EVALUATION OF STONE DUST FOR STABILIZATION OF EXPANSIVE SOIL FOR PAVEMENT CONSTRUCTION

Ankit Kumar Maurya1 , M. K. Gupta2 , Prashant Patel3 and Dharmendra Singh41Master Student, Department of Civil Engineering, KNIT Sultanpur, Uttar Pradesh, India

2Professor, Department of Civil Engineering, KNIT Sultanpur, Uttar Pradesh, India

3,4Research scholar, Department of Civil Engineering, MNNIT Allahabad, Prayagraj, India ***

Abstract - An Expansive soil (ES) is soil that has the ability to swell or shrink significantly due to changes in moisture content. It is also known as swelling soil, shrink-swell soil, or clay soil. Expansive soils are typically composed of clay minerals that have the ability to absorb water and expand, and then release water and shrink. This study used stone dust (SD) for the improvement of engineering properties. Stone dust, also known as crusher dust or quarry dust, is a type of fine material that is made by crushing stones and rocks. It is often used as a subbase material for paving projects such as roads, driveways, and construction projects. Different tests to evaluate the Liquid and Plastic limit, free swell index (FSI), compaction, unconfined compressive strength (UCS), and California bearing ratio (CBR) are used to characterize the effects of adding stone dust in expansive soil. According to the test results, stone dust with a percentage of 0, 10, 20, 30 and 40% improves the engineering characteristics of expansive soil so that it may be utilized for constructing pavement.

Key Words: Expansive soil, Stone dust, UCS and CBR

1. INTRODUCTION

Expansivesoilissoilthatswellsandshrinkssignificantlyas the moisture content in it changes. It is also known as swellingsoil.Expansivesoilsaretypicallycomposedofclay minerals that have the ability to absorb and hold water molecules[1].Whentheseclaymineralsabsorbwater,they expand and push against anything that is above them, including foundations, roads, and sidewalks. The swelling and shrinking of expansive soils can cause damage to structures built on them, such as cracks in walls and foundations,unevenfloors,andotherstructuralproblems. This is because the soil's movement can cause the foundationsofbuildingstoshift,whichcanleadtostructural damage. Expansive soils are found in many parts of the world,buttheyareparticularlycommoninaridandsemiarid regions where there is a large fluctuation in soil moisturelevelsbetweenwetanddryseasons.Tomitigate theeffectsofexpansivesoils,engineersandarchitectsuse specializedfoundationdesignsandbuildingtechniquesthat canaccommodatethesoil'smovement,suchasusingflexible materials and creating a moisture barrier around the foundation.Expansivesoilsareparticularlyprevalentinthe states of Uttar Pradesh, Rajasthan, Haryana, Punjab, Maharashtra, Gujarat, and Andhra Pradesh [2]. In these

states, expansive soils can cover large areas, sometimes encompassingentiredistrictsorregions.Forexample,the Indo-Gangetic plain, which spans across several states in northern India, is known for its expansive soils [3]. Stone dustiscreatedwhenlargerstonesarecrushedintosmaller pieces.Thedustisproducedduringthecrushingprocess,as thestonesarebrokendownintosmallerandsmallerpieces [4].Stonedustisoftenmixedwithothermaterials,suchas sand or cement, to create a stable base for a variety of constructionprojects.Theuseofstonedustforstabilizing expansivesoilforpavementconstructionhasbeenstudiedin severalresearchstudies.Stonedusthasbeenfoundtobean effective stabilizer for expansive soils due to its ability to improvesoilpropertiessuchascompaction,shearstrength, andpermeability.Onestudyevaluatedtheuseofstonedust for stabilizing expansive soil in pavement construction in India[5].Thestudyfoundthattheadditionofstonedustto the expansive soil improved its California Bearing Ratio (CBR), which is a measure of the soil's strength and loadbearing capacity. The study also found that stone dust reduced the soil's plasticity index and improved its permeability.AnotherstudyconductedinNigeriaevaluated the use of stone dust for stabilizing expansive soil in pavement construction. The study found that stone dust improvedthesoil'sCBRandreduceditsswellpotential[6]. The study also found that the addition of stone dust improved the soil's workability and reduced its susceptibilityto erosion. Overall,theuseof stonedust for stabilizing expansive soil for pavement construction has shownpromisingresultsinvariousstudies.However,itis importanttonotethatthe effectivenessofstone dustasa stabilizer may depend on factors such as the type and amount of stone dust used, the soil properties, and the environmentalconditions.Therefore,itisrecommendedto conductsite-specifictestingandevaluationtodeterminethe most appropriate stabilizer and application rates for a particularproject.

