DESIGN AND FABRICATION OF BANANA FIBER EXTRACTION MACHINE

1 Professor , dept. of mechanical engineering , PSG polytechnic college , Coimbatore Tamilnadu, India

2,3,4 diploma , dept. of mechanical engineering ( sandwich) , PSG polytechnic college , Coimbatore Tamilnadu, India ***

Abstract - Nowadaysthereisarapidgrowthtowardsthe naturalfibers.Thenaturalfibersarepreferablethanartificial fibers because they are highly disposable, mechanical propertiesandappropriatestiffness.TheyoungerGeneration ismoreconcernedabouttheenvironmentandpollutioncost byartificialfibers.Thenaturalfiberslikebanana fiberare completelydecomposableandeco-friendly.

ThetraditionaltechniquesforextractingplantainFibers facesvariouslimitationssuchasmoreextractiontimeand fiberproductivityrateispoor.Thestudyaimstoovercome the limitations faced by using traditional method of extracting plantain Fibers by developing electric machine capableofdoingthemanualprocessofextractingplantain fiber. The process used includes selecting suitable design, Materials, selecting, and manufacturing of various componentsforassemblingmachineparts.

1.INTRODUCTION

Interestinusingnaturalfiberhasincreasedsignificantlyin recent years. The abundance of nature combined with exquisitecraftsmanshipisanattractiveattributethatmakes it an important alternative to potentially toxic synthetic fibers. Natural pant leg fibers have many properties that make them advantageous: low cost, low density, biodegradable,renewable,goodmechanicalpropertiesand non-toxic.

Today, natural fibers are favored for their reasonable stiffness, mechanical properties and high usability. Pay special attention to machinery Skills; Processing and Automation Mechanisms Involved in plantain fiber extractionEliminatemanual methodsandincreaseQuality and improvement of processing time .Therefore, the purpose of this study was todevelopandmanufactureone electricalPowerPlantainfiberExtractor.This extractorwill helps reduce the extraction rateof plantain fiber and the humanbodyWork.

1.1

AND PHYSICAL

It is biodegradable and has no harmful effects environment,makeiteco-friendlyfiber.

Itsappearanceissimilartobambooandramiefibers,But bananafibersarefinerandeasiertospin.

Accordingtotheextractionandspinningprocess,itisHas ashinyside

Availablein ringspinning,open-endspinning,thebest fiberspinningandsemi-worstedspinningSkill.

Itreleasesandabsorbsmoisture.

Ithasahighlystrongfiberwitha3-percentageelongation andlightinweight.

2 EXTRACTION METHODS:

ThevariousmethodofspinningbananafiberintoYarnDiffer fromonestagetothenext.Themostwidelyusedmethods arethoseusedbyJapaneseandNepalese.

Rasthali- Tamil Nadu, West Bengal, Kerala, AndhraPradesh,AssamandMizoram

Nendran-Kerala,TamilNadu

Robusta-TamilNadu,Karnataka,Bihar,Kerala, JharkhandandMaharashtra

Red Banana-Gujarat, Madhya Pradesh, Kerala, Jharkhand,KarnatakaandTamilNadu.

2.3PROFITS OF BANANA FIBER:

2.1 JAPANESE METHOD:

Bananaplantingsforclothandotheruseswereusedback in 13th century in Japan. The Japanese method was very intenseoftakingcarerightfromthestageoflandcultivation. Theleavesandshootsorcutonregularbasistomaintainthe bananastem.Firsttheshootsaregatheredandcookedinlye to manufacture Yarn. Due to this the fiber is softened in varied degrees. Due to this different kinds of yarn are produced which is used for different purposes. The outer shootarecoarsestwhichisusedforhomefurnishingslike tablecloths,Rugs,etc.Thesoftersectionistheinnercoreof thebananatreewhichproduceselegantfiberswhichwere used in traditional Japanese clothes. This process of manufacturingclothesisexpensive,andeachstageisdoneby hand.

2.2 NEPALESE METHOD:

InNepalinsteadofusingtheshootthetrunkisusedto extract fibre. yeah, small quantity of the Trunk Are soft MechanicallyfollowedbybleachinganddyingWhichresults TofiberSimilarTosilkKnownasbananasilkfibreyarn.In thisprocesstherefining,processingandseiningthefiberis donebywomen.Tospeeduptheprocesstheagedbarkor Road outer layers of the banana plant are plugged and immersed in water.Now the cellulose remains and all the chlorophyll isdissolved. After Yarnishanddyed and they haveyeahtexturesimilartosilkwhichisusedtoMakeHigh end rugs. The traditional rugs are hand Knitted by Nepal women’s.

