International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 04 | Apr 2023 www.irjet.net

p-ISSN: 2395-0072

1B.E.Student,DepartmentofCivilEngineering,NewHorizonInstituteofTechnologyandManagementThane, Maharashtra,India

2AssistantProfessorDepartmentofCivilEngineering,NewHorizonInstituteofTechnologyandManagement Thane,Maharashtra,India.CorrespondingAuthor:Ms.ResmaB.Vijay

Abstract - Expansive soils are a worldwide problem that poses several challenges for civil Engineers due to its poor bearing capacity, low shear strength, etc. The aim of this project is to stabilize the black cotton soil using RHA and CaCl2 andreinforcing by using Plasticfiber. This would improve the soil properties effectively and are economical. The tests conducted for Physical Properties are Moisture Content, Grain Size Distribution and for Engineering Properties are Standard Proctor Compaction Test, California Bearing Ratio Test, Atterberg’s Limit test, Free Swell Index Test and Unconfined Compressive Strength Test are done for black cotton soil mixed with different proportions of Rice Husk Ash and Plastic Fibers then the results are tabulated.

Key Words: CBR Test, Black Cotton Soil, Plastic Fibres, Rice Husk Ash, CaCl₂

Generallyfromthestudiesweknowthatblackcotton soilisfoundtocontainmontmorilloniteclaymineral which has high expansive characteristics. As the colloidalclaycontentinBCsoilisupto50%.Itisalso foundthatithashighplasticlimit,highliquidlimitand lowshrinkagelimit.Thecompactioncharacteristicof such soil is that they have low dry density and high OMC.TheblackcottonsoilUCCandCBRvaluesarealso lowforthissoil.

Solutiontothisproblemissoilstabilizationisdoneby the processes of blendingand mixing materials with the soil to improve their certain properties and to achieve a desired size particles or the mixing of normally available admixture that may alter the gradation or plasticity may act as an binder for the cementationofthesoil.Thismightresultinreducethe permeability & compressibility on properties of expansive soils and hence increases its bearing capacity.

The Stabilized soils gives us an stronger working platform for the foundation for all other work of

projects.Afterstabilizationprocess,weakensoilgets morestrengthinit.Whichmeansthatsoilisnotweak anymore and has significantly reduced permeability resultinginreduced shrinkage/swellingpotential.In addition, soils that have been stabilized have also undergoessomemodification. Wecansaythatthesoilhasbeenphysicallychanged making it easier for compaction and reducing it’s plasticity. Easier compaction is equal to achieving maximumdrydensityeasier.

MeritsofSoilStabilization

1. Stabilizing soils with binders is now an extremelycosteffectivemethodofconverting poor quality soil into a strong impermeable medium.

2. There is no need to bring other type of soil whenthesoilonsitecanbeusedafterasimple treatmentprocess.

3. Improved to give the properties required for construction

4. Soil stabilization is an different method for improvingthecharacteristicsandperformance ofthesoil.

De-Merits of Soil Stabilization

1. Requires a lot of products per application.

2. Requires extensive soil testing before application.

3. Not always environmentally friendly.

4. Time consuming.

Following testswhichwearegoingtobeperformedon theBlackCottonsoilareaccordingtoallISStandards. Alltheapparatususedduringthetestsareconfirmed from the IS Codes. Further results for the tests aregivenfromtheISStandardslimits.

AfterreviewingdifferentAuthorspapersfirst,wehave tocollectthematerialsthatarerequiredforconducting the project. After collecting the materials, we will determinethestandardsoilpropertiestodetermineits Class.Ournextstepistofindtheoptimumcombination forsoilstabilizationwithRiceHuskAshandCaCl2

Afterfindingtheoptimumcombinationthefurtherstep istodeterminethesoilreinforcement(PlasticFiber) combination.

