Effect of Granite Powder and Polypropylene Fiber on Geotechnical Properties of Expansive Soil

Alshimaa Farghaly1, Prof. Mahmoud Abo Bakr Alsedik2 , Lect. Mustafa Fawzy3

Alshimaa Farghaly1, Prof. Mahmoud Abo Bakr Alsedik2 , Lect. Mustafa Fawzy3

1MSc student, Dept of Civil Engineering Al-Azhar University, Cairo, Egypt

2Professor, Dept of Civil Engineering, Al-Azhar University, Cairo, Egypt

3 lecturer, Dept of Civil Engineering, Al-Azhar University, Cairo, Egypt ***

Abstract - Expansive soil shows dual swell-shrink under changing water content which is not suitable for construction. This soil is found in several places in Egypt, so it must be treated. In this paper, it was studied one of the methods of treating expansive soil, which was using of polypropylene fiber and granite powder to stabilize the expansive soil. In the investigation, the soil was taken from the 5th Settlement in Cairo, Egypt, and mixed with percentages of granite powder (1.5%, 3%, 6%, 9%, 20%,30%, and 40% by weight of soil) and polypropylene fiber (0.25%, 0.5%, 0.75%, and 1% by weight of soil). Specific gravity, Atterberg’s limits, free swell, and compaction tests were applied to natural soil and soil treated with percentages of granite powder. Through tests, it was found that the optimum percentage of granite powder was 30%, so this proportion was mixed with percentages of polypropylene fiber. Then the direct shear and consolidation tests were conducted on these proportions. The direct shear samples were carried out immediately, with 14 and 28 days of curing. The results show the addition of 30% granite powder reduced the free swell index from 120% to 62%, reduced moisture content from 14.8% to 11.5%, increased maximum dry density from 17 KN/m3 to 19.3 KN/m3 , increased the cohesion from 0.46 Kg/cm2 to 0.72 Kg/cm2 and increased the angle of internal friction from 15.38° to 24.23°. These results also indicated that polypropylene fiber with granite powder did not have an effective effect on the expansive soil.

Key Words: Expansivesoil,Granitepowder,Polypropylene fiber,Cohesion&angleofinternalfriction.

1.INTRODUCTION

Expansive soils occur in climatic zones characterized by alternate wet and dry seasons. The expansive soils experience periodic swelling and shrinkage during the alternate wet and dry seasons. The montmorillonite clay mineral contributes mainly to this behavior. Such cyclic swell-shrinkmovementsofthegroundcauseconsiderable damagetothestructuresfoundonthem [1].IntheUnited States, damage caused by expansive clays exceeds the combinedaverageannualdamagefromfloods,hurricanes, and earthquakes [2]. So, it is important to study the propertiesofthesesoilsandhowtotreatthemtoovercome these problems. Stabilization of soils can be done in two mainways,chemical,andmechanicaltechniques.Chemical

techniques like using lime, cement, and granite. The mechanicalapproachsuchaspolypropylenefiberandnylon [3].Severalresearchersstudiedtheeffectofpolypropylene fiberonlyonexpansivesoil,usingpolypropylenefiberwas an effective method in reducing the swell potential and swellingpressureofsoils [2,4].Also,thisresearchreported thattheoptimumpercentageof(PPF)is2%forstabilizing thesoil,with2%fibergiven thehighestfrom(UCS)anda lowervalueofswelling [3].Theadditionofvaryingaspect ratiosoffibersincreasestheoptimummoisturecontentand decreases the maximum dry density, also increasing the value of cohesion and decreasing in value of the angle of internalfriction [5].Otherstudiesthatmixedpolypropylene with materials, such as [6]; investigated the effect of polypropylenefiberandsilicafume.Theinclusionofsilica fumeandPPF reducestheplasticindexandliquidlimitof thesoilandincreasestheplasticlimit,thesoilchangedits classificationfromhigh-plasticclays(CH)tolow-plasticclays (OH). [7]; reported that the effect of using rice husk ash, lime, and polypropylene fibers in expansive soil. The addition of RHA-lime increases the strength. As the pozzolanic reactions are time-dependent, the soil gains strength with an increased curing period. The addition of fiberstoRHA-limestabilizedexpansivesoilmixes,increases the strength. [8]; studied using brick powder and PPF to improvethesoil.Theoptimumquantityofbrickpowderand PPF was found to be 40% and 0.35% for 60% soil. these proportions increased the CBR values.[9]; showed the effectivenessofacollectionofmarbledust,cementkiln,and PPFtoincreasetheunconfinedcompressivestrength. [10]; thestudyfoundthatcoirfiberandNanosilicainfluencethe strength,permeability,andswellingpotential.

