Experimental Study on Pavement Stabilization Using Geosynthetic Solution

Er. Lokesh Kumar Soni M. Tech. Student, Department of Civil Engineering, School of Engineering and Technology, University of Technology, Jaipur

***

Abstract - Major investments are required to build a road. Accurate technical designcan save significant investmentand deliver dependable performance.

Today reinforced road structures, with the suitable stiffness, have been introduced to improve and optimize the performance of traditional road building materials. The performance of reinforcedroadstructuresreliesheavilyonthe condition of surrounding materials and on the traffic loads and therefore each design requires specific analysis and calculations.

To achieve the economy along with long lasting performance of pavement. This demands the adoption of innovative technologies with less carbon footprint. Oneofsuchrevolution is Geosynthetic. The extruded biaxial polypropylene geogridis proposed for stabilizing the pavement. The inclusion of extrudedbiaxial polypropylene geogridingranularlayershall support for increasing the modulus of granular layer and thereby reduces the thickness of bituminous and granular layer. Inthe similar way, thickness reductionisalsopossiblein the case of service road. This is widely used for reducing the layer thickness and for strengthening the pavement. In the IRC: SP 59-2019, extruded biaxial polypropylene geogrid is mentioned for reducing the thickness and reinforcement of pavement.

The reinforced sections can be designed by introducing the geogrid at granular layer. The reinforced pavement, which is composition of bituminous course, granular base, and granular sub-base. Thickness is worked out based on IRC:592019 Guideline andinput received. Biaxialgeogridisproposed at granular base layer and Sub-base layer of Pavement Section.

Key Words: Geogrid, Geosynthetic Stabilization, Pavement Design, Calculate LCR & MIF Values, FWD Test, and PLT Test.

1. INTRODUCTION

This report contains the detailed description of the work done during the final year project namely “Project Detail: Development and Maintenance of Dantiwara-Pipar-Merta City Section of SH-21 in the State of Rajasthan on Engineering, Procurement & Construction (EPC) Mode”. Procedures are given for the characterization of the

pavementmaterialsbothbylaboratory/fieldtestingandby typicalvaluesand/orcorrelationstudies.Thepurposeofthe laboratory testing program is to classify the properties of sub-grade,GSB,WMM,DBMandBCmaterialandevaluate supportpropertiesandmoisturesensitivitythatcanaffect long-termpavementperformance.Testingprogramsconsist ofclassificationtesting(i.e.,gradationanalysis&Atterberg’s Limits)andengineeringpropertiestesting(i.e.,Proctortest, CaliforniaBearingRatioTest&MarshallMixDesigntest).

Flexiblepavementsfailduetorapidvehicletrafficgrowth. There are many ways for a system to fail, but rutting and fatigue are among the most important. We are decided to developnewconstructionmaterialstosolvetheseproblems. In this flexible pavement failure, we decided to use Geosynthetic materials. Most Geosynthetic are made from polypropylene, polyester, or synthetic polymers of polyethylene,PVC,naturalfibers.Thewordisderivedfrom: Geo=earthorsoil+Synthetics=man-made.

TheBenefitof reinforcementinpavementin quantified in terms of the Layer Coefficient Ratio (LCR). LCR of the unreinforcedandreinforcedpavementinquantifiedusinga dynamicloadingtestapparatusthatcloselyrepresentsthe fieldcondition.

1.1 Problem Statement

India's road construction usually faces many problems thatcausetheroadtofail,suchasrutting,fatigueontheroad, andotherproblemsthatresultinroadfailures.

Generally speaking, a rut is defined as a vertical depressioninthevehiclewheeltracksthatoccursasaresult of traffic loading. Itisa typeof surfacedefectthat is more evident in the outer wheel track of the vehicle. Rutting is causedbythepermanentdeformationinanyofapavement's layers or sub grade usually caused by consolidation or displacement of the pavement edge due to traffic loading. Permanentdeformationofpavementmayoccurthatifthe pavementbindersdonothavesufficientelasticity.Becausea poor elastic binder does not return to its original position afterremovingwheelloading.

The process of stabilizing soil with lime and cement is verycostlyandaverylengthyonethatrequiresmanystages. Our goal is to reduce the cost of stabilizing soil by using

GeosyntheticBiaxialGeogridasareinforcedmaterialoverthe GranularSub-baseLayertoreducethecostofstabilization.

