STATISTICAL INVESTIGATION OF LOCALLY SOURCED OILFIELD CHEMICALS FOR DRILLING FLUID DESIGN

*Ndubuisi, E.C, Nwachukwu., C.C., Emeka Iloke and Amadi F. N.

*Ndubuisi, E.C, Nwachukwu., C.C., Emeka Iloke and Amadi F. N.

The University of Port Harcourt, Faculty of Engineering, Department of Petroleum and Gas Engineering, East-West Road, Choba, Port Harcourt, Nigeria, P M B 5323, Choba

Abstract - Overtheyear,importedpolymershavebeenin use to modify rheological properties and reduce fluid loss in drilling fluid performance hence, these imported polymers tend to make the cost of drilling fluid design significantly more expensive, and this imperatively affects the cost of the drilling operation generally. Experimental studies were conducted on locally sourced polymers such as Brachystegia eurycoma (achi), Detarium microcarpum (ofor) to ascertain its ability to enhance viscosity and minimize fluidloss within thetemperatureregimes of 80150degree Fahrenheit. The rheological and fluid loss properties of the local polymers were compared with the imported polymers, Pac-R (polyanionic cellulose regular, and Pac-L. The results gotten from the experiments showedthatthelocalpolymersaregoodcandidatesforthe rheological modifiers and fluid loss reducers at investigated temperatures. Furthermore, investigation statisticalanalysiswascarriedoutandtheresultsindicate thatDetarium microcarpum canbeusedasa replacement forPACR.TheresultsfromANOVAshowedthattherewas no significant difference between detarium microcarpum and PAC R. No doubt, results have shown that locally sourced polymers could be substitute to imported polymers.

Keywords: Brachystegia eurycoma, Detarium microcarpum, polymer, fluid loss, viscosity Drilling fluid technology hasalways been in constant development, and this is due to certain factors which include, the speedy increase in needs due to more crucial conditions such as hightemperaturesandhighpressuresofthewell,etc. The convolution of problems encountered during drilling operations has brought about constant research and development of new techniques and additives for the formulation of appropriate drilling fluids’ The performance of a drilling fluid is a result of the quality of the fluid, and this plays a very vital role in the success of the entire drilling operation thus, an improper drilling fluid design will have a negative economic impact on the costofdrillingthewell 1,.2 Toevaluatetheefficiencyofany drilling fluid, in terms of cutting removal, certain measurable parameters are required, such as the drilling

fluid viscosity, flow rate, pipe rotation, slip velocity, and cutting transport efficiency3. As the drilling fluid is being pumped downhole during the drilling process, contaminants could greatly change the properties of the fluiddownhole.

OVERVIEW OF DRILLING FLUID

Drilling is the process whereby a hole is bored into the earth'ssurfacewiththeuseofadrillbit,togenerateawell for the production of hydrocarbon. It involves the penetration of the earth's crust to several thousand feet where the hydrocarbon is accumulated in the reservoir usinga rotarydrilling process.Intheoilandgasindustry, these drilling fluids are needed to enhance drilling operationsandit executes several functionsinthedrilling operation, thereby drilling fluid is considered one of the key factors in the success of a drilling operation. Drilling fluid is a mixture of chemical additives, water or oil, and clay, pumped down the wellbore from the surface, to cool andlubricatethe bit,control formationpressures,remove drilled cuttings from the wellbore to the surface, and generally help increase the drilling efficiency. A qualitatively formulated drilling fluid is required to avoid drilled cuttings from getting accumulated in the wellbore annulusandtodefraystuckpipesituationsfromoccurring. Poor hole cleaning and inefficient cutting transport may leadtootherunwanteddrillingproblemssuchasexcessive equivalent circulating density ECD, high torque and drag, lost circulation, and formation fracture, all of these could leadtoanincreaseinnon-productivetimeanddrillingcost ofthewellThefunctionsofdrillingfluidwhichiscrucialto drilling operations4 which include: transport drilled cuttings to the surface; control subsurface pressure.; support the walls of the wellbore.; cool and lubricate the drillbitanddrillstringandsoftentheearth,toalloweasier penetrationwiththebit.

However, in drilling operations, because cuttings and carvingsareheavierthanthedrillingfluid,theytendtofall toward the bottom of the wellbore while they are being lifted by the drilling fluid during the drilling and

circulating operations. The rate at which these particles fall through the flowing fluid depends primarily on the density and viscosity of the fluid, the size, shape, and density of the particles. The first objective in planning a mud program is selecting a mud that will minimize the amountoflosttimeindrillingoperations.Beforedesigning and using a drilling fluid, the complexity of the well being drilled, subsurface pressures, temperatures, and local experiences should be put into consideration. Generally, two or three kinds of water-based drilling muds are used bentonitedrillingmud,polymerdrillingmudwithoutclays thatdiminishshaleformationhydration,andadrill-influid that prevents permeability damage as well as possesses inhibitory properties depending on the borehole’s depth and formations drilled at the time borehole drilling. The main ingredient of bentonite drilling mud is bentonite which acts as a structural building component4. However, in clay-free mud the, structure and viscosity is built by polymer XCD, high viscosity, plant-derived organic polymers ,or their mixtures5 Depending on the well designand other factorsto be considered before selecting a drilling fluid, there is a variety of additives that can be usedtodesignthedrillingfluidproperties,whichincludes alkalinity control, lubricants, shale inhibitors, weighing agents,viscosifiers,lostcirculationadditives,etc. Withthe requiredadditives,thedrillingfluidissuitablyformulated forthegivengeologicalformations.Additivesareavailable to enhance the desired properties of the drilling fluid, for maximumperformanceofthefluidtoachievea successful drillingoperation.