Recently,granitepowderhasbeenusedasasoilstabilizer, [11]; studied the effect of granite dust and lime on black cottonsoil.TheresultshowedtheCBRvalueincreased,the optimummoisturecontentreducedandthemaximumdry densityincreased. [12];additionofthefinesilicasandand granite powder waste change the swelling potential of expansive soils sample which classified as a high swelling potentiallysoiltolowexpansivesoils.Here,inthisproject, soilstabilizationhasbeendonewiththehelpofadmixtures ofpolypropylenefibersasamechanicalreinforcementand granitepowderasachemicalstabilization.

2. MATERIALS

2.1 Expansive Soil

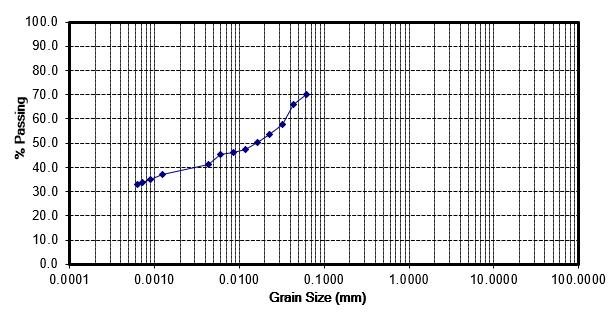

The Expansive soil used in the experimental work was obtained from the 5th SettlementinCairo,Egypt. The soil wasblacktodarkgrayandhighlyclayey.Itwascollectedata depthofonemeterbelowthenaturalgroundsurface.Before beingusedinthisinvestigation,thesoilwasdriedinanoven, pulverized, and then passed through 40 sieve size. The hydrometer analysis curve is shown in Fig.1 which was performedonthenaturalsoilpassingthroughthe75μsieve. Table 1 summarizes the physical properties that were evaluated as a part of this research. Depending on the gradation and Atterberg’s limits values, the soil was classifiedasCHaspertheUSCSclassificationmethod.

low cost, non-corrosive, chemically inert nature, and availabilityinvariouslengths.Polypropylenefiberdoesn’t allow any reaction with soil moisture. The polypropylene fiberwaspurchasedfromSikacompanyasshowninFig.2. Thephysical,chemical,andmechanicalpropertiesofPPFare illustratedinTable2below.

2.2

Polypropylenefiberhasbeenusedinthepresentstudy becausetheyhaveseveraladvantages,suchashighstrength,

2.3

Locally available granite cutting powder was used. Granite powder was obtained from the Shaq Al-Thouban district in South Cairo, Egypt. The granite powder was dried in an oven at 105°C for 24 hours to remove moisture, then pulverized repeatedly with a plastic hammer to remove any agglomeration as shown in Fig. 3. The important characteristic of granite powder as an additive material is the percentage passing through the No.40sieve.

3. METHODOLOGY

Theexperimentalprogramwastousesmallgranitepowder proportions(1.5%,3%,6%,and9%)bydryweightofsoil, butafterthegranitepowderproportionsweretestedonthe

basic soil properties tests. A slight improvement was observedforthesoil,startingwiththeratioof9%ofgranite powder. So, the experimental program was modified suggestedby (Manal and Abdulrazzaq) [12],and (Hassan and Abdelaal) [13] The proportions of the used granite powderwereincreasedto(20%,30%,and40%).According to (Nitin and Neelima) [6], the polypropylene fiber proportionswere(0.25%,0.5%,0.75%,and1%).

The experimental study had two phases. First, specific gravity tests, Atterberg's limits tests, free swell tests, and compactiontestswereappliedtonaturalsoilandsoiltreated withgranitepowder.

