AUTOMATIC BATTERY HEALTH MONITORINGUSING MACHINE LEARNING FOR E-VEHICLES

Abstract-Batteries,whicharemadeofacombinationof electrochemical cells, provide the necessary electrical current for powering electrical equipment. Batteries continuouslytransform chemical energy into electrical energy,and for them to operate at their peak efficiency, appropriate maintenance must be given. Inaddition to the use of batteries, it is also believed that health management systems with expertisein various battery conditioning features, such as temperature, current, and voltage regulation, charging and discharging management mechanisms, and other mechanisms, will help to reduce risks to people's health, safety, and property. These systems regulate battery performance usingmerit-basedstandards. Inthispaper, we provide a data-driven perpetual literacy system for neural networks to cover the foreseen parameters. We use a machine learning technique to extract crucial features from the discharge curves in order to estimate these values. Extensive simulations have been performed in order to evaluate the performance of the suggested techniqueatdifferentcurrentsandtemperatures.

1. INTRODUCTION

The battery management system monitors individual cells in the battery pack. It thencalculates how much current can safely go in (charge) and come out (discharge) without damaging the battery. The current limits prevent thesource(usuallyabatterycharger)and the load (such as an inverter) from overdrawing or overcharging the battery. This protects the battery pack from cellvoltages getting too high or low, which helps increasethebattery’slongevity.

The BMS also monitors the remaining charge in the battery. It continually tracks the amount of energy entering and exiting the battery pack and monitors cell voltages. It uses this data to know when the battery is drained and shut the battery down. This is why lithiumion batteries don’t show signs of dying like a lead-acid, but just shut off.The Battery Management System on an electric vehicle monitorseach cell in the battery pack closely.Itensuresthatthebatterypackissafetouseand protects the car if the cells are not working correctly.In addition, it estimates the range that the vehicle can travel and helps improve the battery pack's overall

lifecycle. Therefore, a Battery Management System is a criticalpart of an electric vehicle, and a good battery management system can improve the life of an electric vehicle by several years. To address this inherent shortcoming of Lithium ion batteries, a battery management system is required to secure the entire system and keep track of the most efficient way to consume energy. These battery management systems mustensurethatbatteryfunctions,suchasSOHandSOC. A battery is used as a secondary power source in automobiles. An electric vehicle battery is a secondary (rechargeable) battery. It useschemical energy stored in rechargeable battery packs for power and therefore does not require any combustion engine for propulsion. Anelectricvehiclebatteryortractionbatterypowersthe propulsion of battery electric vehicles. Forinstance, the SOH and SOC in electrical cars are analogous to an odometer and a gasoline-powered car's fuel gauge, respectively.SOHandSOCarecriticalmetricsbecause,if calculated properly, they can stopovercharging, reduce overheating,andincreasebattery life.

2. RELATED WORK

Limited number of studies have demonstrated the potential of automatic battery health tracking using variousideologies.

An adaptive Gaussian mixture model (AGMM) was created by Yu, Jianbo, et al. for addressing of various changesofbatteryhealthoverthecourseofthebattery's existence.ABayesian-inferencemethodisusedtodetect novelhealthstatesthatareonlinemodelledbyremoving andaddingcomponentsinAGMM.

According to Banaei et al., a novel technique for calculating a Lithium-Ion battery's State Of Health using impulse response has been developed. The proposed approach forecasts the terminal voltage of a battery usingtheterminalcurrentmeasurementandexhibitsthe impulseresponseofahealthybattery.

A system to diagnose a battery cell fault using a Deep Neural Network was developedby Lee, et al. The discharge voltage data that was obtained by operating the lithium battery cell at a high temperature was used bytheDNNstateinthismethod.

Yu et al. developed a battery health prognostics system based on Bayesian-inference probabilistic (BIP) indicator and a state-space model (SSM) thatintegrates logistic regression (LR) and particle filtering (PF). Considering the lack of documented fault patterns, this system use generative topographic mapping to mimic the distribution of multisensor data from a healthy battery.

Using the deep learning (DL) approach, Noman Khan et al. offer a battery management system(BMS) based on MCCPs, where the patterns in these CPs vary as the battery matures over time and is subjected to more cycles.Inordertoofferameaningfulcomparisonstudyof our strategy, we therefore thoroughly investigate both machinelearning (ML) and DL-based methodologies. To find the best method for estimating battery capacityand state of health (SOH), the adaptive boosting (AB) and support vector regression (SVR) are frequently compared with long short-term memory(LSTM), multilayer perceptron (MLP), bi-directional LSTM (BiLSTM), andconvolutionalneuralnetwork(CNN).

