UTILIZATION OF EGG SHELL POWDER AND PLASTIC WASTES IN THE PRODUCTION OF CONCRETE MIX

Jasbinder Singh1 , Sucharu Sharma2

1M.Tech. Student, Department of Civil Engineering, SSCET Badhani, Pathankot, Punjab, India

2Assistant Professor, Department of Civil Engineering, SSCET Badhani Pathankot, Punjab, India ***

Abstract – Concrete known as hard rock mass prepared by mixture of ingredients cement, sand, aggregates, water and sometimes admixtures. Cement plays an important role in concrete production as it works as binder to bind the other constituents together effectively. But the serious thing is that the production of cement adversely affects our environment with emission of enormous amount of CO2 Recycling trash to create usable items is one way to address this challenge. The feasibility,environmentalsuitability,andperformanceofusing waste in the construction field which requires better and more affordable construction materials and the reuse of wastes have all been the subject of numerous studies and researchprojectsundertakenbygovernmentagencies,private organizations and individuals. So, researchers worked a lot on the production of eco-friendly concrete using sustainable constructionmaterials.Inthisresearchwork,weemphasized ontherecycledwastestobeusedinourconstructionindustry such as Egg Shell Powder and Plastic Wastes. ESP partially replaces the cement content by 0 to 20 % with offset of 5% and Plastic wastes are used as Plastic Coarse Aggregates as 0 to 40% with offset of 10% to determine the strength characteristics of the concrete mix. The specimens were prepared and cured for 7, 14 and 28 days. The optimum strengthofthemixafter28daysofcuringshowsresultswithin permissible limits.

Key Words: Concrete, Egg Shell Powder, Plastic Waste Aggregates, Slump Test, Compression Test, Split tensile test, Flexural test, Strength.

1. INTRODUCTION

With the advancement of technology and increase of population, their standard of living and demands also increased day by day. Thereby resulting in wastage of matterswhichleavesinoursocietyasgarbageandaffects ourenvironmentbadly,pollutesoursurroundingwiththe emission of harmful gases. An issue in trash disposal has emerged due to the production of non-decaying and low biodegradablewastematerialsandanincreaseinconsumer population. Concrete construction is prior to other construction materials. Concrete is blend of some ingredients mixed with each other properly at proper desiredratiostopreparedesiredstrengthofconcrete.This type of construction is much preferred over others. Recyclingtrashtocreateusableitemsisonewaytoaddress thischallenge.Thefeasibility,environmentalsuitability,and

performanceofusingwasteintheconstructionfield which requiresbetterandmoreaffordableconstructionmaterials and the reuse of wastes have all been the subject of numerous studies and research projects undertaken by governmentagencies,privateorganizationsandindividuals adversely affects our environment with emission of enormousamountofCO2. So,researchersworkedaloton the production of eco-friendly concrete using sustainable construction materials. In this research work, we emphasized on the recycled wastes to be used in our construction industry. One of the materials used in our research is an Agricultural waste such as Egg shells are agricultural waste products made in bakeries, fast food restaurants, chick hatcheries, and other facilities. Because they can harm the environment, egg shells include environmentalcontaminantsthatrequireproperhandling. Another waste material usedin this researchis electronic plastic wastes which are recyclable in nature used in constructionindustrytoreducetheimpactofplasticsinour environment and helps to production of sustainable strengthenedconcrete.E-wasteisbeingproducedatarateof 3-4% annually over the world, and by 2025, that rate is anticipatedtoriseto55milliontonnesannually.Oneofthe greatestalternativesistoincorporatewasteplasticintothe buildingsectortocreategreenconcreteinordertolessen the negative effects on the environment and conserve naturalresources.

1.1Egg Shell Powder

Copper Slag, Quarry dust, Fly ash, rice husk ash and egg shells are wastes generated largely from industrial and agriculturalfieldsandarecauseofenvironmentalhazards and recycling. About 1.61 million tonnes egg shells are generatedannually,whichmakesIndiaafifthlargestcountry in the world. Both poultry and egg processing units have comepredominantlyinIndia.Usingeggshellwasteinsteadof naturallimeinsteadofcementinconcretecanbringmany benefits,suchasminimizingtheuseofcement,protecting naturallimeandusingwaste.Eggshellisagoodaccelerator forcementbinders.Theeggshellandlimestonearealmost sameinchemicalnature.Tothisend,wecanminimizethe useofcementandwastedisposal.Literaturehasshownthat theeggshellashprimarilycontainslime,calciumandprotein whereitcanbeusedasan alternativerawmaterialinthe productionofwalltilematerial,concrete,cementpasteand others.

