AN EXPERIMENTAL STUDY ON PARTIAL REPLACEMENT OF CEMENT WITH GGBS AND RICE HUSK ASH

1Assistant Professor, Dept. of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Anantapur.

2Final Year Student, Dept. of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Ananthapur.

3Final Year Student, Dept. of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Ananthapur

4Final Year Student, Dept. of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Ananthapur.

5Final Year Student, Dept of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Ananthapur.

6Final Year Student, Dept. of Civil Engineering, Srinivasa Ramanujan Institute of Technology, Ananthapur. ***

Abstract – Cement is one of the most important material in construction.The production of cement increases and results in reduce of availability of lime. So there are various waste materials which are produced in industries which causesenvironment pollution. We areusing wastematerials to reduce pollution in environment. We are using rice husk ash (RHS)which is agricultural waste and ground granulated blast furnance slag (GGBS) which is steel waste. So a considerable amount of rice husk ash and ground granulated blast furnance slag used in concrete improves strength and eco-friendly construction.The cement has been replaced by GGBS in the range of 0%,10%,20%, and 30% by weight of cement and rice husk ash in the constant proportion of 10% by weight of cement for M20 grade mix and compare with plain concrete slump cone test was conducted on the mixture to measure the workability of concrete. The compressive and tensile strength tests are conducted on the cubes and cylinders at 7,14,28 days for determining the strength properties of the hardened concrete. We observe that by replacement of 10% of RHS and 10% GGBS gives more strength as compared with remainingmix.

Key Words: GGBS, RHS, Cement, Fine Aggregates, Coarse Aggregates, Water, Compressive strength, split tensile strength.

1.INTRODUCTION

Concrete is one of the significantly accepted construction materialsinthedevelopmentofinfrastructure.Concreteis versatile and durable material that is widely used in construction. It obeys many properties such as strength, durability, impermeability and fire resistant. The current consumption of concrete is approximately 500 million tons per annum and demand is expected to reach one billion tons in next decade. Concrete is a mixture of cement, aggregates and water. Cement is an artificial materialmanufacturedwithnaturallyavailablelimestone, silicaandgypsum.Aggregatesareconsideredtobeone of maincomponentofconcretesincetheyoccupymorethan

70% of concrete mix. In the recent years, green the construction eco-friendly. The contribution of ordinary Portlandcementproductionworldwidetogreenhousegas emissions is estimated to be approximately 1.35 billion tonsperyear.

1.1OBJECTIVES

The main objective of this study is to determine the strengthofconcretebypartialreplacementofcementwith GGBSandricehuskash.

1.2SCOPE

Todeterminethepropertiesofthematerials.

To examine the mechanical properties of hardenedconcrete.

2.METHODOLOGY

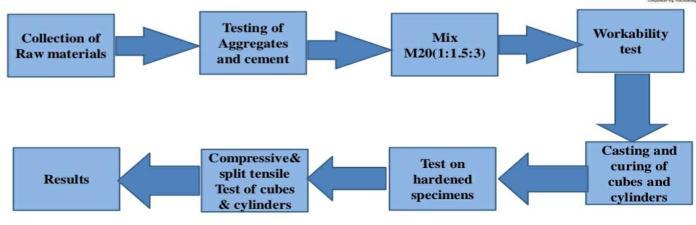

Theproject work hasbeen carriedoutinthefollowing stages

Chart 1:Methodologyofthework

3.MATERIALS USED

Thematerialsusedinexperimentalinvestigationare:

1.Cement

Cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Ordinary Cement OPC53 Gradewasusedinthepresentexperimentalinvestigation.

2. Ground granulated blast furnace slag (GGBS):

GGBSis abyproductobtainedfromsteelindustries.Which is burnt in blast furnace to produce granular material and powder

2.Testsggregates:

Fine aggregates:

a) specificgravityoffineaggregates=2.68

b) FinenessModulusOfFineaggregates=3.85

Coarse aggregates:

1.Specificgravityofcoarseaggregates

G=(w2-w1)/(w4-w1)-(w3-w2)

G=2.75

2.Finenessmodulusofcoarseaggregates=5.45

3.Impact test

The test can be done in toughness test machine to determinetheimpactstrength.Thevalueis18%

3. Rice husk ash (RHS):

Rice husk ash (RHA) is a fine powder left over after burning rice husks, which is high in silica, carbon, and otherminerals.RHAisaversatilematerialthatcanreduce waste

4. Fine Aggregates

Locally available natural river sand is used. It is naturally available.TheAggregateswhicharepassingfrom4.75mm to150micronsaretermedasfineaggregate.