Brachystegia Eurycoma (Achi)

InNigeriaandsomeotherpartsoftheworld,brachystegia Eurycoma (achi) as shown Figure 1 are generally used as soupthickeners.Brachystegiaeurycoma,popularlyknown as achi in the Igbo language in Nigeria is a leguminous plant, belonging to the family caesalpiniceae, phylum spermatophyte, and order Fabaceae. Brachystegia eurycoma (achi) grows mainly along the river bank or swamps in western and eastern Nigeria and western Cameroon.Italsogrowsbestonafertilemixtureoftopsoil andriversandwithawateringintervalofupto3days5.It ispropagatedbyseed.Brachystegiaeurycomaisknownby various tribal names in Nigeria. In Edo state, it is called (Okunen), in Efik, it is called (Okung), in Ejagham it is called(Etare),inEsan,itiscalled(Eku),inIgboitiscalled (Achi), in Igbo ukwuani, it is called (Onyan),. Brachystegia eurycomapowderisagottenbygrindingtheseedintofine powder form. Brachystegia eurycoma (achi) is generally known as a thickener, which are materials that can raise theviscosityofafluidwithoutaffectingitsotherqualities. Thesefruitseedpowderformviscousdispersionsinliquid,

also known as hydrocolloids. Hydrocolloids are colloid systems, made up of particles that form hydrophilic polymerswhendispersedinaliquid

Detarium Microcarpum (Ofor)

Detarium microcarpum (ofor) tree is widespread and common across tropical West Africa. Detarium microcarpum,popularlyknownasoforinIgbolanguageis generally used as thickeners in soups. Detarium microcarpum as shown in Figure 2 is a leguminous plant and it also belongs to family caesalpiniceae, phylum spermatophyte and order fabaccae. Detarium microcarpumtreeisconsideredaveryimportantspecieof tree in the tropical region of West Africa. It is propagated byseed.Detariummicrocarpumisknownbyvarioustribal names in Nigeria.Inigbo, it isknownas(ofor), in Yoruba, itiscalled(ogbogbo),andinHausaitiscalled(taura).Just likebrachystegiaeurycoma,detariummicrocarpumisalso knownasathickener,whichisamaterialthatcanraisethe viscosity of a liquid without affecting its other qualities. The fruit powder also forms viscous dispersions in liquid, alsoknownashydrocolloids.

Availability of Brachystegia Eurycoma (Achi) and Detarium Microcarpum (Ofor) in Nigeria

Overtheyears,companiesinvolvedindrillingfluiddesigns and production, for drilling operations in Nigeria have imported most polymeric additives, which has an adverse effect on the cost of drilling the well, and has not been of economic advantage. Nigeria is replete with natural resources in various forms, thus, researches to find how theserawmaterialscanbeutilizedorhowtofindsuitable substitutes which can be developed and sustained for research and technology advancements of Nigeria is very expedient6. Nigeria is the world largest producer of brachystegiaeurycomaanddetariummicrocarpum.These seeds are largely found in the south eastern parts of Nigeria.

The objectives of this study are to; evaluating the rheological and fluid loss properties of water-based mud designed with brachystegia Eurycoma and detarium microcarpum under temperatures of (80 – 150 0F) and developstatisticalmodelswithexperimentaldata.

Project Activity

The practical was conducted with dry Brachystegia eurycomaanddetariummicrocarpumseeds.TheImported polymers, (polyanionic cellulose regular, and pac-L) were provided by an oil company. The different drilling fluids were formulated with the same concentration of the local and imported polymers, after which, the rheological tests wereconductedonthedifferentmixturesofdrillingfluids at different temperatures. The results of the properties of the drilling fluid samples that were formulated with local andimportedpolymerswerethenanalyzedsystematically andfurthercomparedtoeachother.Theeffectofthelocal polymersonthefluidwasfurtherevaluated.

Materials and Equipment.

The materials and equipment used for the practical are showninTables3.1and3.2respectively.

Materials

Freshwater, Universal solvent, Bentonite Binder/Viscosifier, Brachystegia eurycoma(achi), Viscosifier Detariuem microcarpum (ofor) Viscosifier, Pac-R Viscosifier and Pac-L Viscosifier

Preparation of Drilling Fluid.

Dry samples of the two additives were used at different concentrations (0.1% and 0.5%) were prepared and used for the experiment. The dry samples were blended separatelyintofinepowderform.Afterblending,20grams of detarium microcarpum (ofor), and 20grams of Brachystegia eurycoma (achi) respectively, were further driedinthedrying ovenfor onehour,ata temperature of 105˚C, to remove its moisture content. After the drying process, the quantities were reduced to 18.9 grams and 17.59grams,respectively,andthisisbecausethemoisture present in the samples was dried up in the drying oven. The various samples were weighed with the aid of an electronic balance before being added to the mixing fluid.

HamiltonbeachmixerOFITEmodel9B5spindle,wasused to obtain a very homogenous mixture of the fluid. The Hamilton beach mixer was turned on, and the water was measuredwiththemeasuringcylinder,bentonitewasthen

stirred in the mixer, to completely disperse them before the samples were added. This was done in separate mud cups. After the dry samples were added to the respective mud mixtures, the mixture was left in the mixer to properly mix for 60 seconds. The dry materials and the water temperature were kept at 80˚F before the mixing started. They were used to achieve the drilling mud preparations. The bentonite served as a control in the different mud sample designs. The various drilling fluids formulated were further subjected to rheological tests, fluidlosstests,pHtests,andGelstrength.

Table 5:Drilling Fluid Design for 0.5%

The gel strength for 10 seconds was gotten from the viscometer 10 seconds after the drilling muds had been left static, and the gel strength for 10 minutes was gotten 10minutesafterthedrillingmudshadbeenleftstatic.This isbythestandardAmericanPetroleumInstituteprocedure (APIRp13B-1/ISO10414-1,2016).

