Design and Development of Multipurpose Automatic Material Handling Robot with implementation of Virtual Twin, Digital Manufacturing and Model based system engineering.

1Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

2Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

3Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

4Professor, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India ***

Abstract – This paper deals with the Design and development of multipurpose automatic material handling robottoovercomethelogisticproblemthatoftenoccursinthe warehouseautomation,workplacesandmakeimprovementto the facilities provided in the workplaces. Make efficient processes by enhancing material handling and inventory tracking and management process. Using system-thinking approach (MBSE), design and optimize the system and subsystemrequiredfortheautomaticmaterialhandlingrobot considering interaction between systems, sub-systems and external environment within the workplace. Development of system to complement different functions of navigation, deployment, operational flexibility, responsiveness.

Key Words: System Engineering (MBSE), Factory flow simulation, Digital Manufacturing, Virtual reality, Logistics, Kinematic simulation, Wire harness, Process Planning.

1. INTRODUCTION

This project emphasises use of logistic behaviour and completedigitalmanufacturingtoimplementthesesolutions inwarehouseautomation.Anautonomousmaterialhandling robotisasystemthatuseson-boardsensorsandprocessors to move boxes without the need of human assistance or markers. It understands its surroundings, remembers its path,anddynamicallyplansitsownpathfromonewaypoint to another. The primary stakeholders or users would be manufacturingfacilities,whichrequiresmaterialmovement in and between different stations and lines. The potential target industry would be the logistics and supply chain (warehouse),wherematerialmovementactivities,storage andretrievalafterpredominantworkactivitiesandinother workplaces where material movement activities are prevalent.

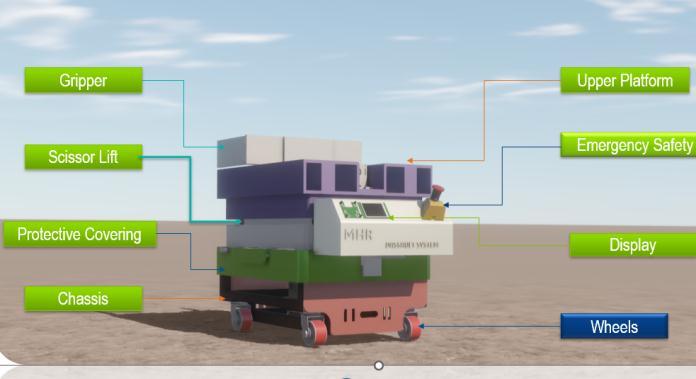

1.1 Actual model for MAMHR

We implemented the MBSE (model based system engineering) in order to build the complex product by distributingitintoseveralsub-systems.Weconsideredthe scissorliftbasedmodelforcurrentdevelopment.Thescissor lift uplifts the complete gripper and object detection assembly at required height of racks in the warehouse environment.Asboxisdetectedusingimageprocessingand livevideofeedthenthegripperstartsreachingoutnearthe boxandhelditfirmlybylinearactuatormechanism.While differentialwheeldrivemaneuveringthecompletesystemat required locations using path detection. The LIDAR,

ultrasonicsensorprovidesassistancetoavoidcollisionwith humanandotherco-operatingMAMHRrobot.

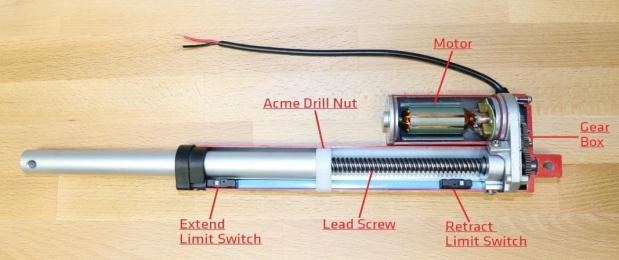

1.2 Linear Actuator and Gripper assembly

Alinearactuatorisaninstrumentthatprovidesmotionin a straight line, by using the circular motion of a electric motor.Anactuatorreceivesacontrolsignalandrespondtoit by converting that signal into controllable mechanical energy.