1.1.1 Advantages of Egg Shell Powder

1. Itisaneffectivecalciumsupplement.

2. It helps to reduce the emission of CO2 from cement clinkersproduction.

3. It improves the compression and flexural strength of concretemix.

4.Itacceleratesthehydrationofcement

5.ItsusageperformsConsiderablereductionin alkali-silica andsulfateexpansions.

6. Using ESP, Saves money and meets the most stringent environmentalregulationsnationwide.

1.2 Plastic Waste Aggregates

Reusewasteproductsisanimportantperspectiveasithelps toconserveenergyintheproductproduction,decrementthe environmentalpollutionandalsohelpstosustainthenonrenewable natural resources. Using plastic wastes in the constructionormaterialindustrybecomesanenvironmental solutiontoreduceitsadverseimpactsonthesurroundings. Promotingrepurposedmaterialsisseenasbeneficialbythe lightweightbuildingmaterialsindustry.Concreteunitweight typically decreases when natural aggregates are replaced withlightweightmaterials.Inthisstudy,Plasticwastageare beingusedascoarseaggregatesintheconcretemixwiththe variationtogetoptimumpercentagereplacementsothatit canminimizetheimpactofwastageinsurroundingsandalso helpsinreductionofextinctionofnaturalresources.

1.2.1 Advantages of Plastic Waste Aggregates

1. Improvemixcohesion,improvingpumpabilityoverlong distances,

2. Improvefreeze-thawresistance,impactresistance–and abrasion–resistance

3. Increaseresistancetoplasticshrinkageduringcuring,

4. Improvestructuralstrengthandductility,

5. Reduce steel reinforcement requirements and improvingdurability.

2. LITERATURE REVIEW

R. Nirmala (2016) makes an experimental study on the partialreplacementofsandwithESPandcoarseaggregates with CW. This study tend to utilize egg shell and ceramic wastebypartiallyreplacingitinconcrete.Theeggshelland ceramic waste is equally replaced for fine aggregate and coarseaggregate respectivelyinpercentagesof5%,7.5%, 10%,12.5%and15%duringthemanufactureofconcrete. Theconcreteiscastincubesandcylindersanditistestedfor

compressive strength and tensile strength to find the optimum percentage of their replacement. Thus, results represents that the egg shell and ceramic waste can be utilizedinthemanufactureofconcreteatreplacementrate of12.5%.

S. Vanitha, V. Natrajan and M. Praba (2015) research dealswithM20gradeofconcretewithpartialreplacementof coarse aggregates by plastic wastage. Usually, grade M20 concretemixisusedformostconstructionalworks.Waste Plasticswereincrementallyaddedin0%,2%,4%,6%,8% and 10% to replace the same amount of Aggregate. To examine the physical properties, tests were conducted on coarse aggregates, fine aggregates, cement and waste plastics.PaverBlocksandSolidBlocksofsize200mmX150 mmX60mmand200mmX100mmX65mmwerecasted andtestedfor7,14and28daysstrength.Theresultshows thatthecompressivestrengthofM20concretewithwaste plasticsis4%forPaverBlocksand2%forSolidBlocks.

Lahakpa WangmoThinghTamanget. al. (2017) conducted anexperimentusingplasticsascoarseaggregateinconcrete. They tested the mechanical properties of concrete that containedplasticaggregatesinproportionsof10percent,15 percent,and20percent.Theydiscoveredaslightdecreasein strengthandsuggesteda15percentreplacementasthebest outcome.

D. Rambabu (2021) makes a study on the partial replacement of cement with egg shell powder in the concrete..TheEggshellusuallywhicharedisposed,isused asanalternateforthecementsincetheshellismadeupof Calcium.Eggshellpowderreplaces0%,10%,20%and30% in addition of weight of cement. Concrete is cast and Compressivetest,TensileandFlexuraltestswerecarriedout to find the best combination which results in optimum percentageofstrength.

