International Research Journal of Engineering and Technology

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

2395-0072

International Research Journal of Engineering and Technology

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

2395-0072

4, Assistant Professor III, Department of Mechanical Engineering, Kumaraguru College of Technology, Coimbatore, India. ***

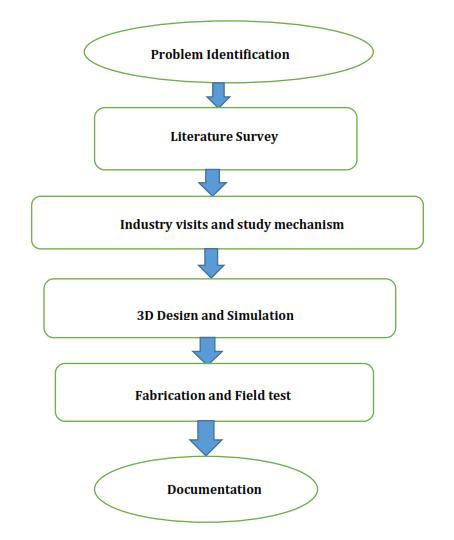

AgricultureisamajorpillaroftheIndianeconomy,soagriculturalindustryemploys60percentofthelaborforceand generates around 17 percent of the country's GDP. But several smallholder farmers struggle to maintain or increase productivity due to improper weed management. Weed control is essential for agriculture. The act of weeding involves removingweedsfrom a field.Weedscompete withcropsfor resourcesincluding nutrients,light, water,and other things needed for growth. There are numerous ways to manage weeds. All agricultural operations in modern agriculture use sophisticatedfarmmachineryliketractors,harvesters,andweeders,whichspeeduptheprocessandsimplifylabor.Large landownersemploymorepowerfulmachinerytoweedalargerarea,butsmalllandownerscannotaffordit.Thegasoline usedbytheseweed-eliminatingdevicesismoreexpensivetoday,andthepollutionitproducesisbadfortheenvironment. To promote plant growth and boost productivity, fertilizing crops is important in agriculture. Farmers use fertilizer sprayers to fertilize their crops, which requires more labor and time. Here, an already-existing weed-elimination equipmentisupgradedtothenextlevelbysubstitutingelectricmotorsandbatteriesasreplacingtheengineandfuel.The replacementismoreenvironmentallyfriendlyandlesspolluting.Byattachingafertilizersprayertotheweeder,hencethe twoprocessesarecombined.Smalllandownerscanaffordit,andfarmerswillbenefitfromit

Keywords - weedmanagement,smalllandowners,promoteplantgrowth,boostproductivity.

Foodisabasicneedofalllivingthings.Forfood,werelyonbothplantsandanimals.Ancientmenstartedfarmingfoodin a smallareaandfollowedspecificpracticesformanagingandenhancingit.Agricultureisthepracticeofcropcultivation.In agriculture, there are several factorstotakeintoaccount,likethetypeofcrop, the soil'scharacteristics,the climate, etc., particularlyweedcontrol.Inagriculture,weedcontrolisessential.However,weedingneedstobedoneinthefields.Asort ofpestcontrolknownas"weedcontrol"aimstopreventorslowthegrowthofweeds,particularlynoxiousweeds,inorder to lessen their competition with desired flora and fauna, including domesticated species. The act of weeding involves removingweedsfromafield.Itisaproductivepre-harvesttechniqueformanagingcropyieldandcropprotection.Weeds compete with crops for resources including nutrients, light, water, and other things needed for growth. There are numerouswaystomanageweeds.Allagriculturaloperationsinmodernagricultureusesophisticatedfarmmachinerylike tractors, harvesters, and weeders, which speed up the process and simplify labor. Large landowners employ more powerfulmachinerytoweedalargerarea,butsmalllandownerscannotaffordit.Theseweed-eliminatingmachinesneed gasoline, which is more expensive nowadays and contributes to pollution that is bad for the environment. To promote plant growth and boost productivity, fertilizing crops is important in agriculture. Farmers use fertilizer sprayers to fertilize their crops, which requires more labor and time. Application of liquid fertilizer is an appropriate technique for usageinavarietyofdrylandandsoilerosion-pronelocations.Here,liquidfertilizerisincluded inthesprayertoimprove the procedure' effectiveness.Aspecific set of crops are targeted by liquidfertilizer, andthere isnochanceoflossdue to evaporation or exposure to the wind.Theseagricultural sprayersaid incrop establishmentand encourage earlyrooting. Liquid fertilizer application also serves as irrigation in addition to providing vital nutrients. Application technique has a significantimpactonhoweffectivelyplantsgrow.Sprayingplantgrowthregulatorshasaspeedierimpactontheflowering andfruitingoffloweringcropsaswellasthefloweroutput.Oneofthisapplication'sbiggestbenefitsisthattreatmentwill be quicker. When agricultural machinery is used in farming operations, human labor is minimized. The introduction of chemical pesticides, better seed varieties, and enhanced farming machinery have all contributed to greater production. Theproductivityofworkershasincreasedasaresultoftheuseofmachines.Thequantityoflaborperformedbypeopleis reduced while using cutting-edge farm technology and equipment. The time spent on unnecessary farming chores was decreasedbecausetheconstructionoffarmmachineryorimplementswascompletedonschedule.Utilizingcontemporary

