Effect Of Polydisperse Cementitious Polymer Based Waterproof Coated Steel Fibers And Polypropylene Fibers In Concrete

Sajeev K.1, Chithira Krishnakumar2 ,Abstract - Civil engineers are facing much problems regarding the quality of structures and also relating to the age prolongation of the structures with direct affects of natural calamities. To overcome above impacts as well as making the structure more stronger in every points, hybrid fiber addition along with the concrete can be introduced. The combination of hybrid fibers with concrete will provide immense physical and mechanical properties. Furthermore, corrosion resistance against the chemical attack , water seepage problems etc can be subdued by making a cementitious waterproof shield cover over the steel fibres. This experimental study comprises the effect of Hybrid fibres i.e. poly-disperse cementitious polymer based waterproof coated steel fibers and polypropylene fibre on M30 grade concrete. The percentage of hybrid fibre added is limited to 1% of volume of concrete, where variation in percentage of steel and polypropylene fibre is made for the study in this 1% . More over Steel fibres are given Styrene Butadiene Rubber (SBR) coating, which provides a massive protection boosting up the energy absorption capacity of the structure. The mechanical properties such as compressive strength, Split tensile strength and flexural strength are studied to obtain the effects of SBR Coated hybrid fibres on performance of concrete

Key Words: (HybridFibers,Waterproofcoating ,Styrene Butadiene Rubber(SBR),MechanicalProperties

1.INTRODUCTION

Thedevelopmentofpromisingandmostefficientconcrete mix with improved performance and durability is an important of modern constructions. Modified cement concretewithhybridfiberreinforcementisincreasinglyused in all structural works. The quality of concrete in the constructionsectordecreasedduetovariousfactorsandcivil engineers are facing much problems regarding the quality andageprolongationofthestructureswithdirectaffectsof natural calamities. Inadditiontoboostup theresistanceof the infrastructures against bending, stretching and impact shockloads,polydispersefiberwithdifferentspecifications andproportionsisusedinconstructionpractice.

Poly disperse cementitious polymer based waterproof coatedsteelfibersandpolypropylenefibersinconcretehave thefollowingadvantages:

1.ImproveCompressiveStrength

2.Betterresultonsplittensileandflexuralstrengths

Waterproof coated steel fiber reinforcement made of resistanceagainstacidandalkaliattacks.Whensuchconcrete wasusedinthattypeofsensitiveportions,mixingwaterproof coated steel fiber and polypropylene fiber (polydisperse) with cementitious composites, are capable of selfstrengthening before failure under a bending load. The hardenedstageofconcreteactsasplasticsamestageofwork in the loaded material. Such concrete, exhibits work hardeningwithfracturebeingaccompaniedbyasuspended brittleeffects.

TheuseofPolypropylenefiber(PPF)inpractice:

Portiononcontinuouswetting

Storagetanks

Underground structures with multiscale variationalloadsanddirections

Whereageprolongationisneeded

2.MATERIALS

2.1 Fiber reinforced concrete

Fiber - reinforced concrete is usually Portland cement concretemixedwitheithermetallicorpolymerfibersorboth. The strength of the fiber reinforced concrete is often determinedbythestrengthofthe interfacialtransitionzone (ITZ).Anincreaseinthestrengthofthecementpastealso causes an increase in the adhesion at the fiber matrix interface.

2.2 Steel fiber (SF) - hooked end

Itismade by millingfrom rolledsteel.Itisa steel strip of regularroundshapeincrosssection.Duetoitshighdensity and easy corrosion, steel fibers (SFs) are not suitable for light weight aggregate concrete and concrete in a high chlorideenvironment.

Themostcommonlyusedmicrofibersinconcretehavebeen widelyusedinrecentyearsduetotheirhighstrength,high elasticmodulus,highcorrosionresistance.Thepropagation ofmicrocracksinconcretewillalsobeblockedordelayedby addingPPF.

2.4.1 Properties of

Goodabrasionresistance

Goodageingstabilitywhenprotectedby additives

2.4 Cementitious polymer based waterproof

ThepolymerusedisStyrene-ButadieneRubber(SBR)asa vehiclefortheslurryandcementisactingastheadditives andalsobindingmaterials.SBRdescribefamiliesofsynthetic rubbersderivedfromtwomonomers,styreneandbutadiene

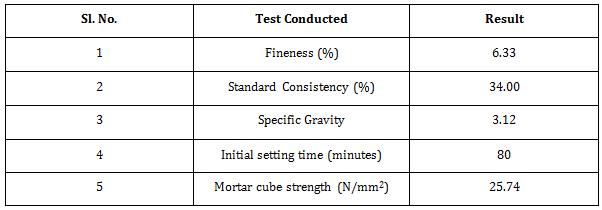

2.5 Cement

Portland Pozzalana Cement (43 grade) – ULTRATECH CEMENTSconfirmingtoIS1489(PartI):1991wasusedfor theexperimentalprogramme.Testswereconductedasper IS:1489(PartI).DetailsofthetestaregiveninappendixA. ThepropertiesofthecementaretabulatedinTable4.1.The varioustestsconductedoncementarefinenessofcement, standard consistency test, specific gravity, initial and final settingtimeandcompressiontestonmortarcube.