2. LITERATURE REVIEW

Inthepastfewyears,alotofworkhasbeendonetostabilize theblackcottonsoil. Hereareafewimportantpapersthat arerelatedtothispaper.

[7]ZuhaibZahoorShawl etal.(2017) withtheadditionof 4%,8%,and12%stonedust,respectively,theclayeysoil's

plasticlimithasraisedfrom24.4%to25.58%,26.2%,and 27.45%,makingthesoilmoreworkable.Itwasdemonstrated thatadding4%,5%,and6%lime,respectively,causedthe liquid limit to first rise from 33.8% to 35.3% and subsequentlyfallto35%and34.6%.Withlimecomparedto stonedust,therewasahigherreductionintheplasticlimit.

[8]RakeshVerma etal.(2017) studiedtheStabilizationof soils is an effective method for improvement of soil properties and the pavement system performance. The poorestsoilamongallisBlackCottonSoil(BCSoil).Itwas observedthattheadditionof2%ofCementand1%Sawdust decreasestheliquidlimitby3.70%. M.D.D.increasedslightly by6.29%and5.59%at2%ofCementand1%Sawdust. It wasobservedthattherewasadecreaseinO.M.C.of3.4%at2 %ofCementand1%Sawdustcontent. TheC.B.R.valueof blackcottonsoilimprovesconsiderablyto4.60timeswith2 %ofCementand1%Sawdustcontent.

[9]SujitVaijwadeetal.(2018)fromthispaper,themaximum drydensity(MDD)ofsoilincreaseswiththeadditionofstone dustandplasticstripswithsoilandtheoptimummoisture content(OMC)isdecreasingwiththeadditionofstonedust andplasticstrips.Themaximumdrydensityis1.94g/ccand theoptimummoisturecontentis18.91%at15%stonedust and 1.5% plastic strip. This is the optimum percentage of addition of material. Further addition of stone dust and plastic strips the maximum dry density decrease and the optimummoisturecontentincreases.

[10]SharmaS.etal.(2018)[10]Thispaperaimsatstudying the effects of marble dust powder and sawdust contentas mixtures in clayey/expansive soil and its engineering properties. OMC was decreased by 10.74% at 10% on the addition of marble dust. Further it is decreased at 20% marbledustby20.26%.MDDofmarbledustpowderat10% isincreasedby2.18%anditisincreasedby9.83%at20% marble dust. The UCS value is increased by 2.12% on the additionof10%marbledustand4.78%at20%ofmarble dust. The C.B.R. value of black cotton soil improves considerablyto10.16%on6%Sawdustcontent.

[11]R.Y.Kaleetal.(2019)OMCdecreasesasthestonedust andLimecontentincreasesupto1%.Thereafteritsuddenly increasesat2%anddecreasesthereafterwithanincreasein stonedustandLimecontent.TheUnconfinedCompressive Strength increases as the stone dust and Lime content increaseupto2%thereafteritdecreasesgraduallywithan increase in stone dust and Lime content. The CBR value increasesasthestonedustandLimecontentincreaseupto 2%thereafteritdecreasesslightlywithanincreaseinstone dustandLimecontent.