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN: 2395-0072

agriculturalmachineryandtechnologylowerslaborcostsandimprovesfarmprofitability.Agriculturaltoolscanincrease agriculturaloutputandmarketfoodsupplies.

Thisconceptsaysaboutsensorsincludingimageanalysisbycamera,GNSS,laserandultrasonicsystems.Thesesensors can improve weed control efficacy in combination with mechanical systems. They also have used RTK-GPS for inter-row hoeing.Theyarenowwidelyusedinmanydifferentcropssuchasespeciallywidespacedcropslikesugarbeets,maizeor soybean [1]. This concept says about various types of mechanical weeder by year wise from 2000-2019.Weeders like Mandava-SingleRowWeeder,Rowcropweeder,Manualweeder(V-frame),HymaticConoWeeders,Rotarypowerweeder, Intra row soil weeder. Mechanical weeder has shown to be evolving in design, principle and mechanism over the years reviewing merits, demerit andlimitations [2]. Thisconcept says thatweedremovingtechnique(i.e.)theautomaticweed control systems provide efficient method of weed removing within the rows and inter rows. The machine vision system hasbeenusedtodetectanddifferentiatetheweedsfromthecrop.Guidancesystemhasbeenusedtotracktherowswith accuracyandtocontrolarowcultivatorandanautonomousagriculturalrobotinreal-time.Mechanicalknifeandrotating hoe are two basic designs in mechanical systems for weed removal [3]. This concept says about automation, integrated weed management, intelligent cultivator, interrow weed control, mechanization, robotic weeding, vegetable crops. Also, machine vision technology to recognize crop row patterns and control automated devices that perform tasks such as removalofinterrowweeds.Futureweedcontrolstrategieslikeweedcontrolactuatorsonfuturemodelsmayuseabrasion with sand blown in an air stream or heating with flaming devices to kill weeds [4]. This concept says that they have designed the three-row manual operated powerweederusingCATIAtool. Theyhaveanalyzedthedesignin Ansys Work Benchforsafedesign.Designanddevelopmentcostreducedforpoorfarmersandfunctionalefficiencyresultsin88%[5]. This concept says that they have investigated about the weed control chemicals and methods used in various countries. Integratedweedmanagement(IWM)aholisticapproachtoweedmanagementthatintegratesdifferentmethodsofweed controltoprovidethecropwithanadvantageoverweeds.IWMhaspotentialtorestrictweedpopulationstomanageable levels, reduce the environmental impact of individual weed management practices, increase cropping system sustainability, and reduce selection pressure for weed resistance to herbicides [6]. This concept says that they have investigatedaboutsolarpoweredweederandalsostudiedthedesignofweedingmechanism,shouldconsiderbothweed parameters and soil parameters. From study it had been found that the solar power system should consist of the solar panel, solar charge controller, battery backup, load controller as per designed parameters. solar powered robot Weeder and also there is a scope of increase in efficiency of developed. solar powered rotary Weeder by modifying design of weedingmechanismandelectriccircuit[7].Thisconceptsaysaboutdevelopmentofagriculturemachinery(i.e.)4stroke weedingmachines.Thismachinesquaremeasurewideusedforweedingcotton,tomato,tapioca,paddy,sugarcane,pulses andnumerousalternativeplantfields.Thus,thedevelopmentwillsatisfythesmall-scalefarmersfor weedremoving[8]. Thisconceptsaysthattheyhavedevelopedsimpledesignofmovablesolaroperatedsprayerforfarmingoperation.Inthis, thesystemoperatesinbothdirectmodeandindirectmode.Inthedirectmode,thesprayerisoperatedfromtheelectricity generated by 50W solar panel mounted on a movable frame and in the indirect mode it is operated on stored electrical energyinthelead-acidDCbattery.Theresultshowsthatthesystemisefficient,portableandprovidesatleast8hoursof operationdaily,butinitialcoatishigher[9].Thisconceptsaysthattheyhaveanalyzedtheprocessofsprayingfertilizer or pesticidesandweedremovaltechnique.Theyusedreciprocating¢rifugalpumps,connectinglink,crank,nozzles,belt drives,wheel.Theequipmentispurposelydesignforthefarmershavingsmallfarminglandsay5-6acre.Itissuitablefor sprayingaswellasweedingatminimumcostforthefarmersothathecanaffordit[10].