Materials used During the Testing

1. SubgradeSoil(BlackCottonSoil).

2. RiceHuskAsh(RHA).

3. CalciumChloride(CaCl₂).

4. PlasticFiber.

Table-1 ExperimentalProgramme. SoilCombination TestsConducted

Soilalone

Soil+RHA

Soil+CaCl₂

Soil+RHA+CaCl₂

Soil + RHA + CaCl₂ + PlasticFiber

Grainsizedistribution

Specificgravity

Atterberglimits

Compactiontest

CBRtest

Freeswellindex

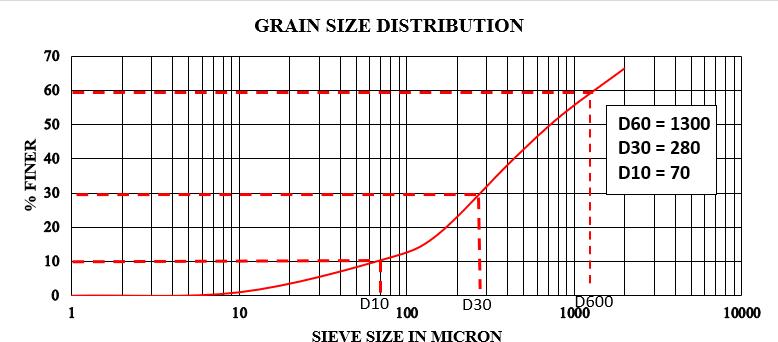

The value of coefficient of curvature, Cc obtained for Black Cotton Soil is 18.57 and that of coefficient of uniformity,Cu isobtainedas0.86.Forthegradedsoil thestandardvalueofCc liesbetween1and3andfor fine soil the Cu value should be greater than 6. Since bothofthesecriteriaarenotmet,thesoilisclassified aspoorlygraded.

The specific gravity of Black Cotton Soil has been obtainedas2.32.Thespecificgravityofsoilnormally hasarangeof2-2.8andhencetheBlackCottonSoilis withinthespecifiedrange.

a. Shrinkage limit-From the experiment the shrinkage limit of soil has been obtained as 12.12%andshrinkageratioisobtainedas1.89. Thisshowsthattheshrinkagelimitofthesoil islow.

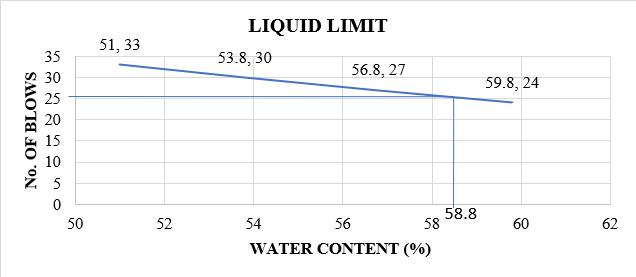

b. Liquid limit:

Theliquidlimitofthesoilisobtainedfromthegraph correspondingto25blowsas58.8%.Hencetheliquid limitofthesoilshigh.

c. Plastic limit

Theaverageplasticlimitofsoilisobtainedas29.72%. Hencethesoilishighlyplastic.

Liquidityindexofthesoilisobtainedas-0.27.Sincethe liquidityindexislessthanzerothesoilisinsemi-solid stateandisstiff.

Theconsistencyindexofthe soilis obtainedas1.27. Sincetheliquidityindexisgreaterthanonethesoilis insemi-solidstateandisstiff.

Theshrinkageindexofsoilisobtainedas17.6%.

Theplasticityindexofthesoilisobtainedas29.08% and the A- line is obtained as 28.324%. As per the plasticity chart we obtained that the soil is above AlineandhencebelongstoCHgroup.Thus,soilishighly clayorhighplasticity.