3. MATERIAL USED

The soil sample was collected from Jabalpur, Madhya Pradesh,IndiaasshowninFig.1(a).Stonedustwascollected

4. SAMPLE PREPARATION FOR THIS STUDY

Oncethesoilisair-dried,itshouldbecrushedandsievedto removeanylargeparticlesordebris.Asoilcrushercanbe used for this purpose, followed by a series of sieves to separatethesoilintodifferentsizefractions.Thefollowing arethesamplepreparationstepsfortheatterberglimit,free swell index, compaction, UCS and CBR test according to IndianStandardIS:2720(Part-5)-1985,IS:2720(Part-40)1977,IS:2720(Part-7)-1980,IS:2720(Part-10)-1991and IS:2720(Part-16)-1987.

5. RESULT AND DISCUSSION

5.1 Consistency Limit

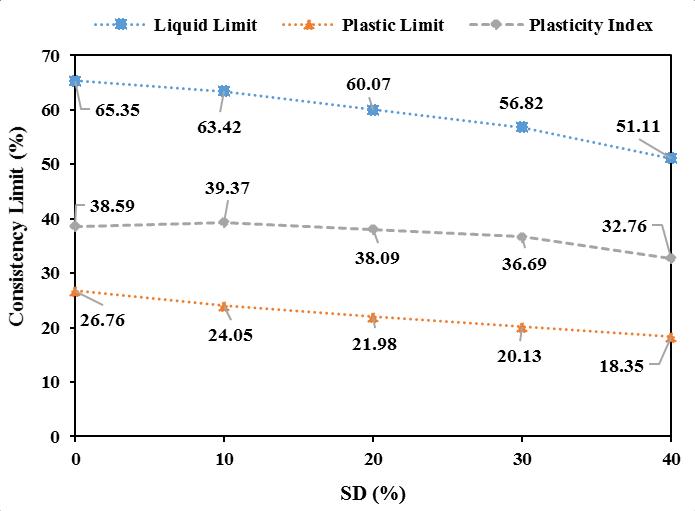

Thevirginsoil'sliquidlimitandplasticityindexwerefound tobe65.35%and38.59%,respectively.For10,20,30,and 40% of SD-treated soil, the liquid limits were found to be 63.42,60.07,56.82,and51.11%,respectively.Accordingto Fig. 2, the Plasticity Index for 10, 20, 30, and 40%, respectively,wasdeterminedtobe39.37,38.09,36.69,and 32.76%[12].