API Fluid Loss Test

Rheological Test

After the various drilling fluids were prepared using the varioussamples, each ofthe samples was transferredinto theviscometercupindependentlyandexposedtoshearin a model 800-8speed viscometer. The torque response to each rotational speed gotten from the viscometer at 600RPM, 300RPM, 200RPM, 100RPM, 6RPM, and 3RPM, were recorded. At each of these rotational speeds, the readings of the revolution per minute (RPM) were taken when the rotation speed was stabilized. At temperatures above 80˚F, the drilling fluids were poured into the thermo-cup,toincreaseitstemperature,andthethermoscup was installed on the viscometer, at the rotational speed of 150rpm for 15 minutes, to obtain test temperatures of 120˚F to 150˚F. At each of the required temperatures, the drilling fluid was subjected to rheological tests and at each rotation speed, the dial readings were recorded when the rotation speed was stabilized. The rheological values obtained from the viscometer and the various calculations from the test results are shown below. The measurements and calculations were done using the American Petroleum Institute specifications. The readings obtained from the viscometerwerefurtherconvertedto oilfieldunits,toget valuesforshearrateandshearstress,using equations 3.1 and3.2respectively.

Calculationsforshearrate:

Shearrate( )=1.7023×RPM,N (1)

Calculationsforshearstress:

Shearstress(lb/100 =1.065×1˚Faan (2)

CalculationofPlasticviscosity(PV):

The plastic viscosity (PV) of the drilling muds was calculatedusingequation(3.3.)

PV(cp)=(ϴ₆₀₀-ϴ₃₀₀) (3)

Whereϴ=dialreading.

ThecalculationforYieldpoint:

The yield point for the drilling fluid was calculated using equation(4)

YP(lb/100 )=(ϴ₃₀₀-PV) (4)

The fluid loss tests of the various drilling muds were carried out using the multiple API filter press following APIstandards.Thevariousdrillingfluidswerepouredinto different API filter press cells, and all were covered properly. 250ml glasscylinders were rightly placed under each of the cells, to get the fluids lost during the test. Carbon dioxide (CO₂) gas was used to apply a pressure of 100psi on top of each of the cells. The test started when the outlet was opened for the Carbon dioxide gas to exert pressure on the cells. The filtrates gotten were measured and recorded, and further plotted against time. It was ensuredthatthisfiltrationlastedfor30minutes.

Rheological Models Fitting

Thevariousresultsgottenfromthedrillingmudsdesigned from the imported additives (Poly anionic cellulose regular, and Pac-L, and the local additives (Brachystegia eurycomaanddetariummicrocarpum), wereall subjected to the constitute models, to ascertain the rheological modelparameters.HerschelBulkley,Binghamplastics,and power law rheological models were used in fitting all the data that were gotten in the rheological tests. The Viscosifiersatthedifferentrotationalspeedswerefurther converted to shear rate and shear stress, to fit the model equations to determine the relationship between shear rateandshearstress

Statistical Analysis

One-way only variance (ANOVA) was used to analyse the viscosity data from the rheological test with the use of statisticalsoftware.Thetest(ANOVA)wasusedbecauseit isusedtoevaluatedifferencesamonggroups

Cost Evaluation Analysis

Cost evaluation analysis was used to determine the least expensive between the imported polymers (PAC R and PAC L) and local polymers (Brachystegia eurycoma,achi, and detarium microcarpum, ofor,). To determine the cost of polymer required to formulate the investigated drilling fluid design as presented in Table 3 and 4, the laboratory

units of the polymers are converted to the oil field units withtherelationship.

RESULTS AND DISCUSSION

The results obtained from the formulation of the various drilling fluids of both imported polymers (Poly anionic cellulose regular and Pac-L), and the two local polymers (Brachystegiaeurycomaanddetariummicrocarpum)were presented.Theanalysistowardsdeterminingtheeffectsof the imported polymers and the local polymers on the rheological properties of the drilling fluid; fluid loss, were recordedanddiscussed.Costanalysisandevaluationwere done and the results were recorded, to ascertain the economic advantage of the local polymers (Brachystegia eurycoma, and detarium microcarpum) as viscosifiers in the drilling fluid compared to the cost of using the imported polymers (Poly anionic cellulose regular, and Pac-L).

Rheological Properties of Drilling Fluids

Formulated with Local Polymers (Brachystegia Eurycoma and Detarium Microcarpum) and Imported Polymers (PAC R and Pac L)

Therheologicalpropertiesofthedrillingfluidsformulated with the local polymers (Brachystegia eurycoma and detarium microcarpum) and the imported polymers (PAC R and PAC L) were gotten with the use of viscometer as shown in Tables 6 to 14. The experiment showed that the viscosity of the drilling fluids formulated with the importedpolymersandlocalpolymerswasaffectedbythe speed of rotation and temperature for both drilling fluids of 0.1% and 0.5% concentrations, within the investigated temperatures (80-150degree Fahrenheit), therefore the dial readings from the rheometer increased with increase intemperature. The resultsobtained fromthe experiment showed that the rheological properties of the local based drilling fluid polymers (Brachystegia eurycoma and detarium microcarpum) performed favorably with the imported-baseddrillingfluidpolymers(PACLandpacR).