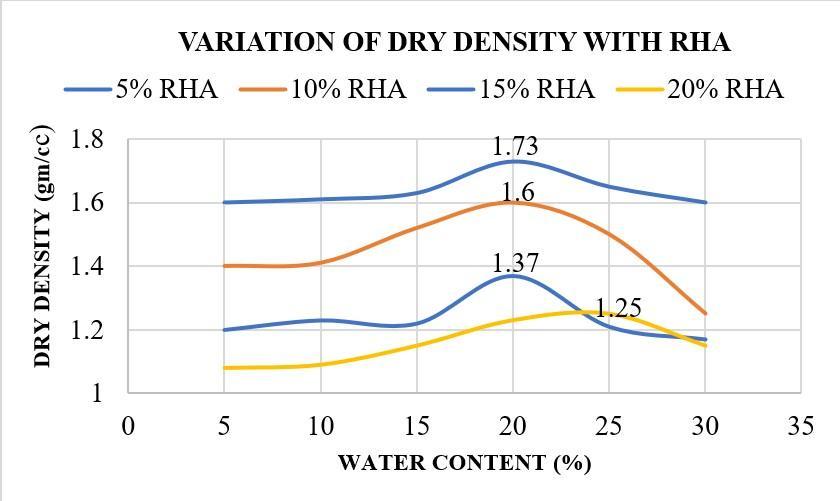

4.1 Effect of RHA (Rice Husk Ash) on Black Cotton

CompactionofsoilwithRHAshowedadecreaseindry densitywithincreasingOMC

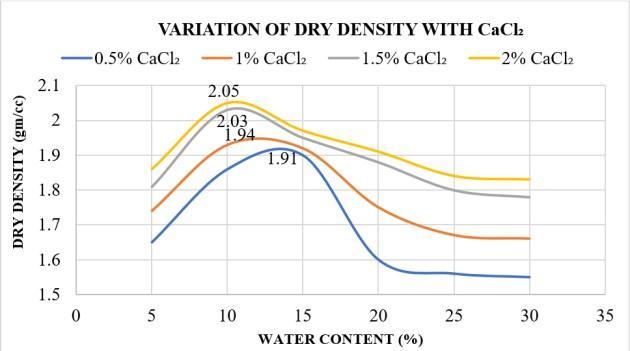

4.2 Effect of CaCl2 (Calcium Chloride) on Black Cotton Soil

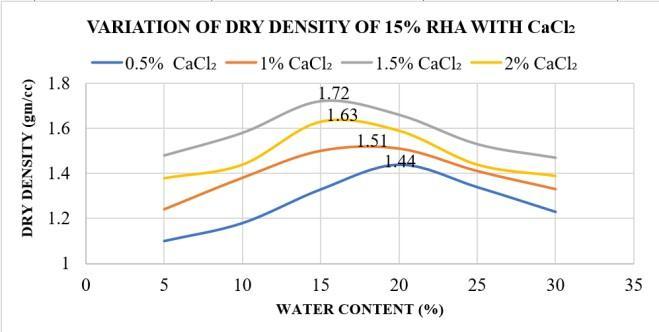

4.5 Effect of CaCl2 and 15%RHA on Black Cotton Soil

Graph-4:EffectofCaCl2 onBlackCottonSoil

CompactionofsoilwithCaCl₂showedanincreasein drydensitywithdecreasingOMC

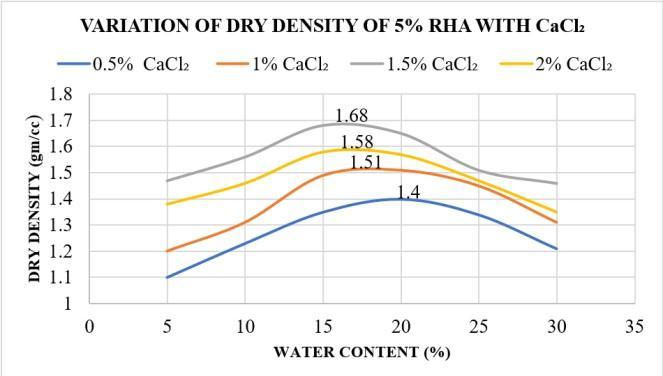

4.3 Effect of CaCl2 and 5% RHA on Black Cotton Soil

Graph-7:EffectofCaCl2 and15%RHAonBlack CottonSoil

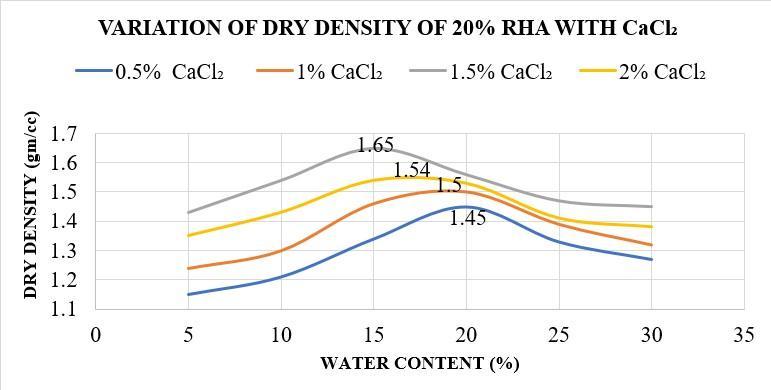

4.6 Effect of CaCl2 and 20%RHA on Black Cotton Soil

Graph-5:EffectofCaCl2 and5%RHAonBlackCotton Soil

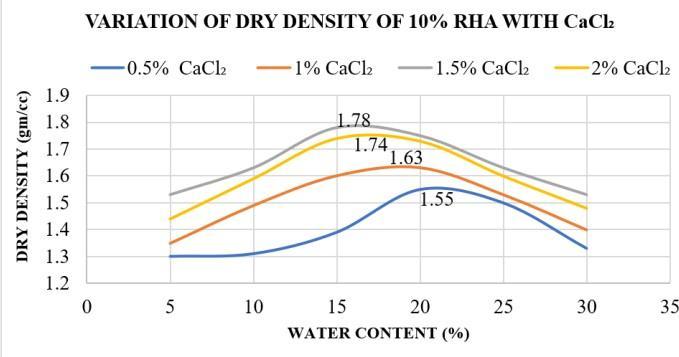

4.4 Effect of CaCl2 and 10% RHA on Black Cotton Soil

Graph-8:EffectofCaCl2and20%RHAonBlack CottonSoil

Theoptimumcombinationistakenas20%RHAwith 1.5% CaCl2 which has maximum dry density with minimumwatercontent.