Hu and colleagues are interested in battery State-ofHealth (SOH) indication and prognosis using machine learning. Short voltage sequence sample entropy is utilized as a reliable indicator of capacity loss. The underlying correlation between the capacity loss and sample entropy is capturedusing sophisticated sparse Bayesianpredictivemodeling(SBPM)methodology.

In this study, Xing, et al. reviewed the most recent techniques for life prediction and condition assessment based on battery health monitoring.Prognostics-based fusion technique is suggested that blends data-driven technology withphysics-of-failure (PoF) by contrasting theirdistinctproperties.

A multistep-ahead prediction model was created by Li, Hong, and colleagues based on the mean entropyand relevance vector machine (RVM) and used to anticipate the battery's state of health (SOH) and remaining life. The RVM model incorporates a wavelet denoising method to determine trend information and to lessen uncertainty. The ideal embedding dimension is then chosen for accurate time series reconstruction using the meanentropybasedtechnique.

To address this problem, Tang et al. addressed battery management system (BMS) as application health monitoring technique. First, the investigation of the estimation dispersion of a single indicator(SI)and the extraction of three health indicators from actual EV operating conditions serve toillustrate the need for multipleindicators(MIs).

Abatterymanagementsystemthatcanmanage,monitor, and log data to an online database was proposed by M.

Senthilkumar et al. to be integrated withthemonitoring framework. The battery's voltage,current, temperature, power, and state of charge are all monitored by this system. These parameters are then transmitted and saved in a database through the internet, which an androidappsubsequentlyusestodisplaytotheuser.

A vibration-based health monitoring system was suggested by Chetan et al. Regular vibration datafor car batteries has proven useful in identifying the need for maintenance or replacement. A series ofvibration sensors, a setup centered around a battery, and a microcontrollerfordataacquisitionfromthesensorsare utilizedtogatherthisdata.

Adiagnosticdesignforlithium-ionbatterieswascreated by Miftahullatif et al. actively detecting the voltage transientresponseduringtherestperiodafterdischarge, when each battery cell reaches equilibrium. We discovered that the battery cells' SOH is represented by this brief response. We can predict theSOH variation inside the battery storage system by measuring the voltage variation because the cell balancing controller is notactiveduringthisrestperiodafterdischarge(BSS).

