AN EXPERIMENTAL INVESTIGATION 0N FLOATING CONCRETE USING LIGHTWEIGHT AGGREGATES

A.GOVANDAN1 , V.ARUNBALAJI2 , M.R.SHAHIDAFRIDI3

1Assistant professor, Department Of Civil Engineering, Parisutham Institute of Technology and Science, Tanjore, TamilNadu, India.

2,3B.E , Department Of Civil Engineering, Parisutham Institute of Technology and Science, Tanjore , TamilNadu, India.

Abstract - This project deals with development of floating concrete by using lightweight aggregates (pumice stone) and other replacing material (scoria). There are many types of lightweight concrete which can be produced either by using lightweight aggregate or by using an air entraining agent. In this study we have worked on combination of above mentioned types. This concrete is a non-structural concrete. In this study, pumice stone is used as replacement materials in concrete where it is found in the abyssal of the red clay. The physical, mechanical and durability properties of concrete was investigated by conduction compressive strength on the ordinary and replaced concrete with varied percentage of pumice from 5% to 30%. It's observed that environmental and economical benefits can be achieved if waste materials can be used to replace the coarse aggregate in order to use the waste materials effectively in areas with abundant availability of materials. Along with pumice, The aim of this project is to analyse the suitability of scoria as a fine aggregate for concrete production and its effect on the properties of concrete. A differing ratio of scoria was considered as a partial replacement of fine aggregate with river sand after analysing its engineering properties, and its effect on the mechanical properties of concrete were examined. The test results on the engineering properties of scoria revealed that the material is suitable to be used as a fine aggregate in concrete production. The replacement of scoria with river sand also enhanced the compressive strength of the floating concrete.

Key Words: Pumice stone, Scoria powder, Conventional concrete, Compressive strength.

1.INTRODUCTION

Concretecanbedefinedascompositematerial,composedof cement, aggregate, water and admixtures in required proportions.Itisconsideredtobemostimportantanduseful materials for many constructional activities . The basic ingredients for a concrete are Portland cement, water, and aggregates. Concrete is generally considered to be the most widelyusedmaterialonEarth.Itcanbeeasilymoldabletoany shape in the elastic stage. Aggregate is a broad category of coarseparticulatematerialmostwidelyusedinconstructional activities. Aggregate act as a reinforcement in a concrete contributing compressive strength to concrete. With the

increasing urban development and population, demand of sustainablestructuresincreased.However,byuseofthewaste materials, the environmental impact may be reduced. Sustainablebyproductsfromvariousindustriesreducesoverall cost and energy. By incorporating industrial by products in concrete meet out the requirement of creating the environmental awareness in the society. Now a days more awarenesshasbeenpaidtothedevelopmentoflightweight aggregate structure having low unit weight and sufficient strength.Oneofthewaytoreducetheweightofthestructureis by using the light weight aggregate concrete which is most probablemethodinreducingtheweightofthestructure.

2.OBJECTIVE

Themainobjectiveofthisprojectistoincreasecompressive strength of the Floating concrete by using lightweight aggregates.

3.SCOPE

The present data indicates that there is significant improvement in the strength properties of the lightweight concrete by using different admixtures. Furtherimprovementinthestudycanhelptoincreases the mechanical properties of lightweight concrete by addingdifferentcombinationofmaterials

4.METHODOLOGY

Identificationofproblem

5.1.3 Coarse Aggregates

The crushed stone aggregate by locally quarry purchased from the supplier. The coarse aggregates used in the experimentationwas20mmanddownsizeaggregate.The physicalandmechanicalpropertiesaregiveninTable.2

Table.2:.PhysicalandmechanicalpropertiesofCoarse Aggregate.

Procurementofmaterials

Conductingtestsonmaterials

Castingofconcretespecimens

Testingthepreparedspecimens

ResultsandDiscussions

5.EXPERIMENTAL PROGRAMME

5.1 Materials used

5.1.1 Ordinary Portland cement (43 Grade)

The cement used in the experimentation was Ordinary Portlandcement.Thephysicalpropertiesoftestedcement aregiveninTable.1

Table.1.PhysicalpropertiesofOrdinaryPortlandcement

5.1.4 Pumice

Pumiceisamaterialcreatedbythearrivalofgasesduringthe cementingofmagma.Thecellstructureofpumiceismadeby thedevelopmentofairpocketsorairvoidswhengasesare trappedintheliquidmagmaspillingoutofvolcanoesbecome caughtoncooling.Cellsarelengthenedandcorrespondingto each other and sometimes interconnected. Once the rock hardens,theresultisaverylight,buoyantmaterial.Themain useofpumiceisformakinglightweightconstructionmaterials suchasconcrete.Pumicehasachemicalcompositionsimilar to that of obsidian, or volcanic glass. It has very thin, translucentbubblewallsofextrusiveigneousrock.Themain researchobjectivewastodeveloplightweightconcreteusing Pumicestonetoreducetheselfweightofthestructures.The focus was on to develop the floating concrete with good strength,lessporous,lesscapillaritysothattheconcretethat willfloatsshouldbedurable.

5.1.2 Fine Aggregates

Manufacturessandpurchasedfromthesupplierwasusedas fineaggregate.Thesandusedconfirmedtogradingzone-2as perIS:383-1970specification.

