COCONUT DEHUSKING MACHINE

1,2,3,4,5Student,Dept.of Electrical Department,Yashwantrao Bhonsale Polytechnic,Maharashtra,India

6Faculty, Dept.of Electrical Engineering , Yashwantrao Bhonsale Polytechnic, Maharashtra ,India

Abstract - After the Philippines and Indonesia, India is the third-largest producer of coconut in the world. Over 70% of the world's coir and coir product output is produced by India alone. Three percent of the world's population uses it. Before being used for any of its functions, the coconut must first be de-husked. Each component of thecoconut, including the husk, shell, copra, and water, has a purpose.The huskofthecoconut, the shell, copra, and coconut water are all used in the production of coir. There are several ways to remove the coconut's husk. Farmers generally use the traditional method of manual dehusking. Dehusking with a conventional hand implement, such as a spike or machete,requirestraininganda skilled worker. There is a shortage of such skilled individuals today. By using machines more frequently, the time and labor costs incurred can be significantly reduced. This machine's primary function is to fully automate the de-husking and husk removal process, doing away with the need for a skilled operator to dehusk the coconut. Due to the expensive expense, not all coconut farmers can afford to acquire the automated equipment utilized in wealthy nations. This project aims to create a dehuskingthat is less expensiveand more productive. The dehusking machine is superior to hydraulic dehusking machines since it is more reasonably priced. Two revolving shafts with spikes are installed on a frame and are part of the machine. A single-phase motor rotates the shafts. Using a gearbox reduces the output speed. The husk of the coconut is removed when it is positioned between two spiky shafts revolving anticlockwise. This project is primarily intended for businesses that scratch coconuts for profit to reduce labor costs and save time.

Key Words: Dehusking,Tynes,Husk,Cylinders

1.

INTRODUCTION

After Indonesia and the Philippines, India is the thirdlargest producer of coconuts worldwide. This project's primarygoalistospeedupthedehuskingofcoconutswhile reducing the amount of labor required from humans. Almostallofacoconut'spartsarebeneficial.

Whilethemeatofamaturecoconutfruitcanbeusedtomake shreddedcoconutor eatenfresh,themeatof animmature coconut fruit can be converted into ice cream. The husk produces fibers that are used to make coir products includingcoircarpetsandcoirgeotextile.

Byintroducingthis machine in farm areas, it is possible to lessen the risk

associatedwithusingspikes toremovethecoconut'shusk and do away with the needfor specialized labor to do so. Dehusking is the processof removing the coconut's husk. Moreover, the systemcould be integrated with additional processing processes.Withtheaidoftworevolvingrollers spiked

ontheirperiphery,thiscoconutdehuskingmachine removes the coconut husk from coconut fruit to produce dehusked coconut fruit. The dehusking arrangement is connectedtoasinglephase1HPinductionmotorwiththe help of a gear & chain. The motor is connected with a changeover switch for protection from an accident. The motorisprotectedbya double pole c-type circuit breaker. Themachinehastworotatingshaftswithspikesandblades mountedonthem. The shaft is rotated by a single phase 1 HP Induction motor. The output speed is reduced by a gearbox. When the coconut is placed between spiked shafts rotating in opposite directions, the husk is peeled offfrom thecoconut. The coconut shafts rotatealong with spikesdirection&huskwillpeelofffrom thecoconut.The coconutisthrowndownwardinatray.

1.1 OBJECTIVES

Toimprovecontinuousworkcapacity.

Toincreaseefficiencythanconventionalsystem.

Tobuilduserfriendlymachine.

Todevelopaffordableautomaticdehuskerunit.

Toreduceshumanefforts

2. METHODOLOGY

Theautomaticdehuskingmachineconsistsoftworotating rollers having spikes on their periphery, whichallows the coconuttoremovethehuskfromit.Theelectricmotorasa power source connected to the gear box to move it in oppositedirection.Theaforementionedcomponentswillbe positionedontopofthesupportingstructure.Totransmitthe power from the motor to cylindrical rollers by gear & pulley transmission system. The dehusking apparatus is madeupofcylinder-shapedrollerscoupledwithcuttingpins overthesurface.Theaverageshape&sizeofthecoconutis considered while designing the space between the two rollers.

©2023,IRJET | ImpactFactorvalue:8.226 | ISO9001:2008CertifiedJournal | Page290

There are two types of dehusking rollers suitable forthis

project

1) Hydraulic rollers: Hydraulic roller has their advantages. It can adjust the spacing between two rollers automatically. In this project cost affordability is more important.Wecan’tusethistypeofroller

2) Manual rollers: The average shape and size of the coconutareconsideredwhiledesigningthespacebetween the two rollers. The main benefit of a manually adjusted rollerislesscostandeasilyaffordable.