3. PROPOSED SYSTEM

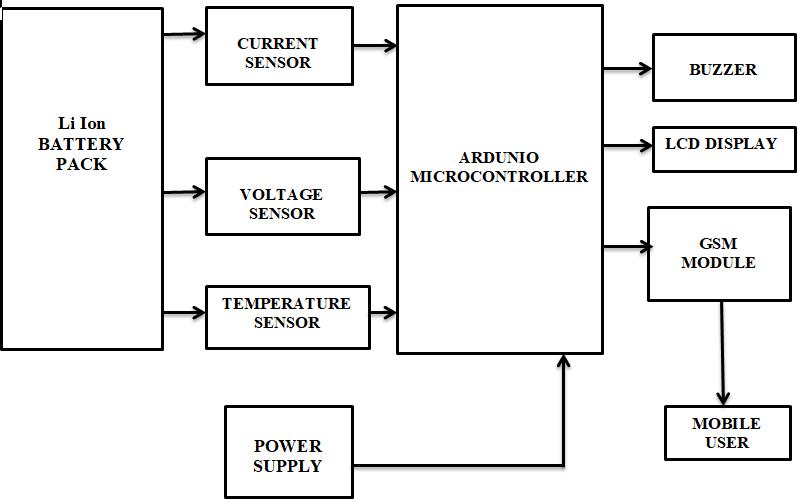

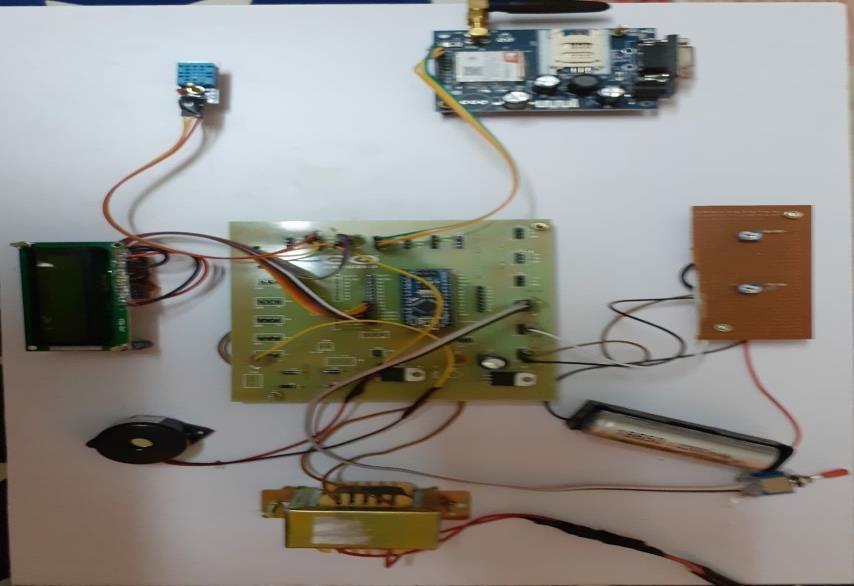

A battery health monitoring system consists of a temperature sensor, a current transformer, an LCD display, a buzzer, and a GSM module. The temperature, current, and voltage levels are continuously monitored afterthesystemisturned oninthecar.Withaconnected liquidcrystal display, this gives accurate readings of the fundamental parameters in real time. The system is madeupofthreemaincomponents:gatheringdatafrom all sensors, sending that data to a microcontroller for processing, and then sending user feedback. To monitor input current and voltage, we use voltage sensors and current sensors.. Also receiving this data is the microcontroller. After gathering all of this information, GSM technology will notify the user whenever a predetermined parameter such asinput voltage, current,orbatterypercentage changes. Withtheaidof the GSM module, the user will get SMS on his or her phone. We utilized the Arduino IDE and embedded C to code the system's components. Before enabling the battery charging circuit,makesureallofthecomponents andtheinputvoltageandcurrentarewithinthespecified limits. The user will also be informed when the battery drops below 10%.The rise and fall in the values are additionally shown through a buzzer-based notification system.Thistechnologywillanalyzethebattery'sprecise condition and notify the user. To make sure that users are adequately informed of the batteries' state, another component of the system has a GSM Module. The controllernotifiestheuserofthebatterystatustogether withtheoutcomeshownontheLCDDisplay.

WORKING

Itprimarily consists ofthreekey components: gathering information from all sensors, sending that information, andprocessingitwithamicrocontrollerbeforedelivering user feedback. Weuse a voltage sensor and a current sensor to measureinput current and voltage. These sensorswillkeepaneyeonthevoltageandcurrentgoing into the UPS battery and transmit the information to themicrocontroller. After gathering all of this information, GSM technology will notify the user whenever any of the preset parameterschange.Withthe aidoftheGSMmodule,theindividualwillreceiveSMSon his or her phone. The user will be able to learn the battery's present statuswiththehelpofthis.Thecodeis setupsothatthemotorwillrotatetoshowthechangein valueintheeventofasuddenriseintemperatureorthe temperature levels exceeding the threshold value, let's say 40 degrees Celsius. When it comes to training a model, the backpropagation method] is utilized rather frequently. This method first estimates the partial derivative of theerror based on thevaluesof the weight and bias, and then adjusts the weight and bias in accordance with those estimations. This helps to keep expenses to a minimum. The total number of epochs equals the number of times the entire training set was completedinits entirety.Thisisthebenchmark thatwill be used to establish whena training programme should cometoanend.

4. COMPONENTS

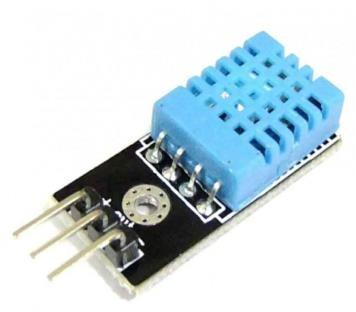

It has an advanced 8-bit microcontroller. Its innovation ensures high dependability and outstanding long haul stability. This sensor is primarily responsible for measuringthetemperatureofthebatteriesinrealtime.It has excellent quality, rapid response, impedance resistance,andhigh performance.

LCDsareusedtodisplaytheoutputsanddesired results

obtained from sensors through the use ofcontrollers. LCD displays are widely utilized in telecommunications and entertainment gadgets. TheLCD Display is primarily usedinourprojecttodisplayreal-timevaluesofcurrent, temperature, andvoltage, as well as to indicate the state ofcharge.