VARIETIESOFBANANATREESGROWNINDIFFERENT STATESOFINDIA:

NeyPoovan-TamilNadu,KeralaandKarnataka

Karpuravalli-Assam,AndhraPradesh,Tamil Nadu

Virupakshi-HimachalPradesh,Assam,Andhra Pradesh,KeralaandTamilNadu

ThemainsourceofincomeinbananatreeisBranchesand leaves,whichcanbealsousedasanorganicplateforserving food at Functions, parties and public gatherings. Although theywereavailablemethodsforextractingsuchfibersand papermakingfromPseudostem,Companieshasyettoutilize them due to high levels transportation fee. However, the potentialforextractingfibersfromthePseudostemArehuge. Itispredictedthat17,500ton’soffiberworthof900crores canextractannuallyfrombananawasteofthebananafactory isapproximatelyRs.50,000perton.Duetoitsrestricteduse incottageindustries,thisfiberisNotabletofindamarket. This fiber appears a huge potential for commercial use in textilesandpaperindustry.Thebananastemcanalsobeused tomakevariousofhighqualityproductssuchasbags,rugs, basketsandTheyhavevariousformsofcrafts.Inconclusion, banana fibre has a promising future and a wide range of applicationsinthenextyears.

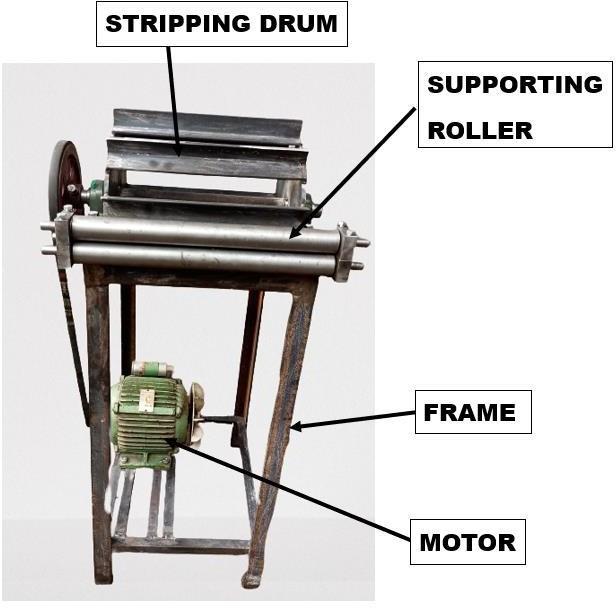

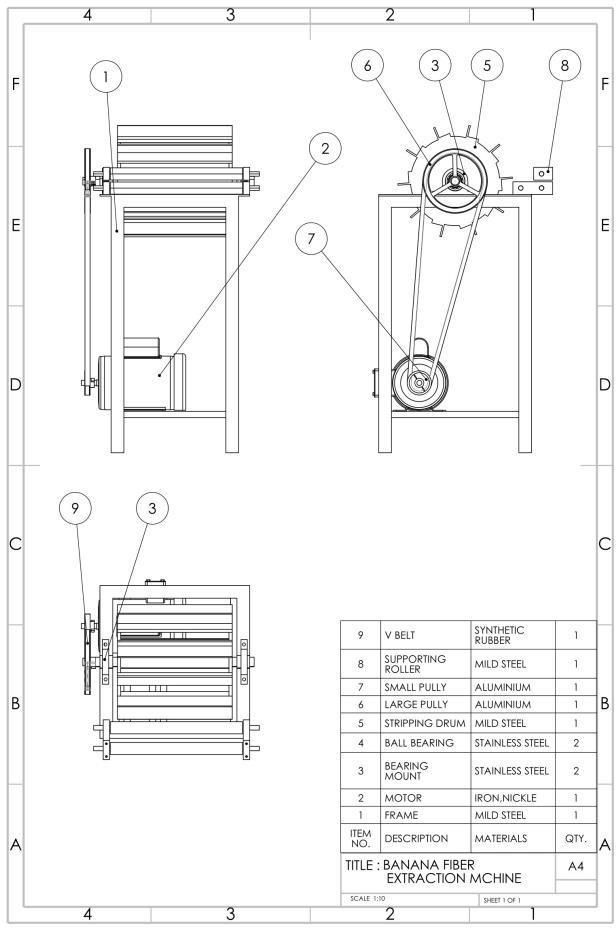

3 DESCRIPTIONS OF COMPONENTS:

3.1 STRIPPING DRUM:

Strippingdrumisoneoftheimportantcomponentsin thismachine.itisthekeycomponentofthemachine.Theno ofbladesandtypeofbladesusedisalsoveryimportantasit affectsthequalityofthefiber.Thisrollerdesigncaneasily separate the banana fiber from the banana stem. The diameteroftherollerdrumis280mmandhas10blades.