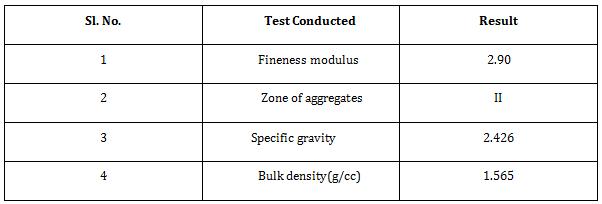

2.6 Fine aggregate

M–Sandwasusedasfineaggregate.Laboratorytestwere conducted on fine aggregateto determine the different physicalpropertiesasperIS2386(Part–III)–1963andIS383 (I) - 1970. Details of the test is given in Appendix B. The propertiesofthefineaggregatearegiveninTable4.2.The testconductedonfineaggregateweregrainsieveanalysis, specificgravityandbulkdensity.

2.8 Water

Waterisrequiredtowetthesurfaceofaggregatetodevelop adhesive quality as the cement paste binds quickly and satisfactorilytothewetsurfaceoftheaggregatesthandry surface.Itiswidelyacceptedthatanyportablewater(pH-7) can be used in the production of concrete. It should have inorganicsolidlessthan1000ppmandshouldbefreefrom injuriousquantitiesofalkalis,acids,oils,salts,sugars,organic materials, vegetablegrowthorothersubstancethatmaybe deleterioustobricks,stones,concreteorsteel.

3. MIX DESIGN

The flow ability and viscosity of cement paste can be controlled by proper proportioning of water/cement ratio andfinenessofthecement.

Theworkabilityofordinaryconcretecanbecharacterizedby thefollowingproperties:

Workability

Compactionfactor

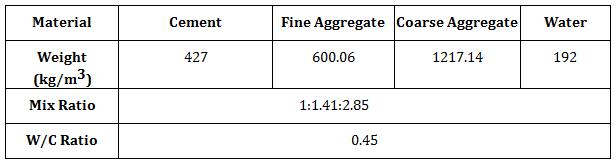

TheIScodemethodwasadoptedformixdesign

In designing the mix it is useful to consider the relative proportionsofthekeycomponentbyvolumeratherthanby mass.

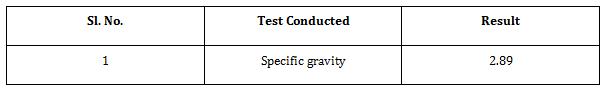

2.7 Coarse aggregate

Coarseaggregateisdefinedasaggregatethatpassesthrough a 20 mm IS sieve but is retained on a 4.75 mm IS sieve

Various coarse aggregate tests were carried out in accordance with IS2386 (Part I)-1963andIS:383–1970. DetailsofthetestsaregiveninAppendixC.Thepropertiesof coarse aggregate determined as given in Table 4.3. Tests conducted on coarse aggregate were grain sieve analysis, specificgravityandbulkdensity.

4 EXPERIMENTAL PROGRAM

4.1 Specimen Details

32numbersofcubesand24numbersofcylinderseachwere casted for determining after 7 days and 28 days curing, compressive strength, split tensile strength and durability test.Thecubesareof150mmx150mmx150mmsize.The diameterofcylinderwas150mmandheightwas300mm. 9 numbers of beams were casted for determining flexural strength.Thebeamsareof500mmx100mmx100mmsize.

4.2 Curing of Specimens

After 24 hours fromcasting,the specimens were removed fromthemould,checkandconfirmtheidentificationmarks for each type and immediately submerged in clean fresh wateri.e,watercuredfor28daysinawatertank.Thewater usedforcuringwassimilarwiththatusedforcasting.After 28 days, specimens were taken out and kept ready for testing. Fig 6 shows the image of specimens immersed in curingtank.

5. RESULTS AND DISCUSSIONS

5.1 Properties of fresh concrete

5.1.1 Workability

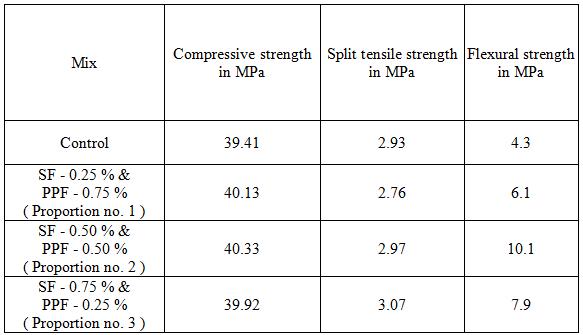

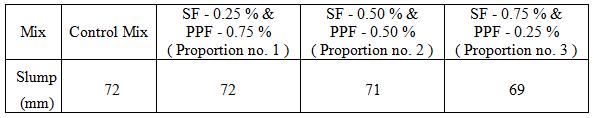

The workability of concrete is measured by slump test in accordance with IS 456 - 2000. Trials are carried out. The resultsshowthatastheSFandPPFindifferentproportions causesvariationinworkability.