Effects of Temperature on Shear Rate and Shear Stress Relationship on Imported Based Polymers (PAC L and PAC R), and Local Based Polymers (Brachystegia Eurycoma Achi and Detarium Microcarpum,Ofor)DrillingFluids

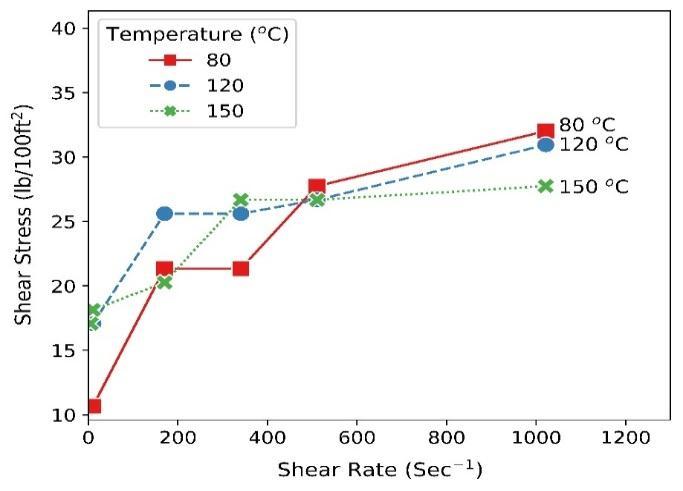

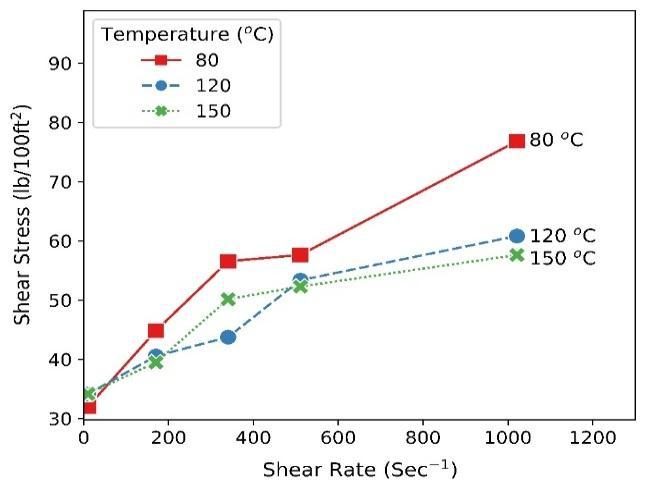

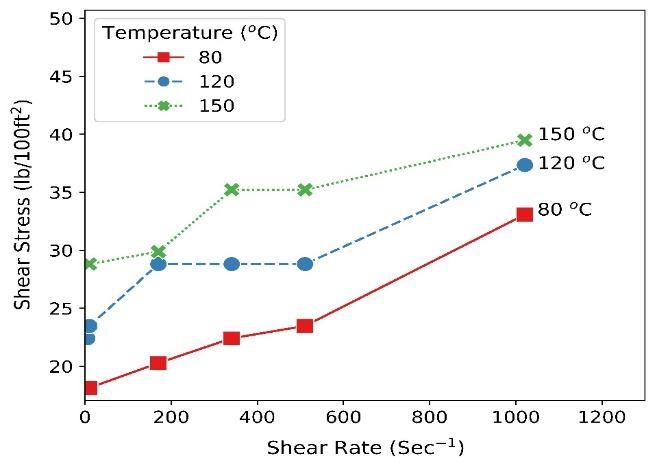

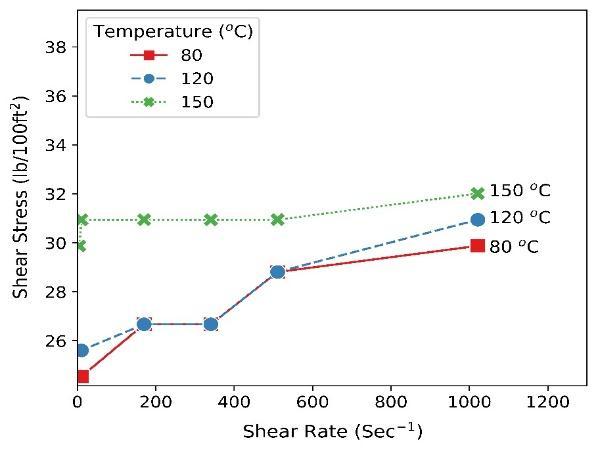

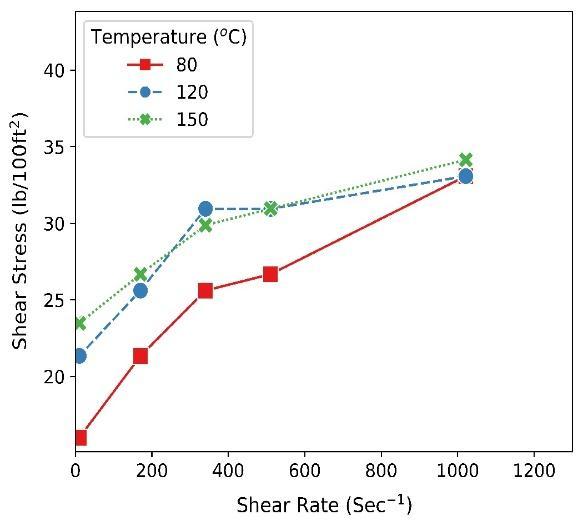

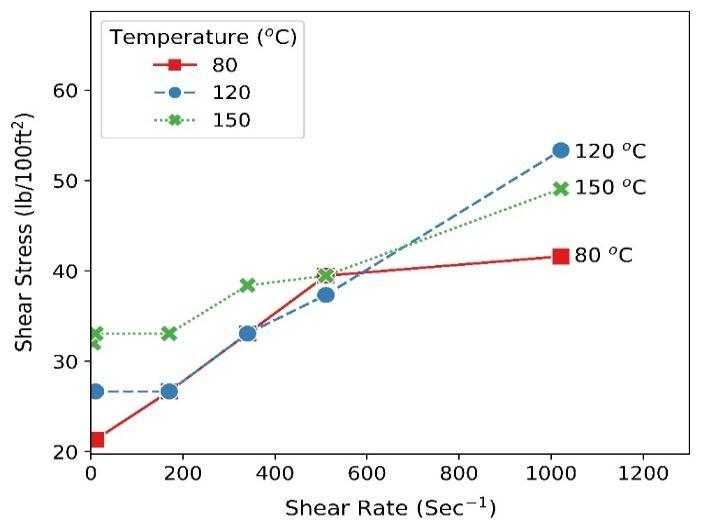

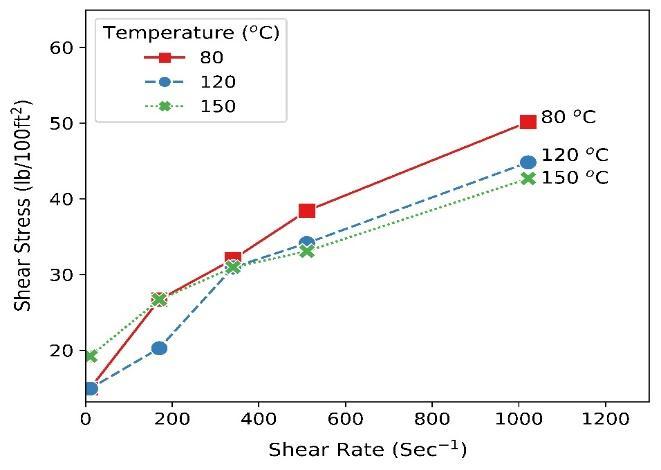

Upon 0.1% concentration of Pac L, Pac R, achi and ofor respectively, the effect of temperature on was ascertained asshowninFigures 3 to11. AtTheLowest ShearRate of 5.11/Sec, PAC R showed maximum shear stress of 34.08lb/100sqft and minimum shear stress of 31.95lb/100sqft. Brachystegia eurycoma (achi), showed a maximumshearstressof29.82lb/100sqft,andaminimum shear stress of 24.495lb/100sqft. Detarium microcarpum, ofor,showedamaximumshearstressof28.755lb/100sqft, and a minimum shear stress of 18.105lb/100sqft. PAC L showedamaximumshearstressof17.04lb/100sqftanda minimum shear stress of 10.65lb/100 sqft. At the highest shear rate of 1021.38/sec, PAC R showed a maximum shear stress of 57.51lb/100 sqft and a minimum shear stress of 76.68lb/100 sqft. Brachystegia eurycoma, achi, showedamaximumshearstressof31.95lb/100sqft,anda minimum shear stress of 29.82lb/100 sqft. Detarium microcarpum ofor showed a maximum shear stress of 39.405lb/100sqft and a minimum shear stress of 33.075

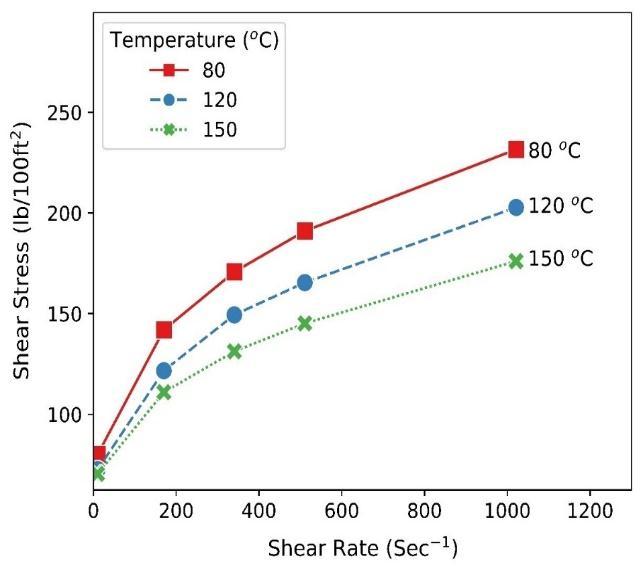