5. Coarse Aggregates

The crushed stone aggregates were collected from the localquarry.Theaggregatewhicharepassingfrom80mm sieveto6.3mmsieveistermedascoarseaggregate.

6. Water

The water which is suitable for drinking can be used for construction.

4.LABORATORY

TESTS

1.Tests on cement: Table - 1:PhysicalpropertiesofOPC

S.No

4. Crushing Test

The aggregate crushing value gives a relative measure of theresistanceofanaggregate.Thevalueis19%.

In this project we are partially replaced the Cement with GGBSandRiceHuskAsh.Sothedifferenttypesoftestare performed

(I) Fineness test of cement and rice husk ash

TheFinenessisdoneto check particle distribution.Hence wegetas3.87%

(ll) Normal consistency test of cement and rice husk ash

We can take 270gm of cement and 30 grams of rice husk ashandthenwaterisadded.Plungerwasplacedontopof mouldandplungerwasreleasedintothepasteallowingit to sink into it.Water content was increased and the same procedurerepeated within 5mmto 7mm from bottom or 33to35mmfromtopofVicatmould. Itisobtainedas38%.

5.1 Mix Design calculation As Per Is: 10262-1982

Grade. =M20

Type =OPC53grade

SizeofAggregates=20mm

(

lll) Initial and final setting time of cement and rice husk ash

For this test Vicat apparatus, Needle and stop watch is used.Take300gmofcementand(270gmcement+30gm RHA) in a pan. For initial setting and final setting time of cementandRHA.

Maximumwatercementratio=0.45(byIS456)

Typeofaggregate=crushedangularaggregate Degreeofworkability=0.8(100mm)

Specificgravityofcement-3.15

SpecificgravityofGGBS=2.90

SpecificgravityofC.A=2.75

SpecificgravityofF.A=2.68

SpecificgravityofRiceHuskAsh=2.25

Exposurecondition=severe

Minimumcementcontent=250kg/m3

Step1: Target mean strength

Fck =fck+(t.s)

S=Standarddeviation=4(asperIS10262Table1) =20+(1.65x4) =20+6.6 =27.6N/mm².

Step2: To find w/c ratio FromIS456

Maxw/cratio =0.45

Step3: Selection of water content: FromIS10262

withRHS

InitialsettingTime 49minutes

Finalsettingtime 7hours

5.MIX DESIGN

Mix design is the process of selecting the suitable ingredients for concrete and determines their relative proportionswiththeobjectofcertainminimumstrength.

Maximumwatercontent=186lit(for25-30mmslump range) =186+((6/100)x186) =197.17liters

Step4: Calculation of cement content: Watercementratio=0.45

Cementcontent =197/0.45 =437.78kg/m3

FromIS456

Minimumcementcontent=240kg/m³ = 437.78kg/m3 . > 240kg/m3 Henceok.

Step5: Volume of aggregate: Weadoptwatercementratio=0.45

Volumeofcoarseaggregatecorrespondingto20mmsize aggregatesandfineaggregateszone4 =0.66

(attherateof-1+0.01for+-0.05changeinwatercement ratio)

=0.66+0.01

=0.67

Forpumpableconcretethesevaluesshouldbereducedby 10%

Volumeofcoarseaggregates=0.67*0.9=0.603

Volumeoffineaggregates. =1-0.603. =0.397

Step6: Mix calculation:

a)Volumeofconcrete=1m³

b)Volumeofcement=(Massofcement/S.Gofcement)x (1/1000) =437.78/3.15x(1/1000) =0.138m³

c)Volumeofwater=(Massofwater/S.Gof water)x (1/1000) =197/1x(1/1000) =0.197m³

d)VolumeofAggregates

Volumeofallaggregates=1-(0.138+0.197) =0.665m3

l)Massofcoarseaggregates=volumeofall aggregates*volumeofC.A*S.GofC.A*1000 =0.665*0.603*2.75*1000 =1102.73kgs

ll)Massoffineaggregates=volumeofall aggregates*volumeofF.A*S.GofF.A*1000 =0.665*0.397*2.68*1000 =707.53kgs

Step7: Mix Proportions

Cement. =437.78kg/m

Water. =197lit

FineAggregates. =707.53kg/m3

CoarseAggregates. =1102.73kg/m3

Watercementratio. =0.45

Procedure to cast concrete cubes and cylinders

1.Batching

2.Mixing

3.Casting

4.Curing

6.TESTS ON CONCRETE

6.1 Workability tests

Slump cone test was done to find the workability performance of the mixes. A slump test is a method used todeterminetheconsistencyofconcrete. Weobtainedatrueslump.

