Subgrade Soil Stabilization Using Ground Granulated Blast Furnace Slag, Fly Ash & Silica Fume

1Mahabubi Sheikh, 2Jyoti Shukla, 3Kousick R V, 4Janhavi Meshram, 5Alkesh Bhalerao.Department of Civil Engineering. New Horizon Institute of Technology and Management, Thane, Maharashtra

ABSTRACT: Subgrade soil is an important part of the road pavement structure because it supports the pavement layers such as the subbase, base, and wearing coursesfrom beneath. The properties of subgrade soil are critical for the design of a pavement structure. Any weakness in the subgrade soil affects all of the overlying layers of pavement, especially flexible pavement. The subgrade should be stable enough under adverse weather conditions to support the pavement. Poor subgrade conditionscausewaves,corrugations,rutting,andshoving inblacktoppavements.Stabilizationisabroadtermforthe various methods of modifying the properties of a soil to improve its engineering performance and use in a variety of engineering works. The varying percentage of Fly ash, SilicafumeandGGBSwerewithmixedwithsoilsampleto conductthesoiltest

Keywords – Soil stabilization; Murrum soil; Fly ash; GGBS; Silica fume; California bearing ratio; Unconfined compressionstrengthtest;Standardproctortest.

I. INTRODUCTION

The soil is weak and unstable enough to support heavy loads. The study's goal is to use waste material for soil stabilisation. For this project, we chose to use waste industrial materials that are commonly available as waste in every nook and cranny of not onlyourcountry, butthe entire world. To improve the strength of sub-grade soils, soil reinforcement techniques can be a significant secondary market for waste industrial materials such as GGBFS, Fly Ash, and SilicaFume. This technique has been found to be an effective and dependable method for increasingthestrengthofsub-gradesoils.Whencompared to an untreated and weaker subgrade, a treated or strongersubgradesoilrequiresarelativelythinnersection of a flexible pavement, resulting in a significant cost advantage. Geotextiles and other polymeric reinforcements, such as geogrids, have become increasingly popular in geotechnical engineering over the years. However, in some cases, particularly for low cost. Theexperimentalworkwasusedtostudythestabilisation of murrum soil using industrial waste. These works are evaluated in light of the methodology, principal, and various aspects of the situation. Based on the literature

review, a gap in research work is identified in order to conductadditionalresearch.

II. LITERATURE REVIEW

Nanda et al. (2016) studied experimental investigations that are made to evaluate the unconfined strength including compaction characteristics of Lithomarge soil (shedi soil) stabilized with ground Granulated Blast furnace Slag (GGBS) and lime. It was found that the inclusion of lime can significantly enhance theUCSvaluesofstabilizedshedsoil.

Abhijit et al. (2015) have conducted an experimentalstudytofindtheeffectofgroundgranulated blast furnace slag (GGBS) and Sisal fibres on the mechanicalpropertiesofblackcottonsoil.Intheinitial,the basic properties of black cotton soil and sisal fibre were found out. The next phase focuses on the unconfined compressive strength and CBR values of the mixture of black cotton soil and the optimum dosage of GGBS randomly reinforced with varying percentages of sisal fibres.TheresultsindicatedthatwiththeadditionofGGBS to black cotton soil the maximum dry density increased, andoptimummoisturecontentdecreased.Theunconfined compressive strength and CBR values increased the additionofsisalfibrestoamixtureofblackcottonsoiland optimumdosageofGGBS.Thehighestresultwasobtained for a mixture of black cotton soil and optimum dosage of GGBSwith0.75%ofsisalfibers

Dayalan et al. (2016) has conducted experiments with different amounts of fly ash and GGBS. The performance of stabilized soil is evaluated using physical and strength performance tests like specific gravity, Atterberg limits, standard proctor test, and CBR testatoptimummoisturecontent.Fromtheresults,itwas found that the optimum value of fly ash is 15% and GGBS is 20% for stabilization of given soil based on CBR value determined.

Dr.A.I. Dhatrak et.al. (2015) After reviewing performance of plastic waste mixed soil as a geotechnical material. It was observed that for construction of flexible pavementtoimprovethesubgradesoilofpavementusing waste plasticbottleschips isanalternativemethod.In his

paperaseriesofexperimentsaredoneonsoilmixedwith differentpercentageofplastic(0.5%,1%,1.5%,2%,2.5%) to calculate CBR. On the basis of experiments that he concluded using plastic waste strips will improve the soil strengthandcanbeusedassubgrade.

Pandey et al. (2014) The investigation showed that generallytheengineeringpropertieswhichimprovedwith addition of GGBS. The addition of GGBS resulted in a dramatic improvement within the test ranges covered in the programme. The maximum dry density increased and the optimum moisture content decreased with the increasingGGBScontentandat25%wegotthemaximum valueofdrydensity.

Sharma et al. (2016) Addition of Fly ash and GGBS based binder was found to decrease liquid limit and plasticityindex of the soil. The increase in shrinkagelimit shows resistance to volume change. Fly ash and GGBS mixture atmixing 70.30 providesa better opportunity for utilizationinvariousGeotechnicalandGeo-environmental application.

