Experimental study on water absorbing pavement through model

2,3,4,5,6Diploma Students, Civil Engineering, Rajarambapu Institute of Technology, Rajaramnagar, Maharashtra, India

1Professor, Dept. of Civil Engineering, Rajarambapu Institute of Technology, Maharashtra, India ***

Abstract - Water absorbing pavement is a type of innovative pavement technology designed to mitigate the negative impacts of urbanization on water resources. This technology allows pavements to absorb rainwater, reducing runoffandfacilitatingwaterinfiltrationintotheground.The water absorbing pavement has been gaining popularity in recent years due to its potential to reduce flooding and erosion,enhancewaterquality,andsupportsustainableurban development. This abstract provides a brief overview of the water absorbing pavement, highlighting its benefits, limitations, and applications. The abstract concludes by identifying future research directions and the need for collaboration among researchers, practitioners, and policymakerstofullyexploitthepotentialofthistechnologyin promoting sustainable urbanization.

Key Words: Waterabsorbingpavement,concretepavement, compressivestrength,permeableconcrete,porousconcrete.

1.INTRODUCTION

Rainwaterandrunoffcanpassthroughporouspavementto the storage layer below and eventually soak into the underlyingsoilthankstothisstormwaterdrainagesystem. Because it may lower air temperatures on hot days, treat storm water quality, restore ground water supplies, and reducestormwatervolume,permeablepavementisgoodfor theenvironment.

Inordertocreateamassofaggregateparticlescoveredina thin layer of paste, porous concrete is a performanceengineered concrete made with controlled proportions of cement,coarseaggregates,water,andadmixtures.Thereisa significantamountofvacuumspaceinaperviousconcrete mixture since it includes little or no sand. When enough paste is used to coat and bind the aggregate particles, a networkofswiftlydraining,highlyporousgapsisformed. Lowwater/cementitiousmaterial(w/c)ratiosarenecessary forstrengthandtopreventthepastefromflowingandfilling thegaps.Theproduction'sperformancedependsonthew/c ratio.

1.1 Relevance

Inthecaseofawaterabsorbingpavementproject,some reasonswhyitmightbechosencouldinclude:

Addressing a pressing environmental issue: Urbanization and increasedrainfall intensity have led to an increase in flooding, erosion, and water pollution. Water absorbing pavement offers a solution to these issues by reducing runoff and improving water quality, which can make a significantimpactontheenvironment.

Advancing sustainability goals: Sustainability is becoming increasingly important in urban development,andwaterabsorbingpavementaligns withsustainabilitygoalsbyreducingenvironmental impactandpromotingtheefficientuseofresources.

Enhancingpublicsafety:Floodinganderosioncan pose risks to public safety and property. Water absorbingpavementcanhelpmitigatetheserisksby reducing the likelihood of flooding and erosion, which can improve the safety of roads and sidewalks.

Demonstrating innovation and leadership: Undertaking a water absorbing pavement project can showcase a commitment to innovation and leadership in urban development, which can enhance the reputation of the individuals or organizationsinvolved.

Overall,thedecisiontochooseawaterabsorbingpavement projectmaybedrivenbyadesiretoaddressenvironmental issues, promote sustainability, enhance public safety, or demonstrateleadershipandinnovation.

1.2 OBJECTIVE

To study water absorbing roads. To create workable model of water absorbing roads. To conduct appropriate testsonmodelofwaterabsorbingroads. Interpretresults withtraditional roads. Toprepareandsubmitproposal of thesame.

2. STUDY WORK

What is the pervious concrete?

Pervious concrete, commonly referred to as water absorbingconcrete,isauniquekindofconcretemadewith theintentionofallowingwatertotravelthroughit.Water-

absorbingconcreteisporousandmayabsorbwaterintoits structure, in contrast to conventional concrete, which is impermeable and allows water to run off its surface. As a result,thereislessstormwaterrunoffandmoregroundwater recharge since the water can be filtered and held in the ground.

2.1 Pattern and texture

Perviousconcretehasarough,opentexturelikearicecake. Becausetheroughtexturelowerstheglareassociatedwith typical concrete pavement, the color may be more noticeable.Thecoarseaggregatesizeandshape(roundor angular)inamixtureareimportantvisualdesignfactors.

