Checking the activities and Performance Management in the Automotive Industry

Shubham

Kadam1 ***Abstract - The subsequent paper details the preliminary findings of a case study being undertaken in the auto industry. Through more effective production sequence planning and its control, the project aims to improve operations management. The report analyses the problems with production plan execution monitoring. The theoretical underpinnings of the study and examine the key issues raised by performance analyses of manufacturing systems.

Key Words: production planning, production control, MPS, performance measures, production sequence

1.INTRODUCTION

Themanufacturingsystemisviewedasa complexsystem made up of several economic, social, and technological subsystems that are influenced by the external business environment.Productionplanningmustbeabletodealwith uncertainty and support the capacity to meet customer expectationsforquickerdeliverytimes,higherquality,and cost effectiveness in a dynamic, ever-changing business environment. The proper procedures for process flow monitoringandnormalisationincaseoffluctuations,whose scopeisgreaterthanthemanufacturingsystem'sbuffering capabilities, are necessary for the effective control of productionprocesses.Theusualapproachestoproduction planning and control are sometimes insufficient in unexpectedsituations.Acrisisthatresultsfrominsufficient planning and control of the manufacturing process could adversely endanger the ongoing operations of the production system. The car manufacturer in the scenario that served as the inspiration for the project has trouble completing the due-to-order deliveries of the completed productwithinthetimeframedemandedbytheclients.The goalofthestudywastoenhanceproductionplanningand controlproceduresinordertoboosttheplannedproduction sequence'sreliability.Thepreliminaryanalysisrevealed a researchgapregardingthemethodsforassessingoperations managementperformanceinuncertaincircumstances.The authorsofthestudythatfollowsclaimthattheeffectiveness of operations management is measured in relation to the final goods that are produced within a certain production cycle.Thepresentationofseveraluniquemetricsthatmight beusedtotrackmanufacturingsystemsintheautomotive industry is the paper's main contribution. The study is structured as follows: in Section 2, where the topic of productionplanningandcontrolunderuncertainconditions iscovered,thetheoretical underpinningoftheresearch is offered. The case study description and the authors'

suggestedremediesareincludedinSection3.InSection4, final conclusions are presented as well as the steps for furtherresearch.Themainshiftsinindustrialstrategiescan beattributedtothedevelopmentofthemarketandvehicle usageconditionsontheonehand,andtotheavailabilityof new technology as well as safety and environmental regulationsontheother.Competitionamongrivalscauses differingratesofdevelopmentatvariousepochs.Duetopreexisting industrial systems and labour agreements, productionsystemsadvancegradually;however,business strategiesmustcontinuallybecentredonproduct/market aims,withregularevaluationsofone'sclosestrivals.

2. Industry Operations Management System

Inordertocreateanalluringproductmixforassemblyplant balancing, the European automotive industry forecasts consumerdemandforvolumeanditemspecificationsmany months in advance. Actual client orders are either accommodatedintotheproductionschedulethathasbeen programmed months in advance or, to the extent that production flexibility permits, the forecasted orders in the systemaremodifiedtomeettheneedsofthecustomer.When real production sequence is disrupted and deviates from imaginedplans,thelinebalancingstrategycreatesaneedfor accuratesequencingmanagementandpromptresponse The managementofbusinessprocedurestoachievethebestlevel ofproductivitywithinanorganizationisknownasoperations management (OM). In order to increase an organization's profit,itisconcernedwithtransformingresourceslikelabor and materials into products and services as effectively as feasible.Operationsmanagementsolutionsaredesignedto enhanceteamperformanceandmotivatethemtoconcentrate on tasks that are essential to the expansion of their organization.Anorganizationhasvariousdepartments,and eachofthemisresponsibleforachievingitsownobjectives. Typically, an OMS acts as a guide to make sure that these diverse departments collaborate to meet shared business objectives.