Piezoelectric Buzzer

Fig.PiezoelectricBuzzer

The Piezoelectric Buzzer is used to provide feedback in the form of a sound or alarm. They are electrically powered sounds that operate on DCvoltage. The core of thisbuzzerismadeupofa piezoelectricelement.Dueto this element the core of the buzzer constantly expands and shrinks when Dc Voltage passes through it. This continuous action produces vibrations which are responsible forthe production of the sound. The use of Piezo electric buzzer in this project is to indicate and alertthe user about the changes in voltage, current and temperature.

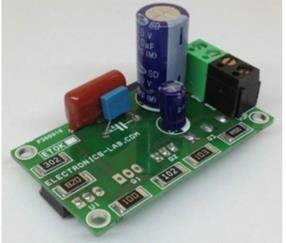

Regulator

A capacitor regulator's operating voltage and capacitance are both crucial characteristics. The operating voltage must be at least as high as the power supply's outputvoltage when there is no load. When current is pulled from the circuit, the capacitance controlshowmuchrippleisvisibleontheDcoutput.

Fig.GSMmodule

A GSM modem is adevice that makes use of GSM mobile phonetechnologytoofferwirelessdataconnectivitytoa network. GPRS/GSM technology allows a mobile sim card to connect with the module. In the 900 and 1800MHzfrequencybands,itallowsuserstoreceiveand send SMS messages as well as make mobile phone calls. Programmers may create customized apps using the keypadanddisplayinterface.Italsohastwomodes:data mode and command mode. Every nation employs a unique set of protocols and frequencies, including GPRS/GSM. Using command mode, developers may changethedefaultsettings.

5.RESULTS AND DISCUSSION

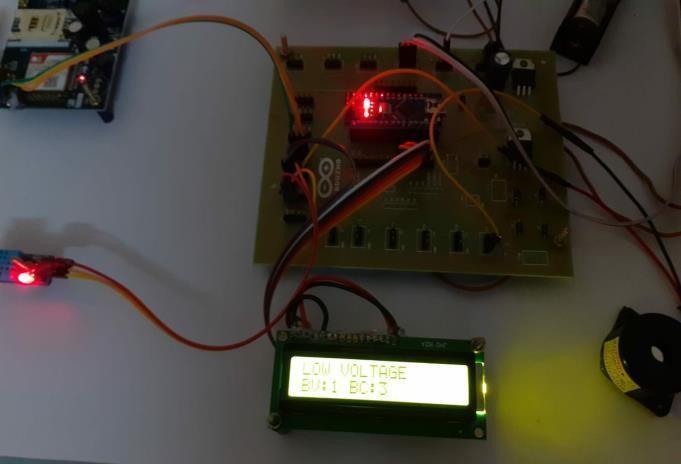

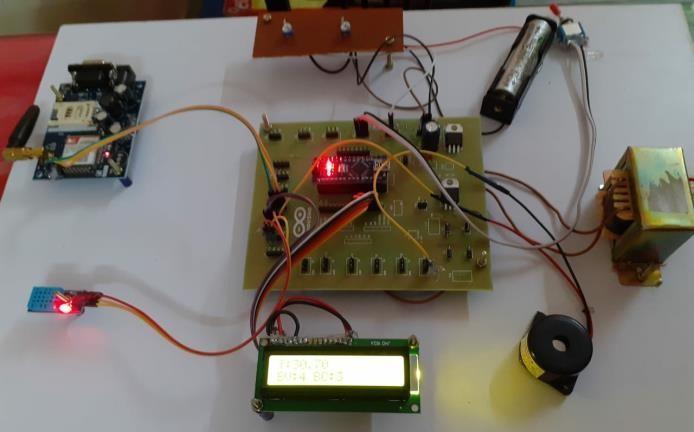

Sensorsareusedinthehardwaretomonitorthehealthof the batteries. These sensors include the DHT 11 Temperature Sensor and regulators to measure the battery'scurrentandvoltage.Thesesensorsareusedfor live monitoring, and the readings are displayed on an LCD display. Hereonce the vehicle is started the temperature, current, voltage and the state of charge parameter readings are shown in the Liquid Crystal display

The changes in the battery are also shown on the LCd Display screen. In case of voltage fluctuation thedisplay will show a message as "Low Voltage". If the battery becomes overcharged, the system displays a "Overload" message..