2.2 Materials used in water absorbing pavement

Coarseaggregates:-

Coarse aggregates such as crushed stone, gravel or recycled concrete are used in the mixture of permeable concrete. These aggregates are typically between 3/8 and 3/4inchesinsizeandprovidethenecessarystrengthand durabilitytothepavement.

Propertiesofcoarseaggregate:

Gradation: The gradation, or size distribution, of coarse aggregate is critical in determining the permeability of perviousconcrete.

Strength: The strength of the coarse aggregate affects the overallstrengthanddurabilityoftheperviousconcrete.

Shape: The shape of the coarse aggregate can affect the permeabilityoftheperviousconcrete.

Cement: -

Themosttypicaltypeofcementutilizedinthecreationof permeable concrete is Portland cement. It serves as a bindingagent,keepingtheaggregatestogetherandgiving thepavementstrength.

Water:

In order to hydrate the cement and start the chemical processesthatresultinconcrete,waterisrequired.

Propertiesofwaterformakingblock:-

Itshouldbepotable.

ThepHofwatershouldnotbelessthan7. Itshouldbefreefromimpurities

3. STEPS FOR PREPARATION OF BLOCK

3.1 Sieving

Onlycoarse-grainedmaterialscanbeusedtomakeblocks; fine-grained materials cannot be used. The 20mm sieve should be used as a particular procedure to reduce large materials. Hand sieves can be used for dirt with minimal content.Asaresult,theparticleswillhaveasmoothtexture.

3.2 Materials selection

Water, cement, coarse and fine aggregates, and other components should all be chosen according to the application.

3.2 Mixing

It is important to thoroughly mix the ingredients. Hand mixingshouldbeusedtocombineallmaterials.Theexpense ofhandmixingshouldbereasonableforsmallvolumes.All thematerialsweutilizedfortheexperimentarebalanced. So, the calculation for our raw material should be made. 1900mlofwaterarerequiredtomakeaconcreteblock.An essentialcomponentofmixingisthebindingofthematerials together; the removal of air gaps must be accomplished through compaction. So that it can reach its optimum strength,theconcreteblock.Wheninspectingit,thefinishing shouldbetakenintoconsideration.

Weareusingdifferenttypeofproportionforpermeable concrete:-cement:coarseaggregate(1:3)

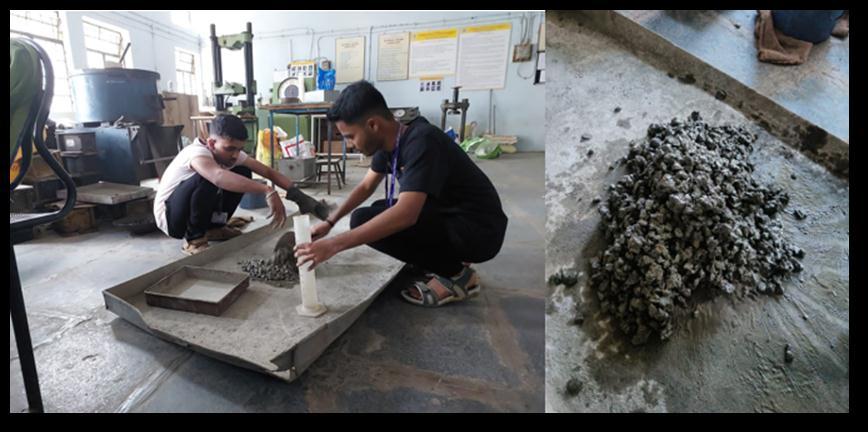

4. PREPARATION OF PERMEABLE SLAB

4.1 Actual Procedure of Slab Casting:

Thematerialsthatwillbeusedtocreatetheslabshouldbe keptinonelocation.thensubtractthecement'sweight.Itis important to confirm the aggregate size, which was previously determined by experimentation. By reading numerouspapersindifferentratios,thewater'scomposition shouldbechosen.

Wewillconstructaboxmeasuring16inchesby17inchesby 5 inches for our experiment. which uses the same proportions of the ingredients as our block. When constructingaslab,mix11kgofcementwith33kgofcoarse aggregateand3.5litersofwater.