Mr. V. Aravind1 , V. Ranjith (2022) Study on Partial ReplacementofCementandCoarseAggregatebyEggShell PowderandSteelSlaginConcrete.Themainobjectiveofthe study was to determine the workability and reinforcing properties including compression, tensile and flexural strength of concrete using various percentages (0, 10, 20,&10)ofESPbyweightinsteadofcement.Thetestresults showed that during the. With ESP 20%, tensile strength increased by 30%, and a maximum strength of 20% was obtained using ESP 20% during 28-day cure. As the ESP content increases, the workability of fresh concrete decreases.

2.1 Objectives

1. To identify that the wastes can be reused as constructionmaterials.

2. TostudytheeffectsofoptimumreplacementofEgg ShellPowderandPlastic Wastes.

3. DeterminationofSlumpofconcretemixusingESPand PWA.

4. TofindtheStrengthbehaviourofconcreteprepared usingESPandPWA.

3.

3.1

CementofOPC43gradeoftrademarkACChas beenusedin ourworkwhichiscollectedfromlocalcementstore.

3.2

Potable water is used for the preparation of concrete mix whichhelpsinhydrationofcement.WaterhavingpHvalues ranges6.5to7arepreferablyusedinthiswork.

Locallyavailableriversandalongthebanksofriverisused inthisstudyconformingtoZoneIIofasperIndianstandard 383-1970.

desired ratios. The different characteristics of the plastic wastagetobeusedasaggregatesaretabulatedinTable3.2.

LocallyavailablecrusherCoarseaggregatesofsize20mm areusedinourstudytoachievetheobjectivesofthestudy.

Inthisstudy,itcanbereplacedpartiallywithcementasit gives binding property. Locally available egg shells are collectedandgrindedthenitcanbesievedthroughthe90 micron sieve size and then packed to use it in the cement replacement.Thechemicalcompositionofeggshellpowder isshowninTable3.1.

3.5 Plastic Waste Aggregates

Plastic wastes are collected from surroundings nearby, crushedtorequiredsizesasthesizesofcoarseaggregates and then sieving can be done to define the different sizes. Finally,usedinourstudytoreplacethecoarseaggregatesat

