MICRO RO DESALINATION UNIT

Abstract - Water is the backbone of our economy and development. An adequate and safe water supply is vital for progress in agriculture, industry, recreation, and human consumption. As a country, we face increasing water supply challenges in the form of droughts, increased water demands due to population growth, densely polluted waters, and demand competitive demand from many different users. To overcome these challenges for the present and future, water treatment technologies including desalination will significantly contribute to ensuring a safe, sustainable, affordable, andadequate water supply for thepublicofIndia. Desalination is commonly applied today to overcome the scarcity of fresh water in some parts of the world such as Israel, Bahrain, Kuwait, China, Qatar, UAE, Saudi Arabia etc. Different types of technologies have been proposed over the past century. In this report, the status of the mainstream solution, reverse osmosis (RO) is reported. In this case, the seawater treatment plants operate the same way as the traditional, except that they are designed to be portable. The document reviews filtration techniques and the evolution of the device into compactness, they can be used without complicated installation procedures, and the treats seawater everywhere.Theclassificationsarethereforegivenfirst,taking into account the principles of operation, the main energy inputs required for the treatment, the parts needed, the processes involved, and the unit test.

Key Words: Desalination, portable, water bodies, water treatment, freshwater, seawater, sustainable, reverse osmosis, installation.

1. INTRODUCTION

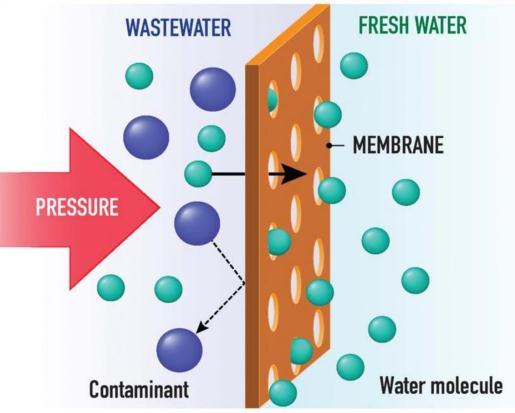

Desalination is a technique of removing salts or other mineralsandcontaminantsfromseawater,brackishwater, andwastewateranditisauniquesolutiontoobtainfresh water for consumption and for domestic/industrial utilization. Desalination plants convert saline water into purewaterthatisfittodrink.Themostcommontechnique usedisreverseosmosis wherehighpressureisapplied to pushsalinewaterfromanareaofhighsaltconcentrationto lowsaltconcentrationthroughamembrane.

1.1 Need

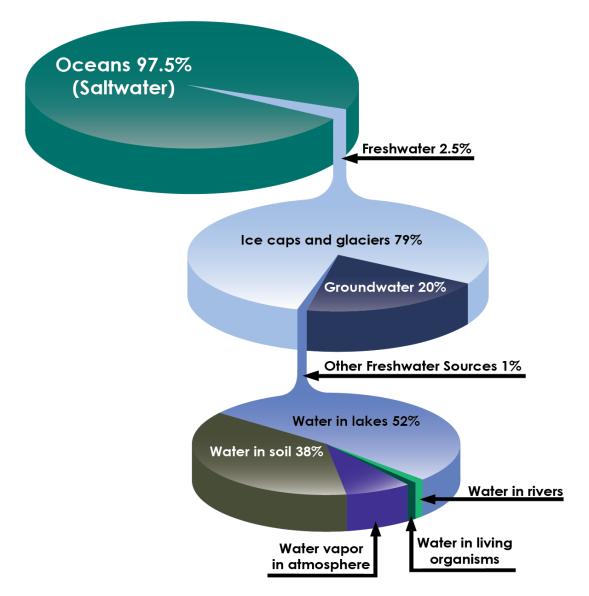

Only2.5%ofthewateravailableonearthisfreshwater.Twothirdofthisfreshwaterispresentinfrozenglaciers.Onan average over 1.1 billion people lack proper access to any freshwaterreservesandover2.7billionpeoplefacescarcity

ofwateratleastonceamonth.Butfortunately,asweknow 71%oftheearth’ssurfaceiswaterand97.5%ofthatwateris seawater.

Fig-1:WaterDistributiononEarth

Inmanypartsoftheworld,thereisascarcityofcleanand freshwater.Forindustriestosurvive,theyneedasystemthat can help them utilize the available water resource more efficiently.Withthehelpofdesalinationplants,Governments and people can be prepared for the times of droughts and ensureanefficientsupplyofwater.