Second, the optimum proportion of granite powder and differentproportionsofpolypropylenefiberswasusedon the direct shear box test and the one-dimensional compressiontest.ThedirectShearboxsampleswerecarried outimmediately,with14,and,28daysofcuringperiod.All testswerecarriedoutaccordingtoASTMandtheEgyptian code of soil mechanics in the laboratory of Al-Azhar UniversityCairo,Egypt.

4. EXPERIMENTAL RESULTS AND DISCUSSION

4.1 Effect of Granite Powder on Atterberg’s Limits

TheLiquidlimit, Plasticlimit,and Shrinkagelimit were carried out for the natural soil and soil treated with granite powder. The relationship between the plasticity index and the swell behaviour has been identified by several researchers; in this study, the relationship suggestedby (O’Neil and Poormaayed) [14] wasusedas showninTable3.

Table -3:RelationshipsBetweenPlasticityIndex(PI)and SwellPotential

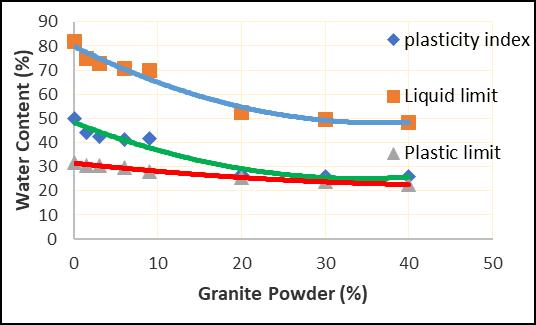

Whentheproportionsofgranitepowderwereaddedfrom 0% to 9%, the plasticity index, the liquid limit, and the plastic limit decreased slightly. Then, when adding higher percentages ofgranite powder (20%, 30%,and40%),the plasticity index, the liquid limit, and the plastic limit decreased to 25.9%, 48.5%, and 22.6%, respectively as illustratedinTable4.

Showsthedecreaseinvalues

Theaddition ofgranite powderfrom 0%to 40%caused a decrease in the capacity of water absorption, as shown in Fig.4, similar results were obtained by, (Manal and Abdulrazzaq) [12]

4.3

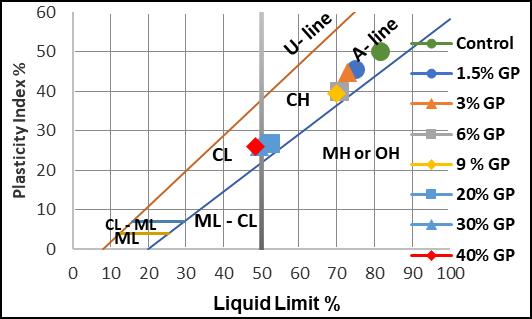

Fig.5showsthattheincreaseinthegranitepowdercontent shifts nature soil from high-plasticity clay (CH) into lowplasticityclay(CL)accordingtotheunifiedsoilclassification system(USCS).

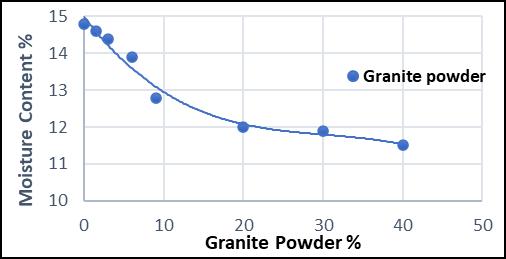

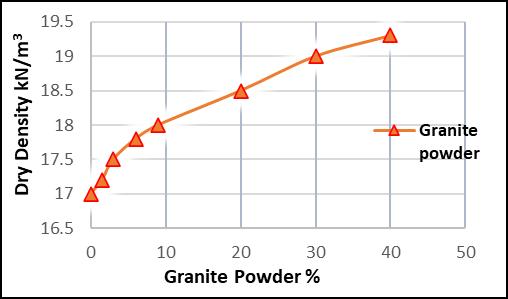

Thecompactiontesthasbeenperformedonsampleswith differentgranitepowdercontentsof1.5%,3%,6%,9%,20%, 30%, and 40% of dry mass. Fig. 7, and Fig. 8 show the variation of maximum dry density MDD and optimum moisturecontentOMCwiththevariationofgranitepowder. It is observed that as increased granite powders the MDD increasedfrom17KN/m3 to19.3KN/m3,andOMCreduced from14.8%to11.5%.