4.4

5. CONCLUSIONS

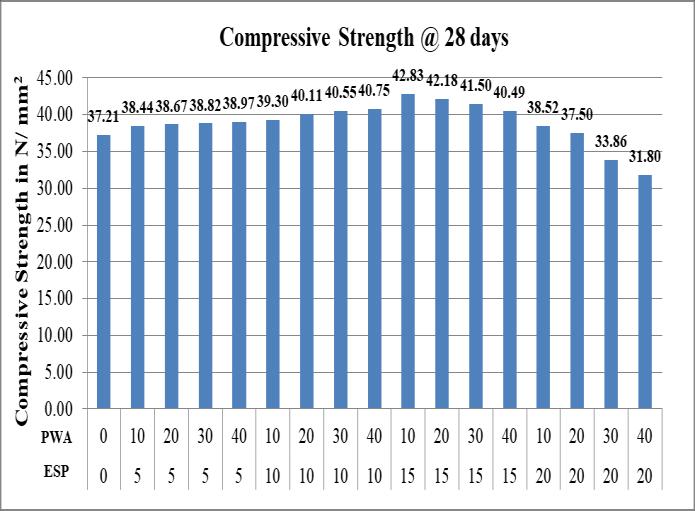

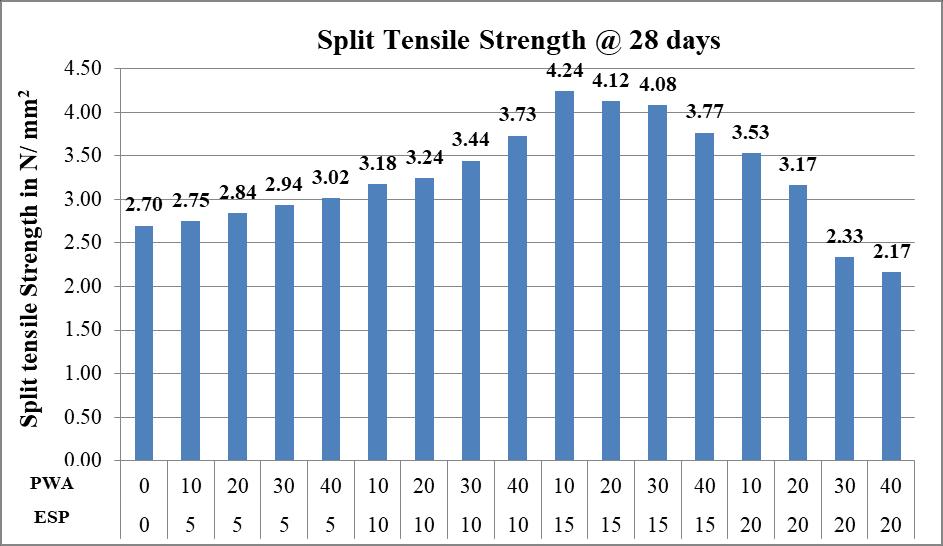

1. Concretemixwithcementreplacementby15%ESPand coarseaggregatereplacementby10%PWAcanbeused as structural concrete without compromising its strengthpropertiesasitistheoptimummixintermsof strengthandeconomy.

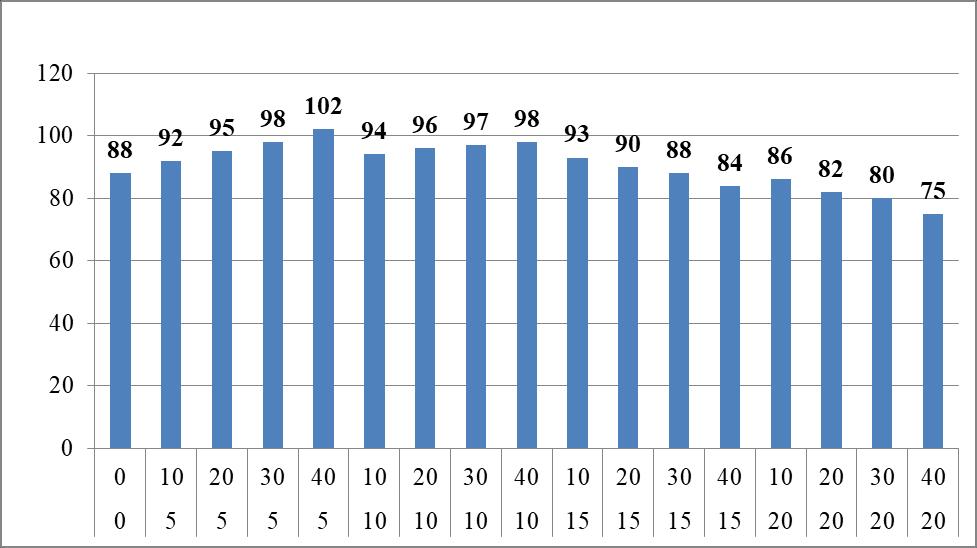

2. TheresultsofworkabilitybySlumptestconcludedthat workability increases with the increase in the Plastic Wastescontent.Thismaybeattributedtoincreasethe water content in the mix as it doesn’t absorb water. Maximum workability attained at mix of 5%ESP and 40% PWA. With the increase in content of ESP, the slumpgetsdegraded.