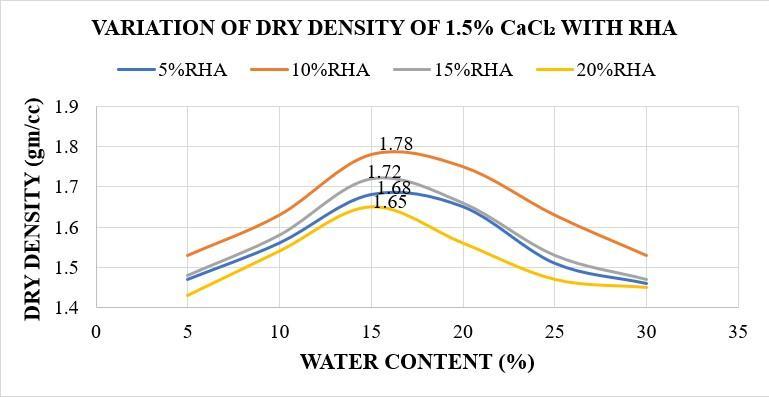

4.7 Effect of RHA and 1.5%CaCl2 Soil on Black Cotton

Graph-6:EffectofCaCl2 and10%RHAonBlack CottonSoil

Graph-9:EffectofRHAand1.5%CaCl2onBlack CottonSoil

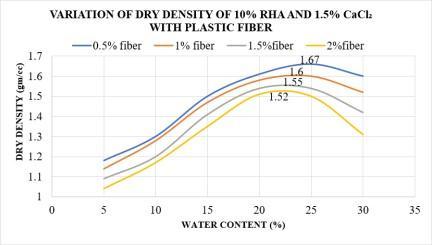

Theoptimumcombinationistakenas10%RHAwith 1.5% CaCl2 which has maximum dry density with minimumwatercontent.

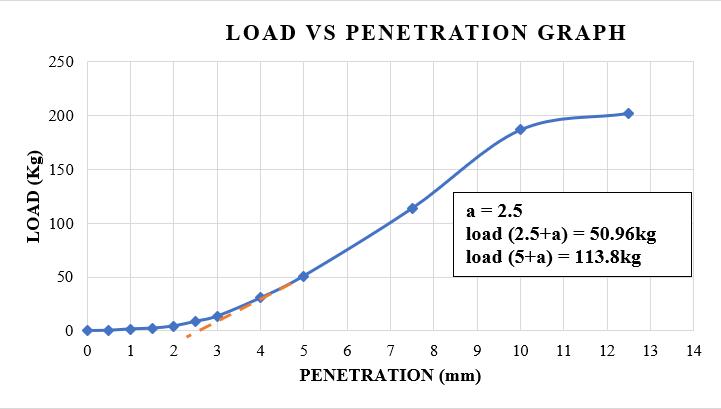

Effect of Plastic Fiber, 10%RHA and 1.5%CaCl2 on Black Cotton Soil

CBRvaluewith10%RHA,1.5%CaCl2and0.5%Plastic Fiberstabilizedsoilisobtainedas9.73%.