2.1 Sequencing in Automotive Industry

Themanufacturingmethodunderconsiderationistypicalof the modern European automobile industry and combines classicmassproductionelementsinthedepartmentincharge ofpre-treatmentwiththeleanproductionideaintheareaof finalassembly[1].

Highstabilitycharacterizestheindustrialsystem.

stableproductionstrategies

Many weeks in advance, the Master Production Schedule(MPS)iscreated.

extremelysimilarproductionprocesses

Despite having a very similar product structure (BOM), they may differ in a few small details like color.

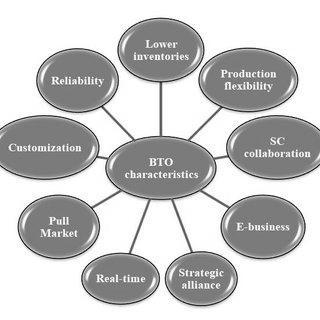

Thefollowingtwoproductionplanningpoliciesarecombined bymanufacturerstosafeguardtheintegrityoftheproduction systemandrealizescale-basedcostsavings:

build-to-order

build-to-forecast

Figure 1: Buildtoorderrequirementmodel

Theabilitytopredictthefutureisaproblemthatispresent in many disciplines, from engineering to physics and economics.Thegreyforecastingmodelhasbecomepopular inmanydifferentstudydomainsinrecentyearsduetoits abilitytoprovideaccuratepredictionswithlittledata.

The car sector is typical for the production sequencing procedure[2]:

Order entry istheprocessofdeterminingwhether anordercanbebuiltand,ifitcan,transferringitinto theorderbank.

Allunsoldordersarekeptinthe order bank until theproductionscheduleisset.

Order scheduling istheprocessofselectingorders from the order bank and allocating them to build intervals (often weeks) at various factories. Daily, biweekly, or weekly delivery are frequent requirements for automakers' stamping vendors. Stampingfactoriescansignificantlylowerschedule variances when they run production on a weekly timetabletosatisfythisdemandpattern.Thelevels of incoming raw materials can be evened out by stampers,encouragingmoredependable,repeatable performance from their own material suppliers. Sequence scheduling becomes useful in this situation. The sequence scheduling approach is helpfulforbalancingproductionwithalittlefinished goods buffer to account for variations in demand, notablyincreases.Thestampercanselectbetween two corrective actions if inventory monitoring revealsanincreaseinfinishedgoods:eitherskipping a week of production of a part when the buffer reaches the level needed to meet the next weekly demand,orreducingtheweeklyproductionamount untilthebufferisdepleted.

Order sequencing istheprocessofrearrangingthe planned orders for a construction week into a sequenceofbuildordersfortheassemblyfacilities. Buildlimitsmustbetakenintoconsiderationbythe sequencing tool. In any event, suppliers do not actually receive their final call-off of what is necessary until after the orders are sequenced becauseonlythenisitdeterminedwhichitemswill berequired.

Manufacturing, the orders are forwarded to the bodyshopafterbeingsequenced,wheretheorderis often identified with the actual floorpan, which is subsequently transformed into a complete body. After the body shop, bodies are gathered to be painted the same colour in order to maximise efficiency in the paint shop. The disadvantage of batching is that it distorts the initial production sequence, making it unpredictable for all future operations to know what automobiles are progressing through the process. Before being placed on the assembly line, the cars are typically rearrangedoncemoreafterpaintingtomakesure themixofcarsadherestotherestrictionsimposed bythelinebalanceoperations.

Anychangesinordersequenceresultinissueswithon-time component deliveries because all raw material and component deliveries are just-in-time deliveries, which substantially impairs the performance of operations managementasawhole.