1.2 Highway Material

Subgrade Soil (Borrow Soil): -

Poorly graded sand, commonly available in the state of Rajasthan,India,wasusedfortheconstructionof500mmof compacted subgrade. The soil was non-plastic with an average liquid limit of 21.6%. The maximum dry density, optimummoisturecontent,andtheCaliforniabearingratio (CBR)wasfoundtobe1.960gm/cm3,9.13%,and17.15%, respectively.

Granular Sub-Base (GSB): -

200mmofgranularsub-base(GSB),gradingV,asperthe specificationof MoRTH (MoRTH2013) wasusedover the subgrade. The gradation of the GSB material is shown in figure2.Thephysicalpropertiesoftheaggregates,asperthe requirementsofMoRTH

Granular Base (WMM): -

Table -1: PhysicalPropertiesofAggregatesusedinWMM

Geogrid: -

A bi-axial UV stabilized polypropylene geogrid (by Maccaferri),havinganultimatetensilestrengthof30x30 KN/m,wasusedforthisstudy.Fig.1showsrepresentative pictures of the geogrid placed at the interface of granular sub-baseandbaselayer.

Bituminous Layer: -

Densebituminousmacadam(DBM),gradingII,asperthe standardsofMoRTH,wasusedonthetopofWMM.Thesieve sizedistributionoftheaggregatesusedfortheconstruction of DBM is shown in Figure 2. The mix design of DBM was doneasperthestandardMarshallMethod(AsphaltInstitute 2014) with a viscosity grade (VG) binder, VG 40. The optimumbindercontent(OBC)ofthemixwasfoundtobe 4.68%. Crushed angular aggregates were used for the productionofbituminousmixture,anditwasensuredthat the aggregate and bitumen properties satisfy the requirementsofMoRTH.

2. Review of Literature

Murad Abu-Farsakh, et.al (2012) Intheirresearchpaper, theyconductedatestexperimentalinthat,thestudycarries outbyrepeatedloadtriaxial(RLT)testevaluatedtheflexible and permanent deformation of Geogrid with the granular base specimens. In that the fivegeogrids specimens were usedsuchasthreerectangleorbiaxialandtwotrianglesor triaxialindifferenttensilemodulusandaperturegeometry. Afterthetestresultfoundthegeogridarrangement/location onthespecimenithadlargestimprovement,andalsointhe effectofmoisturecontentwasalsohigherimprovement,but in the resilient deformation/ resilient modulus had not appreciableimprovementofthespecimens.

Jie Han, et.al. (2014)In their paper, the Geosynthetic material used of recycled aggregate for improve the mechanicalpropertiesandlong-termdurability.Also,they found Permanente formation, creep deformation, degradation,stressdistribution,andcrackpropagation.In that reviews there search work is done on the use of Geosynthetic to stabilize Recycled Aggregate including Recycled Asphalt Pavement (RAP), Recycled Concrete Aggregate(RCA),andRecycledBallast(RB).TheseRAP,RCA, and RB is used for base course materials for sustainable roadwayconstructionandalsousedfortheconstructionof theload-bearinglayerintherailwaytrack.

Satish Pandey, et.al (2015) Intheirresearchpaper,they discussedtheuseofGeosyntheticmaterialslikegeogridand geotextile for the bituminous pavement and for road infrastructure.InthistheGeosyntheticmaterialwasusedin subgradeforseparationandstabilization,inconcludedthat thegeogridreinforcementinthepavementwasplacedina base course and subgrade layer it decreases the vertical strainandinthebottomofthereinforcementitreducesthe horizontaltensilestraininthebituminouspavementsurface. This paper shows that Geosynthetic material improved

servicelife,reducethethicknessofthepavement,andeasy tobuildit.

3. Design Impletion

Proposed Solution Mechanism

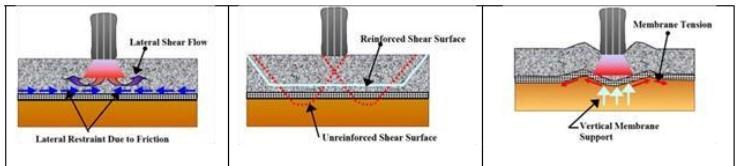

Mac-Grid EG (Extruded biaxial PP geogrid) shall reinforce thegranularlayerandbasicmechanismofreinforcingcanbe identified as (a) lateral restraint, (b) improved bearing capacity,and(c)tensionedmembraneeffect.