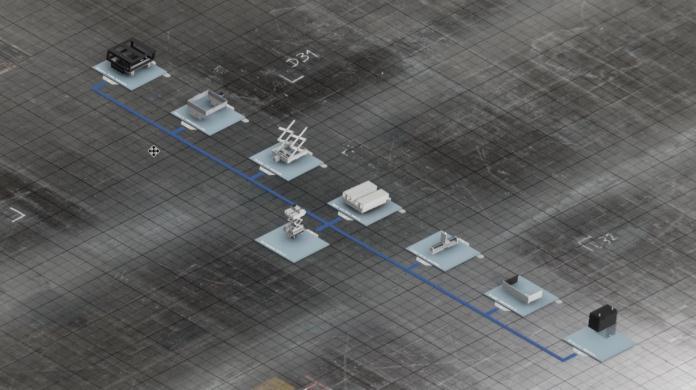

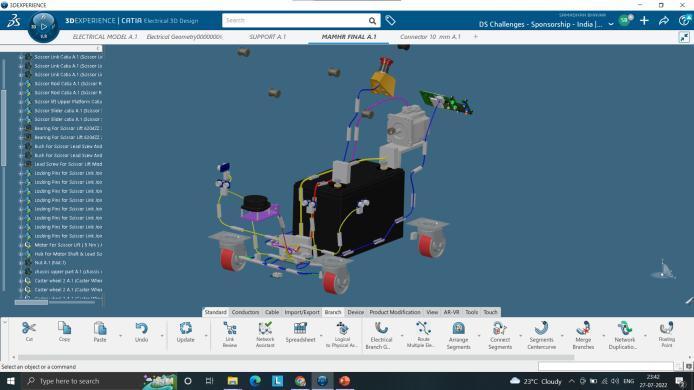

Aboveimagesareshowingthevirtualrealityexperienceof complete product and its working using 3DExperience platform. In order to get perfect validation we have implementedthedigitalmanufacturinganddigitaltwinby using process planning. Process planning helps to analyse completemanufacturingprocessvirtuallyandprovidescope of modifications and gives complete schedule for manufacturingofproduct.Alongwithphysicaldimensions the electronicsystemand wire harnessdesignis a crucial parttovalidateall functionalityusingDYMOLA behaviour and Electrical CATIA. We had designed and demonstrated the complete electronic system design and its algorithms successfullyusing3DExperiencetools.

1.3 Tools and Technology involved in Digital Manufacturing

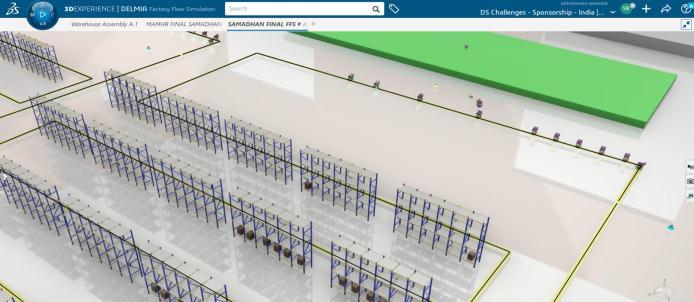

In order to develop, test, implement and verify the new productwehaveutilizedthedigitaltechnologyinorderto make the design industry ready before introducing it to physicalprototyping.3DExperienceplatformhasprovided usthetoolcalledfactoryflowsimulationinordertosimulate the robot working in warehouse using virtual reality experience.

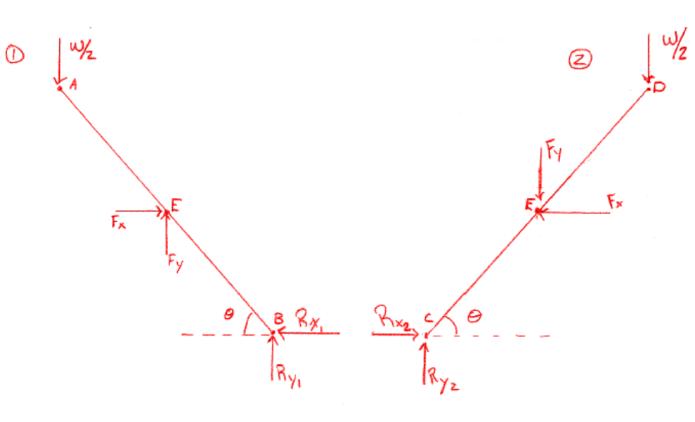

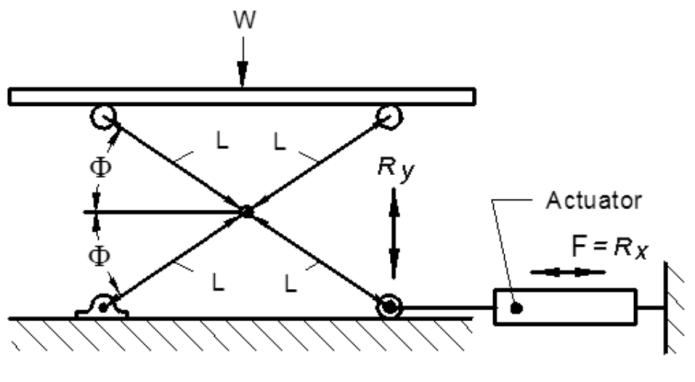

2. CALCULATION FOR SCISSOR LIFT

Scissorliftcanbeofstandarddimensionbutincaseofthis model we have customize the dimensions according to required specifications. The Scissor lift upper and lower platformisof600x500x70(L*B*H)inmm.Thescissor Linksusedare8innumberstoreachaheightof1.5-2mby usingtwolinkages.

2.1 Calculation for dimensions of scissor links

Sinceweareusingamildsteelforconstructionofscissorlift as it has greater durability, strength, easy and cheap availability.Dimensionsofscissorlinkare540x60x10(L* B*H)inmm.Forthesedimensionsofscissorlinkandliftthe prototype model can lift a load of 5 to 7 kg using linear actuatorassembly.Accordingtoliftheightneededandweight tobeliftedthedimensionsofscissorlinksarecalculated.