1.2 India’s Water Resources

In India, an average precipitation of 118 cm per year is experienced. Most of the rains occur during its monsoon seasons with the north-eastern and northern areas like Assam,Meghalaya,andArunachalPradeshreceiving400cm of rainfall. The regions Tripura, Nagaland, and Manipur receive 200-300 cm of rain. Areas such as West Bengal, Bihar, Odisha experience 100-200 cm of rainfall. Maharashtra,Punjab,Haryana,andTamilNadureceive50100 cm of rain. Desert and semi-desert areas including Rajasthan,Gujarat,Ladakhplateaureceivesrainsbelow50 cm.duetothisfloodingoccursintheHimalayanbasinand water scarcity in others. Generally, desalination is consideredtobemoreexpensivecomparedtootherexisting sources,yetitismorereliableinmeetingthecountry’swater needs.DesalinationwillhelptoendIndia’swaterproblems

only because India has sufficient renewable energy resourcesifutilized properlycanbringdownthe costper litreofthedesalinationprocessrapidly.

2. DESALINATION TECHNOLOGY

Desalinationistheprocessofremovingdissolvedminerals includingsaltfromwatersuppliessuchasseawater,treated sewage,orbrackishwater.Severalmethodsofpurification includedistillation,ionexchange,membraneprocesses,solar purification,andmore.Thereverseosmosismethodismost commonlyused.

Thereverseosmosisprocessissimpleandstraightforward. Thisisdonebywaterpressurepushingseawaterthrougha semi-permeable membrane, removing contaminants from thewater.Itisaprocessthatremovesdissolvedsolidsfrom a liquid. This process differs from standard filtration in which contaminants are collected within the filter media. The reverse osmosis process pushes the water through a series of semi-permeable layers and the clean water then goesintoacollectiontankandthecontaminantsareflushed downthedrain.

Objectives

1. ToeliminatedepletionofdrinkingwaterinIndia.

2. To treat seawater so that the water is suitable for drinking.

3. Tomakerobustandportabledevicethatiseasytouse.

4. Tomakethebestuseofseawateravailableinplenty.

5. Tomakeacost-efficientdesalinationunitavailableand affordableinruralareas.

Design

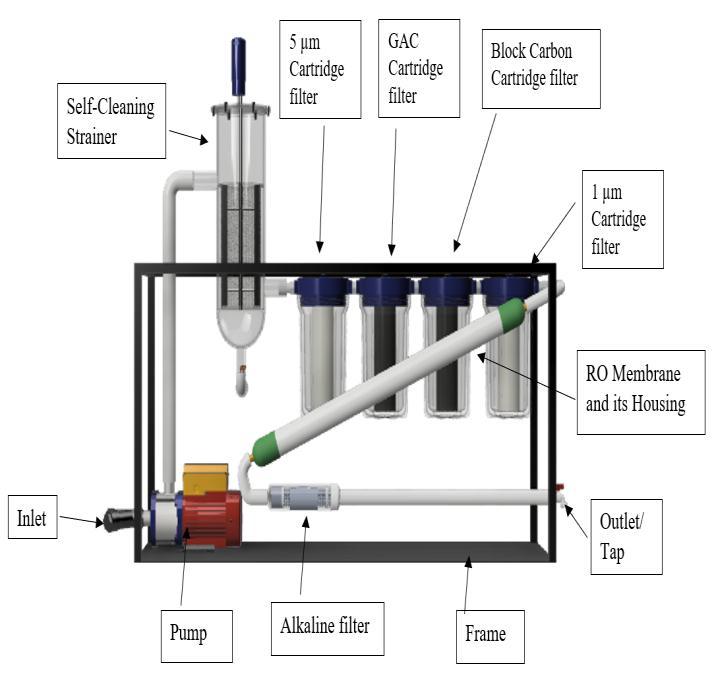

A Micro RO Desalination unit is designed based on the workingprinciplesofactualROdesalinationplant.

Thedesalinationunitworksinthefollowingway:

I.FirstwaterwillbesuckedintotheAutomaticSelf-Cleaning Strainerwhichcontainsameshof250µm.Waterfillsupin the housing and passes through the strainer which will remove sediments, rocks, sand, organic and inorganic components.

II.Thestrainerisattachedbeforepump,atinletline,sothat inorganicmaterialdoesnotgetstuckintopump.

III. Then the water enters the pump and is discharged out withhighpressureat10bar.

IV. Pressurized water is passed through the first Cartridge Filterhousingwherea40µmfilterisusedforfiltration.Here waterisfilledinhousingandwaterentersthecartridgefilter fromitsoutersurfaceandfilterwatercomesoutfrominside offilter.