lb/100sqft. PAC L showed a maximum shear stress of 27.69lb/100 sqft and a minimum shear stress of 31.95lb/100 sqft. For 0.5%, at the lowest shear rate of 5.11/sec, PAC R showed a maximum shear stress of 70.291lb/sqft and a minimum shear stress of 78.810lb/100 sqft. Brachystegia eurycoma showed maximumshearstressof31.951lb/100sqftandminimum shear stress of 21.300lb/100 sqft. Detarium microcarpum showed a maximum shear stress of 42.611lb/sqft and a minimumshearstressof86.265lb/100sqft.PACLshowed a maximum shear stress of 19.271lb/100 sqft and a minimumshearstressof14.911lb/100sqft.Atthehighest shear rate of 1021.38/sec, PAC R showed a maximum shear stress of 175.725lb/100 sqft and a minimum shear stress of 231.105lb/100 sqft. Brachystegia eurycoma showed maximum shear stress of 48.991lb/100 sqft and minimum shear stress of 41.535lb/100 sqft. Detarium microcarpum showed a maximum shear stress of 135.255lb/100 sqft and a minimum shear stress of

199.155lb/100 sqft. PAC L showed a maximum shear stressof42.611lb/100sqftandaminimumshearstressof 50.055lb/100 sqft. This implies that there was a trend of increase and decrease of shear stress vs shear rate at different temperatures for local polymers and imported polymers. The graphs represent a linear relationship between the shear stress and the shear rate, and this impliesthatthedrillingfluiddoesnotflowuntil theshear stress has exceeded the critical values which are also known as yield point, and this gets to a point where the shearstressandtheshearratebecomesproportionalwith temperatureincrease.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072