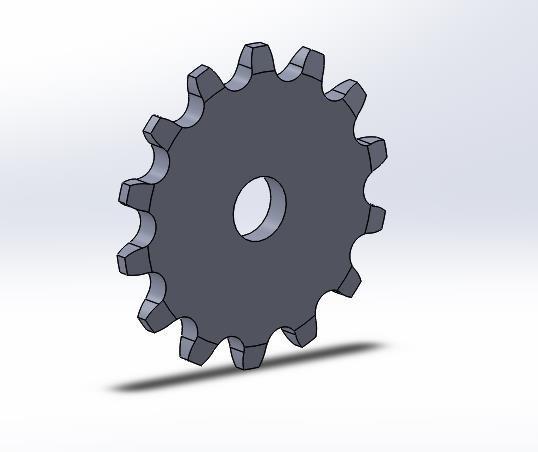

CHAIN SPROCKET:

A sprocket,sprocket-wheel or chain wheel is a profiled wheel with teeth, or cogs that mesh with a chain, track or other perforatedorindentedmaterial.Sprocketsareusedinbicycles,motorcycles,trackedvehicles,andothermachineryeither totransmitrotarymotionbetweentwoshaftswheregearsareunsuitableortoimpartlinearmotion

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

CHAIN:

p-ISSN: 2395-0072

Rollerchainorbushrollerchainisthetypeofchaindrivemostcommonlyusedfortransmissionofmechanicalpoweron many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links.Itisdrivenbyatoothedwheelcalledasprocket.Itisasimple,reliable,andefficientmeansofpowertransmission.

MOTOR:

ThisisMY101625OWeBikeMotorwithElectricBicycleComboKitwhichhasallassemblyproductyouneedtobuildyour eBike.ItisanElectricBicyclepermanentMagnetDCMotor.MY1016 24-volt250-wattoutputforelectricscooterandbike motor. This MY1016 is popular reduction motor, simply the most commonly used motor for Scooters, Bikes and quad’s availableinthemarket!Itisnormallyfoundinthebetter-qualityquadsandscootersonthemarketandisclassedasamidrange combination. Now here it comes combo with all necessary items to build your brand new eBike and to save your effortsinlookingoutforallcompatibleproductsandyoucangetitinjustonegoatreasonablecost.

Motor

Voltage:24VoltDC.

Output:250Watt. RPM(afterReduction)–300.

Fullloadcurrent–13.4A.

NoloadCurrent–2.2A.

TorqueConstant–8N.m(80kg-cm).

Torquestall–40N.m(400kg-cm).

Sprocket:

9Toothonlyfits#410bicyclechains. ForChainSize:Pitch0.5inch.

RollerDiameter0.3inch.

RollerWidth0.16inch.

Volume: 10 Issue: 04 | Apr 2023

WEEDER BLADE:

The crucial component of a stainless steel rotavator that propels the device in seed bed preparation and residual soil mixingistheblade.Rotavatorbladescanalsobeusedasweedeatersbycuttingthroughweedplants.(LxWxH)–(10x 10x10)centimeters.

CYLINDRICAL ROLLER:

Ashaftisarotatingmachineelementwhichisusedtotransmitpowerfromoneplacetoanother.Thepowerisdeliveredto the shaft by some tangential force i.e. twisting moment. In order to transfer the power from one shaft to another, the variousmemberssuchaspulleys,gearsetc.aremountedonitbymeansofkeysorsplines.Wemaysaythatashaftis used forthetransmissionoftorqueandbendingmoment.