Anothermaincomponentisthecoconutcopragrindingunit used to separate the meal from the coconut. The proper grinding is with a sharp grinding unit attached to a dehuskingmachine.

Themainheartofthisprojectisaninductionmotor.There aretwotypesofinductionmotorssuitableforthisproject.

1) Three-phase induction motor:

The three-phase induction motor is self-starting & provides higher torque than single phase one. In an automatic coconut dehusking machine for the husking process, there is no need for higher torque. Higher power means higher energy consumption. So we try to make energy efficient dehusking unit. We cannot use 3 phase inductionmotorforourproject.

2) Single-phase induction motor:

Thecircuitbreakerisconnectedformotorprotection.Type C circuit breaker is used to protect from overload & overcurrent. The changeover switch for motor Forward& Reverseoperationisconnectedinbetween

circuitbreaker& motor. It can avoid the accident when coconut looks in dehusking machine. The tearing effectcauses in between tynes&bladedrotorwillremovetheouter shell of coconut. This process is also called as dehusking process. After dehuskingprocessthecoconutfallsinbottomtray&outer shellthrowoutfromthetynes.Thishelpstocompletemass protection of coconut in less time with fewer efforts. The coconutdehuskingmachineiscarrybyeasilywithtwo wheels.

4. COMPONENTS

1) Frame

A capacitor start capacitor run single phase induction motor is the best suitable motor for this project. The torque generated by this motor is much sufficient. The single phase 1 HP capacitor start capacitor run motor generates approximately S Nm or torque. The cost of a single-phase1HPmotorislessthanathree-phaseone.

Over

project is making it affordable price so we use a single phase 1 HP capacitor start capacitor to run themotor. The power consumed by this motor is less than three a phase motor. So the efficiency increases & runningcost minimized

3. Design and Working

ThecoconutDehuskingmachineworksonsinglephase1HP Induction motor. The motor works on single phase 230 v AC 50 Hz supply. The dehusking machineis electrically operated. The single phase 1 HP motor isfitted on metal framewithgear.Themotoroutputisgiventobladedrotor and gerbox.The gearbox connected to tynes or turbine, which moves reverse direction with respect to blades rotor.

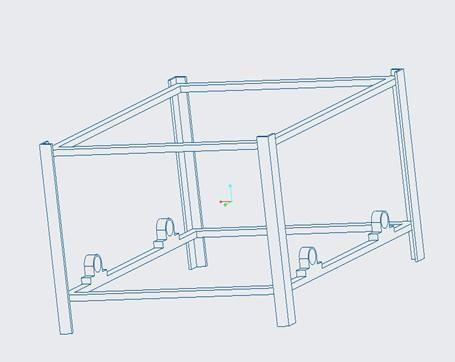

A rigid frame is a structure's load-bearing skeleton made ofstraight L-shapedcomponentsjoined byprimarilyrigid connections that obstruct motions caused by the members' joints. Members of it canwithstand axial, shear, andbendingmoments.

2) Single Phase Induction Motor

The roller shaft, which is fixed to the end of the frame structure,isfound to bedriven byit.Asizablepulley that thebeltgoesaroundisfoundatthemotor'sfreeendofthe shaft. Single-phase induction motors can operatewithjust one power phase. They are frequentlyemployed in lowpower rating applications for both household and commercialuse.AninductionmotorisanACelectric motor in which the magnetic field of the stator winding is used to electromagnetically induce the electric current into the rotor necessary to produce torque. Hence, it is possible to construct an induction motor without electrical connections to the rotor. Either a wound-type rotor or a squirrel-cage-type rotor can be used in an inductionmotor.

3) Ball Bearing

A specific type of rolling element bearing called a ball bearing uses balls to maintain the distance between the bearing races. The primary purposes of a ball bearingare to support radial and axial loads as well as to reduce rotational friction. At least two races are employed to containtheballsandconveythestressesthroughtheballs. The majority of applications link onerace to the rotating assemblywhileleavingtheother stationary(e.g.,a hubor shaft). The rotation of one ofthe bearing races causes the balls to spin as well. Because the balls are rolling, the coefficient of frictionismuchlowerthanitwouldbeiftwo flatsurfacesweremovinginoppositiontooneanother.