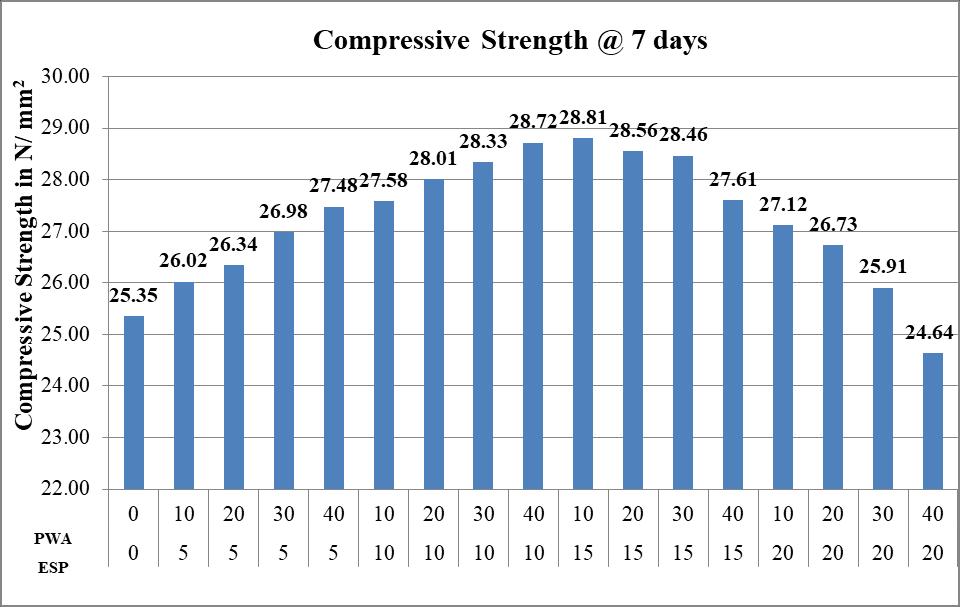

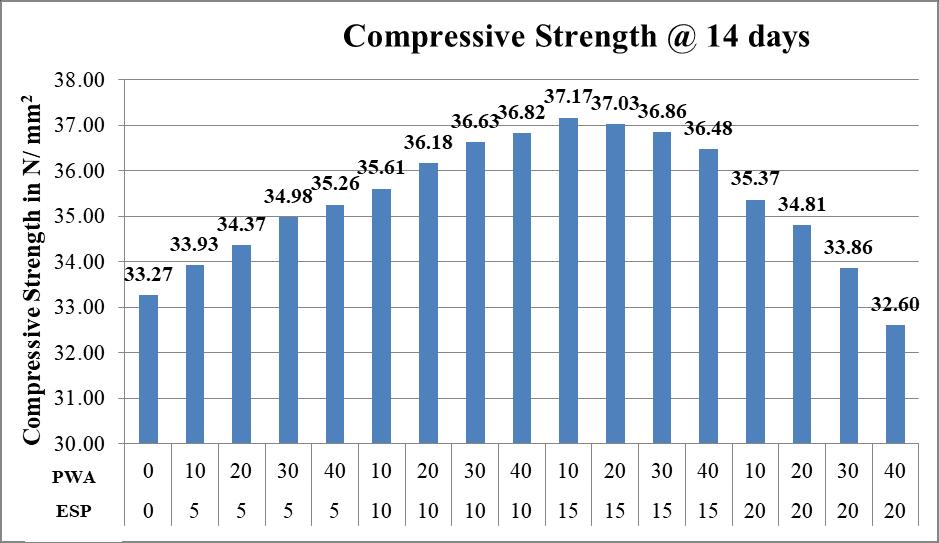

3. The maximum Compressive Strength of Concrete mix after 7days, 14 days and 28 days of curing increases gradually by replacement of cement and coarse aggregateswith15%EggShellPowderand10%Plastic Wastes as 28.81 N/mm2, 37.17 N/mm2 and 42.83 N/mm2