Lateralrestraintreferstotheconfinementoftheaggregate materialduringloading,whichrestrictslateralflowofthe materialfrombeneaththeload.Sincemostaggregatesused in pavement systems are stress-dependent materials, improvedlateralconfinementresultsinanincrease inthe modulusofthebasecoursematerial.

Theeffectofincreasingthemodulusofthebasecourseisan improvedverticalstressdistributionappliedtothesubgrade andacorrespondingreductionintheverticalstrainonthe topofthesubgrade.Fig.2(a)illustratesthelateralrestraint reinforcement mechanism. The second mechanism, improvedbearingcapacity,isachievedbyshiftingthefailure envelopeofthepavementsystemfromtherelativelyweak subgradetotherelativelystrongbasecoursematerial.

Fig.2(b)showstheimprovedbearingcapacityconcept.The third fundamental reinforcement mechanism has been termed the “tensioned membrane effect.” The tensioned membraneeffectisbasedupontheconceptofanimproved verticalstressdistributionresultingfromtensilestressina deformed membrane. Fig.2 (c) illustrates the tensioned membraneeffect.

Allsoils,whethercohesiveorgranular,havepoorresistance to tensile stresses, making them prone to movement and potential failures. Mac-Grid EG has high junction strength hence it distributes applied loads over a greater area to reduceverticalpressureonthesubgrade.

Thisreinforcesandstabilizesthebasecoursematerialsand reducesthethicknessofthelayerrequired.Geogridshallbe resistanttoinstallationdamage,longtermdegradationand chemicalsfoundinmostsoilenvironments.Thehightensile strengthandjunctionefficiencyofbiaxialgeogridsconfines and restrains aggregate from lateral movement, ensuring proper distribution of imposed stresses and ultimately extendingtheservicelife.Extrudedgeogridsexhibitbetter interlocking properties, junction stiffness and very high moduluswhichmeansthiswillpickupthestressesquickly withlittleornomovementintheoverlyingbasematerials comparedtoothergeogrids.

Fig -2:(a)LateralRestraint(b)ImprovedBearingCapacity

(c)TensionedMemberEffect

Solution Component (Extruded Biaxial Polypropylene Geogrid)

Extruded biaxial geogrids are polypropylene geogrids producedbyanextrusionprocesscharacterizedbyatensile resistancebothinthelongitudinalandcrossdirectionthat exhibitshighmodulusandhighstrengthatlowelongations providing tensile reinforcement to soil and aggregate structures.

4. Pavement Design General

New pavements have been designed for the Flexible pavementonexistingalignment,Reconstructionstretches, Realignmentsections&Bypasssectionwithrespecttotraffic andCBRofavailableborrowsoilandROWareasoil.

Factors Affecting Pavement Design

The principal factors that will govern the design of new pavementsare:

StrengthcharacteristicsoftheROWandborrowareasoil.

Traffic loading that the pavement has to withstand duringitsdesignlife.

Availabilityofmaterialsforpavementlayers.

Material Investigation

The objective of surveying the project corridor for constructionmaterials–soil&aggregate,andinvestigating theirpropertiesisto:

The objective of surveying the project corridor for construction materials – soil & aggregate, and investigatingtheirpropertiesisto:

Thepotentialborrowpitlocationswereidentifiedalong the project corridor for embankment and Subgrade material. Their quantity and suitability for use were determined.

Theoriginalgroundsoilalongtheprojectcorridorwas collected and their suitability as foundation for the embankment/Subgradeconstructionwasdetermined.

TheSandQuarriesintheprojectlocationwereidentified and their suitability for use in pavement layers was determined.

TheAggregateQuarriesinthevicinityofprojectlocation were located and their suitability for use in concrete, non-bituminousandbituminouspavementlayerswere determined

The sources for Granular Sub base layer (GSB) were identifiedandtheirsuitabilityforusewasascertained.

Crust Composition of Existing Pavement

8borrowarealocationshavingCBRbetweenmorethan12% wereidentified.TestresultsfortheBorrow/ROWareasoil aregiveninTable27and28.Alllocationsarenotplasticsoil, havingCBRover15%at97%MDD.

Properties of Existing Soil

Test results of existing Subgrade soil are summarized in Table 29 and 30. Pavement subgrade at majority of the locationsiscomposedofSandyLoamwithHardGraveland CBRover12%alongtheprojectalignment.