Fig.HardwarePart

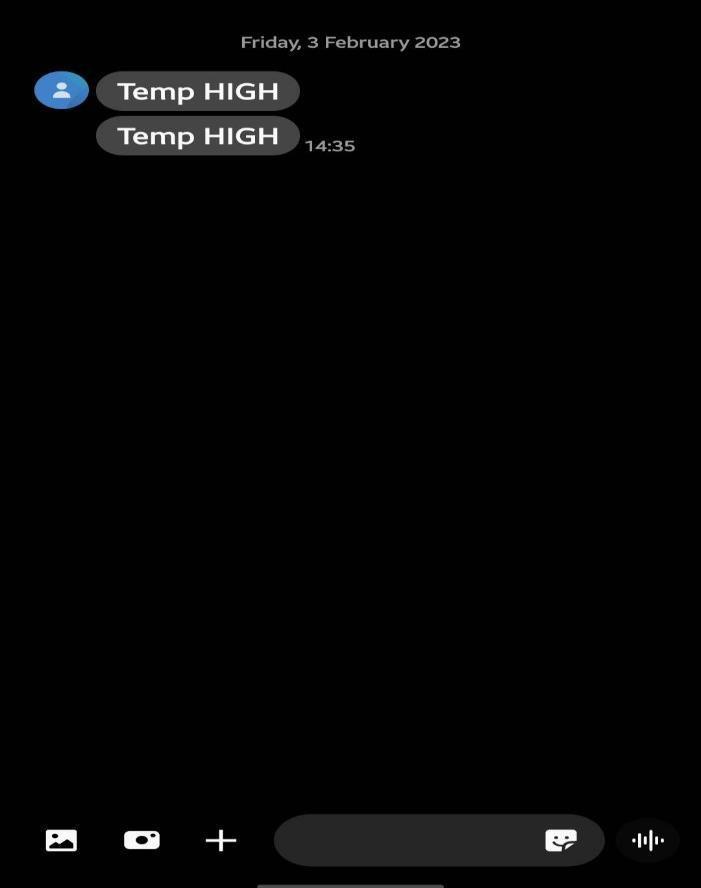

Any deviation in the readings will result in an alert message being sent to the user's phone. If the temperature rises, a message labeled "Temp High" will besenttotheuser'smobiledevice.Thiswillbe

Readings were obtained using the designed systemand compared to sensor readings. The errorpercentage is calculated, and the system is trained again to reduce errors.