Fig. 2 ConsistencylimitofESinclusionofSD

5.2 Compaction Characteristics

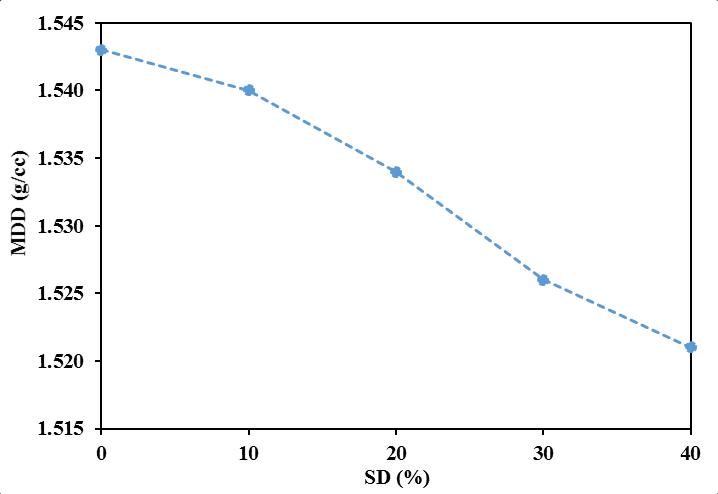

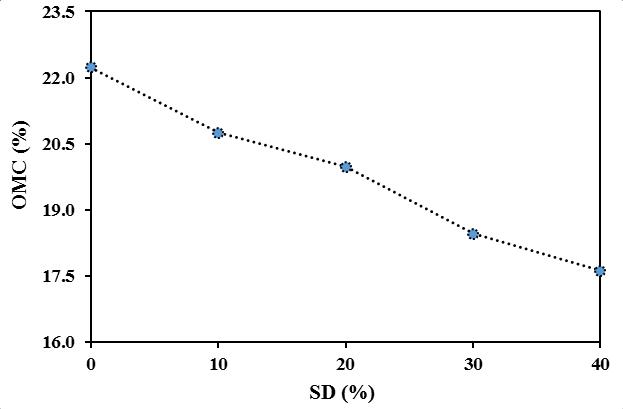

According to IS 2720 (Part-7) 1983, the Standard Proctor MethodisusedtodeterminetheOptimumMoistureContent (OMC) and Maximum Dry Density (MDD) [13]. OMC and MDDaredeterminedtobe 22.23%and1.543g/cc forthe naturalsoil,respectively.AccordingtoFig.3,OMCisfoundto be20.75,19.98,18.46,and17.62%for10,20,30,and40% ofSDtreatedsoilsamples,respectively.AccordingtoFig.4, MDDisdeterminedtobe1.540,1.534,1.526,and1.521g/cc for10,20,30,and40%ofSD,respectively.

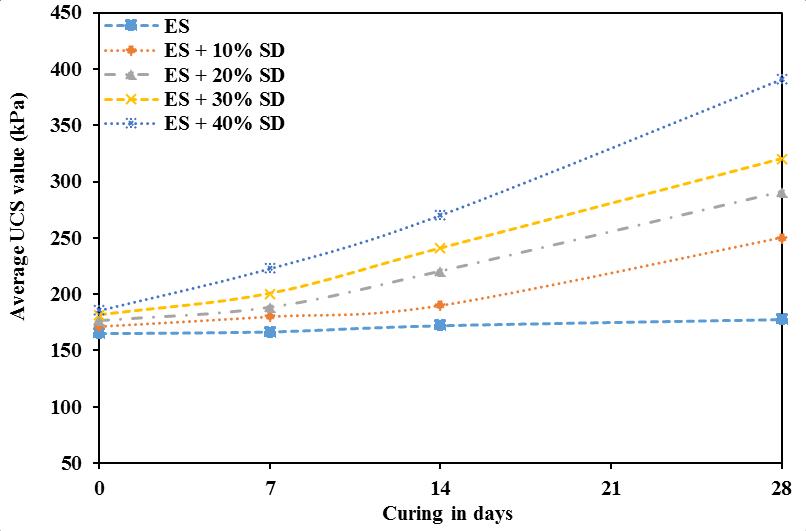

5.3 Unconfined Compressive Strength

UnconfinedCompressiveStrength(UCS)isdeterminedfor naturalsoilandforSDtreatedsoilasperIS2720(Part10) [14]. According to Fig. 5, The UCS value of natural soil is foundtobe165.23kPa.TheUCSvalueofSDtreatedsoilis foundtobe180.23,188.86,200.58and222.89kPafor10, 20,30and40%ofSDat7daysofcuringrespectively.The UCSvalueofSDtreatedsoilisfoundtobe190.12,220.77, 240.82and270.36kPafor10,20,30and40%ofSDat14 daysofcuringrespectively.TheUCSvalueofSDtreatedsoil isfoundtobe250.03,290.85,320.32and390.99kPafor10, 20,30and40%ofSDat14daysofcuringrespectively.