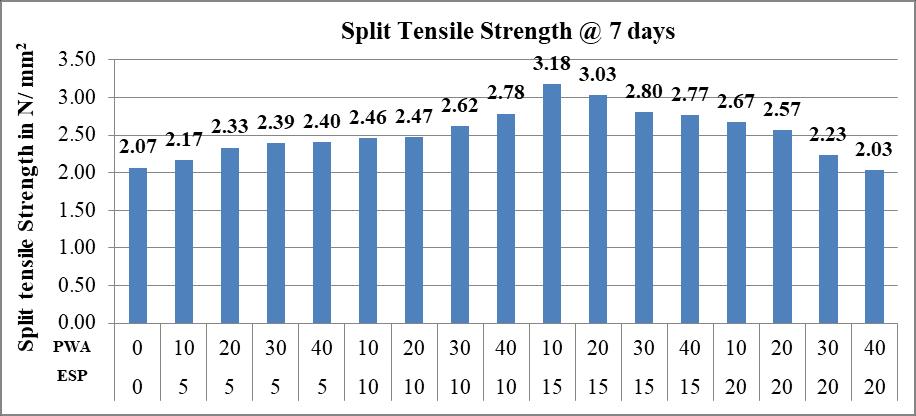

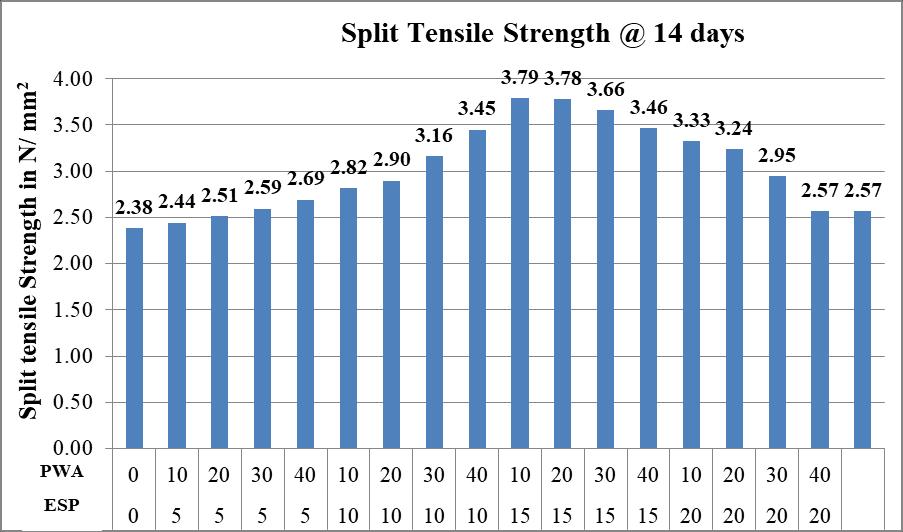

4. The Split Tensile Strength of mix achieves maximum valueof3.18 N/mm2,3.79 N/mmm2 and 4.24N/mm2 when ESP is 15% and PWA is 10% added to concrete mixafter7,14and28daysofcuring.