Graph-10: Effect of Plastic Fiber, 10%RHA and 1.5%CaCl2 on Black Cotton Soil

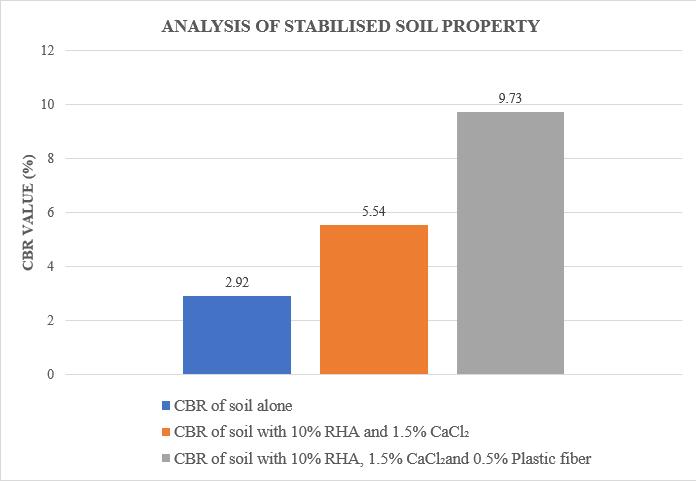

5. ANALYSIS FOR SOIL STABILISED SOILPROPERTY

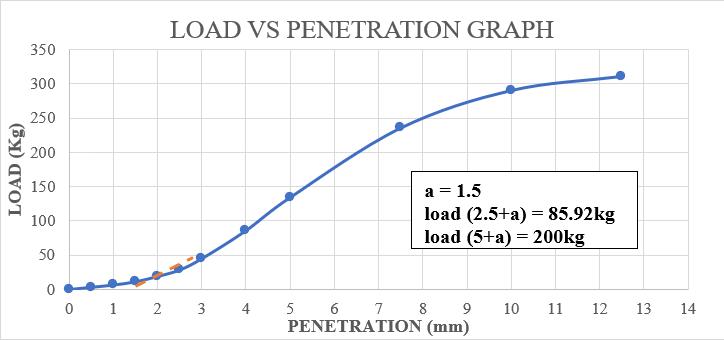

5.1 California Bearing Ratio test with10% RHA and 1.5% CaCl2 stabilized soil

Graph-13:Analysisofstabilizedsoilproperty

6. CONCLUSION

RHA and CaCl₂ can’t be used alone for stabilizing process as they lack cementing agentforincreasedstrengthandaredifficultto pulverized soil at low water content respectively. Thus, optimization of above 2 combinations can be an effective method for soil stabilization and it is found at 10% RHA and1.5%CaCl₂.

Graph-11:CBRofstabilizedsoilwith10%RHAand 1.5%CaCl2Stabilizedsoil

CBRvaluewith10%RHAand1.5%CaCl2stabilizedsoil isobtainedas5.54%.

5.2 California Bearing Ratio test with10% RHA, 1.5% CaCl2and 0.5% Plastic Fiber stabilized soil

4.8 OPTIMISATION FOR SOIL REINFORCEMENT © 2023, IRJET | Impact Factor value: 8.226 |

Reinforcing the soil with Plastic Fibber can improvethestrengthcharacteristicsofthesoil and the optimum performing subgrade is obtained with the application of 10% RHA, 1.5%CaCl₂and0.5%PlasticFibber.

The CBRvalue of BlackCottonSoil increased after addition of 10%RHA + 1.5% CaCl₂ (5.54%) and 10%RHA + 1.5% CaCl₂ + 0.5% PlasticFiber(9.73%)ascomparedtountreated soil (2.92%). Good CBR value increases the stabilityofsoil.

[1] SoundaraBandSenthilKumarK.P, “Effect of Fiber on Properties of Clay”, International Journal of Engineering and Applied Sciences (IJEAS), ISSN: 2394-3661, Volume-2, Issue-5, May2015.

[2] Vidya Tilak B., Rakesh Kumar Dutta and BijayanandaMohanty, “Effect of Plastic Fibres on The Compaction and Unconfined Graph-12

Compressive Strength of Bentonite-LimeGypsum Mixture”, Slovak Journal of Civil Engineering,Vol.23,No.2,pp.1–8,2015.

[3] Khushbu S. Gandhi, “Experimental Study of Surat Region Expansive Soil Modified Using Bagasse Ash and Wood Ash”, International Journal in IT and Engineering [IJITE], Vol.2, Issue-12,pp.62-70,(December2014).

[4] AmitTiwariandH.K.Mahiyar ,“Experimental StudyonStabilizationofBlackCottonSoilbyFly Ash, Coconut Plastic Fibre & Crushed Glass”, InternationalJournalofEmergingTechnology andAdvancedEngineering,Volume4,Issue11, pp.330-333,November2014.

[5] Anil Kumar Singhai and Sudhanshu Shekhar Singh,“LaboratoryStudyonSoilStabilization Using Fly Ash and Rice Husk Ash”, International Journal of Research in EngineeringandTechnology(IJRET),Volume: 0,Issue:11,pp.348-351Nov-2014.

[6] Saibal Chakraborty, S P Mukherjee and B C Chattopadhyay, “Improvement of Sub Grade Strengthby Admixtures”, InternationalJournal of Engineering Research and Science & Technology,Vol.3,No.3,pp.185-194,August 2014.