4.2

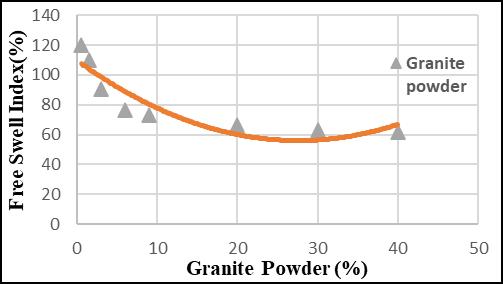

Thefreeswellingindexcanbeconsidereda propertyof expansivesoils.Itreflectsthepotentialofthesoiltoexpand. It is determined by knowing the volume of swollen soil passingthroughsieveNo.40,afterallowing10gofdrysoilto soakinwaterfor24hours.Fig.6showsthatthefreeswell indexfornaturalsoilwas120%then,asthepercentageof granitepowderusedincreased,itdecreasedto62%.

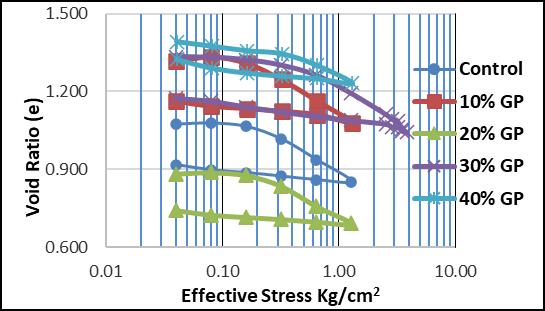

4.4The One-dimensionalCompression Test Results

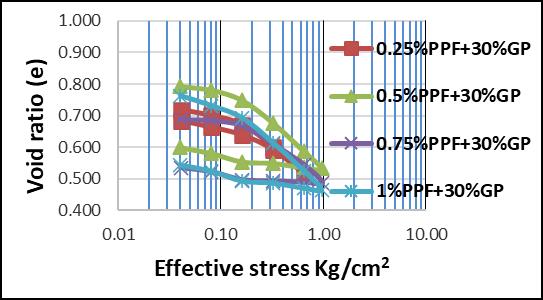

Theone-dimensionalcompressiontestdeterminestherate and magnitude of soil consolidation when the soil is restrained laterally and loaded axially. Soil samples were madefirstbyusingonlygranitepowderasasoiltreatment material,theamountofgranitewas9,20,30,and40percent bythedryweightofthesoil.Thespecimenswerecompacted directlyintotheoedometerring(63mmindiameterand20 mm in height). The initial height of the specimens was approximately16mm.Theconsolidationcellwasmounted ontheloadingplatformoftheodometer.Dialgaugereadings were taken for 24 hours or until the soil specimen was consolidated. After the specimen consolidation was completed under maximum stress, the load was gradually removed.Eachstressincrementduringunloadingwasagain maintainedfor24hours,thenthesoilspecimenwasallowed toswell.Allresultsweredrawnasthevoidratio(e)versus thelogarithmofeffectivestress(logσv)asshowninFig.9. Through tests, it was noted that adding 30% of granite powdertotheexpansivesoilmadeitbearaweightofupto 12kg,whileotherproportionscouldtakeaweightof4kg.

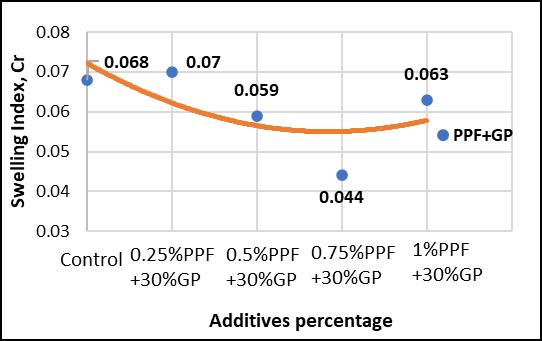

Fig. 11 shows the addition of granite powder causes a reduction in the rebound index; this decrease is due to a reductionintheamountofclaymineralsreplacedbygranite. At30%granitepowder,themaximumdecreaseofCr,48.5% compared tothecontrol sample, then increased at 40% of granitepowder.Inthecaseoftheadditionoffibers,theCc increasedcomparedtothecontrolsample.AndvaluesofCr decreased,duetotheeffectofgranitepowderasshownin Fig.12.