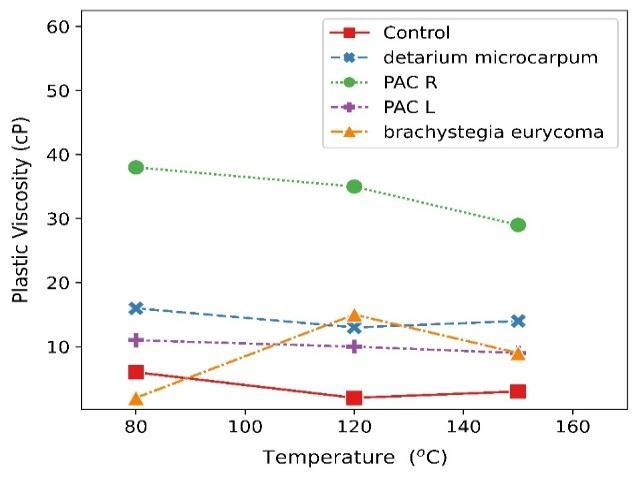

Effects of Temperature on Plastic Viscosity of Drilling Fluids Formulated with Imported and Loaal Polymers

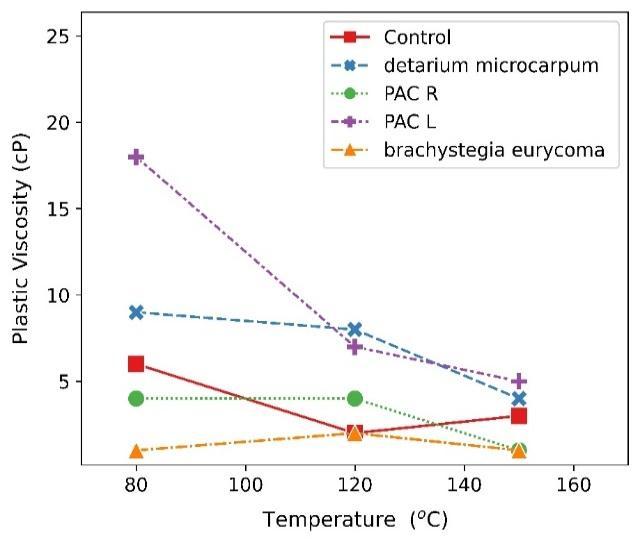

Ataconcentrationof0.1%and0.5%,ofthevariousdrilling fluid polymer samples, it was observed that the plastic viscosity decreased with increasing temperatures of 80 to 150 degrees Fahrenheit, as shown in Figures 12 and 13. This shows that the drilling muds with these samples will pump more rapidlyasa resultofthedecreasein viscosity duetotemperatureincreasebecausehighplasticviscosity will bring rise to problems in the pumping ability to drill fluidpassingthroughthedrillbit.Afterall,anincrementof solid particles in the drilling fluid brings about higher viscosity.

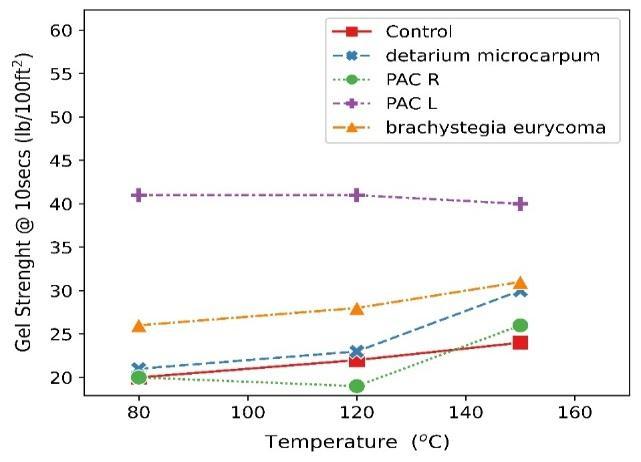

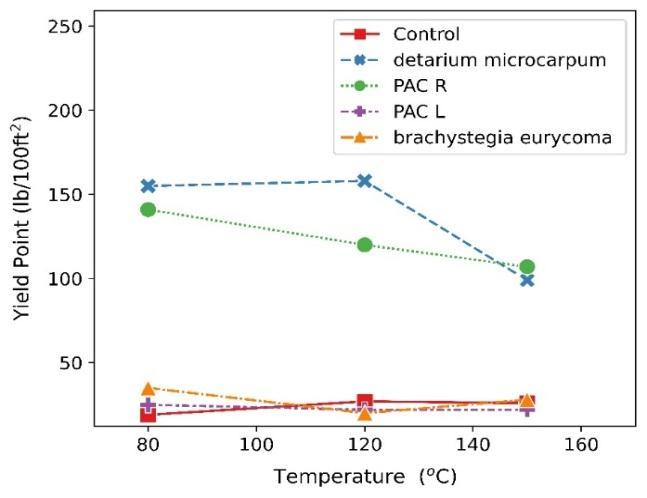

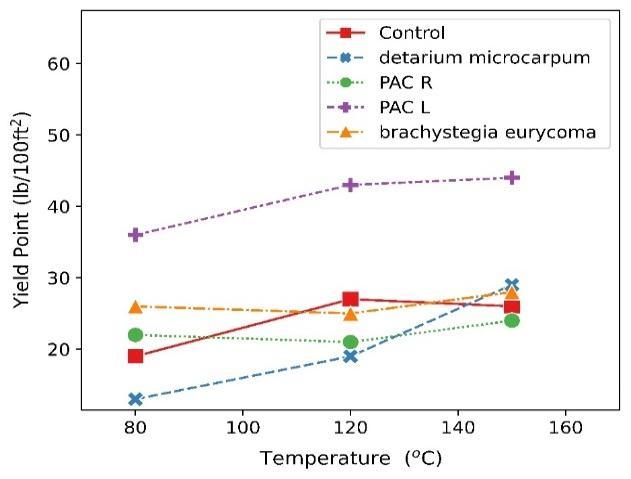

Effects of Temperature on Yield Point and Gel Strength of Imported and Local Polymer-Based Drilling Fluids