2.2 Literature review on production planning and management

Theanalysisoftheliteraturerevealedthatnumerousstudies havelookedintovariousbufferingordampeningapproaches toreducetheimpactofuncertaintyinproductionplanning and control. The majority of them take into account production systems where planning is based on the MRP concept and Planned Order Release schedule. Guide and Shiverasta[3]provideathoroughoverviewoftheliterature. KohandSaad[4,5]examinedamodelforthediagnosticof manufacturingplanningactivitiesinordertodeterminethe rootcausesofproblemswithlatedeliveriesoffinishedgoods and documented the effects uncertainty has on the manufacturing planning system using MRP. When a new production system has been introduced, schedule. The anxiousness in the system is brought on by the high replanningfrequencyusedtoovercomeuncertainty.Changes inMPShaveanimpactontheamount,timing,andduedate foropenordersaswellasplannedordersoffinishedgoods. The aforementionedadjustments are beingconverted into overall changes in component requirements and delivery schedules.Inaddition,theremaybedifferencesbetweenthe plannedandactualreleaseschedules.Unexpectedchangesin MPScanresultinasituationwherethematerialsrequiredfor a certain order may not be accessible, especially if the quantityorderedisincreasedandthedeliverydateispushed back. Changes in MPS that affect customer satisfaction on time in the automotive industry, where Just-in-Time deliveries are a typical business practice, are problematic. Numerous studies that have been done in the automotive industry to improve performance primarily focus on integratingplanningactivitiesandmanagingmaterial flow within the supply chain[6,7,8,9]. Customer projections, pertinentproductioncosts,andcostcharacteristicsrelatedto production planning are assessed in connection to one another.Byusingtheplanningtool,theproductionplanning processmightbeautomated,savingtimeforthescheduler.

There is a study gap in determining the impact that MPS executioninterruptionsmayhaveonoperationsmanagement performance.

2.3 Performance Measures

Theperformanceindicatorsusedintheautomobilesectorfall intotwocategories:

Financial

Non-Financial

Financialmetricsincludingmarketshare,salesvolume,and sales likelihood primarily reflect sales performance. Most non-financialindicatorsemployedbyautomakersfocuson logistical performance, such as lead time, fill rate, on-time performance, damage, or response,and primarilyimprove thecapacityofFirsttiersupplierstomeetOEMneeds.Since therearemanynon-financialmeasuresthatareworrisomely ambiguous and therefore easier to manipulate than financials, it is difficult to demonstrate benefits from measuringnon-financialperformance.Thisisbecauselinks betweennon-financialmeasuresandtheanticipatedresults arenotself-evidentandrequirecarefulverification.Inorder to prevent missing anything crucial, businesses frequently overburdenthemselveswithanincreasingnumberofsigns. Theresearchprojectthatfollowshasshownthatinorderto quickly assess the success of sequencing activities in the automobile industry,a set of clearly defined indicators for operations management performance measurement is required. The indicators should demonstrate the effectivenessoftheoverallplanninginitiativesandpointout areas with potential for rising competitiveness. The assumptions behind the methodology guidelines for indicatorsdefinition(discussedinsection3)arethatthebest measurements,fromamanagerialperspective,achievethe followingfourgoals:

Validity

Usefulness

Robustness

Integration

The ability of an indicator to characterize performance in threedimensions what,where,andhow canbethoughtof astheindicator'svalidity.Thesimplicityofthedefinitionand calculation method, as well as the lack of additional operationalexpense,havebeenusedtodefinetheusefulness oftheindicators.Inthesubsequentresearch,robustnessis definedasthemetrics'applicationtovariousmanufacturing systemcomponents(nodesandlinks).Unfortunately,these requirementscannotbemetatthesametime.Integrationof measures is understood as the capacity to improve performanceattheentiremanufacturingsystemandpermit conductingextensivefieldresearchforprimary.Validityand usefulnessareparticularlyapplicableattheoperationallevel, wheremeasurementsmaybothcapturecharacteristicsofthe activityandofferpracticalassistance.Measureslosevalueas they are incorporated into higher, more strategic levels of reporting. The robustness and integration criteria, whose value is highest at the consolidated or strategic level and lowestattheoperationallevel,operateintheoppositeway [11]. Manufacturers who are able to control availability in this way are able to give customers a larger selection of products while still maintaining the highest standards for quality. Manufacturers can enhance the efficiency of their assemblylinesandsatisfydemandbyflexibleandeffective partsequencing.Manufacturersshouldbecognizantoffresh approaches to satisfy demanding consumer demands as productivityrises.