Table5showsthatthe proportion of 30% granite powder hadasmallsettlementcomparedtocarryingthehighestload. As for using fiber with granite powder, the consolidation settlementincreasedcomparedtothecontrolsample.

4.5

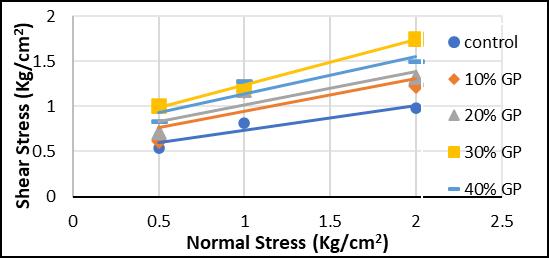

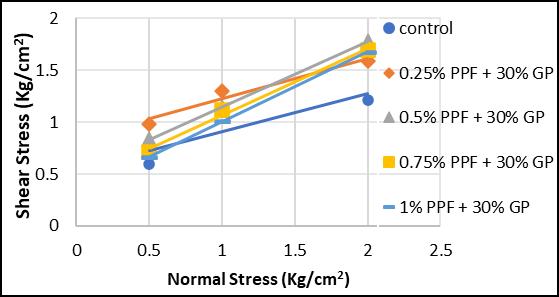

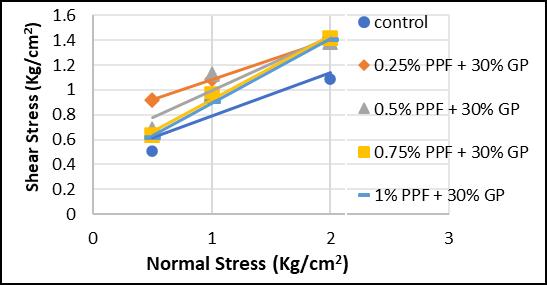

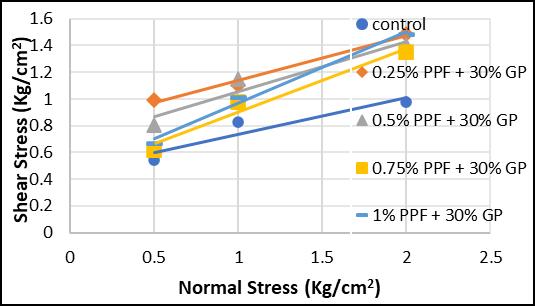

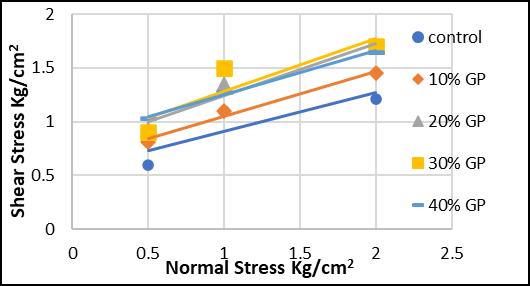

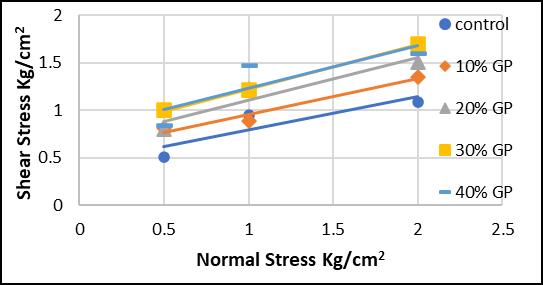

Samples were conducted on soil treated with granite powderbydifferentproportions(9,20,30,and40percentby thedryweightofsoil),andwerepreparedwithrespective OMC obtained from the compaction test. The remolded sampleswereweighedandplacedintheringofthetest,then the direct shear test specimens with size (55x55x25) mm wereextracted,thenthespecimensweretestedinthedirect shearbox.Shearboxsamplesweremadewithoutcuringand withcuringfor14daysand28days,Fig.13,Fig.14,andFig. 15 show that 30% granite powder was the highest shear strengthfornormalstresses.At30%GP,thecohesionand angleofinternalfrictionincreasedwithoutcuringfrom0.46 kg/cm2 and15.38°to0.72kg/cm2 and24.23°respectively, increasedatcuring14daysfrom0.48kg/cm2 and16.20°to 0.79kg/cm2 and25.1°respectively,increasedat28daysof curingfrom0.55kg/cm2and20.28°to0.8kg/cm2and26.52° respectively. When theaddition of 40% of granite powder with and withoutcuring, it was observed that slightly less than or equal to 30%. The increase in shear strength parametersisduetotheadditionofnon-expansivematerial toexpansivesoilsamples,whichreducestheamountofclay minerals and the void spaces between the clay particles (Hassan and Abdelaal) [13] Then, polypropylene fibers wereaddedwiththeoptimumpercentageofgranitepowder as shown in Fig. 16, Fig. 17, and Fig. 18. When the fibers percentage was increased, the cohesion between the soil particlesdecreasedfrom0.8kg/cm2 to0.44kg/cm2 without curing,from0.76kg/cm2to0.38kg/cm2at14daysofcuring, andfrom0.84kg/cm2 to0.34kg/cm2 at28daysofcuring.

Theinternalfrictionangleincreasedfrom19.47°to28.22° withoutcuring,from18.26°to27.46°at14daysofcuring, andfrom21.28°to34.44°at28daysofcuring.Becausethe length of the fibers used was 18 mm, having long fibers causesproblemsinsamplepreparationandwilleventually havelargervoids,theseresultsarecompatiblewiththestudy (Arif and Munwar) [15].Whentoomuchfiberwasadded reducedthebenefit,asthefibersadheretoeachothertoform lumps and cannot contact soil particles fully (Akshaya Kumar) [7]