3.2 MOTOR:

AnACmotorof1.5hpisconnectedtotheshaftwhichdrives theshafttotherollerdrum.

3.3 SUPPORTING ROLLER:

It plays the role of guiding the banana stem to the right position.So,itcanbeevencalledasguideroller.Itismadeof mildsteel.Weneedtworollerswhichisusedinthemachine. Itis30mmdiameteroflength40mm.

3.4 BEARING HOLDER:

Itisusedtoholdthebearingofinnerdiameter62mm.ithas twoholeswhichisclampedtothestand.

3.5 BEARING

Bearingisselectedfromthe6206bearingofouterdiameter 62mmandinnerdiameter30mmandwidth18mm.

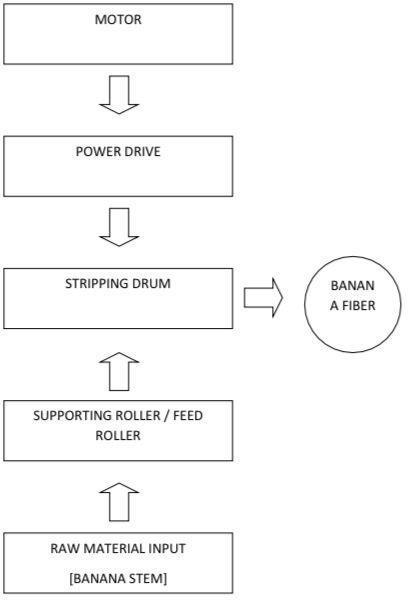

4 WORKING PRINCIPLE:

Thismachineconsistsofa1.5HPmotorwhichisconnectedto asmallpulley.Thestrippingdrumisfixedwithtwobearings inboththeendandonesideoftheshaftisconnectedtoa large pulley. Now both the pullies are connected to each otherusingaBtypeV-belt.ItalsoconsistsofGuidingroller throughwhichthebananastemisinsertedandreachesthe strippingdruminaninclinedposition.Duetotheinclination oftheslotthepulpgeneratedfallsapartfromthefiber.

5 DESIGN CALCULATION

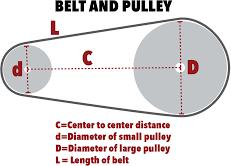

5.1 CALCULATION OF VELOCITY RATIO OF BELT

DRIVE:

N2/N1=d1/d2

N1=rpmofsmallerpulley

N2=rpmoflagerpulley

d1=Diameterofsmallerpulley

d2=Diameteroflargepulley

d1=0.08m

d2=0.2m

As,

N1=1440rpmofmotor

N2/1440=0.08/0.2,

N2=576rpm

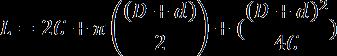

5.2 CALCULATION OF BELT LENGTH:

5.3 LENGTH OF AN ARC: But

N = 10

6 FINAL REPORT

S.NO SPECIFICATION

6.1 MERITS:

Fig -4:Beltandpulley calculation

6.2 APPLICATION:

Rope,matting,andothercompositematerialsare

L= 1260+439.823+31.111

L=1730.933mm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

Automobile manufacturers employ polypropylenereinforcedwithbananafiberto makeunderfloorprotectionpanelsinhigh-end vehiclessuchasMercedes-Benz

Banana fiber is commonly used in handicrafts andhomedécor

8 CONCLUSION

p-ISSN: 2395-0072

Thenewbananafiberextractionmachineisdesignedwith higherefficiency.Thismachinewillreducemanualworkand issuitableformassproduction.Compactstructureandeasy disassembling will be another advantage. The problem of impuritiesandknotscanbesolvedwiththiskindofdesign. The factors affecting quality of fiber are roller speed; feed angle and clearance also affect the production quantity of fiber. By choosing these factors, correctly quality and productionoffibercanbeincreased.

REFERENCES

1. http://www.kiran.nic.in/pdf/farmers_corner/pamp hlets-2016/BananaFiberProduction.

2. ]G.Eason,B.Noble,andI.N.Sneddon,“Bananaparts into Modern Application ,” Phil. Trans. Roy. Soc. London,April2012.

3. IRJET-InternationalResearchJournalofEngineering andTechnology

4. 10 World’s Biggest Banana-Producing CountriesTheScienceAgriculture

5. [PDF] Chemical Compositions of Banana Peels ( Musasapientum)FruitscultivatedinMalaysiausing proximateanalysis|SemanticScholar

6.3 ASSEMBLED VIEW: Fig -5:Assembleddesign Fig -6:fiberproducedbymachine