5.4

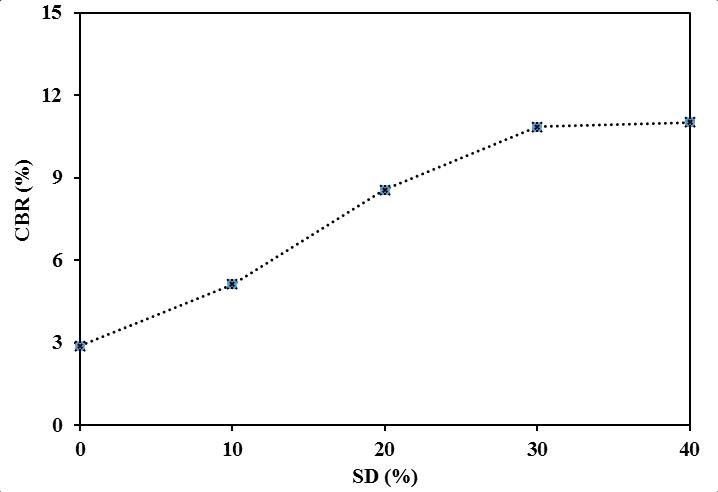

AccordingtoIS:2720(Part16),theCaliforniaBearingRatio (CBR)iscalculatedforbothnaturalandSD-treatedsoil[15]. Thenaturalsoil'sCBRvalueisfoundtobe2.89%.According toFig.6,theCBRvaluesforsoiltreatedwith10,20,30,and 40%ofSDare5.12,8.56,10.85,and11.01%,respectively.

6 CONCLUSIONS

The locally accessible clay soil stabilized with stone dust greatlyenhancedthegeotechnicalqualitiesofthesubgrade inviewofexpectedimprovementsinthesoilsubgrade.The primaryconclusionsthatcanbetakenfromtheresultsand discussionsaboveareasfollows.

1.LiquidLimitandplasticityindexwiththeincreaseinthe percentageofStonedustupto40%increasedby21.79and 15.11%ascomparedtovirginsoilrespectively.

2.AscomparedtothenaturalsoilsamplescontainingSDup to40%,OMCwasreducedby20.74%,andMDDincreasedby 1.43%comparedtovirginsoiltreatedwithSDupto40%.

3.WiththeinclusionofSD,theUCSvaluehasimprovedby up to 33.64, 56.89, and 119.83% at 7, 14, and 28 days of curing,respectively.

4. In comparison to a virgin soil sample, the CBR value increasedby280.96%withanincreaseinSDpercentageup to40%.

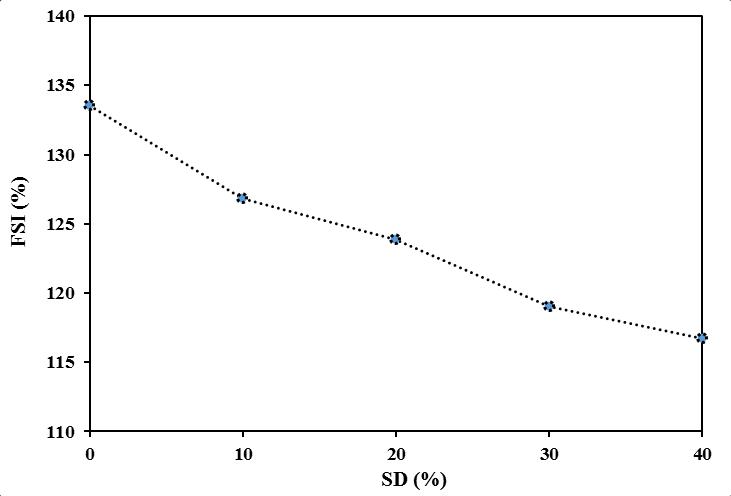

5. FSI of treated soil by mixing of SD was decreased by 12.60%ascomparedtothenaturalsoilsample.

5.5

AccordingtoIS:2720(Part40),theFreeSwellIndex(FSI)is calculatedforbothnaturalandSD-treatedsoil[16].Natural soil has an FSI of 133.56%, which is a very high value. AccordingtoFig.7,theFSIforsoiltreatedwith10,20,30, and40%SDwasdeterminedtobe126.85,123.87,119.02, and116.73%,respectively.