3. Monitoring and improvement for the operations management

3.1 Problem domain

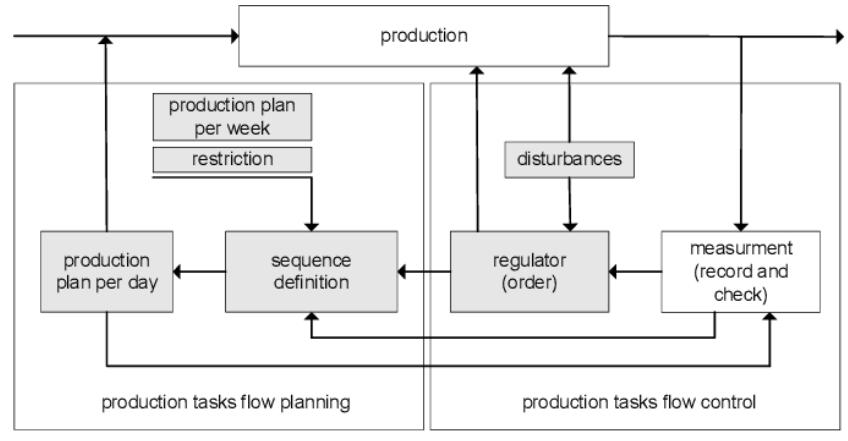

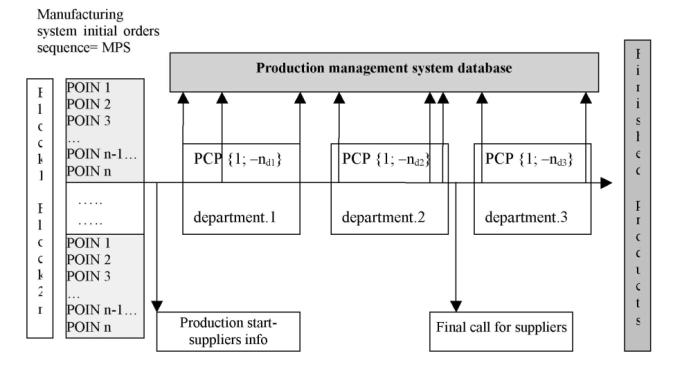

Severaldifferencesareseenintheanalysedmanufacturing system when the complex Master Production Schedule is implemented,bothintermsoftheorderinwhichtheorders arecompletedandtheircompletiontimes.Onthebasisof predetermined criteria that are well-known, the MPS is developed.Theassemblyplant'svariousProductionControl Points (PCP) are where the monitoring system for operations management now records the production sequence(fig.ThemanufacturingsequencebetweenthePCP cannotbemaintainedduetosystemcomplexity.

4: Monitoringofoperationmanagementin manufacturingsystem

Duetoa numberofunsettlingoccurrences thathappened between the time the observation was made and the MPS was prepared, issues with the production system surface. EventsthatoccurredbetweenthedevelopmentofMPSand itsexecutionhavehistoriesthatareknown.Allrawmaterial andcomponentdeliveriesfollowthejust-in-timeprinciple. Suppliers are given prior notice of production schedules (productionplans)byafewdays.Threetimepointsareused totellfirst-tiersuppliersabouttherequirementsforboththe qualitative and quantitative orders. When the Master Production Schedule is established a few weeks before productionbegins,suppliersreceivetheinitialpreliminary informationonthecomponentsandmaterialsneeded.When theproductionorderssequenceisplannedandthefirstPCP order point (a few days prior to production starts) is reached, the more specific orders are defined. When pretreated goods depart Department 2, the final call for component supplies is made. Final assembly is the phase thatgenerates the most value(Dep. 3). Since there are no buffers,allsuppliesofcomponentsshouldarriveatthefinal assembly department in the proper order. Any major deviationsfromtheanticipatedorderofeventsduringthe production process are caused by issues with timely component suppliers during final assembly. The proper sequencingofmanufacturingordersisessentialforbusiness performancebecauseofthelogicoftheproductionprocess (Fig.2).