5. CONCLUSIONS

Aseriesoftestswereconductedtostudytheeffectofgranite powder&polypropylenefiberonswellingcharacteristicsof theexpansivesoilfromthe5thSettlementinCairo,Egypt. Theproportionsofgranitepowderwere1.5%,3%,6%,9%, 20%,30%, and 40% by weight of soil, and polypropylene fiberwere0.25%,0.5%,0.75%,and1%byweightofsoil.As the result of this investigation, it is indicated that the stabilizationtechniquewith30%ofgranitepowderisavery usefulmethodandthestabilizationbyusingpolypropylene fiberwasanineffectivemethod,asproblemsappearedwhen preparingthesampleandincreasedthevoidsinthesoil.The followingaretheconclusionsfromthesetests.

1) Withtheadditionofgranitepowderplasticityindex, liquid limit, and plastic limit of expansive soil decreasedfrom50.1%,81.7%,and31.6%to25.9%, 48.5%, and 22.6% respectively. Due to this alterationinthepropertyofexpansivesoil,thesoil changeditsUCSCclassificationfromhigh-plasticity clay(CH)tolow-plasticityclay(CL).

2) The Addition of granite powder changes the swelling potential of the expansive soil sample whichwasclassifiedasahighswellingpotentially soiltolowexpansivesoil.

3) The granite powder addition decreased the expansivesoil'sfreeswellindexfrom120%to62%.

4) AdditionofgranitepowderincreasedtheMDDfrom 17 KN/m3 to 19.3 KN/m3 and reduced OMC from 14.8%to11.5%.

5) In the case of using granite powder on the direct shear box, shear strength parameters increased, Where the highest value was at 30% of granite powder.Thecohesionandangleofinternalfriction increased without curing from 0.46 kg/cm2 and 15.38°to0.72kg/cm2and24.23°respectively,after 14daysofcuringincreasedfrom0.48kg/cm2 and 16.20°to0.79kg/cm2 and25.1°respectively,and after28daysofcuringincreasedfrom0.55kg/cm2 and20.28°to0.8kg/cm2 and26.52°respectively.

6) As for the addition of 30% granite powder and proportions of polypropylene fiber, the cohesion between the soil particles decreased from 0.8 kg/cm2 to 0.44 kg/cm2 without curing, from 0.76 kg/cm2 to 0.38 kg/cm2 at 14 days of curing, and from 0.84 kg/cm2 to 0.34 kg/cm2 at 28 days of curing. The internal friction angle increased from 19.47° to 28.22° without curing, from 18.26° to 27.46 ° at 14 days of curing, and from 21.28° to 34.44°at28daysofcuring.