REFERENCES

[1] Singh, D., & Kumar, V. (2022). Stabilization of Black Cotton Soil by Using RBI Grade-81: A Review. In Proceedings of Indian Geotechnical and Geoenvironmental Engineering Conference (IGGEC) 2021, Vol. 1 (pp. 53-59). Singapore: Springer Nature Singapore.https://doi.org/10.1007/978-981-19-47391_5

[2] Singh,D.,Kumar,V.,&Tiwari,R.P.(2023).Assessment ofEffectofGlassFiberontheGeotechnicalPropertiesof Black Cotton Soil. In IOP Conference Series: Materials ScienceandEngineering(Vol.1273,No.1,p.012019).

IOP Publishing. https://doi.org/10.1088/1757899X/1273/1/012019

[3] Agarwal, N. (2015). Effect of stone dust on some geotechnical properties of soil. IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE), 12(1), 61-64.

[4] Ramadas, T. L., Kumar, N. D., & Aparna, G. (2010, December). Swelling and strength characteristics of expansive soil treated with stone dust and fly Ash. In Indian geotechnical conference-2010, GEOtrendz (pp. 16-18).

[5] Dixit,M.S.,&Patil,K.A.(2016).Utilizationofstonedust to improve the properties of expansive soil. International Journal of Civil Engineering and Technology(IJCIET),7(4),440-447.

[6] Reddy, D. V. S. S., Anusha, E., Chittaranjan, M., (2017), “Effect of Lime and Stone Dust Admixtures on GeotechnicalPropertiesofanExpansiveSoil”,October 2017,Volume4,Issue10,ISSN-2349-5162.

[7] Shawl, Z., Prakash, V. and Kumar, V., (2017), “ Use of Lime and Saw Dust Ash in Soil Stabilization ”, InternationalJournalofInnovativeResearchinScience, EngineeringandTechnology,ISSN(Online):2319-8753, ISSN(Print):2347-6710,Vol.6, Issue2, February2017, PP.1682-1689.

[8] Verma,R.,Saagar,S.,Ray,C.,Panwar,L.andRathore,M., (2017),“StabilizationofBlackCottonSoilUsingSawdust and Cement”, International Journal for Scientific ResearchandDevelopment, ISSN(online):2321-0613, Issue09,2017,PP.728-731.

[9] Vaijwade,S.,Paithane,p., Dandge,A.,Meraj,S.,Farhan,S, andAdil,B.,(2018),“StabilizationofBlackCottonSoilby UsingStoneDustandPlasticGlassStrips”,International JournalofInnovativeResearchinScience,Engineering and Technology, ISSN(Online):2319-8753, ISSN(Print):2347-6710, Vol. 7, Issue 5, May 2018, PP. 5527-5533.

[10] Sharma, S., Verma, K. and Sharma, J., (2018), “Experimental study of stabilization of Expansive soil mixed with Sawdust and Marble dust” MATEC web of conference162,2018,PP.2/12-7/12.

[11] Kale,R.,Chaudhari,K.,Bhadange,K.,Chune,V.,Kadu,G. andTidke,A.,(2019),“Effectofsawdustashandlimeon expansive soil (black cotton soil)”, International Reasearch Journal of Engineering and Technology (IRJET),e-ISSN:2395-0056,p-ISSN:2395-0072,Volume: 06,Issue:04,Apr2019,PP.3916-3921.

[12] IS:2720(Part5)-1985.Methodsoftestforsoils:Part5 determinationofliquidandplasticlimit.

[13] IS:2720(Part7)-1980.Methodsoftestforsoils:Part7 determination of water content-dry density relation usinglightcompaction.

[14] IS:2720(Part10)-1973.Methodsoftestforsoils:Part 10determinationofunconfinedcompressivestrength.

[15] IS:2720(Partl6)-1979.Methodsoftestforsoils:PartI6 laboratorydeterminationofCBR.

[16] IS:2720(Part40)-1977.Methodsoftestforsoils:Part 40determinationoffreeswellindexofsoils.