarplant= solarrooftoppanelinstallationcapacity

1,45,67,300 / 75,000 = 194.23 MWp, with a power generationof3,30,000–4,50,000units/day.

This prototype could mitigate the carbon emissions from coalpowergeneratingstations.Thecarbonemissionsfrom utilizingcoalcouldbe950GMSperKWp,andhencefor330 KWp, the carbon emissions will be 3,13,500 kg/day. This carbon emission could be mitigated through the solarpoweredindustrialdevelopmentinVirudhunagardistrictin TamilNadu.

9.2.7. BIO-GAS PLANT

Thistextiletownshipdevelopmentwithhousingandhostel facilities tends to emit large quantities of food waste that couldbecollectedeveryday.Thisfoodwastecouldalsobe recycled on site with the installation of a bio-gas plant to providebio-gas,whichcouldbeanalternativesuggestionto using CBG (compressed bio-gas) cylinders instead of LPG (liquifiedpetroleumgas)cylinders.

9.2.8. IBMS INTEGRATION

Integrating the textile township development with intelligencebuildingmanagementfacilitiescouldmakethe process of monitoring and managing the services and facilitiesmoreconservative.Thisinstallationcostcouldbe higher,butprovidingartificialintelligenceservicescouldbe more effective for facility management of the textile complex.

10. RESULTS

Tab -8:On-sitesolarpowergenerationfromtherooftops oftheindustrialshedroofstructuresandterraceofthe slabbedroofstructureswithinthetextilepark.

9.2.6. CONVEYOR SYSTEM FOR TRANSPORTATION OF GOODS FROM EACH PROCESS INVOLVED IN THE PROCESS OF TEXTILE MANUFACTURING

This suggestion could be an innovation in the process of vertical integration in a textile manufacturing region to mitigatethevehiculartransportationnecessarytotransport the finished goods from each process involved in the manufacturingprocessofthetextilegarments.Thissupply chain in the manufacturing processes could be connected with a conveyor system for transportation of the finished goodsfromeachprocess.Thisconveyorsystemcouldalso minimizetheemissionofcarbondioxidethroughvehicular transportation.

Implementationofthesuggestedprototyperesultsinbetter utilizationoflandareaandserviceefficiencyinenergyand water consumption and management within the textile complex.Thiscouldalsosupportmitigatingtheemissionof carbon within the textile complex. A proper vertical integration of the textile complex through sustainable and modern prototype technologies could also enhance the seamless flow of operations with a better outcome in the quality of finished textile products. This sustainable production could also probably attract foreign buyers to providejobordersfortheirdevelopmentintheproductionof theirproductsinanenvironmentallyfriendlymanner.This vertical integration can also support the nation’s goal of becominganet-zerocarbonemitterby2070.

CONCLUSION

The application of an integrated textile complex is a profitableprocesstobeincorporatedinthemanufacturing of textile garments. This vertical integration mitigates the delaysindeliveryofthejobordersineachprocessduetothe involvement of a third party for the production process, which involves a lot of vehicular transportation with the loadingandunloadingof thefinished materialsfrom each process. By providing vertical integration, the buyers feel secureintheirjoborderswithoutdelaysindeliveryofthe finalfinishedproductsthataretobeexported.Thiscareful verticalintegrationofallsustainableandmodernprototype technologieswiththeirprovenbenefitscouldaddvalueto the international competitors of the nation in the textile manufacturingandexportmarketsglobally.

RECOMMENDATIONS

Several recommendedprototypes canbe providedfor the verticalintegrationofthetextilecomplex,suchasroof-top solar power generation, Man-made poly pond to cater to water needs met through the collection of surface run-off water from the roofs, terraces, and roads; ZLD plant for treating,recycling,andreusingtheeffluentwaterfromthe dyeing units; Dyecoo's water-less dyeing proposal to mitigatethelargewaternecessityforthemanufacturingof dyeingyarnsandfabric,Xeriscapingtoprovidelesswater fortheirirrigationpurposes;aconveyorsystemmitigating the usage of vehicles for transportation of finished goods from each manufacturing process involved in the textile industry to have a seamless flow of operations leading to betteroutcomesfortheirfinishedfinalproducts;

REFERENCES

[1] SamitChakraborty,“Adetailedstudyonenvironmental sustainability in knit composite industries of Bangladesh” , https://www.researchgate.net/publication/311881677

[2] Arindam Basu, “SustainabilityinTextilesand Apparel industry”, https://www.researchgate.net/publication/343064583

[3] Catarinacosta,CarlaJSilva,Nunog.Azoia,EduardoF. Marques, “Textile Industry in a changing world: Challenges of Sustainable development”, https://www.researchgate.net/publication/346420826

[4] Rinsey Antony, “Eco friendly Textiles,” https://www.researchgate.net/publication/327498497

[5] Md. Touhidul Islam, “Sustainable TextileIndustry: An overview”, https://www.researchgate.net/publication/361851233

[6] Sarif Patwary,“Clothing and Textile Sustainability: CurrentstateofEnvironmentalChallengesandtheWays Forward”,https://doi.org/10.31881/TLR.2020.16

[7] Sohel Rana, Shabaridharan Moorthy, Subramani Pichandi,AmitavaBhattacharyya,“CarbonFootprintof Textile and Clothing Products”, https://www.researchgate.net/publication/276193965

[8] Walter Leal Filho, Maria Alzira Pimenta Dinis, Hilde Heim, Haruna Musa Moda,“An overview of the contribution of the textiles sector to climate change”, https://www.researchgate.net/publication/363270376

[9] AbuShaid,Md.ShowkatOsman,Md.AbdulHannan,M. A. Rahman Bhuiyan,“Direct Reusing of Textile Watsewater in Scouring-Bleaching of Cotton Goods Devoid of Any Treatment”, International Journal of

EngineeringResearchandDevelopment,e-ISSN:2278067X,p-ISSN:2278-800X,www.ijred.com,Volume5, Issue8(January2013),PP.45-54

[10] ToralShindhal,ParitaRakholiya,SunitaVarjani,Ashok Pnadey, Huu Hao Ngo, Wenshan Guo, How Yong Ng, MohammadJ.Taherzadeh,“Acriticalreviewonadvances in the practices and perspectives for the treatment of dyeindustrywastewater”,BIOENGINEERED2020,VOL. 12, NO. 1, 70-87, https://doi.org/10.1080/21655979.2020.1863034

[11] RachanaS.Harane,RavindraV.Adivarekar,“Sustainable processes for pre-treatment of cotton fabric”, Harane and Adivarekar Textiles and Clothing, Sustainability (2016)2:2,DOI10.1186/s40689-016-0012-7

[12] F. Orts, A.I. del Rio, J. Bonastre, F. Cases,“Study of the reuse of Industrial Wastewater After Electrochemical TreatmentofTextileEffluentswithoutExternalAddition ofChloride”,www.electrochemsci.org