7) In the case of using granite powder on the consolidation test, 30% of granite powder decreasedtheCrvaluesfrom0.068to0.035.While usingpolypropylenefiberwithgranitepowder,the Crdecreasedcomparedtothecontrolsample,due tothepresenceofgranitepowder.

ACKNOWLEDGEMENT

The author wishes to acknowledge the support of the Laboratory of Civil Department, Faculty of Engineering at Al-AzharUniversity,Cairo,Egypt.

REFERENCES

[1] S.Twinkle, M.K.sayida, "EFFECT OF POLYPROPYLENE FIBER AND LIME ADMIXTURE ON ENGINEERING PROPERTIESOFEXPANSIVESOIL,"inConf.Proceedings ofIndianGeotechnical,Kochi,2011,No.H-085.

[2] A.S.Soganci, "The Effect of Polypropylene Fiber in the StabilizationofExpansiveSoils,"InternationalJournalof GeologicalandEnvironmentalEngineering,Vol.9,No.8, pp.994-997,2015.

[3] Sarah A. Hussein, Haifaa A. Ali, "Stabilization of expansive soils using Polypropylene Fiber” Civil EngineeringJournal",Vol.5,No.3,pp.624-635,2019.

[4] H.Manesh,M.Anilkumar,"TheEffectofPolypropylene Fibers on Properties of Expansive Soil" International JournalofRecentTechnologyandEngineering(IJRTE), Vol.7,2019.

[5] Firake.DipeekaB,Borole.Seema,KulkarniM,"Effectof Polypropylene Fibers on Properties of Black Cotton Soil", International Journal of Latest Technology in Engineering, Management& Applied Science (IJL TEMAS),Vol.VII,No.IV,PP.361-363,2018.

[6] Nitin,Neelima,"Experimentalstudyontheinfluenceof polypropylene fiber on swelling pressure- expansion attribute of silica fume stabilized clayey soil," doi:10.20944/prprints201907.0203.v1,2019.

[7] Akshaya. kumar, "Effect of Polypropylene Fiber on Engineering Properties of Rice Husk Ash – Lime Stabilized Expansive Soil,"Electronic Journal of GeotechnicalEngineering,Vol.17,pp.651-660,2012.

[8] Rachit,Mohit,"EffectofSurkhiandPolypropyleneFiber on Geotechnical Properties of Expansive Soil," International Journal of Recent Technology and Engineering(IJRTE),vol.6,No.1,pp.1468-1470,2019.

[9] Vishwanath.Vishwakarma,"StabilizationofExpansive soilReinforcedwithShortPolypropyleneFibersTreated with Admixtures,"International Transaction on Engineering&Science,Vol.1,No.2,2019.

[10] R. Suresh, V. Murugaiyan, "Improvement of Clay soil UsingNaturalFibersandNanoSilica:AReview,"Indian j.Sci.Res,2018.

[11] JagmohanMishra,R.K.Yadav,"EffectofGraniteDuston EngineeringPropertiesofLimeStabilizedBlackCotton Soil,"International Journal ofEngineeringResearch& Technology(IJERT)Vol.3,pp.832-837,2014

[12] Manal O. Suliman, Abdulrazzaq. Jawish, "Using Fine SilicaSandandGranitePowderWastetoControlFree Swelling Behavior of High Expansive Soil," Modern AppliedScience;Vol.15,No.1,pp.53-62,2020.

[13] Manal O. Suliman, Abdulrazzaq. Jawish, "Using Fine SilicaSandandGranitePowderWastetoControlFree Swelling Behavior of High Expansive Soil," Modern AppliedScience;Vol.15,No.1,pp.53-62,2020.

[14] O’neıll,Poormoayed,"MethodologyforFoundationson Expansive Clays," Journal of the Geotechnical Engineering Division, American Society of Civil Engineers,pp.1345-1367,1980.

[15] Arif.Moghal,B.MunwarBasha,"EffectofPolypropylene Fiber Reinforcement on the Consolidation, Swell and Shrinkage Behavior of Lime Blended Expansive Soil," RoadMaterialsandPavementDesign,availableonlineat doi:10.1080/14680629.2016.1272479,2018