Table

Design CBR

EffectiveCBRofthesubgradehastobederivedbasedonthe investigationofBarrowAreasamplesandembankmentsoils (OGLsoil),thedesignshouldbebasedoneffectiveCBR. As per IRC: 37 - 2018, pavement design is based on the Effective CBR of the subgrade. Where there is significant difference between the CBRs of the select subgrade and Embankmentsoils,thedesignshouldbebasedonEffective CBR.

TheeffectiveCBRofthesubgradeisdeterminedasperthe proceduregiveninclause6.4.1ofIRC:37-2018.

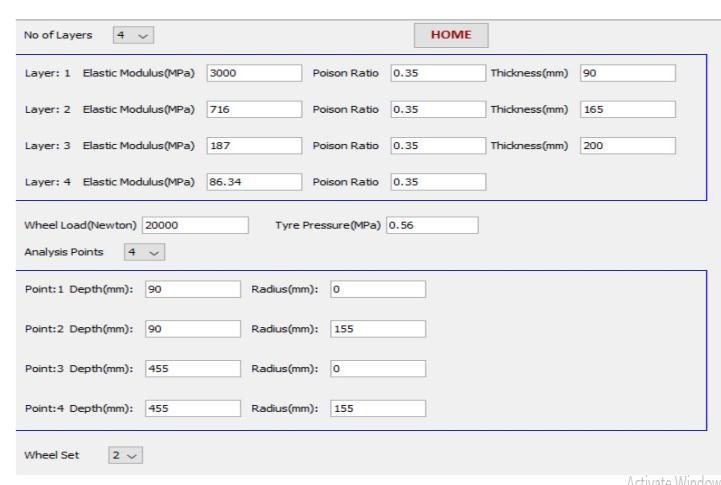

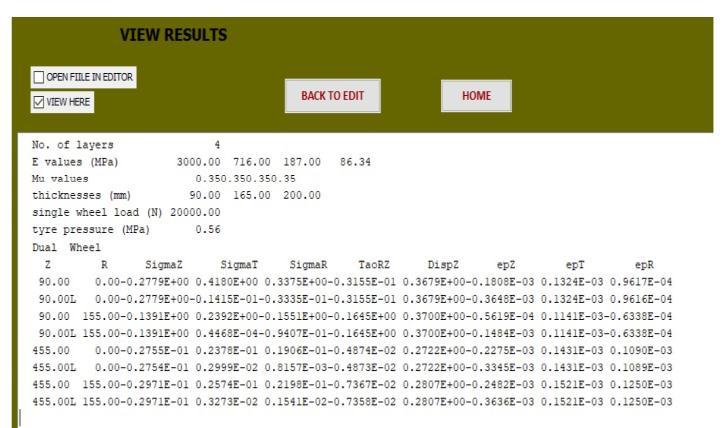

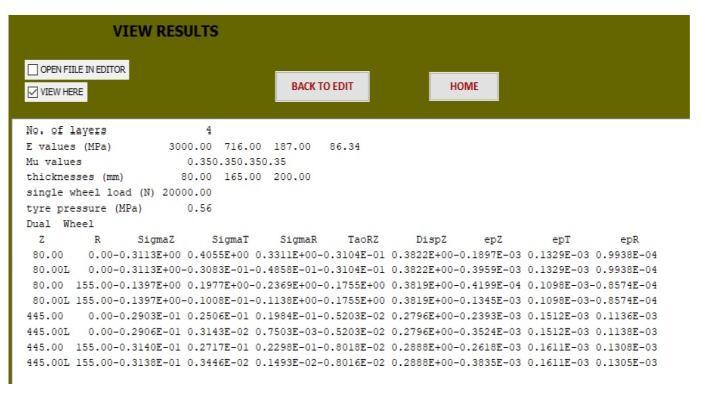

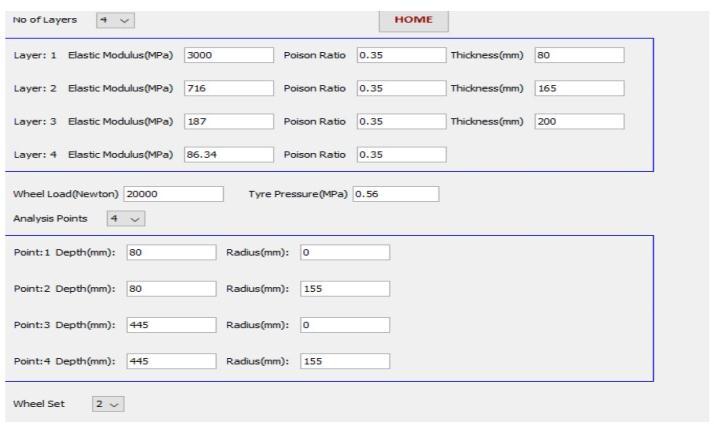

������ =2(1 − µ2)pa/ δ

MRS=ResilientModulusofEquivalentsinglelayer,

P=contactpressure=0.56MPa

a = radius of circular contact area, which can be calculated using the load applied (40,000 N) and the contactpressure‘p’(0.56MPa)=150.8mm