Rajkumar Nagle et.al. (2014)] It performed CBR studied for improving engineering performance of sub grade soil. They mixed polyethylene, bottles, food packagingandshoppingbags etc.,asreinforcementwithin black cotton soil, yellow soil and sandy soil. Their study showedthatMDDandCBRvalueincreaseswithincreasein plastic waste. Load bearing capacity and settlement characteristicsofselectedsoilmaterialarealsoimproved.

Manjunath.et al. (2012) carried out research on the influenceofGGBSandlimeontheunconfinedcompressive strength properties of black cotton soil. Lime and GGBS wereaddedinvariouscombinationwithcuringof0,7&28 days.TheresultsshowedthatsoilstabilisedwithGGBSand lime gave strength higher than that with lime only. The optimum mixture identified that with 30% GGBS and 4% lime,thestrengthwas18timesmorethantheblack.

III. PROPOSED WORK

The material used for experimental study was murrumsoil.Thevariouslaboratorytestswereperformed on murrum soil with relevant IS codes. Laboratory test were performed on murrum soil are Water content in murrumsoil,SpecificGravity,LiquidlimitandPlasticLimit of murrum soil. The various tests conducted to obtain EngineeringGeotechnicalpropertiesofmurrumsoil.

1. SpecificGravity

2. LiquidLimit

3. PlasticLimit

4. Standardproctortest

5. Unconfinedcompressiontest.

6. CaliforniaBearingRatiotest.

Followingaretheresultsobtainedfromthevarioustests conductedonthemurrumsoil:-

IV. TESTS PERFORMED

1 ATTERBERG LIMITS

1.1 LiquidLimit

The liquid limit of a soil water content at which the soil behaves practically like liquid, but it has small shear strength. It flows to close the groove in just 25 blows in Casagrande’s liquid limit device. Take about 120g of air died soil sample passing 425 µ IS Sieve. Mix the sample thoroughlywithdistilledwaterinanevaporatingdishora glass plate to form a uniform paste. Place the specimen in anairtightcontainerforthewatercontent determination. Determine the water content. Draw the flow curve between water content and number of blows, and determinetheliquidlimitcorrespondingto25blows.

1.2PlasticLimit

The plasticlimit of the soil isthe watercontent of the soil belowwhichitceasestoplastic.Itbringstocrumblewhen rolled into threads of 3mm diameter. Take about 20gm of airdriedsoil thoroughly,mixed sample of thesoil passing 425 µ sieve. Mix the soil with distilled water in an evaporating dish on a glassplateto make it enough shape

into a small ball. Collect the pieces of the crumbled soil thread in a moisture content container. Repeat the procedureatleasttwicemorewithfreshsampleofplastic soil.

Variation of Plastic Limit with % of GGBS, Fly Ash and Silica Fume

AveragePlasticLimit=30.22%

Plasticity index sample on replacement of Fly ash and GGBS

%GGBS,FlyAshand SilicaFume

Variation of Liquid Limit with % of GGBS, Fly Ash and Silica Fume

Graph2:Plasticlimitresultvaryingwith%ofFlyash,GGBS andSilicaFume

2. STANDARD PROCTOR TEST

Compaction is the process of dandification of soil by reducingairvoids.Thedegreeofcompactionofagivensoil ismeasured interms ofits dry density. Thedry density is maximum at optimum water content.2.5 kg of dry soil passing through 4.75 mm IS sieve was taken. The 8% of water is added to the soil and it was mixed thoroughly to ensuretheuniformdistributionofmoistureandattachthe collartothemould.Onepartofsoilisplacedinthemould and it was compacted with 25 blows by using 2.5 kg rammer.Thesecondlayershouldalsobecompactedby25 blows.

Dry density of sample replaces with 15 % Fly ash & 10% GGBS and 5% Silica Fume

withvaryingwith%of Flyash, GGBSandSilicaFume

Dry density(g/cc)

CBR value for replacement of 20% of Fly ash and 20% of GGBS and 3 % Silica Fume

CBRvalue@2.5mmpenetration=9.5%

CBRvalue@5mmpenetration=13.94%

Graph

Report:Themaximumdrydensityis1.878andOMCis12 %forsoilmixedwith15%ofFlyash&10%GGBS