Ingredients were added to the pan proportionately. The waterisaddedusingthesprinklingmethodafterithasbeen thoroughly mixed. To eliminate voids, prepared materials areputintoamouldandcompacted.Itneedstobepounded withtheblows.

Oncetheslabismade,itshouldbekeptforcuringupto28 days. After the curing of block, we are conducting compressivestrengthtest.

Aftertestingoffirstsetofblockswechangedproportionof waterasbelow.Andcarryoutsameprocedureasmentioned above.

1) 1:3(35%w/cratio)

2) 1:3(32%w/cratio)

Comparison between convention pavement and our pavementarebelow.Thefinishingofourpavementisnot equaltotheconventionalconcretepavement.

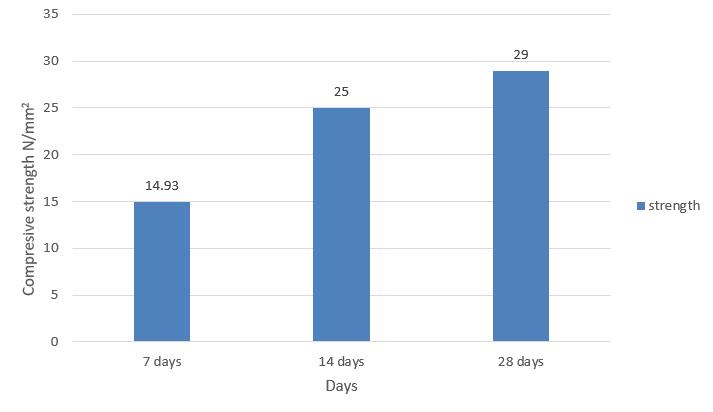

5.1 Test performed on block

1)Nameoftest:Compressivestrength:

ObservationTable:-

Forproportion:-1:3

6. COMPARISON

6.1 Comparison between water absorbing pavement and traditional pavements

Waterabsorbingpavementsandtraditionalpavementshave severaldifferencesintermsoftheirdesign,effectiveness,and cost.Herearesomeofthekeydifferencesbetweenthetwo:

Design: Rainwater can infiltrate through porous waterabsorbingpavementsandintotheearthbelowthankstotheir design.Theyareoftenconstructedfromporousmaterialslike asphalt,sand,andgravel.Traditionalpavements,ontheother hand, are constructed of impermeable substances like concrete or asphalt, which stop water from penetrating through.

Effectiveness: Whenitcomestominimizingrunoffduring intenserainfall,water-absorbingpavementsaresignificantly more effective than conventional pavements. Unlike conventionalpavements,whichcanonlyabsorbabout20% oftherainwater,theycanabsorbupto80%ofit.Asaresult, metropolitanareascangreatlybenefitfromtheuseofwaterabsorbingpavementstoreducefloodingandwaterdamage.

Cost: Installingwater-absorbingpavementstypicallycosts more than installing standard pavements. In the long run, nevertheless, they are more cost-effective since they eliminatetheneedforpriceyfloodpreventionsystemslike stormdrainsandretentionponds.Theyarethusapractical option for municipalities and cities seeking to lower the overallcostoffloodprevention.

Maintenance: When compared to standard pavements, water-absorbingpavementsrequireadditionalupkeep.Over time,thepavement'sporesmayclogandlosesomeoftheir capacity to absorb water. Water-absorbing pavements can stillbehelpfulatpreventingflooding,though,withroutine upkeepandcleaning.

6.2 Cost Comparison

Here is a cost comparison between water absorbing pavementsandtraditionalpavements:

1. Costs of Installation:

Becausewaterabsorbingpavementsrequiremorematerials andlabourduringinstallationthanregularpavementsdo, these costs are often greater. The cost of putting waterabsorbingpavementscanbeupto50%greaterthanthecost ofinstallingconventionalpavements,accordingtoareport by the National Research Council of Canada. The type of permeablepavementutilizedandtheamountoftheareato bepaved,however,mayaffectthiscost.

Depending on the pavement type, size, and location, the price to construct water-absorbing pavements can range fromRs.500to1600persquarefoot.Theaveragecostper squarefootforconventionalpavementsmadeofasphaltor concreteisbetweenRs.250 and850.Asa result,building water-absorbingpavementsmightcostupto50%morethan doingsowithstandardpavements.