SPRAYER:

Asprayerisadeviceusedtosprayaliquid,wheresprayersarecommonlyusedforprojectionofwater,weedkillers, crop performance materials, pest maintenance chemicals, as well as manufacturing and production line ingredients. In agriculture, a sprayer is a piece of equipment that is used to apply herbicides, pesticides, and fertilizers on agricultural crops. Sprayers range in size from man-portable units (typically backpacks with spray guns) to trailed sprayers that are connectedtoatractor,toself-propelledunitssimilartotractorswithboommountsof4–30feet(1.2–9.1m)upto60–151 feet(18–46m)inlengthdependingonengineeringdesignfortractorandlandsize.

SPEED CONTROLLER:

Acircuitthatelectronicallymonitorsandcontrolsanelectricmotor'sspeedisknownasanelectronicspeedcontrol(ESC). Furthermore, it might offer dynamic braking and motor reversal. In radio-controlled models with electrical power, tiny electronic speed controls are employed. Systems for managing the drive motors' speed are also included in fullsizeelectriccars.

SHEET METAL:

Sheet metals are used historically for plate armor worn by cavalry and widely used for decorative purposes. The applications of sheet metals include automobile and truck (lorry) bodies, medical tables, airplane fuselages and wings, roofs for buildings (architecture), and many other applications. Sheet metal made of iron and other materials with high magnetic permeability has good applications on electric machines and transformers. Thickness of sheet metals are specified in millimeters all around the world. But in US it is commonly specified by a traditional, non-linear measure knownasgauge,thelargerthegaugenumberthethinnerthemetal.Themostcommonusedsteelsheetmetalrangesfrom 30toabout7gauges.

Volume: 10 Issue: 04 | Apr 2023

A lithium-ion (Li-ion) battery is an advanced battery technology that uses lithium ions as a key component of its electrochemistry.Duringadischargecycle,lithiumatomsintheanodeareionizedandseparatedfromtheirelectrons.The lithium ions move from the anode and pass through the electrolyte until they reach the cathode, where they recombine with their electrons and electrically neutralize. The lithium ions are small enough to be able to move through a micropermeableseparator betweentheanodeandcathode.Inpartbecauseoflithium’ssmallsize(thirdonlytohydrogenand helium),Li- ionbatteriesarecapableofhavingaveryhighvoltageandchargestorageperunitmassandunitvolume.

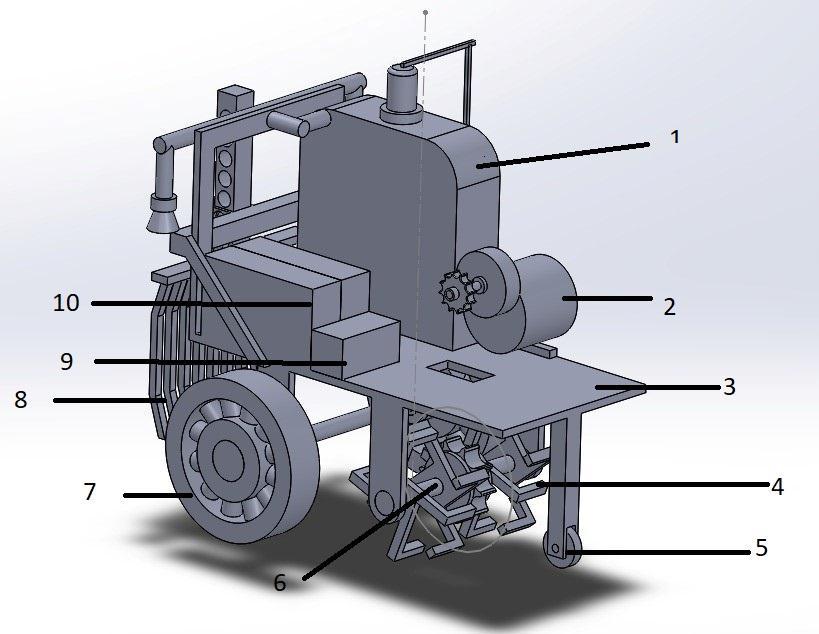

Theweederwasdesignedforuplandcrops. Three-dimensionaldrawingofthepowerweederwasdonebySOLIDWORKS 2018.Fromthatdrawingfrontandsideviewsweredrawnandallfunctionalpartsweredrawnwithdimensionsinmm.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN: 2395-0072

Sr. No Title Value

1. Fertilizertank (lxhxw) (34x44x18)cm

2. Bladeradiusfromcenter 12.5cm

3. Wheeldiameter 40cm

4. Pumpstrokeperrotationofwheel 1

5. Pumprateofdischarge 0.5litreperminute

6. Fertilizertankcapacity 16litres

7. Overallheightofprototype 90cm

Theprototypeistestedontheagriculturallandandgotthebetterresultsthancomparedwith traditionalmethod.