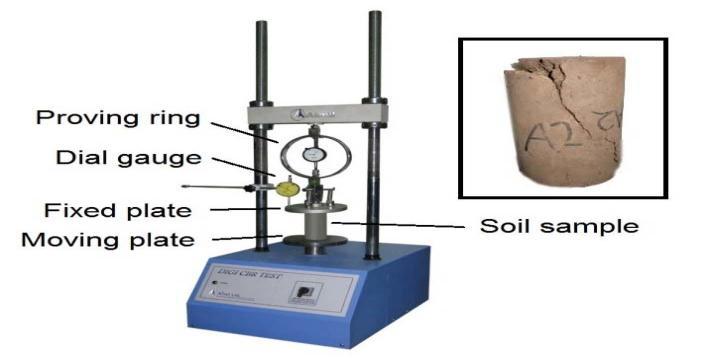

3. CALIFORNIA BEARINGRATIO TEST

The California Bearing Ratio is conducted for evaluating the suitability of the sub grade and material used in sub base used and base of a flexible pavement. Takeabout 4.5 to5.5kgmaterial.Mixitthoroughlywithrequiredquantity of water. Fix the extension collar of the top mould also fix the base plate of the bottom. The soil is to be compacted into 3 equal layer; each layer is given 56 blows by 2.6kg rammerwithdropof310mm.Removetheextensioncollar. Trim even the excess compacted soil carefully with a straight edge with top of mould. Place a filter disc on the base plate. Invert the mould with compacted soil. Clamp thebaseplateAppliedloadontheplunger.Recordtheload corresponding the penetration of 0.0,0.5, 1.0, 1.5,2.0,2.5,3.0,4.0,5.0,7.5,10.0and12.5mm.

Theshearingstrengthiscommonlyinvestigatedbymeans of compression tests in which an axial load is applied to the specimen and increased until failure occurs. The unconfined compressive strengthistheload perunit area at which and unconfined cylindrical specimen of soil will fail in a simple compression test. If the unit axial

compression force per unit area has not reached a maximum value up to 20 percent axial strain, unconfined compressive strength shall be considered the value obtained at 20 percent axial strength. This test was conductedasperIS2720(Part10):1973.

UCSApparatus

UCS Value for Murrum Soil with 10% of GGBS ,10% of Fly Ash And 3 % of Silica Fume

Graph5:Compressivestrengthvaryingwith%ofFlyash, GGBSandSilicaFume

V. CONCLUSION

ThestudyhasbeenconductedtoassessthepotentialofFly Ash, GGBFS and Silica Fume for stabilization of Murrum soil and detailed comparison has been presented based onvariouspropertiesofsoil.

ItisobservedthatwiththeincreaseofFlyashand GGBFS percentage, optimum moisture content goes on decreasing, while maximum dry density goesinincreasing.

Theadditionof15%ofFlyashand10%ofGGBFS and3%ofSilicaFumechangesthesoilgroupfrom CHtoMLgroupaccordingtoIS1498:1970.

The shear stress increases with addition of 15% Flyashand10%GGBFSand3%SilicaFumetends todecreasebeyondthislimit.

TheCBRvalueincreaseswithincreasesinamount of Fly ash and GGBS and Silica Fume attained maximumvalueat20%,20%,3%respectively.

It is concluded that the use of 15%of Fly ash and 10% of GGBS and 5% by weight of soil is recommendedforbetterresult.

It is also concluded that combined use of Fly ash, GGBFSandSilicaFumecanbeadvantageouswhen comparedtousingthemindividually.

REFERENCES

1. Ref.IS:2720(Part2)-1973,formoisturecontent.

2. Ref.IS:2720(Part7) -1974,forstandardproctor test.

3. Ref.IS:2720(Part16)-1987(Re-affirmed2002), forCBR

4. IS: 2720 -Part 3-1980,” Determination of Specific gravity

5. Dayalan. J. Comparative study on Stabilization of soil with fly ash and Ground Granulated Blast Furnace Slag (GGBS). Int. Res. J. Eng. Technol. (Irjet.)2016,3,2198

2204.

6. Ashish Kumar Pathak, Dr.V.Pandey, (2014), “Soil Stabilization Using Ground Granulated Blast Furnace Slag”, International Journal of Engineering Research and Application, Vol-4, issue-4,May-2014,pp,164-171.

7. Anil Kumar Sharma, A.M.ASCE; and P.V.Sivapullaiah(2016),“FlyashGGBSmixturefoe Geotechnical and Geo-Environmental Applications”,GSP272.

8. Kumar,BRP.,Sharma,RS.,(2004).“Effectofflyash on engineering properties of expansive soils”, J Geotech Geoenivronmental Engineering ASCE 130(7):pp764-767.

9. Asish Kumar Pathak, Dr.V.Pandey, (2014), “Soil Stabilization Using Ground Granulated Blast Furnace Slag”, International Journal of Engineering Research and Applications, Vol4, Issue4,May2014,pp.164-171.

10. Oormila T.R., Preeti.T.V. (2014), “Effect of Stabilization Using Flyash and GGBS in Soil Characteristics”, International Journal of Engineering Trends and Technology (IJETT) –Volume11Number6-May2014,pp284-289.

11. Karthik.S,etal.(2014),,”SoilStabilization by Using flyash”, ISOR Journal Of Mechanical and Civil Engineering,Vol10,Issue6,PP20-26.

12. Laxmikanth yadu and Dr. Tripathi.R.K.,(2013), “ Effects of Granulated Blast Furnace Slag in the Engineering Behavior of stabilized soft soil” International Conference in Chemical, Civil and Mechanical Engineering, Procedia Engineering 51(2013)pp125-131.

13. Bhuvaneshwari.S, Robinson.R.G, Gandhi.S.R (2005) “Stabilization of Expansive Soils Using Flyash”FlyAshIndia,NewDelhi.