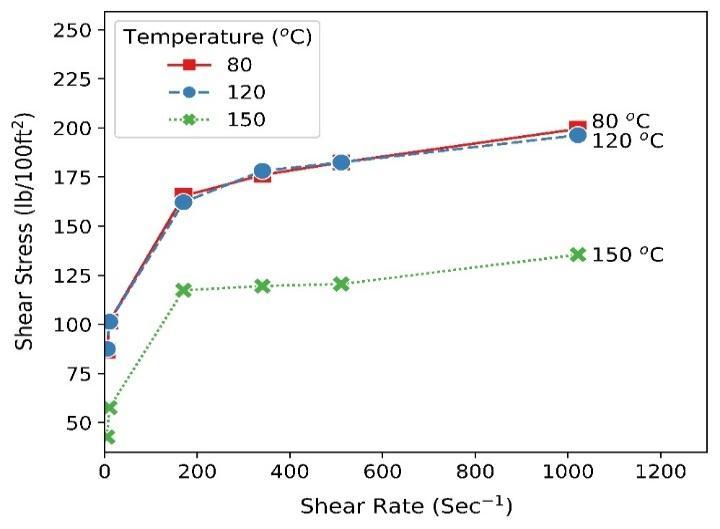

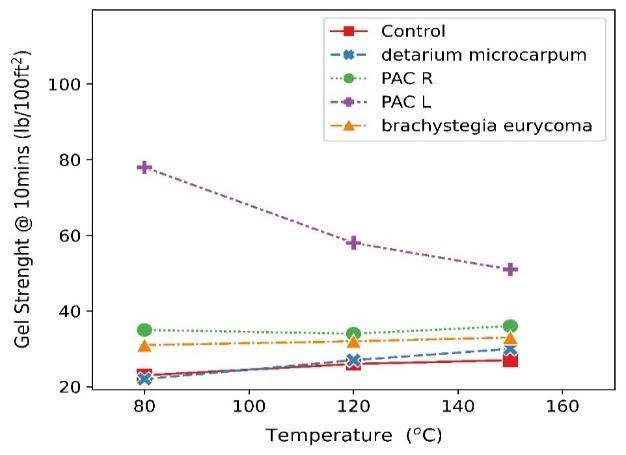

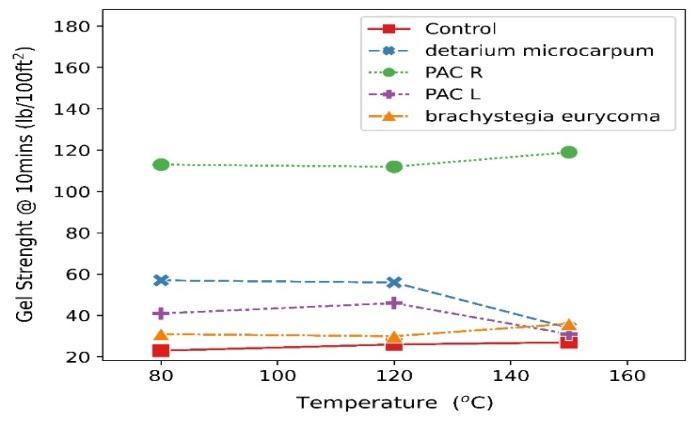

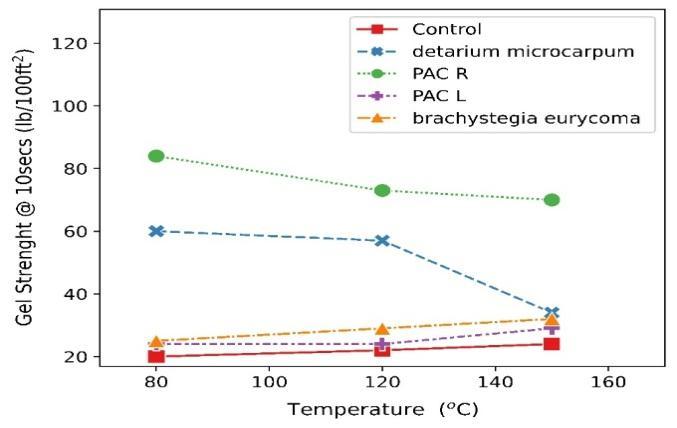

Theyieldpointandgel strengthofthedrillingfluidswere shown in Figures 14 and 17, at 0.1% and 0.5% concentrations. At 0.1%, there was a corresponding increaseinyieldpointandgelstrengthwithanincreasein temperatures on the drilling fluids formulated with Brachystegia eurycoma and detarium microcarpum and Pac L, while the yield point and gel strength of the mid formulated with PAC R decreased with increasing temperatures. The yield point of the drilling mud can lift cuttings to the surface, there is a fluid with a higher yield point that can lift drilled cuttings better than a fluid that has a lower yield point. At 0.5%, there was a corresponding decrease in yield point with increasing temperatures. These results indicate that temperature affects the rheological properties of drilling fluid significantly.