TotalVehicleweight

40-50kg

Wheelmotortorque 45Nm

BatteryBackup

4.5-5 Hours in Dynamicoperation

TheabovetableshowsgeneralizedspecificationsofMAMHR. These specifications are suitable for AGV robot to work efficientlyinwarehouseworkingenvironment.

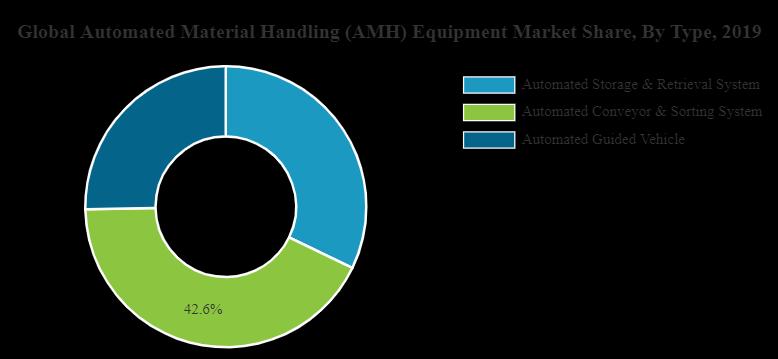

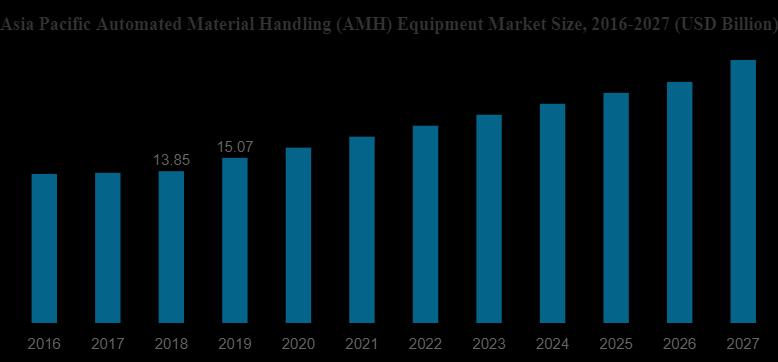

Chart -1:MaterialHandlingrobotmarketsize

This chart shows how the equipment market size of the materialhandlingrobotisincreasingdaybydayinarapid manner.Byconsideringthemarketscenariothisproductis helping out in order to automate material handling in warehouses.

2.1 Calculation of AGV dimensions

This product will be working in a warehouse automation where frequent operations are needed in close proximity space. In order to accommodate space issue, torque and maximum speed of vehicle and operational flexibility the dimensions of MHR robot is kept as 600 x 500 x 300 mm (L*B*H).

These images show our cad model in a realistic world rendered using 3DExperience native application These Rendered images illustrate virtual reality appearance of MAMHRrobotinwarehouseenvironment.

ACKNOWLEDGEMENT

Special thanks to La Fondation Dassault Systemes for seedingtheidea,guiding,mentoringandprovidingfinancial support.

WewouldliketoexpressourspecialthankstoMr.Hemant Gadgil, Mr. Praveen Bhagoji, Mr. Biswajyoti Shome, Mr. VineetGaba, Mr. Anshuman Singh &Mr.VaradGolefortheir valuableguidanceduringthisresearchwork.

3. CONCLUSIONS

Asweknowthattheday-by-daydemandandoperationsof E-commerce systems and increasing post pandemic. To tackle this increasing demand with higher output, operationalflexibility,lesserhumaninteractionandincost effective manner. Hence the product we developed is the best solution for logistics and supply chain (warehouse) automationwithleastpossiblecostthanothersystems.This productinvolvesplentyofresearchareasandfuturescopes andadvancementaslookingaftertheincreasingdemand.

REFERENCES

[1] https://www.mordorintelligence.com/industryreports/automated-material-handling-market

[2] https://www.databridgemarketresearch.com/reports/g lobal-material-handling-robotics-market

[3] https://en.wikipedia.org/wiki/Linear_actuatorK.Elissa, “Titleofpaperifknown,”unpublished.

[4] https://en.wikipedia.org/wiki/Modelbased_systems_engineering

BIOGRAPHIES

SamadhanBhavar BE scholar in Mechanical EngineeringDepartmentofPVG’S COET,Pune.

E-mail:smbhavar01@gmail.com

NikhilKoshti BE scholar in Mechanical EngineeringDepartmentofPVG’S COET,Pune.

E-mail: koshtinikhil073@gmail.com

ShantanuKulkarni BE scholar in Mechanical EngineeringDepartmentofPVG’S COET,Pune.

E-mail:kshantanu324@gmail.com

Prof.VishalChavan Professor in Mechanical EngineeringDepartmentofPVG’S COET,Pune.

E-mail:vsc_mech@pvgcoet.ac.in