2. Maintenance costs:

To keep their ability to absorb water, water-absorbing pavements needto bemaintained on a regular basis.This entailsroutinesurfacecleaningtopreventporeclogging,the elimination of dirt and vegetation, and sporadic repairs. Although this cost might vary depending on the level of maintenance required, maintenance costs for waterabsorbingpavementsaretypicallygreaterthanmaintenance costsforstandardpavements.

Pavementsthatcollectwaterneedroutinecare,whichmay include cleaning, fixing, and even replacing the surface. Dependingonthelevelofmaintenancenecessary,thecostof maintainingwater-absorbingpavementscanrangefromRs. 41 to 160 per square foot per year. Contrarily, the annual maintenance expenditures for traditional pavements typicallyrangefromRs.17to40persquarefoot.

3. Flood Damage Costs:

Reducingtheriskofflooddamageinurbansettingsisoneof themainadvantagesofwater-absorbingpavements.Flood damagemaybeexpensive,withexpendituresforemergency services,propertydamage,andrepairsalladdingup.Waterabsorbingpavementshavethepotentialtosavecitiesand municipalities a lot of money over time by lowering the dangerofflooddamage.

4. Savings from Reduced Flood mitigation systems: Citiesandmunicipalitiesmayalsobeabletosavemoneyby using water-absorbing pavements instead of pricey flood mitigationsystemslikestormdrainsandretentionponds. The use of water-absorbing pavements can minimize the demandforstormwatermanagementinfrastructurebyupto 80%, according toa study done by the National Research CouncilofCanada.

Note:ThecostsIgavearebasedonanalysisfromavarietyof sources, including industry data, scholarly research, and official publications. The real cost of water-absorbing pavements and conventional pavements, however, might varybasedonseveralfactors,includingthelocation,thetype ofpavementutilized,andthesizeofthearea to be paved. The prices I gave should be regarded as rough estimates sincetheymightnotberelevantinallcircumstances.

7. CONCLUSIONS

Water-absorbing pavements are a viable method of minimizing the harmful effects of urbanization on the hydrological cycle. These pavements provide various advantages, including reduced runoff, improved water quality,reducedfloodingdanger,andincreasedgroundwater recharge.Water-absorbingpavementshavebeenfoundtobe moresuccessfulthanregularpavementsindecreasingrunoff andflooddamagewhilealsoencouragingsustainableurban development.

Water-absorbing pavements have been shown in experiments to effectively reduce runoff in metropolitan areas,resultinginenhancedwaterqualityandreducedflood danger.Furthermore,thecost-benefitanalysisshowsthat, while water-absorbing pavements are more expensive to installandmaintainthanstandardpavements,theymaybe more cost-effective in the long term due to lower flood damageandfloodmitigationmeasures.

Itiscrucialtonote,however,thattheperformanceofwaterabsorbing pavements can be influenced by a variety of factors,includingthetypeofpavementused,thesizeofthe areatobepaved,andtheamountofupkeep.Toensurethe success of these pavements in metropolitan areas, meticulousplanninganddesignarerequired.

Overall, the use of water-absorbing pavements is a viable strategyforfosteringsustainableurbangrowth,mitigating flood risk, and enhancing water quality. More study and experimentationarerequiredtoimprovetheirperformance andapplicabilityinvariousurbansituations.

REFERENCES

[1] A REVIEW AND EXPERIMENTAL STUDY ON WATER ABSORBINGPAVEMENTMr.RohanKumarChoudhary, International Research Journal of Modernization in EngineeringTechnologyandScience(Peer-Reviewed, Open Access, Fully Refereed International Journal ) Volume:04/Issue:06/June-2022

[2] AProjectReportOn“WaterAbsorbingPavementUsing Pervious Concrete” MR. DANISH ANSARI SIR, International Journal of Research in Engineering and Science(IJRES)ISSN(Online):2320-9364,ISSN(Print): 2320-9356www.ijres.orgVolume10Issue3ǁ2022ǁ PP.27-38

[3] WaterAbsorbingPavementsbyusingPorousConcrete Jannathul Thasni.P, International Research Journal of EngineeringandTechnology(IRJET)e-ISSN:2395-0056 Volume:05Issue:05|May-2018