µ=Poisson’sratio

δ = maximum surface deflection computed using the IITPAVEforatwo-layersystemof500mmthicksubgrade layer over the semi-infinite embankment layer by applyinga singlewheel loadof40,000N andacontact pressure of 0.56 MPa. The Subgrade and Embankment Modulusvalueshavebeenestimatedusingtheequation 6.1 and 6.2 of IRC:37-2018 using their laboratory CBR values. As the project alignment has ROW soil and Borrow area soil CBR More than 12%, so Design is carried out with 12% CBR.

Design Methodology

FlexiblepavementdesignasperIRC:SP59-2019(ClauseNo. 3.1.2)

Geogrid reinforced flexible pavement section is designed based on LCR design approaches. This design approach is describedintheIRCSP:59-2019.Theapproachtoflexible pavementdesignaccordingtomodifiedAASHTOmethodis similarforreinforcedandunreinforcedpavementsandcan bedividedintotwosteps:

Determination of structural number for a given traffic load,projectconditionsandarrivingunreinforcedsection thicknessforindividualpavementlayers.

Determinationofreducedthicknessbyincorporatingthe effectofGeosyntheticintheformofimprovementfactor intheobtainedSN.

Design Considerations & Proposed Solution Analysis

Details

Table -5: DesignConsiderationforAnalysis

Effective

Fig

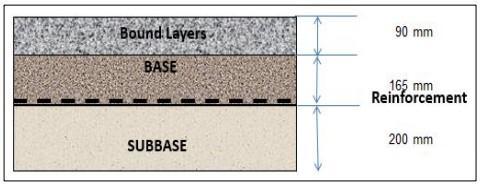

Compositionfor50MSAand12%CBR

Table -6: DesignReportfor50MSA,12%CBR

1. Input

a. DesignTraffic(Dt) 50MSA

b. SubgradeCBR 12%

c. TypepfBitumento beused(VG) VG40(AsperCl.9ofIRC37-2018)

d. Temperatureof Pavement(T) 35DegreeCelsius

2. ResilientModulus (MR) 17.6xCBR^(0.64)(AsperCl.6.3IRC 37-2018)

a. ResilientModulus ofSubgradeSoil 86.34Mpa

b. ResilientModulus ofBituminous Layer

3000Mpa(AsperTable9.2ofIRC 37–2018)

(MR_Bitumen)

3. FatigueModel(As perCl.3.6.2IRC37 –2018)

Reliability

Percentage(%) 90%

ByMarshall Method(Nf)

Where:-

C=10^M

M=4.84x ((Vbe/va+Vbe)0.69)

Va=Percentage Volumeofairvoids inmixusedinthe bottombituminous layer=3.5

Vbe=Percentage Volumeofeffective bitumeninmix usedinthebottom bituminouslayer= 11.5

M=0.371

C=2.3500

4. RuttingModel(As perCl.3.6.1ofIRC 37-2018)

0.5161x10^(-4)xCx (1/Et)^(3.89)x (1/MR_Bituminous)^(0.854)

Et=1.78E-04(byCalculation)

Reliability

Percentage(%) 90%

ByMarshall method(Nr)

1.41x10^(-8)x(1/Ev)^4.5337

Ev=3.72E-04(ByCalculation)

PoisonRatio(Mu) 0.35(AsperCl.7.3.1ofIRC372012)

WheelLoad(W) 20000N(AsperIRC3(Halfof6 TonneAxleLoad))

TyrePressure

0.56Mpa(AsperCl.13partviiof IRC37-2012

0.171X(LN(MR))-1.784(Asper AASTHO1993)

a1=0.436(MR_Bitumenconverted fromMPAtoPSI)

Coefficient forbaseLayer(a2) 0.249x(LOG10(MR_Base))-0.977

a2=0.202(MR_Baseconverted fromMpatoPSI)

x(LOG10(MR_Subbase))-

a3=0.168(MR_Subbaseconverted fromMpatoPSI)

11.