V. Next process of filtration takes place in GAC Filter (Granulated Activated Carbon). Here the microparticles, microbes,dirt,etc areremoved.

VI.ThenthewaterisagainpassedthroughCarbonFilterbut thistimeaBlocktypecarbonfilterwhichremovesviruses, microparticleswhichescapedfromtheGACfilter.

VII.Andlastpre-filteroftheprocessisagainaCartridgeFilter withamicronratingof5µm,thisisjustfortheprecautionso thatanyremainingparticulatefromcarbonfilterisremoved

VIII. The next step is to pass the water from the RO membranewheretheROprocesswilltakeplaceandTDSof thewaterisreducedforhumanconsumption.Herethewater isconvertedtopurewater,whichhasextremelylowmineral containwhichcanbeharmfulforhumans

IX.Forthisparticularreason,post-filtrationisdonewhere minerals are added to the water and in this case Alkaline Filter is used which adds minerals and soothing taste to water.

X.Finally,weobtainpotablewaterfromdesalinationprocess.

Fabrication

For pre filtration automatic self-cleaning filters are used automaticself-cleaningstrainersaremotorizedstrainerthat isusedtocontinuallyremovecontaminantsanddebrisfroma fluidpipesystem.Theflowofliquidentersthestraineratthe topinletandworksitswaydownwardsthroughthestrainer andthenoutfromthebelowoutlet.Anyunwanteddebrisis caughtinsidethestrainerandpushedtothebottom.When thedifferentialpressurereachesacertainpressurepointthe flush valve at the bottom opens and removes the contaminants.

The figure shows the assembled model of the micro desalinationunit.Theself-cleaningfilterandROhousingis madeupofSuperDuplexSteelASTMSA790.Cartridgefilter ofACMEEngineeringProductsPvt.Ltd.ofsize40μmand5 μm is being used to achieve micro filtration. Material of cartridge filter is Polypropylene. As Polypropylene can withstandintensephysicalstressandcorrosioncausedbythe sun,mold,bacteria,rot,oilsascomparedtonylon,bleached cotton, and polyester. It is also highly moisture-resistant. Carbon filter Cartridges are most effective at removing chlorine, sediment, volatile organic compounds, taste and odourfromwater.Typicalparticlesizesthatcanberemoved by carbon filters range from 0.5 to 50 µm; the lower the micronratingthegreaterthefilter.Forthisunittwotypesof carbonfiltersarebeingused;

i. GranulatedActivatedCarbonfilter

ii. Activatedcarbonblockfilter.

Regularstrainersrequiremanualcleaning,butself-cleaning strainers do it themselves through backwashing and mechanicalcleaningtechnology,allwhileallowingthesystem tocontinuetowork.Forthecurrentapplicationofcompact desalinationunit1-1/2”pipesizeself-cleaningthestrainer willbeused.Sincetheworkingfluidisseawater,SS316isthe best suitable option for the material of the strainer body/housing.Thematerialforthemeshscreenandinternal mechanism will be SS316L as both materials possess excellentcorrosionresistance.MeshSizeis250μm.

CartridgefilterhousingsareusedforholdingPolypropylene andcarboncartridgefilters.

Forthisunit,ROmembraneofHongtekFiltrationCo.Ltd.is usedSW-2521(25isdiameterwhichis2.5”and21islength whichis21”).Pressuregaugesandballvalvesareusedfor measuringandcontrollingthepressureinthelines.

Testing

Initiallytochecktheleakagesincomponentsfittings,water was passedthroughthecomponents,and it alsohelped to clean the internals of the housings and filter. Once the cleaning and leak test was done cartridge filters, Carbon filters and seawater RO membrane were installed in the housings.Actualtestrunwasstartedbystartingthepumps whichpumpedthedirtysalinewaterwithhighTDSlevel.

TDSandpHofsalinewaterwas checkedwithTDSandpH meterbeforerunningthroughthedesalinationunit.

TDSvalueofsalinewater–8791ppm

pHvalueofsalinewater–8.57

LaterTDSandpHofSalinewaterwascheckedafterrunning throughthedesalinationunitatthepressureof10bar.

TDSvalueofFilteredwater–46ppm

pHvalueofFilteredwater–7.99

Basedontheoutput,desalinationunitprovedtobeworking on a satisfactory level It is determined that TDS of saline water can be reduced with this system and it can remove unwantedelementsfromseawater.

Basedontheexperimentationresultwasfoundoutthatthe desalinationunitiscapableofprovidingfilteredwaterof70 LPH. It was experimented and found out that the RO membrane is capable of providing 95 LPH of water if the pressure was increased up to 20 bar, but the pump we selectedwasnotcapabletodeliveroutputpressureof20bar.

