IOT Based Machine Health Monitoring System

Asavari Anil Kulkarni1 , Prajkta Santoshrao Muneshwar2 , NikhitaAbstract - Machine health monitoring in today’s complex plant systems has gained more prominence than ever before because of steep increase in machinery costs, plant investments and maintenance expenses. A breakdown in any one machine or a component in a plant could mean huge lossescoupledwithsafetyandenvironmentalthreatsasinthe case industrial and commercial plants. The advances in manufacturingtechnologyandthecompetitioninthemarket necessitate the continuous availability of machinery for production. This has created a need for integrating maintenance with other manufacturing activities for better plant availability and efficiency. The objective of present research work is to present one such Machine health monitoring(MHM)system developedusing knowledge-based systems.Theproposedmodelcanbeausefulmaintenancetool in majority of small and medium scale manufacturing plants. A comprehensive knowledge-based system (KBS) could be developedoveraperiodoftimeforindustrialmachinerywhich can monitor the major machinery faults and provide expert maintenance solutions through measurement and analysis of machine parameters such as power, vibration, noise, temperature, wear debris, lubricant condition, etc. A fault diagnosis system with KBS is based on computer programs interlinking fault symptoms, faults and remedies.

Key Words: Industrial3phaseload,Speed,Weardebris, Lubrication,Temperature,Vibrationetc

1. INTRODUCTION

Themachinehealthmonitoringsystemisusedtomeasure variousparametersof3phasemachineslike1)overvoltage andundervoltage2)overcurrentandundercurrent3)over temperature 4) over speed by using Arduino and IOT technology. The proposed system uses sensors like temperature sensor and inductive type proximity sensor. These sensors mainly involve monitoring of temperature andspeed.Wedivideprojectin3unitslikeindicatingunit, sensingunitandcontrollingunit.inindicatingunitweshow theelectricalparameterslikevoltageandcurrentperphase. Insensingunit,thestandardratingofvariousdevicesisset andwhentheelectricalquantityisincreasedordecreased according to that Parameter this relay will turn off the systeminabnormalcondition.InControllingunitwhenthe electrical parameters are same as set value then machine turns on automatically. We use IOT based GSM for the

sendingmessagetotheoperatorforknowingthecondition ofmachine.

1.1 Problem Statement and Remedies

Themachinehealthmonitoringsystemisbasedonareal timemorningapplicationtherefore,wehavevisitedasmallscale industry named as ‘Kambale Textiles’. There are 40 motorsinstalledinindustryfor40loommachines.Ifanyone motor gets affected by a minor fault, then whole system dependingonthatmotorwillstopoperating.

LossduetoonemachineshutdowncancauselossofRs 70/- thenapproximatedloss of 40loom machines for 1Hr willbecauselossofRs2800Rs.Thislosshappensbecauseof theminorfaultsinmotorlikevoltagespickandalsoduring operation mechanical faults in machines produce unique vibrationswhichdependuponthegeometryofthemachine elementssuchasshaft,spindleetc.,andshaftrotationspeed which is main cause to damages the motor. Minor faults whichwillifnotcorrectedatthatinstantthentheywillcause abigdamagetomachine

Hence,weworkedonprojectandgetthesolutions:-

1)For bearing problem we are using proximity sensor thatwillsenseminorchangeindistanceofbearingwhichwill if ignoredthen itleads toblocking of shafthence it avoids usingthissensor

2)If single phasing occurs then the motor will get shut downtoavoidfurtherdamage.

3)Bybalancingvoltageandcurrentstartingtorquewill notgetaffected.

1.2 Objective and Scope of Project

The objective of present research work is to present one suchmachinehealthmonitoring(MHM)systemdeveloped usingknowledge-basedsystems.Theproposedmodelcanbe ausefulmaintenancetoolinmajorityofsmallandmedium scalemanufacturingplant.

Machine health data takes the guesswork out of which machines in our line we need to optimize, and predictive insights allow us to implement changes in production to

maintain high-quality output standards in weeks or even days instead of the typical year-long implementation process.Withmachinehealthdata,wecanalsoseethetrue indicatorsofproductivityandefficiency.Amachinehealth platform can give us real-time insights into how machine performancecorrelatestothequalityofouroutputsandthe potentialtomaintainthatqualitydowntheline.

2. WORKING

Working of the Project is mainly classified by following sections:

DisplayUnit

ControlUnit.

Display Unit: - The display Unit is the information status about all devices. In display unit all the Electrical Parameters like Voltage, Current, Frequency, Speed, Temperature, power factor, phase reversal, phase asymmetryisdisplayed.