Due to the smaller contact surface between the balls and races, ball bearings typically have a lower load capacity for their size than other varieties of rollingelement bearings. They are tolerant of minor inner and outside race misalignment, though. Because hammering the bearings could cause them to break, they are pressed smoothly into the shafts. Mild steel makesupthebearingcapandthebearingis composed ofsteel.

4) Changeover switch

switch

The power circuit for the motor control receives a 440V single-phase supply. Finally, the Forward Start button is depressed. The Forward contactor in the power circuit isactuated when the Control Supply is applied to the NC contacts of Limit Switch 1 and Reverse Contactor, causing the motor to rotate forward (clockwise). As soon as Limit Switch 1 received the signal, it changed from NC to NO, deactivating the Forward Contactor coil. The Reverse Start button must be pressed to activate the Reverse Contactor for reverse control. Here, the control circuit energizes the reversecontactorcoil,activatingthereversecontactorin the power circuit. The power for the motor was provided bythereversecontactor.

The motor's input speed is decreased while its output torque is increased by using a reduction gearbox, also referred to as a speed reducer. The gadget is used to convertthe basic engine's outputshaftrevolutionsintothe propeller-moving revolutions. The wheels and pinions in the reduction gearbox have teeth that mesh,transferring power from a drive shaft to a driven shaftand lowering speed.

The chain, which can be used to lift or drag objects, can occasionally be rotated to generate power. Other times,a second gear is used, and the power is reclaimed by securing shafts or hubs to this gear. While though drive chains are frequently only two simple oval loops,theycan also bend around curves if there are more than twogears attachedtothechain.Theseadditionalgearsarereferredto as idler-wheels when they neither send power into the system nor take it out. The gear ratio can be changed by changing how big the input and output gears are in relation to one another. Forinstance, when thegear on a bicycle pedal spins once, the gear that drives the wheels alsorotates.

Usingachaindrive,mechanicalpowercanbemoved from onelocationtoanother.Itisfrequentlyutilizedtopower a vehicle's wheels, particularly the ones onmotorbikes and bicycles. It is used in a vast array of other machinery in additiontoautomobiles.Inordertotransmitpower,adrive chainortransmissionchain whichismostusuallyused passesoverasprocketgear,andtheteethofthegearmesh with the holes in the chain links. The gear is turned, and thispullsthechainputtingmechanicalimposingforceonthe system.

Thisisutilizedincommercialorindustrialapplicationswhen there is a potential for increased short circuit current levels in the circuit. 5 to 10 times the full loadcurrent triggers a trip on this sort of MCB. The associated loads generally have an inductive character (e.g. induction motors) Protection against overloads and short circuits, controlofcircuits,andprotectionforresistiveandinductive loads with low inrush current are all functions of type C MCBs.

8) CONCLUSIONS

In this project, we try to minimize the expenditure ofan automatic Dehusking Machine. We try to build a machine that helps farmers to reduce the time and effort to husk thecoconutusingaconventionaltool.Thismachinecanbe cost-effective compared to the existing hydraulic automatic dehusking machine. In a rural area, the conventional dehusking tool is used, which skilled labourerstodehusk coconuts,butthis machineneedscan doitinminimumtime&fewereffort.Themainpurposeof ourprojectistomake availableamachineforpeopleatan affordableprice&whichconsumeslesstime.

Variousprocessesalongwithdehuskingcouldbedonesuch asconveyerbeltbyaddingmoreattachments.InIndia due to increasing population and economy expansion, the coconutdemandandsupplymoredemanded.Totacklethe massproductionofuncoveredcoconut we need to develop the automatic aid this leads to the expansion of coconut dehusking.

On completion of this research, we would like to acknowledge the efforts of our respected faculty member Ms.T.R.Shenai,HODMr.B.M.Patil,andPrincipalMr.G.A. Bhosale for their support in conducting research and practicalimplementationoftheproject.

REFERENCES

[1] J. Jacob and K.S. Rajesh, "Design and Fabrication of Coconut Dehusking Dehusker", Institute of Electrical and ElectronicsEngineers

[2] P.V.Amal,S.Sibin,B.E.Abhiram,J.S.AlbinandProfSony Kuriakose, Design, and Fabrication of Coconut Dehusking Machine.

[3]Piyathissa.S.D.S and Kahandage.P.D, ‘Introducing an appropriate mechanical way for Coconut dehusking’, ProcediaFoodScience,6,pp.225–229,2015.

[4] R. Baracaldo and M.C. Manuel, "Design Fabrication and Performance Evaluation of a Vertical-Cylinder", SemiAutomaticCoconutDEhusker,2017