Statistical Analysis

Analysis of Variance of Plastic Viscosities and Yield Point of the Imported and Local-Based Drilling Fluid Polymers

Tables 15 and 22 shows the turkey multiple comparison testsandtheanalysisofvarianceof plasticviscositiesand yieldpointofdrillingfluidfor0.1%and0.5%respectively. For drilling fluid design for 0.1% concentration, the mean plastic viscosity for PAC R was 3.00, the mean plastic viscosityforpacLwas10.00,themeanplasticviscosityfor detarium microcarpum was 7.00, the mean plastic viscosity for Brachystegia eurycoma was 1.33, and for control was 3.66. There was a significant difference between the plastic viscosities of the four polymers that were used as viscosifiers. For drilling fluid of 0.5% concentration, the mean plastic viscosity for pac R was 34.00, the mean plastic viscosity for detarium microcarpumwas14.33,themeanplasticviscosityforpac L was 10.00, the mean plastic viscosity for Brachystegia eurycoma was 8.66, and for control was 3.66. This also shows that there was a significant difference between the plastic viscosities for the four polymers. These results showedthatwhenpacRadditivewasaddedtothedrilling mud,itproducedsignificantlyhigherplasticviscositythan the remaining additives. It also showed that detarium microcarpumhadarelativelygoodplasticviscosity,which impliesthatitcanserveasasubstituteforPACR.

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Table 17: AnalysisofVarianceforplasticviscosityfor0.5%concentration

Table 18: Tukeymultiplecomparisontestsforplasticviscosityfor0.5%concentration

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Table 19: AnalysisofVarianceforyieldpointfor0.1%concentration

Table 20: Tukeymultiplecomparisontestsforyieldpointfor0.1%concentration

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Analysis of variance for gel strength of 10 seconds and 10 minutes of imported and local-based drilling fluid polymers

The results of the analysis of variance for gel strength at 0.1% and 0.5% concentration, respectively are presented in Tables 23 to 30. The mean gel strength for 10 seconds fordrillingfluiddesignfor0.1%concentrationwas40.667 for pac L, while gel strength for 10 seconds for Brachystegia eurycoma, detarium microcarpum, PAC R, and control was 28.33, 24.66, 21.66, and 22.00 respectively.ThisresultshowsthatPACLhadahighergel strength, compared to the other polymers, and there was nosignificantdifferencebetweenthegelstrengthofPACR, detarium microcarpum, and Brachystegia eurycoma. The mean gel strength for 10 minutes for drilling fluid design for 0.1% concentration was 62.33 for PAC L, while gel strength for PAC R, brachystegia eurycoma, detarium microcarpum, and control were 35.00, 32.00, 26.33, and 25.33 respectively. These results also showed that PAC L

had a significantly higher gel strength, compared to the rest polymers, and there was no significant difference between the gel strengths of PAC R, Brachystegia eurycoma, and detarium microcarpum. The mean gel strength for 10 seconds for drilling fluid design of 0.5% concentrationwas75.667forPACR,whilethegelstrength for 10 seconds for Brachystegia eurycoma, detarium microcarpum, PAC L, and control were 28.667, 50.33, 25.667,and22.00.TheseresultsshowedthatPACRhada significantly higher gel strength than the rest polymers, and there was a significant difference between the gel strength of PAC L, detarium microcarpum, and Brachystegia eurycoma. The mean gel strength for 10 minutesforthedrillingfluiddesignfor0.5%concentration was114.667forPACR,49.000fordetariummicrocarpum, 39.333 for PAC L, 32.333 for brachystegia eurycoma, and 25.333forcontrol.TheseresultsshowedthatPACRhada significantly higher gel strength, compared to the other polymers.

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Table 27: AnalysisofVarianceforgelstrength@10secfor0.5%concentration

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

Table 29: AnalysisofVarianceforgelstrength@10minsfor0.5%concentration

model Y=Mean(Y)

Table 30: Tukeymultiplecomparisontestsforgelstrength@10minsfor0.5%

Values with different superscripts (a, b, c) were significantly different from each other (p < 0.05) and those with the same superscriptswerenotsignificantlydifferent.

CONCLUSION

The following listed below are the conclusions gotten in thisstudy.

1. The local polymers (Brachystegia eurycoma ,achi,and detarium microcarpum, ofor,) used in the drilling fluid design performed significantly good as a rheological agent at various temperatures studied at 80 degree farhenheit to 150degreefarhenheit

2. Bingham plastic model gave more favorable predictions of the rheological properties of the drillingfluid

3. The drilling fluids formulated with brachystegia eurycoma,achi,hadalowerfluidlosscomparedto themudformulatedwithdetariummicrocarpum

ACKNOWLEDGMENTS

The authors would like to thank the University of Port Harcourtforthefacilitiesandsupportforthiswork

REFERENCE

Uliasz, M., Chudoba, J., Herman, Z., 2006. Pluczkiwiertniczez inhibitoramipolimerowymiiichoddzialywanienaprzewierc aneskaly.PraceINiGNo139,s.1-76.

Steliga, T., Uliasz, M., 2014. Spent drilling muds management and natural environment protection Gospodarka Surowcami Mineralnymi-Mineral Resources Management30(2),135,156.

Kerunwa A., and Gbaranbiri B.A., (2018): “Evaluation of localviscosifiersasanalternative ToconventionalPAC-R”. Advancesinpetroleumexplorationanddevelopment Vol 15.No1,2018pp1-8.

Lewicka, E., Wyszomirski, P., 2008. GospodarkaSurowcamiMineralnymi-MineralResources Management24/4,s.2-250

Bentonityslowackieiichwykorzystanie w przemyœlepolskim.

Uluocha O B., Daniel I. E. and Ogbonna A N, (2018):” Assessment of Some Socioeconomic Aspects of Achi (Brachystegia Eurycoma Harms) in Nsukka Local Government Area of Enugu State, Nigeria. Researchgate. https://www.researchgate.net/publication/331999145_

Elizabeth B.I., Ndubuisi A. A., Lovelyn N.O., (2014): “Physical properties of brachystegia Eurycoma seeds as affected by moisture content”. International journal of Agricultureandbiologicalengineering7(1):84-93.