ControlUnit: -InthecontrolUnitisthecontrolofvarious Electrical parameters are controlled. In control unit we controlthefollowingparameters:-

VoltageController:

• UnderVoltage

• Overvoltage

• VoltageAsymmetry

• Powerfactor

• Phasereversal

CurrentController:

• UnderCurrent

• Overcurrent

FrequencyController:

• Underfrequency

TemperatureController:

• Overtemperature

SpeedController:

• Underspeed

• Overspeed

Machine health monitoring is the ability to access the electrical parameters of a machine over a period of time. Firstly,weentertheratedvalueofthethree-phaseloadin thecontrollerunitasperIndianstandard.Whenthefaults occur the electrical parameters like voltage, current, PF, frequency,speedare changes.These valuesarecompared withtheratedvalueandtheaccordingtowhichparameter areabnormal (aboveorunder)these relayunitsensethis and send signal to the microcontroller to turn off the respected unit of the machine. Then IOT based GSM unit sendtextmessageofallrealtimevalueofthemachinetothe Operator. In this way project provides an automated and Real-Timed monitored solution for the traditional water

supply system through smart features of the project ‘MACHINE HEALTH MONITORING SYSTEM’

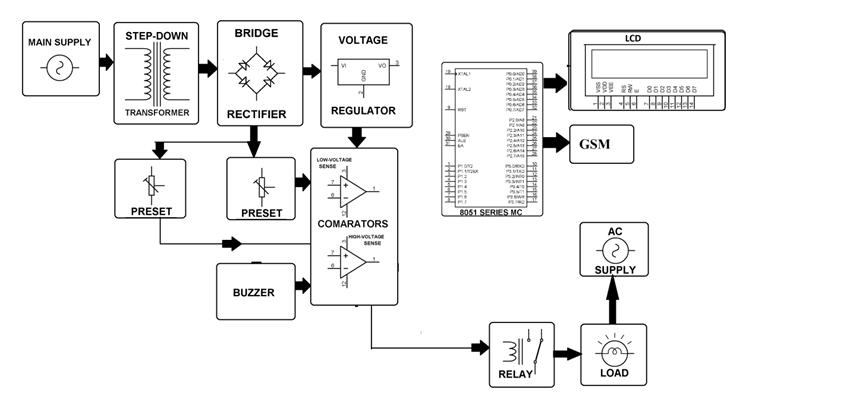

Blockdiagram

Table-1:MainSensorsused

FUTURE SCOPE

In proposed system, there is a flexibility of adding new technologies and advanced equipment’s like advanced sensorsforexample,waterproofsensorscanbeemployed forapplicationlikeJackwellorSubmergedmotors,etc.

4. CONCLUSION

Thisprojectholdstheconceptofmodifyingthetraditional machinehealthmonitoringsystemintoaIOTbasedmachine healthmonitoringsystem.Itencompassestheprogrammed way of monitoring and auto correcting the industrial or commercialusersandmakingareliablesolutionforthose users. This project contributes for reliable and efficient solutionbyprovidingthescheduledwayofminimizingthe faultsandalsoatthesametimealltheelectricalparameters ofthesystemcanbemonitoredinrealtimeusingIOT.The

Real-Timeoperatingconditionofthesystemismonitored andduringboththecondition’sthatisnormalandabnormal itgivessignalthroughtextmessagetotheoperator.

ACKNOWLEDGEMENT

Wewouldliketoexpressourspecialthankswithgratitude toourguideProf.VaibhavB.Magdum,AssistantProfessorin Electrical EngineeringDepartment,forthewholesupport, innovativeideasandencouragementthatwereceivedduring theentirecourseofprojectwork.

Oursincerethanksgotoallthefacultyandsupportingstaff oftheElectricalEngineeringdepartment,forhelpingdirectly orindirectlyasandwhenrequired

REFERENCES

1)D.LooneyM(2014)AnintroductiontoMEMSvibration monitoring.AnalogDialogue48(06).

2)Bruel&Kjaer(1982)Measuringvibration-anelementary introduction. K Larson and Son Publication; Denmark, Revisededition.

3)FengZ,LiangM,ChuF(2013)Recentadvancesintime–frequencyanalysismethodsformachineryfaultdiagnosis:a review with application examples. Mechanical system process.

BIOGRAPHIES

Miss.AsavariAnilKulkarni BtechfromDKTESociety’sTextile andEngineeringInstitute. Has completed diploma from Shri SiddheshwarWomen’sPolytechnic Solapur.

Miss.PrajktaMuneshwar.

BtechfromDKTESociety’sTextile andEngineeringInstitute. Has completed diploma from GovernmentPolytechnicYavatmal.

Miss.NikhitaMarutiParit.

BtechfromDKTESociety’sTextile andEngineeringInstitute. Has completed diploma from GovernmentPolytechnicKolhapur.

Miss.PallaviBhimraoMistry. BtechfromDKTESociety’sTextile andEngineeringInstitute. Has completed HSC from M. H. HighschoolJuniorCollege,Thane

Mrs.DnyaneshAmarTarlekar. BtechfromDKTESociety’sTextile andEngineeringInstitute. Has completed HSC from Sangola Vidyamandir Prashala and Junior College,Sangola.

Mr. Vaibhav Baburao Magdum is M.E. in Electrical Power systemfromPVGCOET,Pune(MS). He is B.E. Electrical from AISSMS, COE, Pune, (MS). Presently he is working as Assistant Professor in DKTE Society’s Textile & EngineeringInstitute,Ichalkaranji. His research areas include ElectricalMachines,Drives,Power System, Switchgear & Protection. He has published and presented thepapersinInternationalJournals and International/National conferences.HeisaLifememberof Indian Society of Technical Education,NewDelhi.