6.2 Specimens for Compressive strength test

Compressive strength test is done to measure the maximumamountofcompressiveloadamaterialcanbear before fracturing. The strength of concrete is determined bythecrushingstrengthof150mmx150mmx150mm,at anageof7days,14daysand28days.

fc=(load(P)/Area(A))N/mm2 where,

P=LoadatwhichthespecimenfailsinNewton(N)

A=Areaoverwhichtheloadisappliedinmm

Fc=CompressivestressinN/mm2

S.N

6.3 Specimens for Split tensile strength test

The strength of concrete is determine the load at which the concrete member cracks. In this test, cylindrical specimens of dimension 150 mm diameter and 300 mm lengthwerecast.Thespecimensaretestedafter7days,14 days and28days.Thesplittensiontestwasconductedby using digital compression machine having 2000 kN capacity.

ft =2P/πDL(N/mm2)

where,P=MaximumLoad(kN)

D=DiameterofSpecimen(150mm)

L=LengthofSpecimen(300mm)

f t =TensilestrengthN/mm2

14,

7.CONCLUSION

We can observedthat 10%&10%replacementof cementwithGGBSandRHS inmildconditionare showing an increase in compressive strength for 28days.

By increasing more %of GGBS the strength of concretedecreases.

By addition of 10% of RHS and 20% of ggbs the strengthofconcretedecreases.

Bythisweobservethat10%ofricehuskashand 10% of ground granulated blast furnance slag gives more strength when compared with plain concretemix.

By using this materials we can increase strength andreducepollutionintheenvironment

REFERENCES

1. Rughooputh, Reshma, and Jaylina Rana. "Partial replacement of cement by ground granulated blast furnace slag in concrete." Journal of Emerging Trends in Engineering and Applied Sciences 5.5(2014):340-343.

2. Prasanna, P. K., K. Srinivasu, and A. Ramachandra Murthy. "Strength and durability of fiber reinforced concrete with partial replacement of cement by Ground Granulated Blast Furnace Slag." Materials Today: Proceedings 47 (2021): 5416-5425.

3. Ahmad,Jawad, etal."Acomprehensive reviewon the ground granulated blast furnace slag (GGBS) in concrete production." Sustainability 14.14 (2022):8783.

4. Suresh, Dr, and K. Nagaraju. "Ground granulated blast slag (GGBS) in concrete–a review." IOSR journal of mechanical and civil engineering 12.4 (2015):76-82.

5. Samad, Shahab, Attaullah Shah, and Mukesh C. Limbachiya. "Strength development characteristicsofconcreteproducedwithblended cement using ground granulated blast furnace slag (GGBS) under various curing conditions." Sādhanā 42(2017):1203-1213.

6. Mosaberpanah, MOHAMMAD A., and SADIQ A. Umar. "Utilizing rice husk ash as supplement to cementitious materials on performance of ultra high performance concrete:–a review." Materials TodaySustainability 7(2020):100030.

7. Hawileh, Rami A., et al. "Performance of reinforced concrete beams cast with different percentages of GGBS replacement to cement." Archives of Civil and Mechanical Engineering 17(2017):511-519.

8. Sun, Bo Cheng, and Shao Qing Wang. "Rice Hull Ash Concrete Mechanical Properties." Applied Mechanics and Materials. Vol. 193. Trans Tech PublicationsLtd,2012.

9. Arivalagan, S. "Sustainable studies on concrete with GGBS as a replacement material in cement." Jordan journal of civil Engineering 8.3 (2014):263-270.

10. Paul, Abhinaba, and Monowar Hussain. "Sustainable Use of GGBS and RHA as a Partial Replacement of Cement in the Stabilization of IndianPeat." InternationalJournalofGeosynthetics andGroundEngineering 6(2020):1-15.