Laborcost=Rs300perday

Laborcost=Rs300perday

(Butitwoulddo3laborsworkasasinglemachine)

Costoffertilizerspraying=Rs50perfulltank Bothoperationsaredonesimultaneously.Hencenocost

Thenormalengine-basedweederruns1hourperlitrewhereastheprototyperuns1.5hourspersinglefullchargeandit carriesbothoperationssimultaneously.Hencetheefficiencyoftheprototypeisgreaterthanotherengine-basedweeders.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN: 2395-0072

Sincetheprototypeismadeforsmallscalefarmerstosavetimeandlaborcost.Easilyfarmerscouldhandlethisprototype. The prototype is mini electric weeder attached with fertilizer sprayer which could be an effective for weeding and fertilizingthecropssothiscouldhelptoincreaseproductivityinthefields.Byusingthisprototype,thecropsliketomato, potato,cabbage,guava,pomegranatecanbeweeded Thefuturescopeofthisprototypewouldbedonefullyautomatically withthehelpofsensors,IOT,etc...,

[1] Jannis Machleba, Gerassimos G. Peteinatosa, Benjamin L. Kollendaa, Dionisio Andújarb, Roland Gerhards (2020) "Sensor-based mechanical weed control: Present state and prospects", Centre for Automation and Robotics, CSIC-UPM, ArgandadelRey,Madrid28500,Spain.

[2] AdewaleMosesSEDARAID,OluwadunsinSeunSEDARAI(2020)"AReviewonInter-rowCropsMechanicalWeeder", Department of Agricultural and Environmental Engineering, School of Engineering and Engineering, The Federal UniversityofTechnology,Akure,NIGERIA.

[3] Mantraksha Jamdade, Radhika Yadav, Sanskriti Patil (2020) " WEED REMOVING ROBOT", Research Scholar, ElectronicandTelecommunication,AISSMS,IOIT,Pune,India.

[4] StevenA.Fennimore,DavidC.Slaughter,MarkC. Siemens,RamonG.Leon,andMazinN.Saber(2016)"Technology forAutomationofWeedControlinSpecialtyCrops",PublishedonlinebyCambridgeUniversityPress.

[5] Rajashekar M, V K Heblikar, S. Mohan Kumar " SIMULATION AND ANALYSIS OF LOW-COST WEEDER", Research Scholar,Mech.Engg.Department,SDMCET,Dharwad,Karnataka,INDIA.

[6] K. Neil Harker and John T. O’Donovan (2013) "Recent Weed Control, Weed Management, and Integrated Weed Management",PublishedonlinebyCambridgeUniversityPress.

[7] HemantMeenaandDr.SSMeena(2021)"AreviewstudyonsolarpoweredWeeder",DepartmentofFarmMachinery and Power Engineering, College of Technology and Agricultural Engineering, Maharana Pratap University of Agriculture andTechnology,Udaipur,Rajasthan,India.

[8] DivyanshChaturvedi,SahilKhan,ShivamDeshpande,KrishnaSingh(2022)"DEVELOPMENTOFAUTOMATICPOWER WEEDERCUMFERTILIZERSPREADERMACHINE",Dept.ofMechanicalEngineering,OrientalUniversity,India.

[9] Abdulmumuni, B, Azeez, R.O, Okpara I.N, Fanifosi, J.O and Ologunye O.B (2020) " DESIGN, FABRICATION, AND TESTING OF A MOVABLE SOLAR OPERATED SPRAYER FOR FARMING OPERATION", Department of Mechanical EngineeringTechnologyFederalPolytechnicEde,OsunState,Nigeria.

[10] Laukik P. Raut, Smit B. Jaiswal, Nitin Y. Mohite (2013) " Design, development and fabrication of agricultural pesticidessprayerwithweeder",SVSSNagpur,India.