Fig.MessagesentwhenHighTemperatureismeasured

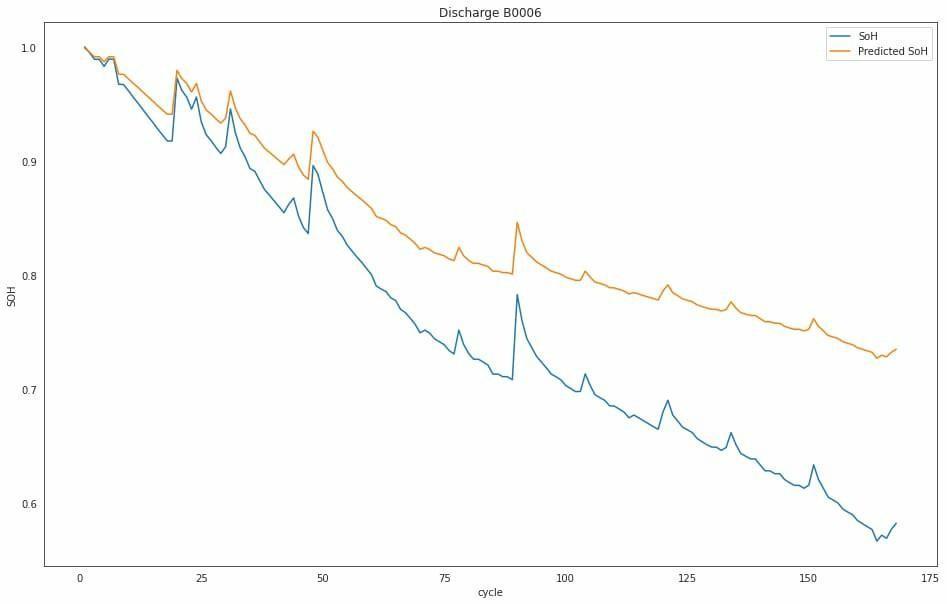

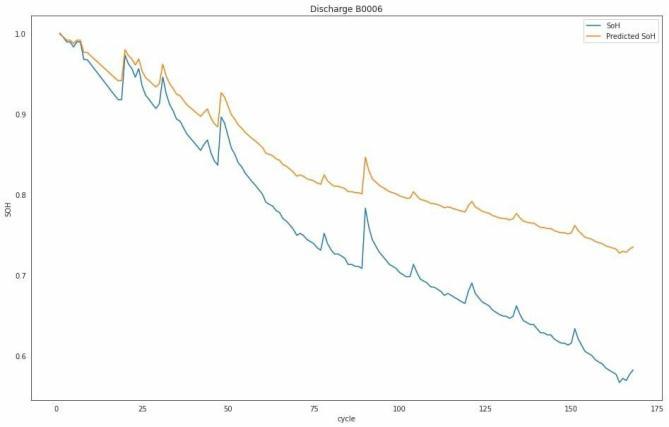

Thedatasetispreparedinsuchawaythatitcanbeused by Tensorflow in the training phase, for this, two structures are created corresponding to the input and output expected to be obtained. For the input data, the relevant characteristics of the dataset are filtered, Instant of time. For the output data, the SoH of the battery is calculated and in both inputandoutputcases, the values are normalized to a range of values between [0-1].For the estimation of SoH, it can be seen that the data pattern is learned by the model correctly, as predicted by the theory, since the shape of the curves is almostidentical.TheSoHshownhasthesamebehavior

as expected in theory, which is corroborated with the root mean square error value of the graph in illustration8, whose value of 9% is very similar to that found previously.Thisreaffirmstheprecisionwhenmakingthe prediction.For the estimation of SoH, it can be seenthat the data pattern is learned by the model correctly, as predicted by the theory, since the shape of the curvesis almost identical. The SoH shown has the same behavior as expected in theory, which is corroborated with the

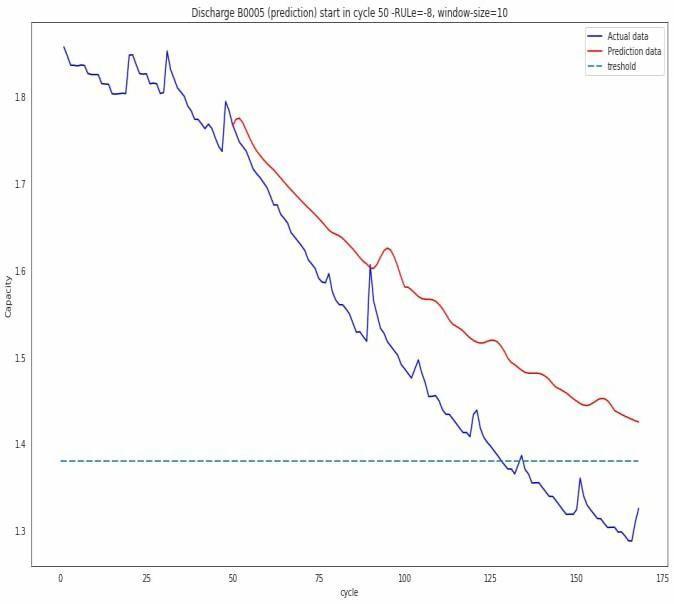

root mean square error value of the graph, whose value of 9% is very similar to that found previously. This reaffirms the precision when making the prediction. By RUL estimation, in the same way thatwas done for the estimation of SoH, the training and testing dataset is prepared,inthisparticularcasethebatterycapacitydata isusedusingthefirstdataofthefirst50cyclestopredict thecapacityinthefollowingcyclesinsuchawayastobe able to know when the threshold of the battery is reached and estimate the remaining cycles to reach the EndofLifeofthebattery.

6.CONCLUSION

To achieve almost minimal equipment downtimeand optimum productivity, battery health degradation detectionandmonitoringareessential.Thedifficultylies in developing an efficient monitoring system that can reliably show how battery health degrades over the course of its lifespan. This study suggests acontinuous learning system for tracking the health of batteries (SOH).The goal of this critical analysis is to provide a strategy for the advancement of these technologies. Whenoneconsidersthepossibilityofaninformationand energy internet for the purpose oftransferring data and power, the significance of this issue becomes further clearer. Among its most significant problems are limitations on storage space,charging speed, safety, and theabilitytoproduceaccuratereal-timeforecastsofLIB states using a realistic dataset. The ultimate objective is to create alive, data-driven electrothermal model that can be used for state prediction, health monitoring, and charge regulation in real time. This will be accomplishedoverthecourseofseveralyears.