3.2 Problem Solution

The production order sequence at the beginning of the manufacturingsystemshouldmatchtheoneshownatthe controlpointattheendofproductioninanidealsystem.The changesintheactualmanufacturingsystemaresubstantial. Theorderofthedefinedblockofordersattheconclusionof the production system is inconsistent and jumbled when compared to the entry in the manufacturing system. The perceptionoftheinconsistencyisthattheoriginalblockof objectswasbrokenupintosmallerblocksandmixedwith additionalblocks.Asaresult,itisimpossibletopredictwith accuracy either the moment at which a defined block of orderswillbeproducedorthemomentatwhichtheorder

followingaPOINinsidethatblockwillappear.Thecapacity to deliver clients' requested goods on time is severely impactedbythiscircumstance,whichalsoaffectsthetimely supplyofcomponentsforfinalassembly.Thefollowingtwo indicatorshavebeensuggestedforgaugingthediscrepancy betweentheidealandactualsystemstates:

AblockofPOIN'ssequencedispersionrange(SDR) iscalculatedasthedifferencebetweentheblock's maximum and minimum order identification numbers as detected at a selected production controlpoint.

The number of pairs of order identification numbersthatoccurattheendproductioncontrol point in the same order as they did at the initial productioncontrolpointisknownasthesequence order displacement (SOD) for a block of POIN. However,isitalsopossibletomeasurethepartial SODwithinthemanufacturingsystem'sdefinedPCP scope, for instance at the entry and exit of the productiondepartment1

3. CONCLUSIONS

Thereportdescribestheinitialfindingsofacasestudydone intheautoindustry.Throughtheoptimizationofproduction planningandcontrolactivities,thestudiesseektoenhance operationsmanagementperformance.

REFERENCES

[1] WomackJ.P,JonesD.T.,RoosD.,1991.Themachinethat changetheworld,thestory

[2] HolwegM.,JonesD.T,Thechallengeofbuildingcarsto order,cancurrentautomotivesupplychainscope?,from: www.3dayscar.com

[3] GuideV.D.R.,ShiverastaR.,2000,Areviewoftechniques forbufferingagainst

[4] Koh L.S.C., Saad S.M., 2003, How Uncertainty Disturbs SMEManufacturers,

[5] KohL.SC.,SaadS.MandJones,2002,Uncertaintyunder MRP-planned manufacture:review and categorisation, JournalofProductionResearchvol.31,pp.2399-2421.

[6] Childerhouse, P. and Towill, D.R. 2001. Simplified MaterialFlowHoldstheKeytoSupplyChainIntegration". OMEGA, The International Journal of Management Science,no.31,pp.17-27.

[7] Mason-Jones,R.andTowill,D.R.1998.Shrinkingthe Supply Chain Uncertainty Circle, 'Control', the Journal oftheInstituteofOperationsManagement,vol.24no.7,pp. 17-22.

[8] Towill, D.R., Childerhouse P. and Disney, S.M. 2002. Integrating the Automotive Supply Chain: Where are weNow?"InternationalJournalofPhysicalDistributionand LogisticsManagement,vol.32,no.2,pp.79-95.

[9] Towill, D.R. Simplicity 1999. Wins: twelve rules for designingeffectivesupplychains.Control,theJournalof theInstituteofOperationsManagement,vol.25,no.2,pp. 9-13.

[10] Towill,D.R."TheSeamlessSupplyChain",International JournalofTechnologyManagement,vol.13,no.1,1997b, pp.37-56.

[11] Islei G., Cuthbertson R., Measuring performance in SupplyChains,ProceedingsofLSCM2006,HongKong,57.01.2006.