Advantages

1. Waterproductionrateis850litersperday.

2. Unitiscompactandsimpleindesign.

3. Lowoperationalandmaintenancecosts

4. Unitiseasytouseandportable.

5. Highcorrosionresistance.

6. Feedwatercanbetakenfromtheseaitself.

7. Watersofteningdoesnotrequiretheuseofany chemicals.

Disadvantages

1. Frequentcleaningofmembranetoavoidfouling.

2. Unitrequiresroutinemaintenance.

3. Undetectedleaksleadtowastageofwater.

4. Requirehighpressurepumptopasswaterthrough membraneorelsethesystemwon’twork.

5. Clogginginfiltersormembranemayleadtoshutting downoftheentiresystem.

3. RESULTS

Robustunitdesigningwasthemainareaofconcerninorder to convert seawater and brackish water to pure drinking water.Thedesignwasmadeonthebasisoftheworkingof anactualdesalinationplant.Forthedesiredoutput,various materialswerestudiedandbasedontheirspecificationlike compactness, water purification and production capacity components were selected. Based on the components selecteddesalinationprocesswasdesignedandCADmodels were prepared, following that pressure drop calculations wereperformedforeachandeveryfiltrationmedia.

Table-1:ResultObtainedfromDesalinationUnit

REFERENCES

[1] D. Alfred Mutai “A research paper on desalination in Australia”,Researchgatepublications,November2013.

[2] Greenlee,L.F.,Lawler,D.F.,Freeman,B.D.,Marrot,B.,& Moulin,P.(2009).Reverseosmosisdesalination:water sources, technology, and today's challenges. Water research,43(9),2317-2348.

[3] Baker, R. W. (2012). “Membrane technology and applications”,JohnWiley&Sons.

[4] Ezzeghni, U. A. (2018). Design of 10,000 m3/d SWRO desalinationplant.LAPLAMBERTAcademicPublishing

[5] Prusty,P.,&Farooq,S.H.(2020).Seawaterintrusionin thecoastalaquifersofIndia-Areview. HydroResearch,3, 61-74.

ForthesameapplicationMSF,MEDandEDRarebeingused, buttheyhavesomelimitationsthatneededtobeovercomed duringoperation.Consideringthose,MICRODESALINATION UNIT USING RO MEMBRANE was designed. This unit can replace the usage of other complex process in order to increaseefficiencyandlowerthecosts

4. CONCLUSION

As increasing water pollution and decreasing fresh water supplyisbecominganunignorableissue,demandofwater for various purposes is going on exceeding day by day. Reducing pollution caused in water bodies and reusing waste water in some or the other form, or looking for an alternativewatersource aretheonlysolutionstocopeup with the depleting water supply. To combat this issue, a study was carried out related to adopting a typical desalination process and a compact MICRO RO DESALINATIONUNITwasdesigned.Thissimpleunitcanbe usedtotreatanykindofseawater,brackishwater,ground water,etc.Astherearemanydifferenttypesofdesalination processes for the same type of application which are somewhatmorecosteffectiveandhighlyefficientthanRO system, but they have their own limitations as well. This method is adopted in most of the water purifiers such as Kent,AOSmith,Pureit,Aquaguard,BlueStartonameafew thatareavailableatourhomes.Anumberoftechniquesare under R&D for desalination. Though its cost seems to be decreasing,theyarestillcostlierthanconventionaldrinking water filtration processes. Desalination will improve the situation of millions of people across the globe that are facingwatercrisisandstriveforcleandrinkingwater.

[6] Curto,D.,Franzitta,V.,&Guercio,A.(2021).Areviewof thewaterdesalinationtechnologies.AppliedSciences, 11(2),670.

[7] Deshmukh,S.S.,&Childress,A.E.(2001).Zetapotential ofcommercialROmembranes:influenceofsourcewater typeandchemistry.Desalination,140(1),87-95

[8] Sabry,A.S.,Youssef,Y.M.,&El-Kilany,K.S.Productivity PredictionofSeaWaterReverseOsmosisDesalination PlantUsingRobustRegression.

[9] ACME Engineering Products Pvt. Ltd., Strainers and Cartridge filter manufacturer and Filtration solutions, “https://www.acmeprod.com/strainers”

[10] Hongtek Filtration, RO Membrane manufacturer “https://www.hongtekfiltration.com”

[11] Rajah Filter technics, Carbon Filter Manufacturer “https://rajahfiltertechnics.com/”