REFERENCES

1. Preethika. J,Priya. P,Ramya. U.P,Surendhar.K, Vijayakumari.G (2016)- “AntiKidnapping System for Women with Security Alert”,International Journal of Advanced Researchin Biology Engineering Science and Technology (IJARBEST), Volume 2, SpecialIssue10.

2. HemaShalini. M,Liya. B.S,Monisha. V,Nandhinidevi.R (2018 January)-Prathyusha Engineering College, Chennai “Smart Device to alert Bystanders of the abductedchild”,IJCRT,Volume6,ISSN:2320-2882.

3. Shivashankar B.Nair,Sonia,Suraj Kumar Pandey, TusharSemwal,(2020) “Smart Patch: An IoT Based Anti Child-Trafficking Solution” The 2020 IEEE International Conference on Internet of Things and IntelligenceSystem(IoTaIS),Volume2.

4. Sachin Damke,YogitaK.Dubey (August 2019) “BabyMonitoringSystemusingImageProcessingand IoT”, International Journal of Engineering and Advanced Technology (IJEAT), Volume8, ISSN:22498958.

5. Deepika.L,Indu.R,JasminBanu.R,Shakunthala.M (June 2018)“NeonatalHealthcareMonitoringinIncubator Using IoT”, International Journal of Electrical,Electronics and Data Communication, Volume6,Issue6,ISSN(p):2320-2084.

6. Anwesha Mukherjee,Arkaprabha Sau, DebashisDe.Ishita Bhakta (August 2016)“Design of Smart Neonatal Health Monitoring System using SMCC”,HealthCare Technology, pp.1-7,Volume 4,Issue1.

7. Chiranjeevi Mondikathi,SilvyAchankunju (2015) “Voice based Security System Using Matlab& EmbeddedSystem”,InternationalJournal of ScientificResearch,Volume:4,Issue:5,ISSN No 2277-817.

8. GuazziA,JorgeJ,Villarroel M (2014) ‘Continuous noncontact vital sign monitoring in neonatal intensive careunit’,Healthcare Technology Letters,pp. 87– 91, Volume1,Issue3.

9. Chen W,Coops R, Nguyen S.T (2009): ‘Wireless transmission design for health monitoring at neonatal intensive care units’.Second International Symposium onApplied Sciences in Biomedical and CommunicationTechnologies,pp.1–6,Volume4.

10. AlbersheimS,HolstiL,Mahon P (2015) ‘The fathers support scale:neonatal intensive care unit (FSS: NICU): development and initial content validation’,Journal of NeonatalNursing,, pp. 63–71, Volume21,Issue:2.

11. Chaseling G.K, DabovalT,Molgat-SeonY(2016) ‘Body temperaturemappingincriticallyillnewborninfants nursed under radiant warmers during intensive care’,JournalofPerinatology,Volume36.

12. Basha.C.Z,Durga.S,Itnal.S,Saxena.C,Soujan ya.K (2021)‘Advancedandeffectivebabycaremonitoring Smart CradleSystem using Internet of things’,2nd International Conference on Smart Electronic andCommunication(ICOSEC),pp.35-42.

13. AkbiyikM.E,AygunE,Coban C S, GurgunogluD, Ider.D, Imamoglu H Z(2020) “ThermoCam: Smart Baby Monitoring Assistant”,2020 IEEE 44th Annual Computers,Software,and (COMPSAC),pp.636-643. ApplicationsConference

14. Ahmad M.I,Ali.H,Malik.A (2019) “Li-FiBased Health Monitoring System for Infants,”2nd International Conference on Communication, Computing and DigitalSystems(C-CODE),pp.69-72.

15. Raina G,Semwal.S,Tiwari R (2022) “An Innovative ApproachtoNeonatalIntensiveUnitCareSystemfor NewBornbabies”,2022InternationalConferenceon Advances in Computing, Communication and Materials(ICACCM),pp.1-6.

16. AnnadO, CheggouR, KhoumeriE.H,Mohand S.H (2020)“AnIntelligentBabyMonitoringSystembased on Raspberry Pi,IoT sensors and Convolutional Neural network”, 2020 IEEE 21st International Conference on Information Reuse and Integration forDataScience(IRI),pp.365-371.