5.1.5 Scoria powder

Scoria,whichisaproductofexplosivevolcaniceruptions, hasbeenusedforcenturiesintheworldasaconstruction material.Differentresearchershaveexaminedtheuseof scoriaasaconstructionmaterialinconcreteproduction. Accordingtoresearches,scoriausedasacoarseaggregate wasfoundtobeveryusefulintheproductionoflightweight concrete,withsufficientstrengthgivingittheadvantageof reducingthedeadloadinbuildingstructures.Scoriaisalso usedasalightweightaggregatewithsilicafumeandflyash mineral admixture in the production of lightweight structuralconcreteinwhichanoutstandingperformance wasobservedwithregardstothestrengthtounitweight ratio.Improvementsinthemechanicalstrengthofmortar werealsoobservedwhenusingvolcanicscoriaassandin theproductionofPortlandcementmortar.

dimensions150×150×150mm.Thesespecimenswerecastand testedafter7days,14daysand28daysofcuringasperIS specification.

7. RESULTS AND DISCUSSIONS

7.1 Compressive Strength test

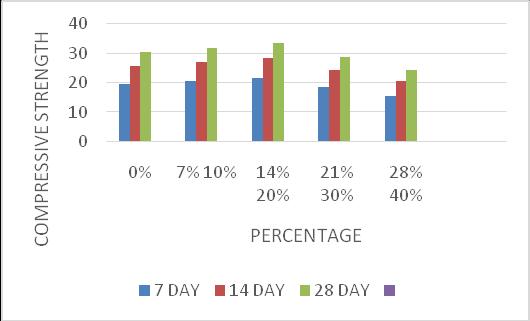

Using cube samples of M25 Grade concrete, compression strengthtestswerecarriedoutusingacompressiontesting equipment.Theaveragestrengthvalueswereevaluatedon threesampleseachbatch.AstheproportionofScoria and pumice to cement weight risesup to0.2%,thecompressive strengthofFloatingconcreteat7days,14days,and28days exhibits an increasing trend. Further observation reveals thatafter28daysofcuringatM25,thehighestcompressive strengthisattained.

6. MIX PROPORTION

Designofconcretemixneedsnotonlytheknowledgeof materialpropertiesandpropertiesofconcreteinplastic condition,Italsoneedswiderknowledgeandexperience ofconcreting.Eventhentheproportionofthematerialsof concretefoundoutatthelaboratoryrequiresmodification andreadjustmeanttosuitthefieldconditions.

5.1.6 Casting of Concrete Specimen

ConcretewaspreparedbyamixproportionsofM25grade concrete. The different percentage of fiberslike0.1,0.2,0.3 wereadoptedintheexperimentalprogramme.Glassfibers wereaddedinthemixbyweightofcement.Theentiremix washomogeneouslymixedwithcalculatedamountofwater. The compressive strength test specimens were of

8. CONCLUSION:

Inthisstudy,itisconcludedthatthedensityofconcreteis verymuchreducedascomparedtonominalconcretesothe self-weight of structure is also reduced. Concrete density wasdecreasesasweincreasethereplacementpercentageof normal coarse aggregate with pumice aggregate and Fine aggregatewithScoriapowder.Byreplacing14%and20%of normalaggregatewithpumiceaggregateandFineaggregate withScoriathecompressivestrengthisPromisingandgives betterresultscomparetonominalconcrete.

9. REFERENCES

[1] Rayees Ahmad Ganie, “Floating Concrete by using PumiceStoneandFoamingChemical”,International journal of civil engineering, e-ISSN: 1694-2280, pISSN:1694-2396,Volume4,Issue2,2017.

[2] Malik Mehran Manzoor, Abhishek Gupta, RukhsanaGani,AnkushTanta,“FloatingConcreteby usingLightWeightAggregates(PumiceStones)and Air Entraining Agent”, International journal of scienceandengineeringdevelopmentresearch,ISSN: 2455-2631,Volume3,Issue6,June2018.

[3] Thousif Khan, Ibrahim Killedar, Sharu Malik H N, MuhathasheemRF,JagannathaGM,Dr.Shivakumara B, “An Experimental Study on Floating Concrete UsingLightWeightMaterial”,InternationalResearch JournalofEngineeringandTechnology,e-ISSN:23950056,p-ISSN:2395-0072,Volume:05,Issue:05,May 2018.

[4] Nikhil S. Chavan, Dhiraj Yadav, ShrikantGadhe, DnyandeepBachipale, Shweta Kale, Mahesh V. Tatikonda, “Mechanical Properties of Floating Concreteby using Expended Polystyrene Beads as ReplacementofAggregates”,InternationalResearch journalofengineeringandtechnology,e-ISSN:2395-

0056,p-ISSN:2395-0072,Volume:05,Issue:05,May 2018.

[5] (136-162)RoshanGawale,ShubhamMishra,Harshal SambareJidhneshKothari,AssistantProf.MonaliPatil, "Lightweight concrete by using EPS beads”, International journal of innovative research in scienceandengineering,ISSN:2454-9665,Vol.No.2, Issue03,March2016.

[6] YohannesM(2015)Investigationonthesuitabilityof pumice and scoria aggregates in ribbed-slab construction.JCivEngRes5(4):75–82.

[7] Roshan Gawale, Shubham Mishra, Harshal Sambare, Jidhnesh Kothari, AssistantProf. Monali Patil, "Lightweight concrete by using EPS beads", International journal of innovative research in scienceandengineering,ISSN:2454-9665,Vol.No.2, Issue03,March2016.

10. AUTHORS BIOGRAPHY

A.GOVANDAN, Assistant professor of Civil department ,Parisutham institute oftechnologyandscience,Tanjore, Tamilnadu,India.

V. ARUNBALAJI, FinalyearB.Estudent,Department of Civil Engineering,Parisutham InstituteoftechnologyandScience, Tanjore,Tamilnadu,India.

M.R.SHAHIDAFRIDI, FinalyearB.Estudent,Department of Civil Engineering, Parisutham InstituteoftechnologyandScience, Tanjore,Tamilnadu,India.