Table

5.2 Properties of hardened concrete

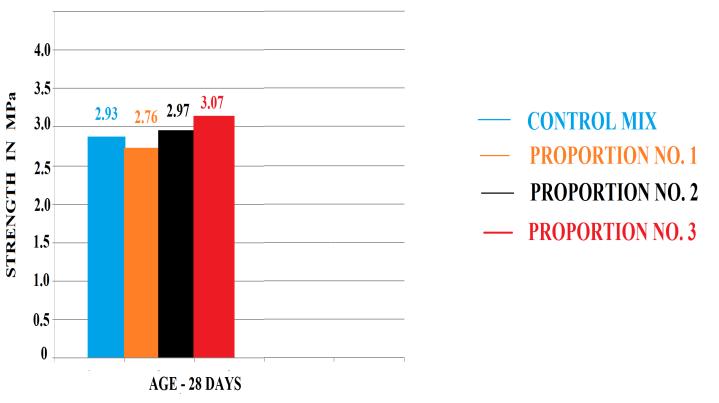

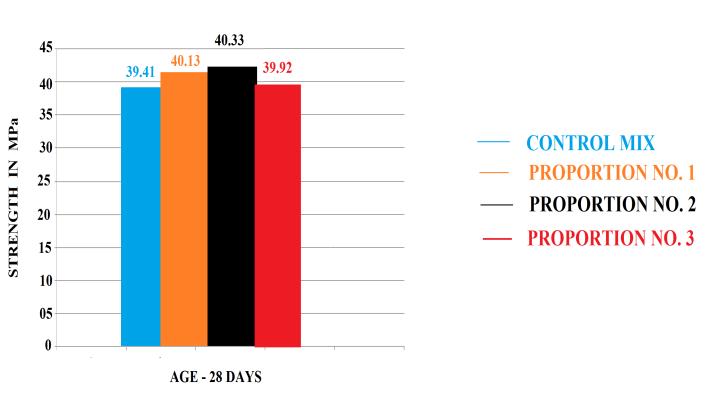

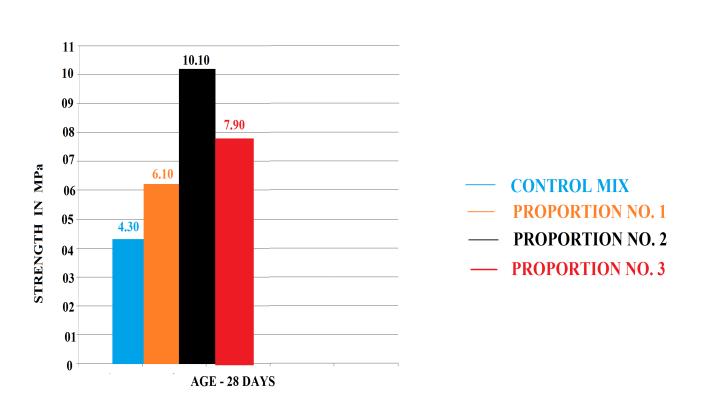

5.2.1 Compressive Strength , Split Tensile Strength and Flexural Strength

The average compressive strength, split tensile strength andflexuralstrength,after 28 daysofcuring, for different concretemixareshowninTable7

6. CONCLUSIONS

Themainconclusionsderivedfromthisexperimental studymaybesummarizedasfollows:

1. AsthepercentageofSteelfiber (SF) increases or the percentage of Polypropylene fiber(PPF)decreases,itshowstheloweringof workability. To improve the workability by increasingwater/cementratioorbytheuseof somepolymerbasedwaterreducingadmixtures.

2. The experimental results had shown that the compressive strength, split tensile strength andflexuralstrengthofpolydisperse (SFand PPFindifferentproportions)concreteincreases inallproportions(exceptsplittensilestrengthof proportionno.1)thanthecontrolmix.

REFERENCES

[1] Ruslan Ibragimov, Ruslan Bogdanov, et. al. (2022) “EffectofPolydispersereinforcementonthefreshand physical-mechanical properties of self-compacting concrete” ,Elsevier Case Studies in Construction Materials

[2] RamkumarK.B.,KannanRajkumarP.R.,(2022),“Impact ofhybridsteelfibresonfreshandmechanicalproperties ofself-compactingconcrete”,ElsevierCaseStudiesin ConstructionMaterials.

[3] Zhang Junwei, Yang Zhe (2022), “Investigation on mechanical property adjustment of multiscale hybrid fiber - reinforced concrete ”, Elsevier Case Studies in ConstructionMaterials.

[4] Bing Liu, Xuanyu Zhang et. al. (2022), “Mechanical propertiesofhybridfiberreinforcedconcrete”,Elsevier CaseStudiesinConstructionMaterials