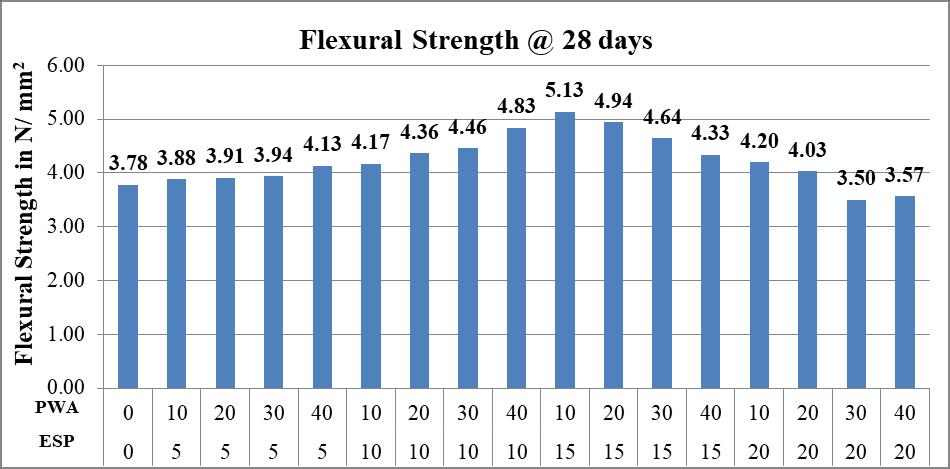

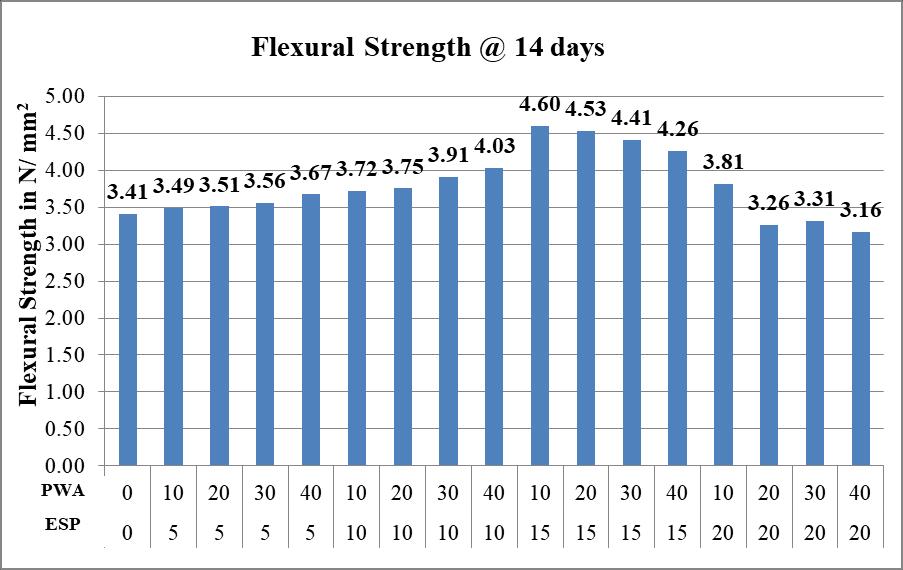

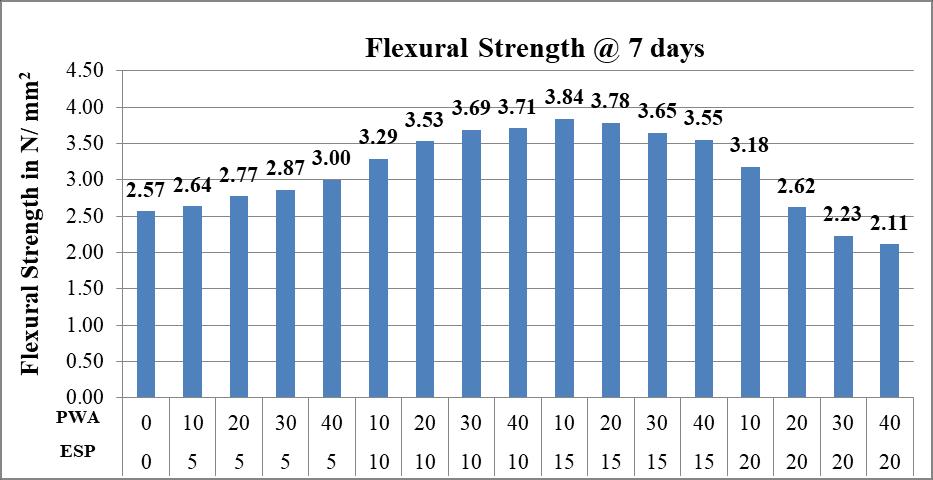

5. TheUltimateFlexuralStrengthobservedmaximumwith ESP is 15% and PWA is 10% i,e 3.84 N/mm2, 4.60 N/mm2and5.13N/mm2ofmixaftercuringof 7days,14 daysand28days.

6. REFERENCES

1. S.Vanitaet.al.(2015)“UtilisationofWastePlasticsasa Partial Replacement of Coarse Aggregate in Concrete Blocks” Indian Journal of Science and Technology, Vol 8(12), DOI: 10.17485/ijst/2015/v8i12/54462, June 2015

2. ManzoorAhmadAllieet.al.(2018)“AREVIEWSTUDYOF EGG SHELL POWDER AS A CEMENT REPLACING MATERIAL IN CONCRETE” International Journal of Scientific Development and Research (IJSDR) Volume 3 Issue 5 May 2018

3. Prasanna,P.K.;Rao,M.K.(2014)“Strengthvariationsin concretebyusingE-wasteascoarseaggregate.” J. Educ. Appl. Res. 2014, 4. Available onlinehttp://ijear.org/vol4/spl2/ec0046.pdf

4. Akram, A.; Sasidhar, C.; Pasha, K.M.(2015) “E-waste management by utilization of E-plastics in concrete mixtureascoarseaggregatereplacement” International Journal ofInnovative Research,Science Engineeringand Technology, Available

online:http://www.ijirset.com/upload/2015/july/8_EWaste.pdf(accessedon23November2021).

5. ParveenKumar,VijayaSarathy,“ExperimentalStudyon PartialReplacementofCementwithEggShellPowder”, International Journal of Innovations in Engineering and Technology (IJIET),Volume5Issue2April2015.

6. AmitShiulyet.al.(2022)“Performanceandoptimisation study of waste plastic aggregate based sustainable concrete–Amachinelearningapproach” CleanerWaste Systems,https://doi.org/10.1016/j.clwas.2022.100014