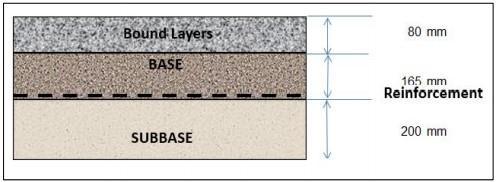

Fig -7:PavementCompositionfor40MSAand12%CBR

Table -7: DesignReportfor40MSA,12%CBR

1. Input

a. DesignTraffic(Dt) 40MSA

b. SubgradeCBR 12%

c. TypepfBitumentobe used(VG) VG40(AsperCl.9ofIRC372018)

d. Temperatureof Pavement(T) 35DegreeCelsius

2. ResilientModulus (MR) 17.6xCBR^(0.64)(AsperCl. 6.3IRC37-2018)

a. ResilientModulusof SubgradeSoil 86.34Mpa

b. ResilientModulusof BituminousLayer (MR_Bitumen)

3. FatigueModel(Asper Cl.3.6.2IRC37–2018)

3000Mpa(AsperTable9.2of IRC37–2018)

ReliabilityPercentage (%) 90%

ByMarshallMethod (Nf)

Where:-

C=10^M

M=4.84x ((Vbe/va+Vbe)-0.69)

Va=Percentage

Volumeofairvoidsin

0.5161x10^(-4)xCx (1/Et)^(3.89)x (1/MR_Bituminous)^(0.854)

mixusedinthebottom bituminouslayer=3.5

Vbe=Percentage

Volumeofeffective bitumeninmixusedin thebottombituminous layer=11.5

M=0.371

C=2.3500

4. RuttingModel(Asper Cl.3.6.1ofIRC372018)

Et=1.89E-04(byCalculation)

ReliabilityPercentage (%) 90%

ByMarshallmethod (Nr) 1.41x10^(-8)x (1/Ev)^4.5337

Ev=3.90E-04(By Calculation)

PoisonRatio(Mu) 0.35(AsperCl.7.3.1ofIRC37 -2012)

WheelLoad(W) 20000N(AsperIRC3(Halfof 6TonneAxleLoad))

TyrePressure(Mpa) 0.56Mpa(AsperCl.13part viiofIRC37-2012

MaximumInduced Verticalstrain(Ev induced’)

a2=0.202(MR_Base convertedfromMpatoPSI)

x(LOG10

pave)

3.84E-04(FromIITpave)

Conclusion

Geogridreinforcementhasincreasesignificantlythebearing capacity of soils. However, allowable settlements, and not ultimate bearing capacity, generally dictate the design of spreadfoundationsoncohesionlesssoils.TheCBRofmarine clay increases by 50-100% when it is reinforced with a single layer of geo-grid. The amount of improvement of strengthdependsuponthetypeofsoilandpositionofgeogrid.

REFERENCES

[1] Krishnaswamy,N.R.andSudhakar,S.(2005).Analytical andexperimental Studies on geo-synthetic reinforced roadsubgrade.JournalofIndianRoadCongress,66(1), 151-200

[2] IRC:SP72(2007).Guidelinesforthedesignofflexible pavementforlowvolumeroads.Tavel,P.2007Modeling

andSimulationDesign.AKPetersLtd.R.Nicole,“Titleof paperwithonlyfirstwordcapitalized,”J.NameStand. Abbrev.,inpress.

[3] Subba Rao K.S (2000), Swell-shrink behavior of expensive soils, Geo-technical challenges. Indian GeotechnicalJournal,30,1-69

[4] IndianStandard:2720(Part16):1987,Methodsoftests for soil- part (16): Laboratory determination of Californiabearingratio

[5] Gosavi, M. Patil, K.A Mittal, S. Saran, S. (2004), Improvementofpropertiesofblackcottonsoilsub-grade throughsyntheticreinforcement.Journal,Institutionof Engineers(India),Volume84,pp.257-262.

[6] Chandra, S and Mehndiratta, H.C (2002), effect of shoulderonlifeof flexible pavement. HRB -67,Indian RoadCongress,NewDelhi,pp37-46.G.Eason,B.Noble, and I.N. Sneddon, “On certain integrals of LipschitzHankel type involving products of Bessel functions,” Phil.Trans.Roy.Soc.London,vol.A247,pp.529- 551, April1955.

BIOGRAPHIES

Er. Lokesh Kumar Soni Research of M. Tech, Department of Civil Engineering, University of Technology,Jaipur